Professional Documents

Culture Documents

Arc Stud Welding

Uploaded by

Khwanas LuqmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arc Stud Welding

Uploaded by

Khwanas LuqmanCopyright:

Available Formats

The P r oc es s

Ar c Stud W el din g

1 2

S tud and ceramic

ferrule agains t the S tud lif ts and ar c

work plate is drawn

A rc S tud Welding involves the same basic principles

and metallurgical aspects as any other arc welding procedure,

in that a controlled electric arc is used to melt the stud or

electrode and a portion of the base metal. The stud is thrust

automatically into the molten metal and a high quality fusion

weld is accomplished where the weld is stronger than the

stud itself. S tud Welding is applicable to mild steel, stainless

and aluminum.

Welded fasteners or studs may be almost any size, or

type and there are literally hundreds, however, they must be

made of weldable materials and one end of the fastener must

be designed for welding. C onventional DC welding machines

of all types may be used, but special power units designed

specifically for stud welding are also available.

3 4

C ontr ol times out Metal s olidifies and

and s tud plunges into weld is completed in

molten s te el a s plit s econd

Gen er a l I n f o r ma t i o n

B asic engineering specifications which cover all of TH R E ADS

the studs listed in this publication regardless of size The standard threads on studs are UNC -2A. Other

or shape are detailed below. threads are available on reques t. S tandard

ma ximum thread length is 3".

S TU D DIME N S ION S (A f t er W el d L en gt h )

The length dimension (L) carried throughout the

FLUX

s pecifications is the overall length of the s tud

All S tuds 1 4"diameter and over are solid fluxed.

B efore Weld. The After Weld length will be shor ter B elow 1 4"diameter solid flux or non fluxed studs are

dependent upon the size of the stud as shown in the available upon reques t. The rectangular s tuds

following table. shown in this publication are not fluxed.

Stud D i a me t e r L en gt h R edu c t ion

ANNE AL ING

1

4" Dia. Through 2" Dia.

1 1

8"

S .W.A. S tuds can be annealed to a ma ximum of 75

5

8" Dia. Through 7 8" Dia. 3

16" R ock well B for low carbon steel and 85 R ock well B

1 Dia. and Over

3

16"- 1 4" for S tainless S teel. An ex tra charge is applicable for

annealing and will be quoted if desired.

MATE R IAL S

All of the studs shown are available in mild or

stainless steel. When a stud is stocked, the steel

grade it is stocked in is indicated.

The low carbon steel or mild steel studs conform

with reasonable limits to the analysis shown:

C - 0.23% Ma x. P - 0.040% Ma x.

Mn - 0.090% Ma x. S - 0.050% Ma x.

S TAINL E S S S TE E L S : S tainles s s te els mos t

commonly used is 18-8 stainless steel.

A L U M I N U M : In aluminum, alloy 5356 is most

commonly used for stud welding.

ME C H A N IC A L P R OP E R TIE S

(as cold drawn)

STUD TYPE MATE R IAL TE NS IL E ( u l t i ma t e ) R E DU C TION IN A R E A

PD, FT, FB , R B C -1010/C -1020 55,000 psi Min 50% Min.

TP, C L, S H, NT AS TM-A108

R 6, R 7, R 2

HA, S C C -1010/C -1020 60,000 psi Min 50% Min.

AWS D1.1 & AS TM-A108

DA Low C arbon/AS TM 496 80,000 psi Min

CD C -1010/C 01020 50,000 psi Min.

AS TM-A108

A c c o mmo d a t i n g The F il l et

When a stud is end-welded, a fillet forms around its base with the

fillet dimensions being closely controlled by the design of the fer-

rule used. S ince the diameter of the fillet is generally larger than the

diameter of the stud, some consideration is required in the design

of mating parts. C ounter bore and counter sink methods are com-

monly us ed. Dimens ions will var y with s tuds and ferrules .

Additional methods of accommodating fillet include oversized

clearance holes, use of a gasket material around the fillet or use of

a dog-type construction.

