Professional Documents

Culture Documents

Apcodur HB

Uploaded by

gowtham_venkat_4Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Apcodur HB

Uploaded by

gowtham_venkat_4Copyright:

Available Formats

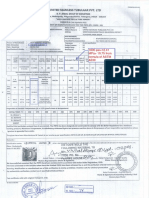

APCODUR HB ZP PRIMER

Two component, epoxy primer with zinc phosphate pigment

Designed as an epoxy primer with very good resistance to saline,

? Good adhesion on steel and aged epoxy coatings

?

marine and chemical environments Ease of application by spray & brush

?

Free from lead and chromate containing pigment

? Can be over coated with alkyd, chlorinated rubber, acrylic, epoxy,

?

polyurethane coating

TECHNICAL DATA

Colour Red oxide & Grey Drying time at 30o C Surface dry : 1 hour

Hard dry : 16 hours

Gloss Matt Full cure : 7 days

Volume Solids Approx. 40 %

Recommended DFT/ Coat 35 - 50 microns Over coating Interval at 30o C Min. : 16 hours

Max.: 1 month, provided surface

Theoretical covering capacity 11.4 sq.mtr/ l @ 35 microns DFT is dry and clean from all

8.0 sq.mtr/ l @ 50 microns DFT contamination

Flash point Base : Not less than 24o C Shelf Life (cool and dry place) At least 12 months

Hardener : Not less than 24o C

DIRECTIONS FOR USE

SURFACE PREPARATION & SUBSTRATE CONDITION:

?Steel; blast cleaned to Sa 2.5 of Swedish specification

?If blast cleaning is impractical, remove loose rust/ scale using power/ hand tool to achieve St 3/ St 2 grade of surface preparation, as per Swedish

standards. Remove contaminants like grease, oil etc. with aromatic solvents. Ensure the surface is clean and dry before priming

o o

?Substrate temperature should be at least 3 C above dew point but not above 50 C

MIXING

Stir the base and hardener separately. If settling is observed in the base or hardener, loosen the settled material with the help of hand stirrer followed by

power driven stirrer for quick homogenous mixing. Mix hardener gradually into the base under continuous stirring.

Mixing Ratio Base : Hardener Induction time 30 minutes

(by volume) 3 : 1 Pot life at 30o C 6 hours

APPLICATION

Application Method Brush/ Roller Air Spray Airless Spray

Recommended thinner T - 121/ T - 141 T - 121/ T - 141 T - 121/ T - 141

Volume of thinner 0 - 10 % 10 - 20 % 0 - 10 %

Nozzle Orifice 1.5 - 3.0 mm 0.33 - 0.41 mm

Nozzle pressure 0.3 - 0.4 MPa (= approx. 16 - 20 MPa (= approx.

3 - 4 atm; 43 - 57 p.s.i.) 160 - 200 atm; 2300 - 2800 p.s.i.)

STORAGE & PACKING

Storage : Store in a cool, dry place. Store in accordance with local regulations.

Packing : 20 litres

SAFETY INFORMATION

As a general safety measure, inhalation of solvent vapours or paint mist and contact of liquid paint with skin & eyes should be avoided. Forced ventilation should be

provided when applying paint in confined spaces or stagnant air. Even when ventilation is provided, respiratory, skin and eye protection are always recommended

when spraying paint.

Please refer our Material Safety Data Sheet prior to using the product.

Disclaimer:To the best of our knowledge the information provided herein are true and accurate at the date of issuance. Since we have no control over the quality or condition of the substrate or the various

factors affecting the use and application of the product, we do not accept any responsibility or liability arising out of use of the product.

The company reserves the right to modify data contained herein without prior notice. Any change in data would normally be followed by issue of a new data-sheet. The user should check with the

nearest sales office of the company and confirm the validity of the information, prior to using the product.

Regd. Office: Asian Paints Ltd., 6 A, Shanti Nagar, Santacruz (E), Mumbai - 400 055, India.

