Professional Documents

Culture Documents

Understanding the 8 Areas of Waste in Lean Principles

Uploaded by

Viswanathan SrkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Understanding the 8 Areas of Waste in Lean Principles

Uploaded by

Viswanathan SrkCopyright:

Available Formats

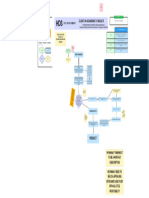

Understanding8AreasofWaste:

IntroductiontoLeanPrinciples WAITING:

Systemdowntimeorresponsetime

History: Approvalsfromothers

ProcessFlow: Informationfromcustomers

HenryFordcreditedwithstartingoriginal Lookatprocessthrough Meetingsstartinglate

DownstreamFlow

movement thecustomers Latereports,paychecks,orprojects

KiichiroToyodaandTaiichiOhno:1930s Task TaskB TaskC perspectiveandidentify INVENTORY:Toomuchofanythingandanyformofbatch

developedtheToyotaProductionSystem. wasteintheprocess. processing

PopularizedbyJimWomack,authorofLean Excessiveofficesupplies

Upstream Fullinboxes(electronicorpaper)

Thinking,TheMachinethatChangedtheWorld

Computerfilesneverused

andLeanSolutions

UNDERUTILIZATIONOFPEOPLE

Limitingemployeeauthorityandresponsibilityfortasks

WhyUseLean? Inadequatebusinesstoolsavailable

Delayingimplementationofcomputersystemcomponents

Leanprincipleshelptoexaminebusinessprocesses Restrictingornotofferingtrainingontechnicalresources

andfocusonminimizingunnecessarycosts,reducing

wasteandimprovinginefficientprocedures. CORRECTION/REWORK:Correctionofanyerror

Orderentryerrors

Benefits: Grammarandpunctuation

Identifiesproblemareasandbottlenecks Inaccuratereportsordata

Lackofstandardizedwork

Increasesbusinessefficienciesmakesurestaff

Incompletecommunications

timeisspentonvalueaddedactivities.

OVERPRODUCTION:Producingmoresoonerorfasterthanis

Savemoneyreduceoverheadinpaperwork requiredforthenextprocess

Simplifyprocesses

Printinghardcopiesofforms

Purchasingitemsjustincasetheyareneeded

Conformtorules®ulationsandcodesof Processingpaperworkbeforethenextpersonintheprocessis

conductstandardizingprocessesusingLean ready

Preparingreportsthatarenotusedorread

WhatisLean? MOTION:Unnecessaryphysicalmovement

Copymachinetoofarawayfromusers

Leanconsistsofproventoolsandtechniquesthat Diggingthroughstacksofpaper

focusonminimizingwastefulactivityandadding Reachingforcommonlyusedtools

valuetotheendproducttomeetcustomerneeds. Misplacingequipment/items

LeanTerminology/Metrics: Usingtoomanylayersforelectronicfolders

The8areasofwastecanbeusedtounderstandthe

inefficiencies: Nonvalueadded:Activitiesoractionstakenthataddnoreal KaizenPhilosophy:Japaneseforimprovementorchange MATERIALMOVEMENT/TRANSPORTATION(transporting,sorting,

Waiting Inventory Under

Correction/ valuetotheproductorservice,makingtheactivityoractiona forthebetter.Frequentsmallimprovements,thecycleis: orarrangingitemsunnecessarily)

Rework Filingpapersthatwillneverbeusedagain

formofwaste.

Standardizeanoperation Stockpilingsuppliesfarfromtheirpointofuse

Material Valueadded:Activitiesoractionstakenthataddrealvalueto Measurethestandardizedoperation

Buryingextrasuppliesindrawersorstorerooms

Extra

Overproduction Motion Movement/ Gaugemeasurementsagainstrequirements

Processing theproductorservice. Requiringmultipleapprovals

Transportation Innovatetomeetrequirementsandincreaseproductivity

Standardizethenew,improvedoperations

HandDelivery

IncidentalWork:Activitiesneededtostayinbusinesslegally. Latereports, paychecks,orprojects

AmappingmethodcalledValueStreammappingis LeanMetrics:

InternalCustomer:Receiveroftheproductorserviceinside EXTRAPROCESSING:Extramentalorphysicalnonvalueadded

typicallyusedtocapturethecurrentstateprocess, 1. ProcessTime(P/T)actualtouchtimeofoneworkitem;exclude

theorganization,oftentheindividualdownstreamprocess. interruptions steps

includingboththevalueaddedandnonvalueadded

2. DelayTime(D/T)timeworkitemisdelayedornottouched Producingrepetitivedocumentsfromscratch

steps.Valuestreammappingprovidesanoverall ExternalCustomer:Receiveroftheproductorserviceoutside

3. LeadTime(L/T)starttimetofinishtime;L/T=P/T+D/T Poorfilingsystem

viewofbusinessprocessesastheyarenow,mapping theorganization. 4. %CompleteandAccurate(%C/A)%ofworkenteringaprocessthatis Lackofvisualcontrols

completeandaccurate.

thematerialandinformationflowsandcanbeused Toomanyapprovalsrequiredforaction

tocreatethefuturestateprocessafterthe Unclearreports/memospublished

DesignedbyAlexisNaiknimbalkar,CSUQualityInitiatives,

leaninghastakenplace. permissionrequiredforduplicationoutsideoftheCSUsystem(anaik@calstate.edu)

Reviewingadocumentmultipletimestodetermineaction

Meetingswithoutagendasforaction

WASTEWALK 5SORGANIZATIONSYSTEM

Auditquestionstodeterminepainpointsin TooltoorganizespacesandintroduceLeanconcepts

Auditquestionsfor5Sarea.

anareatobeLeaned Descriptionofconducting5S

Ratings:Noproblems0,1problem1,2problems2,

improvement:

3problems3,and4ormoreproblems4.

WAITING OVERPRODUCTION Sort,SetinOrder,Shine,Standardize,Sustain Goalistohavealowtotalnumber.Correctproblemsimmediately.

1. Aremakingextracopies,morethanneeded?

1. Arethereexcessivesignaturesorapprovalsrequired?

2. Areweprinting,faxing,emailingmorethanwhatis Excess/unneededequipment,tools,furnitureinarea

2. Istheretoomuchdependencyonotherstocompletea

needed?

SORTWhenindoubt,sortitout!

task? Askquestionsaboutuse ___Unneeded/outdateditemsonwalls

3. Areweenteringrepetitiveinformationonmultiplework

3. Aretheredelaysinreceivinginformation? SetCriteriaforsorting

documentsorforms? ___Itemsarepresentinaisleways,corners,etc.

4. Aretherecomputerprogramversionproblemscausing Placeitemsinholdinguntilallhavehadachance

4. Areweorderingmoretestsorservicesthanwhatis

delays? toreviewitemsbeingdiscarded ___Excess/unneededinventory,supplies,materialinarea

requiredbythecustomer?

5. Systemdowntimeorresponsetimecausingdelays?

5. Arewepurchasingitemsjustincasetheyareneeded?

6. Aretherecrossdepartmentalresourcecommitment

6. Arewepreparingreportsthatarenotusedorread?

issues?

7. Arewehavingmeetingswithoutthenecessary

informationforaction? SETINORDERAplaceforeverythingand ___Correctplacesforitemsarenotclearlymarkedorlabeled

INVENTORY

everythinginitsplace! ___Itemsarenotmarkedorlabeledwithreturnaddresses

1. Arefiles(orwork)awaitingexcessivesignaturesor MOTION Identifylocationforitems ___Aisleways,workplace,equipmentlocationsarenotmarked

approvals? Relocateditems

1. Areyousearchingforcomputerfilesonyourdesktopor

2. Arefilesawaitingtaskcompletionbyother? ___Itemsarenotputawayimmediatelyafteruse

usingtoomanylayersforelectronicfolders? Usevisualcontrolslabels

3. Aretheredelaysinreceivinginformation? 2. Areyousearchingforworkdocuments(files)incabinets Logicaldesignflow ___Heightandquantitylimitsarenotclearlymarked

4. Arewepurchasingexcessivesuppliesofanykind? and/ordrawers?

5. Dowehaveanyobsoletefiles(electronicorhardcopy)in 3. Areyouconstantlyreviewingthesamemanualsfor

information?

thearea?