F il l et C l ea r a n c e F or E l e c t r i c -A r c W el ded F u l l B a s e S t u ds

C

B

< A >

O

S TUD S IZE C OUNTE R B OR E 90 C OUNTE R S INK

(in.) (in.) (in.)

A B C

1

/4 0.437 0.125 0.125

5

/16 0.500 0.125 0.125

3

/8 0.593 0.125 0.125

7

/16 0.656 0.187 0.125

1

/2 0.750 0.187 0.187

5

/8 0.875 0.218 0.187

3

/4 1.125 0.312 0.187

(a) Overs ize clearance hole (b) G as ket material (c) Dog clamp

Welded studs designed with reduced weld bases so that weld

fillet does not exceed ma ximum diameter of fastener.

This design is not recommended if fastener strength is important.

T e mp l a t e D e s i g n F o r

S t u d L oc a t in g

This method of templating is recommended for use be used. The recommended hole sizes on the

with all ferrules. The template is usually a steel plate template to locate the ferrules should equal the

3

/32" to 3/16" thick. S pacers are required to allow the ma ximum outside diameter of the ferrule plus 1 32".

gases to escape during the welding cycle. The Holes may be drilled or bored at required locations.

ferrule can be held by a standard ferrule grip or S ee stud specification sheets for ferrule detail.

where clearance is prohibitive a tube type set-up can

Stud S ize D L

1

/2" and

under 1.250 2.000

5

/8" and

3

/4" 1.562 2.500

7

/8" and

larger 2.125 2.500

This method of templating is recommended for use template. S tandard copper ferrule grips are used

with all stud styles. The design makes it possible to with the tube adapter. This permits standardization of

accurately hold angular alignment of the studs as templates since it is only necessary to change the

well as stud location. The template should be made copper ferrule grip to weld studs of different diame-

of ebonite or masonite of a thickness sufficient to ters. The hole diameter of the bushing or template

afford good alignment. B ushings may be used to should be approximately .010 larger than the ma xi-

insure greater accuracy and ex tend the life of the mum outside diameter of the template tub adapter.

R e c o mme n d e d M i n i mu m P l a t e T h i c k n e s s Of S t eel

A n d A l u mi n u m F o r E l e c t r i c - A r c S t u d W el din g

S TE E L ALUMINUM

B ase Dia. of

WITHOUT B AC KUP WITH B AC KUP

S tud (in.) (in.) (gage)

WITHOUT B AC KUP

(in.) (in.)

0.187 0.0359 20 0.125 0.125

0.250 0.0478 18 0.125 0.125

0.312 0.0598 16 0.187 0.125

0.375 0.0747 14 0.187 0.187

0.437 0.0897 13 0.250 0.187

0.500 0.1196 11 0.25 0.250

0.625 0.148 9 0.250

0.750 0.187

0.875 0.250

1.000 0.375

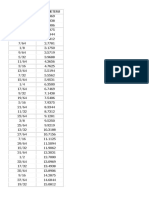

W eigh t Char t

E s t i ma t e d W eigh t s Of Th r ea ded S t u ds In P ou n ds P er 1000 P iec es

1 5/ 3 7 1 5 3 7

LE NG TH /4 dia. 16 dia. /8 dia. /16 dia. /2 dia. /8 dia. /4 dia. /8 dia.

