Professional Documents

Culture Documents

Emergency Shutdown Ps

Uploaded by

winarnob0 ratings0% found this document useful (0 votes)

39 views2 pageseps

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenteps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views2 pagesEmergency Shutdown Ps

Uploaded by

winarnobeps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

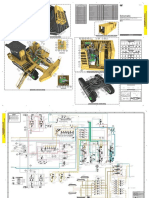

Well Test Emergency Shutdown System

Control flowline valve on flowhead and surface safety valve

remotely and simultaneously

Applications The ESD system and a minimum of two remote control stations are recommended for all well test

All well test operations operations. The remote stations are to be located at the separator and in an area removed from

H2S environments and wells in which all pressurized equipment on an escape route.

wellhead pressures are greater than

During testing operations, the shutdown system controls the hydraulically operated flowline

5,000 psi [34 MPa]

valve on the flowhead and permits manual or remote closure in response to a pipe leak or break,

Benefits equipment malfunction, fire, or similar emergency. The ESD system is also used to reopen the

Improved safety for personnel and valve and, if needed, can control an additional surface safety valve upstream of the choke.

equipment, with established fail-safe

Pressure from the systems air-driven hydraulic pump is applied to open the valves and released

well test conditions

to close them.

Features

Backing up the remote stations are high- and low-pressure pilots that are installed on the flowline

Skid-mounted control console

to automatically close the flowline valve in case of an emergency. The high-pressure pilots initiate

Air-driven hydraulic pump with four well closure when the pressure in the flowline rises above a high-level threshold, as would occur

air outlets if the line were plugged. The low-pressure pilots initiate well closure when pressure falls below

Preset pressure values for well closure a low-level threshold, as it would in the event of a flowline rupture or leak.

Storage space for remote emergency In an H2S environment or for high-pressure tests of 5,000 psi [34 MPa] or greater, one of the remote

shutdown (ESD) stations and three control stations must be at the separator. Other stations can be set up at the customers discretion.

hose reels One station must be on an escape route and in an area away from all pressurized equipment.

Ports for additional or optional pilots

Hydraulic tank

High-pressure hose for use with

a shutdown-valve actuator

Low-pressure hoses for connection

to the ESD stations or the high- and

low-pressure pilots

Well test ESD system.

Well Test Emergency Shutdown System

Specifications

Model ESD-C ESD-CB

Height, ft [m] 3.94 [1.2] 3.94 [1.2]

Footprint, ft [m] 3.02 3.02 [0.92 0.92] 3.02 3.02 [0.92 0.92]

Weight, lbm [kg] 795 [340] 882 [400]

Hydraulic actuator hose, 38-in NPT male; 38-in BSP female

Pressure, psi [MPa] 6,000 [41] 6,000 [41]

Length, ft [m] 25 [7.6] 25 [7.6]

Pneumatic hoses, 38-in NPT male

Pressure, psi [MPa] 200 [1.4] 200 [1.4]

Length, ft [m] 25 [7.6] and 50 [15.2] 25 [7.6] and 50 [15.2]

Hydraulic quick coupling 38-in NPT female 38-in NPT female

Pneumatic quick coupling 38-in NPT female 38-in NPT female

Manufacturing Certificate of conformity Certificate of conformity

Documentation Quality file and load test Quality file and load test

National

Pipe Thread

British

Standard Pipe

Schlumberger recommends the use of an ESD system with at least two pilots during each test.

www.slb.com/welltesting

*Mark of Schlumberger

Other company, product, and service names

are the properties of their respective owners.

Copyright 2012 Schlumberger. All rights reserved. 12-TS-0140

You might also like

- Barebow Archery NotesDocument11 pagesBarebow Archery NoteswinarnobNo ratings yet

- Issues No 27 ContentDocument11 pagesIssues No 27 ContentwinarnobNo ratings yet

- Structural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFDocument3 pagesStructural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFwinarnobNo ratings yet

- Pipeline Annual ReportDocument9 pagesPipeline Annual ReportwinarnobNo ratings yet

- Deep Bed Nutshell Filter Evolution English LetterDocument15 pagesDeep Bed Nutshell Filter Evolution English LetterArun GuptaNo ratings yet

- 13 Tips Presentasi Efektif - A Madeandi's Life PDFDocument9 pages13 Tips Presentasi Efektif - A Madeandi's Life PDFwinarnobNo ratings yet