6. Dowehaveobsoleteequipmentinthearea? 4. Areyouhandcarryingpaperworktoanotherprocessor SHINEInspectionthroughcleaning! ___Floors,walls,stairs,andsurfacesaredirty

departmentregularly?

7. Istherebatchprocessingoftransactionsorreports? Clean ___Equipmentisdirty

5. Areyoumisplacingequipment/items?

Organizeloosecords ___Appropriatecleaningmaterialsarenotavailableinarea

6. Areyoureachingforcommonlyusedtools?

Replacedamageditems

UNDERUTILIZATIONOFPEOPLE ___Lines,labels,signs,etc.aredirtyandhardtosee

Placesmallitemsontraysforeasycleaning

MATERIALMOVEMENT/TRANSPORTATION ___Othercleaningproblemsarepresent

1. Areweinpositionsweweretrainedtodo?

2. Canweassistotherareaswhenworkisslowinanarea? 1. Areyoudeliveringdocumentsthatarenotrequired?

3. Canwebetrainedtodomorewithintheorganization? 2. Areyoudoingexcessivefilingofworkdocumentsorfiling

STANDARDIZEEverythinginastateof ___Standardstomaintainsortandsetinorderdonotexist

4. Arethebusinesstoolsadequateforthejob? documentsthatwillneverbeusedagain?

readiness! ___Checklistforallcleaningandmaintenancejobsdonotexist

5. Areyourestrictingornotofferingtrainingontechnical 3. Areyourequiringmultipleapprovals?

resources? Rulestomaintainandcontrolsystem(checklist,audits, ___Standardsarenotvisibleintheareaandknowtoareastakeholders

4. Areyouhanddeliveringitemsthatcanbesentin andvisualcontrols)

6. Areyoudelayingimplementationofcomputer ___Quantitiesandlimitscannoteasilybeseen

componentsorsoftware?

interofficemail? Minimumandmaximumlimits

Quickreferencechecklist ___Itemsneededtodojobfunctioncannotbelocatedin30seconds

EXTRAPROCESSING

CORRECTION/REWORK

1. Areweproducingrepetitivedocumentsfromscratch?

1. Dowehaveanydataentryerrors?

2. Dowehaveapoorfilingsystem? SUSTAINTraining,reinforcementand ___Workersinareahavenotbeentrainedin5S

2. Dowehavepricing,quoting,billing,orcodingerrors?

3. Istherealackofvisualcontrols? measurement! ___Daily5Swasnotdonethisweek

3. Doweforwardpartialdocumentation?

4. Arewetoomanyapprovalsrequiredforaction? Communicateimportance ___Personalbelongingscannotbeeasilystored

4. Doweeverlosefilesorrecords?

5. Areweenteringrepetitiveinformation? Trainonrules

5. Doweeverencounterincorrectinformationona ___5Schecklist/standardsarenotavailableoruptodate

document? 6. Arewedoingmoreworkthanisrequiredforthat Sharesuccessinmeetings

___Scheduled5Sauditshavenotbeencompletedthisweek

6. Istherealackofstandardizedwork? process? Effectivevisualcontrols

DesignedbyAlexisNaiknimbalkar,CSUQualityInitiatives,

permissionrequiredforduplicationoutsideoftheCSUsystem(anaik@calstate.edu)

You might also like

- Citizen CharterDocument1 pageCitizen CharterReynalisa MonencilloNo ratings yet

- BP040 Current Process ModelDocument12 pagesBP040 Current Process ModelarubharraniNo ratings yet

- Taproot®: Version 5 Software TutorialDocument38 pagesTaproot®: Version 5 Software TutorialEmilNo ratings yet

- Client ON-BOARDDocument1 pageClient ON-BOARDrealxpmythNo ratings yet

- 3.0 Japanese Words Meaning in TPSDocument16 pages3.0 Japanese Words Meaning in TPSShashi Kant GuptaNo ratings yet

- Concurrent Managers SolutionDocument2 pagesConcurrent Managers SolutionMukarram KhanNo ratings yet