3

/4 8.3 12.8 18.8 25.5 34.5

1 11.0 17.0 25.0 34.0 46.0 70.0

1

1 /4 13.8 21.3 31.3 42.5 57.5 87.5 133.8

1

1 /2 16.5 25.5 37.5 51.0 69.0 105.0 160.5 243.8

3

1 /4 19.3 29.8 43.8 59.5 80.5 122.5 187.3 284.4

2 22.0 34.0 50.0 68.0 92.0 140.0 214.0 325.0

1

2 /4 24.8 38.3 56.3 76.5 103.5 157.5 240.8 165.6

1

2 /2 27.5 42.5 62.5 85.0 115.0 175.0 267.5 406.3

3

2 /4 30.3 46.8 68.8 93.5 126.5 192.5 294.3 446.9

3 33.0 51.0 75.0 102.0 138.0 210.0 321.0 487.5

1

3 /4 35.8 55.3 81.3 110.5 149.5 227.5 347.8 528.1

1

3 /2 38.5 59.5 87.5 119.0 161.0 245.0 374.5 568.8

3

3 /4 41.3 63.8 93.8 127.5 172.5 262.5 401.3 609.4

4 44.0 68.0 100.0 136.0 184.0 280.0 428.0 650.0

1

4 /4 46.8 72.3 106.3 144.5 195.5 297.5 454.8 690.6

1

4 /2 49.5 76.5 112.5 153.0 207.0 315.0 481.5 731.3

3

4 /4 52.3 80.8 118.8 161.5 218.5 332.5 508.3 771.9

5 55.0 85.0 125.0 170.0 230.0 350.0 535.0 812.5

Addl Inch 11.0 17.0 25.0 34.0 46.0 70.0 107.0 162.5

Ferrule 2.0 2.5 3.0 3.5 4.0 5.0 10.0 12.0

E s t i ma t e d W eigh t s Of N o -T h r e a d S t u ds In P ou n ds P er 1000 P iec es

3 1 5 3 7 1 5 3 7

LE NG TH /16 dia. /4 dia. /16 dia. /8 dia. /16 dia. /2 dia. /8 dia. /4 dia. /8 dia.

3

/4 6.0 10.5 16.4 23.5 31.9 41.7

1 8.0 14.0 21.8 31.3 42.5 55.6 86.6

1

1 /4 10.0 17.5 27.3 39.1 53.1 69.5 108.3 156.0

1

1 /2 12.0 21.0 32.7 47.0 63.8 83.4 129.9 187.2 225.0

3

1 /4 14.0 24.5 38.2 54.8 74.4 97.3 151.6 218.4 297.5

2 16.0 28.0 43.6 62.6 85.0 111.2 173.2 249.6 340.0

1

2 /4 18.0 31.5 49.1 70.4 95.6 125.1 194.9 280.8 382.5

1

2 /2 20.0 35.0 54.5 78.3 106.3 139.0 216.5 312.0 425.0

3

2 /4 22.0 38.5 60.0 86.1 116.9 152.9 238.2 343.2 467.5

3 24.0 42.0 65.4 93.9 127.5 166.8 259.8 374.4 510.0

1

3 /4 26.0 45.5 70.9 101.7 138.1 180.7 281.5 405.6 552.5

1

3 /2 28.0 49.0 76.3 117.4 148.8 194.6 303.1 436.8 595.0

3

3 /4 30.0 52.5 81.8 125.2 159.4 208.5 324.8 468.0 637.5

4 32.0 56.0 87.2 125.2 170.0 222.4 346.4 499.2 680.0

1

4 /4 34.0 59.5 92.7 133.0 180.6 236.3 368.1 530.4 722.5

1

4 /2 36.0 63.0 98.1 140.9 191.3 250.2 389.7 561.6 765.0

3

4 /4 38.0 66.5 103.6 148.7 201.9 264.1 411.4 592.8 807.5

5 40.0 70.0 109.0 156.5 212.5 278.0 433.0 624.0 850.0

Addl. Inch 8.0 14.0 21.8 31.3 42.5 55.6 86.6 124.8 170.0

Ferrule 3.0 3.5 4.0 5.0 6.0 7.5 9.0 27.0 37.0

You might also like

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationFrom EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNo ratings yet

- STRUCTURAL - Chapter 14 - Explicit Dynamics Analysis (UP19980818)Document26 pagesSTRUCTURAL - Chapter 14 - Explicit Dynamics Analysis (UP19980818)Rory Cristian Cordero RojoNo ratings yet

- Docking FacilitiesDocument23 pagesDocking FacilitiesAthulvasnikNo ratings yet

- Geotech ELDocument6 pagesGeotech ELnithesh kumar jNo ratings yet

- Introduction To Heat Exchangers (HXS) : DR Rashid AliDocument36 pagesIntroduction To Heat Exchangers (HXS) : DR Rashid AliUsama IbrahimNo ratings yet