Tel: 022 - 39818000, Fax: 022 - 39818888, E-mail: customercare@asianpaints.com, Website: www.asianpaints.com

March 2009

Product Information Sheet - PC 1713

You might also like

- Exhibition Stand - REV 0Document12 pagesExhibition Stand - REV 0shibu4321No ratings yet

- Route To Academic SpeakingDocument150 pagesRoute To Academic SpeakingBull3asaur100% (3)

- Intecut ManualDocument84 pagesIntecut ManualjramirezNo ratings yet

- 1 .ASM HandbookDocument3 pages1 .ASM Handbookgowtham_venkat_40% (2)

- Skin Deep - July 2018 PDFDocument116 pagesSkin Deep - July 2018 PDFgant15No ratings yet

- Good Christian Friends Rejoice PDFDocument1 pageGood Christian Friends Rejoice PDFHousi WongNo ratings yet

- Josep Lluís Sert, Eric Mumford, Mohsen Mostafavi - The Writings of Josep Lluís Sert-Yale University Press (2015)Document185 pagesJosep Lluís Sert, Eric Mumford, Mohsen Mostafavi - The Writings of Josep Lluís Sert-Yale University Press (2015)Atl YólotlNo ratings yet

- Master Wu's Chinese Shamanic Cosmic Orbit QigongDocument2 pagesMaster Wu's Chinese Shamanic Cosmic Orbit QigongBronson FrederickNo ratings yet

- Bach, J. S. Little Prelude BWV 936 in D MajorDocument2 pagesBach, J. S. Little Prelude BWV 936 in D MajorCath0% (2)

- Specification SRE-004-SFBDocument1 pageSpecification SRE-004-SFBvictorNo ratings yet

- Crown Izonil Damp Solution - 1Document10 pagesCrown Izonil Damp Solution - 1Hadee Saber100% (1)

- Partex CatalogDocument199 pagesPartex CatalogjamilNo ratings yet

- Analisa FRPDocument31 pagesAnalisa FRPdzahab aliNo ratings yet

- Binder1 PDFDocument43 pagesBinder1 PDFKyNo ratings yet

- Analysis of Reinforced Slopes Input Data: ProjectDocument30 pagesAnalysis of Reinforced Slopes Input Data: ProjectNOEL RODRIGUEZNo ratings yet

- MerantiDocument1 pageMerantiDipin Nediya ParambathNo ratings yet

- GM7R Tower PhotosDocument9 pagesGM7R Tower PhotosAmlan DasNo ratings yet

- 025 - Guard Zinc Phosphate Epoxy PrimerDocument3 pages025 - Guard Zinc Phosphate Epoxy PrimerBalgo BalgobinNo ratings yet

- 4620D Test Report (For Thickness AA15)Document2 pages4620D Test Report (For Thickness AA15)weiiiiiNo ratings yet

- Fixed Moment Condition Design Based On ACI 318-14: Input Data & Design SummaryDocument1 pageFixed Moment Condition Design Based On ACI 318-14: Input Data & Design SummaryEnrike GarciaNo ratings yet

- Bolt Torque ValuesDocument1 pageBolt Torque ValuesAliNo ratings yet

- Gyproc 2Document3 pagesGyproc 2Govind NataniNo ratings yet

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEDocument1 pageHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeNo ratings yet

- Seismic Analysis IBC 2000Document1 pageSeismic Analysis IBC 2000SELVA MUTHUKUMARANNo ratings yet

- Material Test Certificate: For: Priminox OverseasDocument2 pagesMaterial Test Certificate: For: Priminox OverseasDSAFNo ratings yet

- Offshore Testing Services Lab ReportDocument3 pagesOffshore Testing Services Lab ReportKandula RajuNo ratings yet

- Q Railing KatalogDocument416 pagesQ Railing KatalogТомић ЕминаNo ratings yet

- Test Certificate for Hex Bolts According to ISO 10474-3.15 / EN 10204-3.1Document1 pageTest Certificate for Hex Bolts According to ISO 10474-3.15 / EN 10204-3.1GHULAM NABINo ratings yet

- Water tank beam calculationsDocument4 pagesWater tank beam calculationsSiew Kok HongNo ratings yet

- Infracem - WK-19Document1 pageInfracem - WK-19Sirajul IslamNo ratings yet

- Boundary WallDocument1 pageBoundary WallnaseerNo ratings yet

- Properties and Grades of FastenersDocument4 pagesProperties and Grades of Fastenerschez ezNo ratings yet

- AISC-360-16 Composite Column Design ExampleDocument3 pagesAISC-360-16 Composite Column Design Examplealejandro mantillaNo ratings yet