- Hinulugang Taktak Sewage Treatment Plant Odor Control System Construction Method StatementDocument71 pagesHinulugang Taktak Sewage Treatment Plant Odor Control System Construction Method StatementMeng PamplonaNo ratings yet

- LA 21 Laws of Governance: SynonymsDocument39 pagesLA 21 Laws of Governance: SynonymsROLIPOPSTERNo ratings yet

- Restructuring COA within Oracle AppsDocument1 pageRestructuring COA within Oracle AppsNatarajan AgoramNo ratings yet

- Knowledge Audit KA IQ Forms and TemplateDocument10 pagesKnowledge Audit KA IQ Forms and Templatetamrat g.meskelNo ratings yet

- Ap - Export - k2 User Manual (Miti)Document24 pagesAp - Export - k2 User Manual (Miti)makhsmyNo ratings yet

- HP Jet Fusion 3D Printing Solution: Reinventing Prototyping and ManufacturingDocument3 pagesHP Jet Fusion 3D Printing Solution: Reinventing Prototyping and ManufacturingElias ImuchacNo ratings yet

- An Introduction To Object Technology: The Traditional ApproachDocument35 pagesAn Introduction To Object Technology: The Traditional ApproachBharathi IndhuNo ratings yet

- T24 Close of Business (COB) - T24 HelperDocument17 pagesT24 Close of Business (COB) - T24 HelperNett2k100% (8)

- Don Tapping, Tom Shuker-Value Stream Management For The Lean Office - Eight Steps To Planning, Mapping, & Sustaining Lean Improvements in Administrative Areas-Productivity Press (2003)Document163 pagesDon Tapping, Tom Shuker-Value Stream Management For The Lean Office - Eight Steps To Planning, Mapping, & Sustaining Lean Improvements in Administrative Areas-Productivity Press (2003)Ronald Pedroza Rodriguez100% (4)

- BPMN Poster v1.0.10 (A2)Document1 pageBPMN Poster v1.0.10 (A2)calypso342No ratings yet

- Robotic Process Automation Cheat SheetDocument1 pageRobotic Process Automation Cheat Sheetearnestgoh3635No ratings yet

- Disclosure Summary Page DR-2: Reset FormDocument21 pagesDisclosure Summary Page DR-2: Reset FormZach EdwardsNo ratings yet

- BPMN Poster A4 Ver 1.0.10 PDFDocument1 pageBPMN Poster A4 Ver 1.0.10 PDFSatrio N. W. NotoamidjojoNo ratings yet

- Khadka 2013Document8 pagesKhadka 2013nkiran022No ratings yet

- Attendance FormDocument2 pagesAttendance FormNadjib DHMNo ratings yet

- Srinivasa Rao 2016Document4 pagesSrinivasa Rao 2016Shashi KantNo ratings yet

- The Purchasing Process PowerPoint Presentation, Free Download - ID - 6520285Document1 pageThe Purchasing Process PowerPoint Presentation, Free Download - ID - 6520285mdurre82No ratings yet

- IntroductionDocument15 pagesIntroductionmonitoring suhu ruanganNo ratings yet

- Manufacturing Waste - Sri Sayekti - PPTX (Repaired)Document37 pagesManufacturing Waste - Sri Sayekti - PPTX (Repaired)ike mayaNo ratings yet

- Redundancy Enhanced Dependability (Oct - Dec 03)Document4 pagesRedundancy Enhanced Dependability (Oct - Dec 03)santhoshNo ratings yet

- Presentation EMPADocument13 pagesPresentation EMPAapi-26219976No ratings yet

- 1.1.3.11 Lab - Draw A Process DiagramDocument4 pages1.1.3.11 Lab - Draw A Process DiagramJoshua ManalotoNo ratings yet

- 02 Lean ManufacturingDocument32 pages02 Lean ManufacturingKristine Mae CabreraNo ratings yet

- The Relevance of Auditing in A Computerized Accounting SystemDocument5 pagesThe Relevance of Auditing in A Computerized Accounting SystemEmebet TesemaNo ratings yet

- Build Quality Culture with Jidoka and Andon SystemsDocument8 pagesBuild Quality Culture with Jidoka and Andon SystemsKenzie PawelczykNo ratings yet