- Pressure Vessel DesignDocument8 pagesPressure Vessel DesignHector Javier Cruz CampaNo ratings yet

- JIS G4103 SNCM420 Steel Properties & ApplicationsDocument2 pagesJIS G4103 SNCM420 Steel Properties & Applicationsamit2688No ratings yet

- Buckling of Flat PlatesDocument106 pagesBuckling of Flat PlatesdabrooksiNo ratings yet

- Bending and Buckling of Thin PlatesDocument44 pagesBending and Buckling of Thin PlatesHazem EmamNo ratings yet

- Elevated Water TankDocument16 pagesElevated Water TankRANJITH PULIKESHINo ratings yet

- Regulatory Guide 1.13 Spent Fuel Storage Facility Design BasisDocument12 pagesRegulatory Guide 1.13 Spent Fuel Storage Facility Design BasisEnformableNo ratings yet

- 2021 Theme 1 - Homework ProblemsDocument6 pages2021 Theme 1 - Homework ProblemsMartin MugoniNo ratings yet

- CEE 330L Manual (Modified 13-01-2020) - Converted-Compressed PDFDocument55 pagesCEE 330L Manual (Modified 13-01-2020) - Converted-Compressed PDFT Srinivas ReddyNo ratings yet

- Memorias de Calculo PDFDocument61 pagesMemorias de Calculo PDFAlexander Correa TabordaNo ratings yet

- Gujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2Document5 pagesGujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2THANGAVEL PNo ratings yet

- Buckling of Conical Shells Under ExternalDocument81 pagesBuckling of Conical Shells Under Externalabdulsalam yousifNo ratings yet

- Habte Atle (Parafin Oil)Document87 pagesHabte Atle (Parafin Oil)aberNo ratings yet

- Architecture Design Handbook - Flashings and Copings - Coping CoversDocument5 pagesArchitecture Design Handbook - Flashings and Copings - Coping CoversDukeNo ratings yet

- KT & Ky Parafin OilDocument45 pagesKT & Ky Parafin OilaberNo ratings yet

- 2.CALENBERG Vibration Insulation Bearings - Ciparall - Sliding - Bearing - en PDFDocument8 pages2.CALENBERG Vibration Insulation Bearings - Ciparall - Sliding - Bearing - en PDFAlexandra SanduNo ratings yet

- Basics of A ScaffoldDocument8 pagesBasics of A ScaffoldAhmed IsahNo ratings yet

- Sci Publication p387 Steel Building Desi 2Document4 pagesSci Publication p387 Steel Building Desi 2Visuvaratnam Suseendran100% (1)

- Is 866 1957Document7 pagesIs 866 1957sarath6725No ratings yet

- Thin Walled Pressure Vessels: 1 Er. Shova ShresthaDocument43 pagesThin Walled Pressure Vessels: 1 Er. Shova Shresthacoded coderNo ratings yet

- Cathodic ProtectionDocument26 pagesCathodic Protection20pcha122 20pcha122No ratings yet

- Examples of The Principle of Superposition: 1. Source Plus A Uniform FlowDocument6 pagesExamples of The Principle of Superposition: 1. Source Plus A Uniform FlowJay Vora100% (1)

- Skmm4513 Cad Project Sem 1 1516Document4 pagesSkmm4513 Cad Project Sem 1 1516Puvendran Balakrishnan100% (2)

- Lecture 8 Problems On SFD and BMD On Beams With Point LoadsDocument33 pagesLecture 8 Problems On SFD and BMD On Beams With Point Loadsshaheer asifNo ratings yet

- Melaku Tesfaye (Parafin Oil)Document55 pagesMelaku Tesfaye (Parafin Oil)aberNo ratings yet

- Mechanicl EngineeringDocument981 pagesMechanicl EngineeringBobby WaltersNo ratings yet

- Compression Test On MS and CI RevisedDocument7 pagesCompression Test On MS and CI Revisedafzal taiNo ratings yet