- Induction Melting Furnace Quotation 010720Document4 pagesInduction Melting Furnace Quotation 010720ranamzeeshanNo ratings yet

- HILTI RE-500 Rebar ConnectionDocument7 pagesHILTI RE-500 Rebar ConnectionAlma M. LaraNo ratings yet

- GratingDocument8 pagesGratingGhanshyam PandeyNo ratings yet

- Hilti-Fischer Anchor BoltDocument2 pagesHilti-Fischer Anchor Boltpavitrakedar100% (1)

- High HDT Superior Vinyl Ester Resin - Crest731Document3 pagesHigh HDT Superior Vinyl Ester Resin - Crest731GautamNo ratings yet

- Ubc 97 Type 1 Irregularity CheckDocument11 pagesUbc 97 Type 1 Irregularity CheckShekh Muhsen Uddin AhmedNo ratings yet

- MTC Details-MS: Client:-Spacemaker P.O.No: JOB No.: 1122/19 Report No-1122/01Document6 pagesMTC Details-MS: Client:-Spacemaker P.O.No: JOB No.: 1122/19 Report No-1122/01sankarapandianNo ratings yet

- Test Certificate: (, Phone: 26751763 MillDocument1 pageTest Certificate: (, Phone: 26751763 MillQc QatarNo ratings yet

- Anchor Bolt Types A and B SpecificationsDocument1 pageAnchor Bolt Types A and B SpecificationsmodarthNo ratings yet

- Foundation LoadingsDocument1 pageFoundation Loadingsmanish318No ratings yet

- Covering Letter-For Karanam Ind-PebDocument13 pagesCovering Letter-For Karanam Ind-PebswapnilNo ratings yet

- Wind LoadDocument5 pagesWind LoadPATEL JIGARNo ratings yet

- PurlinDocument10 pagesPurlintheengineersaNo ratings yet

- Ss Grade 50 - Galvanized Steel Coils & SheetsDocument1 pageSs Grade 50 - Galvanized Steel Coils & SheetshealgoseNo ratings yet

- Stainless Steel Bolts ManufacturerDocument3 pagesStainless Steel Bolts ManufacturerRajtilak MetalNo ratings yet

- MOE Simplex - 24.06.2016 PDFDocument4 pagesMOE Simplex - 24.06.2016 PDFSabyasachi BangalNo ratings yet

- SPECIFICATIONS FOR STRUCTURAL STEEL AND SHEET PILEDocument9 pagesSPECIFICATIONS FOR STRUCTURAL STEEL AND SHEET PILEAbdul Syukur ZNo ratings yet

- Weld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is AdequateDocument9 pagesWeld Capacity of Eccentric Connection Based On AISC 360-05: The Connection Design Is Adequatechristian abogadoNo ratings yet

- Ponton Drawing v6Document2 pagesPonton Drawing v6KrzysztofNo ratings yet

- Sistem M 11000 Alutherm PlusDocument159 pagesSistem M 11000 Alutherm PlusAlb AlbNo ratings yet

- Schedule of anchor bolts and typical detailsDocument1 pageSchedule of anchor bolts and typical detailsShuvam SarkarNo ratings yet

- Tension RodDocument4 pagesTension RodMarkNo ratings yet

- 1613 00442 PDFDocument59 pages1613 00442 PDFzaheerNo ratings yet

- API 5L Grade X65 Pipe Chemical Composition and Mechanical PropertiesDocument1 pageAPI 5L Grade X65 Pipe Chemical Composition and Mechanical PropertiesGEORGE VARGASNo ratings yet

- Fixotec Technical CatalogueDocument71 pagesFixotec Technical CatalogueSaqib AliNo ratings yet

- Shear Reinforcement of RC BEAM With FRP Plates ACI 440-02: V 29.628 KN V 77.081 KN V 125.000 KNDocument2 pagesShear Reinforcement of RC BEAM With FRP Plates ACI 440-02: V 29.628 KN V 77.081 KN V 125.000 KNBimalBhandariNo ratings yet

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- Commented - 8' PIPE TCDocument1 pageCommented - 8' PIPE TCAqib Khan VCSPNo ratings yet

- Torque and Tension RelationshipDocument23 pagesTorque and Tension RelationshipChris MedeirosNo ratings yet