- Lecture 1Document41 pagesLecture 1Mai Uyên MyNo ratings yet

- Application Handbook VM005 Option Selection Mining Value ManagementDocument8 pagesApplication Handbook VM005 Option Selection Mining Value Managementsopon567No ratings yet

- 2020 Raconteur Procurement-Supply-Chain-Innovation-2020Document16 pages2020 Raconteur Procurement-Supply-Chain-Innovation-2020CarlosBritoVonBodenburgNo ratings yet

- Workflow of Injection Molding Simulation & VerificationDocument6 pagesWorkflow of Injection Molding Simulation & Verificationluan_ba100% (1)

- Sammler Jim - 1672 - ScannedDocument3 pagesSammler Jim - 1672 - ScannedZach EdwardsNo ratings yet

- Miller Thomas J - 5064 - ScannedDocument8 pagesMiller Thomas J - 5064 - ScannedZach EdwardsNo ratings yet

- 2021-10-13 Project Quality Plan Rev. ADocument1 page2021-10-13 Project Quality Plan Rev. AjaymarNo ratings yet

- Python Book Management ReportDocument16 pagesPython Book Management ReportTahesin TNo ratings yet

- t24 Close of Business Cob t24 HelperDocument17 pagest24 Close of Business Cob t24 HelperAswani MucharlaNo ratings yet

- Conversation Two (Questions 5 - 8) Part One Questions 1 - 12Document7 pagesConversation Two (Questions 5 - 8) Part One Questions 1 - 12Gaais TrotNo ratings yet

- Stakeholders Register: Wilmont's Drone Project 001 Wilmont's Pharmacy Diogo Pimenta Concept 01 30/04/2020Document3 pagesStakeholders Register: Wilmont's Drone Project 001 Wilmont's Pharmacy Diogo Pimenta Concept 01 30/04/2020freddy ramdinNo ratings yet

- Lyco Manufacturing, Inc.: Offers A Full Line of World-Class Food Processing Equipment IncludingDocument4 pagesLyco Manufacturing, Inc.: Offers A Full Line of World-Class Food Processing Equipment IncludingMelissa ZelayaNo ratings yet

- Production and Operations ManagementDocument8 pagesProduction and Operations ManagementManpreet Singh SainiNo ratings yet

- CITIZEN'S CHARTER PERSONNEL SERVICESDocument1 pageCITIZEN'S CHARTER PERSONNEL SERVICESLyn RuizNo ratings yet

- 056 Evento ITS 2014Document7 pages056 Evento ITS 2014Ugs nguNo ratings yet

- Disclosure Summary Page I ®'177?. I ') NN DR-2: Statement of Cash On HandDocument5 pagesDisclosure Summary Page I ®'177?. I ') NN DR-2: Statement of Cash On HandZach EdwardsNo ratings yet

- IT4IT Reference Card4Document1 pageIT4IT Reference Card4GuillermoVillalonNo ratings yet

- AWS Periodic TableDocument1 pageAWS Periodic Tabledouglas.dvferreiraNo ratings yet

- Lean Manufacturing Chapter 2Document14 pagesLean Manufacturing Chapter 2WinterMist11No ratings yet

- CF Meridium Binder1Document89 pagesCF Meridium Binder1TommyNo ratings yet

- Lean Management AssignmentDocument14 pagesLean Management AssignmentNatala WillzNo ratings yet

- Ginlong - LAN Stick Quick User Guide-Ver1,3Document1 pageGinlong - LAN Stick Quick User Guide-Ver1,3Petflo FloNo ratings yet

- JITfinalDocument32 pagesJITfinalPradeepNo ratings yet

- Matrik PelatihanDocument1 pageMatrik PelatihanYogi RadityaNo ratings yet

- Batch ProcessingDocument3 pagesBatch ProcessingNiño Rey LopezNo ratings yet

- Disclosure Summary Page Dr-2: Michael L. Knedler For County Board OfsupervisorsDocument3 pagesDisclosure Summary Page Dr-2: Michael L. Knedler For County Board OfsupervisorsZach EdwardsNo ratings yet

- Project Title Approval: College of Computer StudiesDocument1 pageProject Title Approval: College of Computer Studiesragz autenticNo ratings yet