- Inflow & Outflow Performance Archives - Production TechnologyDocument7 pagesInflow & Outflow Performance Archives - Production Technologywinarnob100% (2)

- Fax - 600-EP2200-2015-S0 - 64821 - Presentasi Operation Integrity Management For Oil and Gas IndustryDocument2 pagesFax - 600-EP2200-2015-S0 - 64821 - Presentasi Operation Integrity Management For Oil and Gas IndustrywinarnobNo ratings yet

- Glycol DehydrationDocument1 pageGlycol DehydrationwinarnobNo ratings yet

- Structural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFDocument3 pagesStructural Vibration and Ways To Avoid It - Vibration, Dynamics and Noise PDFwinarnobNo ratings yet

- Pipeline Annual ReportDocument9 pagesPipeline Annual ReportwinarnobNo ratings yet

- Inflow & Outflow Performance Archives - Production TechnologyDocument7 pagesInflow & Outflow Performance Archives - Production Technologywinarnob100% (2)

- Basic Practices in Compressors Selection PDFDocument11 pagesBasic Practices in Compressors Selection PDFwinarnob100% (1)

- Commuterline Schedule Update 22 July 2017 Yellow Line Jatinegara BogorDocument40 pagesCommuterline Schedule Update 22 July 2017 Yellow Line Jatinegara BogorBayuNo ratings yet

- Risk AssessmentDocument2 pagesRisk AssessmentwinarnobNo ratings yet

- Process Safety Management Guidelines For ComplianceDocument16 pagesProcess Safety Management Guidelines For CompliancewinarnobNo ratings yet

- 2014 Lean Management Enterprise Compendium With LinksDocument164 pages2014 Lean Management Enterprise Compendium With LinksSajid AliNo ratings yet

- How To Start Building Your Next-Generation Operating Model - McKinsey & CompanyDocument13 pagesHow To Start Building Your Next-Generation Operating Model - McKinsey & CompanywinarnobNo ratings yet

- D-PGS3-0-1225-306-C 1 of 2Document1 pageD-PGS3-0-1225-306-C 1 of 2winarnobNo ratings yet

- E 881511 Om GSCTP C P RC GBR 6-A4Document72 pagesE 881511 Om GSCTP C P RC GBR 6-A4winarnobNo ratings yet

- An Improved Method For Evaluating Compressor Rod Bushing DesignsDocument5 pagesAn Improved Method For Evaluating Compressor Rod Bushing Designswinarnob100% (1)

- Indocita Annual Training Schedule 2017 (Update)Document4 pagesIndocita Annual Training Schedule 2017 (Update)winarnobNo ratings yet

- Why Compression Ratio Matters PDFDocument10 pagesWhy Compression Ratio Matters PDFwinarnobNo ratings yet

- D-PGS3-0-1225-306-C 2 of 2Document1 pageD-PGS3-0-1225-306-C 2 of 2winarnobNo ratings yet

- Why Compression Ratio Matters2 PDFDocument10 pagesWhy Compression Ratio Matters2 PDFwinarnobNo ratings yet

- Chevron Business Conduct Ethics CodeDocument31 pagesChevron Business Conduct Ethics CodewinarnobNo ratings yet

- Why Compression Ratio MattersDocument10 pagesWhy Compression Ratio MatterswinarnobNo ratings yet

- Brochure & Registration Form 13-15 March 2017Document3 pagesBrochure & Registration Form 13-15 March 2017winarnobNo ratings yet

- How To Start Building Your Next-Generation Operating Model - McKinsey & CompanyDocument13 pagesHow To Start Building Your Next-Generation Operating Model - McKinsey & CompanywinarnobNo ratings yet

- CM Vs GC 7pages PDFDocument7 pagesCM Vs GC 7pages PDFwinarnobNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Plano CatDocument2 pagesPlano CatLuis Ladino100% (1)

- CDB 1033 Fluid Mechanics Tutorial 3Document2 pagesCDB 1033 Fluid Mechanics Tutorial 3Marzs MarNo ratings yet

- Athi Water Services Board: Kiserian Sewerage ProjectDocument29 pagesAthi Water Services Board: Kiserian Sewerage ProjectKip RotichNo ratings yet