- Rectangular Bin Designs - Steve AshDocument3 pagesRectangular Bin Designs - Steve AshVictor BoderoNo ratings yet

- Mechanics of MaterialsDocument21 pagesMechanics of MaterialsUbaid Ahmed Mughal100% (1)

- Blast Event Simulation For A Structure Subjected To A Landmine ExplosionDocument8 pagesBlast Event Simulation For A Structure Subjected To A Landmine ExplosionaishurenjsNo ratings yet

- Fatigue Consideration DesignDocument68 pagesFatigue Consideration DesignSaravanan Srvn TNo ratings yet

- STRUCTURAL - Chapter 2 - Structural Static Analysis (UP19980818)Document36 pagesSTRUCTURAL - Chapter 2 - Structural Static Analysis (UP19980818)Rory Cristian Cordero RojoNo ratings yet

- Lecture 2. Riveted Joints PDFDocument20 pagesLecture 2. Riveted Joints PDFhasanNo ratings yet

- Stress CalculationDocument5 pagesStress CalculationJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Unit 7 Shafts: StructureDocument23 pagesUnit 7 Shafts: StructureSabareesan SubramanianNo ratings yet

- Project-1 - Design of Pressure Vessel DonDocument29 pagesProject-1 - Design of Pressure Vessel DondagemNo ratings yet

- Shear Failure of Bolted Joints Lab ReportDocument1 pageShear Failure of Bolted Joints Lab Reportboo huNo ratings yet

- Work Bench VerificationDocument220 pagesWork Bench Verificationchkarthiksai0% (1)

- ThickWalledCylinder and PressShrinkFit ShigDocument17 pagesThickWalledCylinder and PressShrinkFit ShigArooj WaniNo ratings yet

- Chap 4 Bolted JointsDocument25 pagesChap 4 Bolted JointsMelese AschalewNo ratings yet

- Design of Gating System for CastingDocument17 pagesDesign of Gating System for CastingAshish ManwarNo ratings yet

- ENGINEERING GUIDELINES THESIS FORMATDocument13 pagesENGINEERING GUIDELINES THESIS FORMATShubham PawarNo ratings yet

- Waves in The OceanDocument51 pagesWaves in The OceanSuntoyo SajaNo ratings yet

- Copper Pipe SupportDocument2 pagesCopper Pipe SupportAmirudin SallehNo ratings yet

- USD T BeamDocument10 pagesUSD T BeammanowarNo ratings yet

- Chapter 6 Material ScienceDocument42 pagesChapter 6 Material Science9al6oonNo ratings yet

- FPS Riser Design Challenges in Deep WatersDocument6 pagesFPS Riser Design Challenges in Deep WatersRajeuv GovindanNo ratings yet

- Chapter XiiDocument12 pagesChapter XiiKenneth AndayaNo ratings yet

- Design and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodDocument7 pagesDesign and Static Analysis of Different Pressure Vessels and Materials Using Fem MethodSuryaprakashNo ratings yet

- Lichtgitter GRP ManualDocument68 pagesLichtgitter GRP ManualGeorgi KalchevNo ratings yet

- Wedling ModelingDocument32 pagesWedling ModelingManish KumarNo ratings yet

- Riveted Joint Design GuideDocument20 pagesRiveted Joint Design GuidegurdyalNo ratings yet

- Design of RCC ColumnsDocument8 pagesDesign of RCC Columnshitendra_gkNo ratings yet

- Horseley Bridge Tanks BrochureDocument12 pagesHorseley Bridge Tanks BrochureObinna OkaforNo ratings yet

- W.A.T.T.: World Association of Technology TeachersDocument2 pagesW.A.T.T.: World Association of Technology TeachersAna Carmen Marqués MagallónNo ratings yet

- Wax Removal in Pipeline PDFDocument291 pagesWax Removal in Pipeline PDFKhwanas LuqmanNo ratings yet

- En 1435-RT PDFDocument24 pagesEn 1435-RT PDFKhwanas LuqmanNo ratings yet

- 44-Iso 3834-2 - 2005Document54 pages44-Iso 3834-2 - 2005Khwanas LuqmanNo ratings yet