- Apcodur Epoxy Mio Paint: Technical DataDocument1 pageApcodur Epoxy Mio Paint: Technical DataSagar BhosaleNo ratings yet

- Asian Epoxy HB CoatingDocument1 pageAsian Epoxy HB CoatingNS2 Engineering and ConstructionNo ratings yet

- APCOTHANE CF 674 Two-Component Acrylic Aliphatic Polyurethane CoatingDocument1 pageAPCOTHANE CF 674 Two-Component Acrylic Aliphatic Polyurethane CoatingANUP KUMAR MITRANo ratings yet

- Red Gray Oxide Data SheetDocument2 pagesRed Gray Oxide Data Sheetmahesh mahadkarNo ratings yet

- FDA 21 CFR Part 11 Compliance DocumentDocument15 pagesFDA 21 CFR Part 11 Compliance DocumentRamón CéspedNo ratings yet

- Caltech - Coatem NF6Document1 pageCaltech - Coatem NF6gowtham_venkat_4No ratings yet

- QA & QC Shift Details - February 2021Document2 pagesQA & QC Shift Details - February 2021gowtham_venkat_4No ratings yet

- PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation EditionDocument3 pagesPDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Edition PDF Processed With Cutepdf Evaluation Editiongowtham_venkat_4No ratings yet

- Staff Details - GOWTHAMDocument1 pageStaff Details - GOWTHAMgowtham_venkat_4No ratings yet

- Respirator Vs Surgical Mask Flyer - Final PDFDocument2 pagesRespirator Vs Surgical Mask Flyer - Final PDFshanu khanNo ratings yet

- FlowcharTDocument1 pageFlowcharTgowtham_venkat_4No ratings yet

- Thermaline 4700: Selection & Specification DataDocument4 pagesThermaline 4700: Selection & Specification Datagowtham_venkat_4No ratings yet

- Properties of Common AbrasivesDocument1 pageProperties of Common Abrasivesgowtham_venkat_4No ratings yet

- Staff Details - SANKARANDocument1 pageStaff Details - SANKARANgowtham_venkat_4No ratings yet

- WHO 2019 Ncov IPC - Masks 2020.4 Eng PDFDocument16 pagesWHO 2019 Ncov IPC - Masks 2020.4 Eng PDFSyed DanishNo ratings yet

- Untitled DiagramDocument1 pageUntitled Diagramgowtham_venkat_4No ratings yet

- Indian Standard875Document10 pagesIndian Standard875Mohammad Tawfiq WaraNo ratings yet

- Gas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task AnalysisDocument6 pagesGas Metal Arc Welding and Flux-Cored Arc Welding: Instructional/Task Analysisgowtham_venkat_4No ratings yet

- Is 2830 1992Document9 pagesIs 2830 1992Sunny SaparNo ratings yet

- Avesta Welding ManualDocument300 pagesAvesta Welding Manual66apenlullenNo ratings yet

- VSM 1Document1 pageVSM 1gowtham_venkat_4No ratings yet

- Indian Standard: Code of Practice FOR Design and Construction of Shallow Foundations On RocksDocument15 pagesIndian Standard: Code of Practice FOR Design and Construction of Shallow Foundations On RocksjndlsmtNo ratings yet

- Pregatirea Suprafetelor Pentru VopsireDocument4 pagesPregatirea Suprafetelor Pentru VopsireValentin GalbenNo ratings yet

- Supply and Fabrication Steel Structures SpecificationDocument18 pagesSupply and Fabrication Steel Structures Specificationgowtham_venkat_4No ratings yet

- Weldability of High Performance SteelsDocument16 pagesWeldability of High Performance Steelsgowtham_venkat_4No ratings yet

- VSM For Job No J1947 A1 Time Log SheetDocument6 pagesVSM For Job No J1947 A1 Time Log Sheetgowtham_venkat_4No ratings yet

- Cosmos Products: Technical Service Data SheetDocument1 pageCosmos Products: Technical Service Data Sheetgowtham_venkat_4No ratings yet

- Surface Preparation Standards OverviewDocument38 pagesSurface Preparation Standards OverviewEric So100% (1)

- Nitric Acid Manufacturing ProcessDocument7 pagesNitric Acid Manufacturing ProcessLenin PrabhuNo ratings yet