- Contract Review Rev2 1208Document19 pagesContract Review Rev2 1208Viswanathan SrkNo ratings yet

- Passivate Stainless Steel PartsDocument2 pagesPassivate Stainless Steel PartsViswanathan SrkNo ratings yet

- Araldite Ay 103 1Document1 pageAraldite Ay 103 1Viswanathan SrkNo ratings yet

- Araldite Ay103 1hy991 PDFDocument4 pagesAraldite Ay103 1hy991 PDFViswanathan SrkNo ratings yet

- GLORIA MATERIAL TECHNOLOGY CORP. EVERCUT 316 STAINLESS STEEL SPECIFICATIONDocument1 pageGLORIA MATERIAL TECHNOLOGY CORP. EVERCUT 316 STAINLESS STEEL SPECIFICATIONViswanathan SrkNo ratings yet

- SW DailyDocument32 pagesSW DailyViswanathan SrkNo ratings yet

- GLORIA MATERIAL TECHNOLOGY CORP. EVERCUT 316 STAINLESS STEEL SPECIFICATIONDocument1 pageGLORIA MATERIAL TECHNOLOGY CORP. EVERCUT 316 STAINLESS STEEL SPECIFICATIONViswanathan SrkNo ratings yet

- Tables of International Standards, A ComparisonDocument22 pagesTables of International Standards, A ComparisonViswanathan SrkNo ratings yet

- Technical Reference Guide Fastenal K Factor and MoreDocument62 pagesTechnical Reference Guide Fastenal K Factor and Moredlight0No ratings yet

- A 240 - A 240M - 04 - Qti0mc0wnaDocument12 pagesA 240 - A 240M - 04 - Qti0mc0wnaViswanathan SrkNo ratings yet

- Araldite Ay103 1hy991 PDFDocument4 pagesAraldite Ay103 1hy991 PDFViswanathan SrkNo ratings yet

- Araldite Ay103 1hy991 PDFDocument4 pagesAraldite Ay103 1hy991 PDFViswanathan SrkNo ratings yet

- SSWWWWDocument6 pagesSSWWWWViswanathan SrkNo ratings yet

- SW InsightDocument13 pagesSW InsightViswanathan SrkNo ratings yet

- Antelope 21 December 2015Document3 pagesAntelope 21 December 2015Viswanathan SrkNo ratings yet

- Wi 2015 12Document64 pagesWi 2015 12Viswanathan SrkNo ratings yet

- Create Shaper Tool Head Assembly and Exploded View in CADDocument6 pagesCreate Shaper Tool Head Assembly and Exploded View in CADjagadeesh01No ratings yet

- Moneylife 12 November 2015Document68 pagesMoneylife 12 November 2015Viswanathan SrkNo ratings yet

- GateDocument6 pagesGateParveen SwamiNo ratings yet

- Project1 - Diagram1Document1 pageProject1 - Diagram1Viswanathan SrkNo ratings yet

- Ex 3 BDocument1 pageEx 3 BViswanathan SrkNo ratings yet

- Ex 4 BDocument1 pageEx 4 BViswanathan SrkNo ratings yet

- Ex 2 ADocument2 pagesEx 2 AViswanathan SrkNo ratings yet

- Ex 4 ADocument3 pagesEx 4 AViswanathan SrkNo ratings yet

- Ex 3 ADocument2 pagesEx 3 AViswanathan SrkNo ratings yet

- Working Mind and The Thinking Mind - Lifestyle Article On SpeakingtreeDocument3 pagesWorking Mind and The Thinking Mind - Lifestyle Article On SpeakingtreeViswanathan SrkNo ratings yet

- Ex 4 ADocument3 pagesEx 4 AViswanathan SrkNo ratings yet

- For The First Time in India, Electrodes Put in Australian Man's Brain To Curb Depression - The Times of IndiaDocument6 pagesFor The First Time in India, Electrodes Put in Australian Man's Brain To Curb Depression - The Times of IndiaViswanathan SrkNo ratings yet