- ASME B18 24 2004 B18 Fastener Products PDFDocument156 pagesASME B18 24 2004 B18 Fastener Products PDFKhwanas LuqmanNo ratings yet

- Grinding Machine PDFDocument23 pagesGrinding Machine PDFNagi NayakNo ratings yet

- W.A.T.T.: The Shaping MachineDocument3 pagesW.A.T.T.: The Shaping MachineKhwanas LuqmanNo ratings yet

- W.A.T.T.: The Shaping MachineDocument3 pagesW.A.T.T.: The Shaping MachineKhwanas LuqmanNo ratings yet

- Boxford 8 Inch Shaper PDFDocument21 pagesBoxford 8 Inch Shaper PDFOlavo PastoreNo ratings yet

- CH 1 General DescriptionDocument4 pagesCH 1 General DescriptionKhwanas LuqmanNo ratings yet

- Lathe Machine OperationDocument68 pagesLathe Machine OperationKarthick N100% (8)

- ASME/ANSI B18.2.2 SAE GR.2 THREAD UNF 1/4-28; 1-12 INDEXDocument2 pagesASME/ANSI B18.2.2 SAE GR.2 THREAD UNF 1/4-28; 1-12 INDEXKhwanas LuqmanNo ratings yet

- Shaper Chapter From Manufacturing Technology PDFDocument8 pagesShaper Chapter From Manufacturing Technology PDFDharmendra KumarNo ratings yet

- Lathe Machine OperationDocument68 pagesLathe Machine OperationKarthick N100% (8)

- Boxford 8 Inch Shaper PDFDocument21 pagesBoxford 8 Inch Shaper PDFOlavo PastoreNo ratings yet

- Method Statement For Pipeline WeldingDocument21 pagesMethod Statement For Pipeline WeldingKhwanas Luqman100% (1)

- All in To MM PDFDocument3 pagesAll in To MM PDFKhwanas LuqmanNo ratings yet

- TDW PIGG SpecificationsDocument157 pagesTDW PIGG SpecificationsKhwanas LuqmanNo ratings yet

- Steel Wire, Deformed, For Concrete ReinforcementDocument5 pagesSteel Wire, Deformed, For Concrete ReinforcementKhwanas LuqmanNo ratings yet

- In To MM PDFDocument3 pagesIn To MM PDFKhwanas LuqmanNo ratings yet

- Standard Test Method ForDocument3 pagesStandard Test Method ForKhwanas LuqmanNo ratings yet

- ASME/ANSI B18.2.2 SAE GR.2 THREAD UNF 1/4-28; 1-12 INDEXDocument2 pagesASME/ANSI B18.2.2 SAE GR.2 THREAD UNF 1/4-28; 1-12 INDEXKhwanas LuqmanNo ratings yet

- Welding Pipeline HandbookDocument63 pagesWelding Pipeline Handbookchanchai T100% (9)

- Weld TechDocument18 pagesWeld TechAhmad Nabil ElsharkawyNo ratings yet

- Welding Electrode Classifications 123Document2 pagesWelding Electrode Classifications 123Unnikrishnan RajanNo ratings yet

- Carbon Steel h4r Electrode Classification MeaningDocument1 pageCarbon Steel h4r Electrode Classification MeaningZahi DrawNo ratings yet

- Welding ElectrodeDocument6 pagesWelding ElectrodeKhwanas LuqmanNo ratings yet

- ch5Document14 pagesch5Rolando DaclanNo ratings yet

- Welding PositionDocument6 pagesWelding Positionenels77No ratings yet

- Turan Balik - ResumeDocument3 pagesTuran Balik - Resumeapi-250561031No ratings yet

- Narrative Report 2BDocument14 pagesNarrative Report 2BMarc Edson CastroNo ratings yet

- ASTM E164 2019 Standard Practice For Contact Ultrasonic TestingDocument24 pagesASTM E164 2019 Standard Practice For Contact Ultrasonic TestingCesar RodriguezNo ratings yet