- Flow Side Asy LHDocument1 pageFlow Side Asy LHgowtham_venkat_4No ratings yet

- Threads Standard Reference Guide Rev4 PDFDocument21 pagesThreads Standard Reference Guide Rev4 PDFPham CongNo ratings yet

- 21055-Acoustics India - 15nosDocument27 pages21055-Acoustics India - 15nosgowtham_venkat_4No ratings yet

- EN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 OnwardsDocument1 pageEN8 Steel: BS970: 1955 EN8, BS970/PD970: 1970 Onwardsgowtham_venkat_4No ratings yet

- Gemstone Quality AnalysisDocument10 pagesGemstone Quality AnalysisTharanga Sujeeva MadalakandaNo ratings yet

- DR Suess LandscapesDocument6 pagesDR Suess Landscapesapi-502866275No ratings yet

- A Companion to Feminist ArtDocument1 pageA Companion to Feminist ArtRuxandra-Maria RadulescuNo ratings yet

- Grade 3 Holiday RiverdaleDocument61 pagesGrade 3 Holiday Riverdalemongiwethu ndhlovuNo ratings yet

- English (Advanced) Paper 2Document12 pagesEnglish (Advanced) Paper 2Kelvin ChenNo ratings yet

- Matthew Arnold As A Literary CriticDocument9 pagesMatthew Arnold As A Literary CriticAnant KumarNo ratings yet

- A Project On Nagarjuna DamDocument3 pagesA Project On Nagarjuna Damapi-19889358No ratings yet

- Visions of The Apocalypse - Beatus Manuscripts and 13th Century Apocalypse ManuscripsDocument15 pagesVisions of The Apocalypse - Beatus Manuscripts and 13th Century Apocalypse Manuscripsalice85aliceNo ratings yet

- Glass ManufacturingDocument17 pagesGlass ManufacturingArslanAliNo ratings yet

- Visual Arts FAT Grade 5Document10 pagesVisual Arts FAT Grade 5Jerome FankomoNo ratings yet

- Listening ExercisesDocument5 pagesListening ExercisesCandelaria LuqueNo ratings yet

- CKHG Online Resources From The Renaissance To Englands Golden AgeDocument12 pagesCKHG Online Resources From The Renaissance To Englands Golden AgeMaggie van GelderenNo ratings yet

- The VirginDocument2 pagesThe VirginRhona Zein NiezNo ratings yet

- Baby RoosterDocument4 pagesBaby RoosterAYLIN caraveoNo ratings yet

- Restructuring, Dengan Menekankan Pada Aspek Accuracy, Naturalness, ReadabilityDocument3 pagesRestructuring, Dengan Menekankan Pada Aspek Accuracy, Naturalness, ReadabilityGungaleNo ratings yet

- No Fines Concrete:: A Practical GuideDocument2 pagesNo Fines Concrete:: A Practical GuideAdhil RamsurupNo ratings yet

- International Kangaroo Linguistic Contest QuestionsDocument4 pagesInternational Kangaroo Linguistic Contest QuestionsFarzeen Fatima100% (1)

- Natural Lighting at The Kimbell Museum: Gifford Pierce of IdahoDocument5 pagesNatural Lighting at The Kimbell Museum: Gifford Pierce of IdahoBtn SayadNo ratings yet

- Bill of Quantity:: Tiger Circle - ManipalDocument8 pagesBill of Quantity:: Tiger Circle - Manipalyamanta_rajNo ratings yet

- Where It All Began: 14 Early Architectural Drawings by Zaha HadidDocument18 pagesWhere It All Began: 14 Early Architectural Drawings by Zaha HadidSpam TestNo ratings yet

- Router Table - RTA300: Supercedes Earlier Model RTA300 - July 2002Document2 pagesRouter Table - RTA300: Supercedes Earlier Model RTA300 - July 2002j_abendstern4688No ratings yet

- Copyright LawDocument21 pagesCopyright LawBelle MadreoNo ratings yet

- Indice: Contenido - 1 - Digital TutorsDocument79 pagesIndice: Contenido - 1 - Digital TutorsJavier CardinalNo ratings yet

- Netflix Data AnalysisDocument6 pagesNetflix Data Analysispubg boy ASNo ratings yet