- Ex 1 BDocument1 pageEx 1 BViswanathan SrkNo ratings yet

- Ex 1 ADocument2 pagesEx 1 AViswanathan SrkNo ratings yet

- Cable Laying Equipment: CCC (Underwater Engineering) SalDocument5 pagesCable Laying Equipment: CCC (Underwater Engineering) Sallaleye_olumideNo ratings yet

- Industrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDDocument17 pagesIndustrial Training: Muhammad Amiruddin Bin Hassan 161382895 Ry44 - Integrated Electronic Alps Electric (M) SDN BHDAmiruddin HassanNo ratings yet

- Stockdale Method Roundabout PDFDocument50 pagesStockdale Method Roundabout PDFAnonymous O7BzqVvmINo ratings yet

- Assignment of Information Technology of MbaDocument11 pagesAssignment of Information Technology of MbaMohit Bhardwaj0% (1)

- T100 Thrusters PropellerDocument15 pagesT100 Thrusters PropellerNikhilkrishna NairNo ratings yet

- Technical Reviewers ListDocument4 pagesTechnical Reviewers ListAnita KarlinaNo ratings yet

- Aviation Paperbacks 2012Document4 pagesAviation Paperbacks 2012tomas.kujal8455No ratings yet

- Support Dept Cost Allocation - 3 Allocation MethodsDocument6 pagesSupport Dept Cost Allocation - 3 Allocation MethodsSophie PearsonNo ratings yet

- Company Introduction PDFDocument11 pagesCompany Introduction PDFVishwanath ShervegarNo ratings yet

- Method Statement For Installation of Aftercooler Compressor E-2180Document11 pagesMethod Statement For Installation of Aftercooler Compressor E-2180Anyanele Nnamdi FelixNo ratings yet

- Brochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionsDocument8 pagesBrochure - FTTH Drop Cabinet For 48f & 96f Customer ConnectionskmalNo ratings yet

- Equipment Initial Production Control SystemDocument1 pageEquipment Initial Production Control Systemsrmohapatra5086No ratings yet

- Procu Man Supple 9Document3 pagesProcu Man Supple 9ruwanNo ratings yet

- FAST Project Phase 2 Submission UpdatesDocument91 pagesFAST Project Phase 2 Submission UpdatesEzon AguilaNo ratings yet

- Simulado 2 MMDocument16 pagesSimulado 2 MMThiago LimaNo ratings yet

- Rotex Poly-Norm: Torsionally Flexible CouplingsDocument27 pagesRotex Poly-Norm: Torsionally Flexible CouplingsAngelica Ochoa FlorezNo ratings yet

- bb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)Document6 pagesbb9df927-5af1-44e0-ae49-d3fd10a5eb4b (1)anonymphantomNo ratings yet

- Lawaan Cemetery Part 2Document17 pagesLawaan Cemetery Part 2Mark Joseph ArellanoNo ratings yet

- Mohamed Badr CVDocument2 pagesMohamed Badr CVMohamed BadrNo ratings yet

- Problem Set Ee8205 PDFDocument4 pagesProblem Set Ee8205 PDFksajjNo ratings yet

- IBM Maximo Products V7.1Document143 pagesIBM Maximo Products V7.1dayooyefugaNo ratings yet

- Tugas Enterprise Resource Planning: Kelas ADocument4 pagesTugas Enterprise Resource Planning: Kelas ARizka HadiwiyantiNo ratings yet

- ATFMDocument4 pagesATFMYuranan LimpananvadeeNo ratings yet

- Cause & EffectDocument5 pagesCause & EffectKit Champ50% (2)

- CH 02Document39 pagesCH 02enamislamNo ratings yet

- CRM TemplateDocument17 pagesCRM TemplateAli MohamedNo ratings yet

- Contractor Pre RegistrationDocument13 pagesContractor Pre Registrationmccallum1983No ratings yet

- Mechanical Engineer Resume For FresherDocument5 pagesMechanical Engineer Resume For FresherIrfan Sayeem SultanNo ratings yet

- D9 MG GensetDocument4 pagesD9 MG GensetAji HandokoNo ratings yet

- DESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Document5 pagesDESIGN AND FABRICATION OF WIRE ROPE MAKING MACHINE Ijariie12690Tanishq ShettyNo ratings yet