- Bca Oct2010Document118 pagesBca Oct2010lalitmunawat100% (1)

- About The Business 1.1 Business Profile Positif CorporationDocument7 pagesAbout The Business 1.1 Business Profile Positif CorporationLinh DalanginNo ratings yet

- Pakistan HandicraftsDocument19 pagesPakistan HandicraftsabdullahkhalilgNo ratings yet

- Final Case Study 2018Document12 pagesFinal Case Study 2018Ahmed Ràffi100% (1)

- Maintenance Manual LH 350 Flight Helmet: Confidential IndustryDocument18 pagesMaintenance Manual LH 350 Flight Helmet: Confidential Industrynelson vasquezNo ratings yet

- Valvulas Solenoides - Parker - SkinnerDocument148 pagesValvulas Solenoides - Parker - SkinneraspoiaspoiNo ratings yet

- PSR 640Document188 pagesPSR 640fer_12_328307No ratings yet

- ActiveReports Allows You To Create Master Detail Reports With Grouping by Using The GroupHeader and Detail Sections To Contain Data From Master Files and Detail FilesDocument3 pagesActiveReports Allows You To Create Master Detail Reports With Grouping by Using The GroupHeader and Detail Sections To Contain Data From Master Files and Detail FilesRyan AndrNo ratings yet

- 4 V2 2250 PR Pid 000001 - 1 - PDFDocument1 page4 V2 2250 PR Pid 000001 - 1 - PDFdavidNo ratings yet

- IEC 61850 and ION Technology: Protocol DocumentDocument52 pagesIEC 61850 and ION Technology: Protocol DocumentCristhian DíazNo ratings yet

- The Law of NationsDocument667 pagesThe Law of NationsJo Jo100% (1)

- Petrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BDocument11 pagesPetrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BAliasgar100% (1)

- VeinFinder_VE800 Brochure V1.0Document2 pagesVeinFinder_VE800 Brochure V1.0hanrong912No ratings yet

- Gas Pressure Regulator Installation InstructionsDocument10 pagesGas Pressure Regulator Installation Instructionssayem biswasNo ratings yet

- Problem Based Task Dfc2043Document3 pagesProblem Based Task Dfc2043player6675100% (1)

- Marlin Ch14 PDFDocument26 pagesMarlin Ch14 PDFAlyaNo ratings yet

- Bernstein ToolsDocument138 pagesBernstein Toolsjoeblow56100% (1)

- Introduction To Data Analytics - AnnouncementsDocument16 pagesIntroduction To Data Analytics - AnnouncementsAmit GuptaNo ratings yet

- Bip 0072-2014 PDFDocument94 pagesBip 0072-2014 PDFgrNo ratings yet

- Group 6 - Chapter 1 RevisedDocument15 pagesGroup 6 - Chapter 1 RevisedJAMES ELIJAH BALDERRAMANo ratings yet

- DiMaggio Et Al 2001 Social Implication of The InternetDocument30 pagesDiMaggio Et Al 2001 Social Implication of The InternetDon CorneliousNo ratings yet

- Alejandrino, Michael S. Bsee-3ADocument14 pagesAlejandrino, Michael S. Bsee-3AMichelle AlejandrinoNo ratings yet

- Modules Test ReportDocument4 pagesModules Test ReportprojectsNo ratings yet

- مساهمة البرمجيات المدمجة في تحسين جودة خدمات الإدارة الجبائية (عرض برمجية جباية -تيك نموذجا) PDFDocument18 pagesمساهمة البرمجيات المدمجة في تحسين جودة خدمات الإدارة الجبائية (عرض برمجية جباية -تيك نموذجا) PDFAnis AnisNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentNajaf BatoolNo ratings yet

- Items List ProcessorDocument4 pagesItems List ProcessorDiego Escobar MoncadaNo ratings yet

- Sistemas Hidromecánicos 1 - ENGLISHDocument12 pagesSistemas Hidromecánicos 1 - ENGLISHerick aguilarNo ratings yet