- Biological Wastewater Treatment III - MBR Processes R1Document26 pagesBiological Wastewater Treatment III - MBR Processes R1NUR ASYIQIN BINTI AZAHARNo ratings yet

- Installers Manual ING 2010Document161 pagesInstallers Manual ING 2010aco1970No ratings yet

- Desain IPAL Domestik Central Processing Plant (CPP) Gundih: PT. Pertamina EP Asset 4 Cepu FieldDocument10 pagesDesain IPAL Domestik Central Processing Plant (CPP) Gundih: PT. Pertamina EP Asset 4 Cepu FieldChrista GabrielaNo ratings yet

- Addi Examples Pipe3Document10 pagesAddi Examples Pipe3Diego MorenoNo ratings yet

- Chapter 8 - Aerobic ProcessDocument48 pagesChapter 8 - Aerobic ProcessMohd Hairul100% (1)

- Ashirvad CPVC Pricelist 20-Jul-23Document18 pagesAshirvad CPVC Pricelist 20-Jul-23AniruddhaPalriwalaNo ratings yet

- Inquiry ACDocument172 pagesInquiry ACBeghyNo ratings yet

- 07 Sistema Piloto Cargador Frontal 928GDocument19 pages07 Sistema Piloto Cargador Frontal 928GLeydi Diana Chuquirimay HuamaniNo ratings yet

- Mendoza, Rod - Activity 4 - Meuti230 Engineering Utilities2Document4 pagesMendoza, Rod - Activity 4 - Meuti230 Engineering Utilities2Rovic VincentNo ratings yet

- 14 MarksDocument4 pages14 MarksmohanNo ratings yet

- DepEd Red Cross 3 4 Seater Detached PoWs BoQsDocument42 pagesDepEd Red Cross 3 4 Seater Detached PoWs BoQsRamil S. ArtatesNo ratings yet

- Dam Engineering CIE 522 - Lecture 2 Chapter 1 - Part 2 - 19032023Document77 pagesDam Engineering CIE 522 - Lecture 2 Chapter 1 - Part 2 - 19032023Emmanuel MwabaNo ratings yet

- Series 909 Specification SheetDocument4 pagesSeries 909 Specification SheetWattsNo ratings yet

- Water Treatment Training ReportDocument3 pagesWater Treatment Training ReportFadli MuhammadNo ratings yet

- Series 825Y Specification SheetDocument2 pagesSeries 825Y Specification SheetFEBCONo ratings yet

- CE Board Nov 2021 - Hydraulics - Set 8Document3 pagesCE Board Nov 2021 - Hydraulics - Set 8Lemuel Teope100% (1)

- SPG en ProductCatalogue VFTDocument34 pagesSPG en ProductCatalogue VFTRoo FaNo ratings yet

- Review of The Technological Approaches For Grey Water Treatment and ReusesDocument12 pagesReview of The Technological Approaches For Grey Water Treatment and ReusesMashaelNo ratings yet

- Petronas Technical Standards: Drainage and Sewer Systems For Onshore FacilitiesDocument23 pagesPetronas Technical Standards: Drainage and Sewer Systems For Onshore FacilitiesMohd Nizamuddin Mohamad NoorNo ratings yet

- WWTP System (BOP)Document22 pagesWWTP System (BOP)robiansah100% (1)

- School of Engineering and Computer Studies Divine Word College of Legazpi Legazpi CityDocument2 pagesSchool of Engineering and Computer Studies Divine Word College of Legazpi Legazpi CityEddie GuiribaNo ratings yet

- HDPE Corrugated Pipes & Fittings GuideDocument16 pagesHDPE Corrugated Pipes & Fittings GuidereemNo ratings yet

- Banana Peel Water TreatmentDocument3 pagesBanana Peel Water TreatmentRIZERTS GAP0% (1)

- Fusible Dev 15RS128 Rev 0110Document2 pagesFusible Dev 15RS128 Rev 0110Ali YusufNo ratings yet

- Product Catalogue: World Class Quality Products Proudly Made in ZambiaDocument18 pagesProduct Catalogue: World Class Quality Products Proudly Made in ZambiaBhosle ImpexNo ratings yet

- IFAS MediaDocument2 pagesIFAS MediaagusrahayuNo ratings yet

- Safety Valves For Industrial ApplicationDocument164 pagesSafety Valves For Industrial ApplicationJOHNNo ratings yet