Professional Documents

Culture Documents

Choosing the right hydraulic separator

Uploaded by

amandaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Choosing the right hydraulic separator

Uploaded by

amandaCopyright:

Available Formats

Faq

301

info@ctenergia.it newsletter@tiemme.com

QUESTION:

Generally we have different Ts. How can we choose which hydraulic separator to install between the

primary and secondary circuit?

ANSWER:

The hydraulic separator is composed of a primary and secondary circuit.

- The primary circuit is connected to the energy source

- The secondary circuit is prearranged for rational thermal energy distribution

to the different users.

The hydraulic separator can be employed in endless types of systems using different

energy sources. Here we show a few examples where the thermal head between

delivery and return is required to be within the operating and mechanical safety limits

of the primary energy system:

High temperature boilers T = 70-80C T = 15-20C

Condensing boilers T = 65-70C T = 30-35C

District heating T = 80-110C T = 25-30C

Heat exchangers T = 65-90C T = 20-25C

Heat pumps Hydraulic

T = 5C T = 7C separator

Art. 7165

When using the primary energy, the secondary circuit dictates its own rules according to the user

system. Consequently, the following will be possible:

Two-pipe heating system, with shut-off valves T = 50-55C T = 10-12C

Two-pipe heating system, with thermostatic valves T = 50-55C T = 12-15C

Fan coil heating T = 55-60C T = 20C

Floor heating T = 30-45C T = 4-7C

Ceiling heating T = 30-45C T = 3-7C

Wall heating T = 30-35C T = 3-5C

Air-conditioning T= 5C T = 7C

Floor/ceiling cooling T = 15-19C T = 5-3C

Wall cooling T = 17-20C T = 5-3C

With the hydraulic separator we can talk about thermal (hot or cold) fluid flow rate. The energy power

depends on the thermal head between delivery and return.

The hydraulic separator calculations are made in relation to the thermal fluid flow rate of the secondary

circuit which always has a lower T compared to that of the primary circuit.

From the flow rate formula:

!" 0.862 1,000

! !/ = = 2.826 ! ! !

!

The diameter of the branch unions is obtained as follows:

!" 0.862 1,000

!=

2.826 ! !

Example 1

Calculating the secondary circuit:

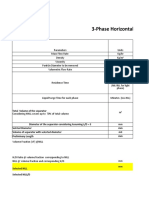

Two-pipe system kWh = 60 T = 15C v = (of the central system) 1.2m/s

60 0.862 1,000

!= = 32 !! (11/4)

2.826 15 1.2

Calculating the primary circuit:

Condensing boiler kWh= 60 system efficiency 85% T = 30C

v = 1.2 m/s

60 0.862 1,000

!= = 25 !! (1)

2.826 30 1.2 0.85

Note: the size of the hydraulic separator is chosen on the basis of

the secondary circuit.

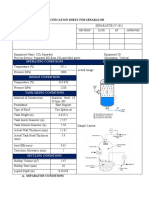

Example 2: residential unit on 3 levels.

Condensing boiler temperature T = 65C

- Basement room circulator unit for fan coil heating

Absorbed power 11,000 kcal/h = 12.8 kW

Pump capacity (T = 20C) 550 L/h

- Ground floor circulator unit for radiant panel heating with temperature control

Absorbed power 6,000 kcal/h = 7 kW

Pump capacity (T = 7C) 857 L/h

Bleed-off rate (30%) 857 x 0.3 = 257 L/h

- First floor circulator unit radiant panel heating with temperature control

Absorbed power 7,400 kcal/h = 8.6 kW

Pump capacity (T = 7C) 1,057 L/h

Bleed-off rate (30%) 1,057 x 0.3 = 317 L/h Gruppo di rilancio

Art. 5535G

Sum of thermal energy absorbed by the secondary circuit:

11,000 + 6,000 + 7,400 = 24,400 Kcal/h = 28.4 kW

Sum of circulator unit supply circuits flow rates:

550 + 257 + 317 = 1,124 L/h

Thermal head in the secondary circuit supply:

T = 24,400 / 1,124 = 22C

Thermal energy required by the primary circuit on the basis of an 85%

system efficiency and a 95% boiler efficiency:

24,400 / (0.85 x 0.95) = 30,200 kcal/h = 35.12 kW

Thermal head required T = 30C

Pump capacity 30,200/30 = 1,006 L/h

Boiler temperature T = 65C Circulator unit

Primary circuit return temperature T = 65-30 = 35C Art. 5535G3P

Secondary circuit average delivery temperature T = 35+22 = 57C

Calculation of the primary and secondary circuit diameters on the basis of a v speed = 1.2 m/s:

primary piping diameter =

1,006

!= = 18 !! (1!! )

2.826 1.2

secondary piping diameter =

1,124

!= = 18 !! (1!! )

2.826 1.2

Therefore:

Hydraulic

separator

Art. 7165

Art. 5538G3M6

Here is another example with circulator units

with a total flow rate of 3300 L/h, operating

with fan coils.

The system requires the use of a 11/4

manifold and 21/2 coplanar manifold, as

T22C DT30 shown in the picture here below.

C

21/2 brass coplanar

manifold

11/2 circulator unit

gruppi di rilancio d=1 ports

11/4

1 1

T20C

1 Art. 5540G3M6

11/4

T20C

1

You might also like

- كل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمDocument42 pagesكل انواع الفلاش سبريتر الطورين والثلاث اطوار مهمamir loloNo ratings yet

- LAMPIRAN C Spesifikasi PeralatanDocument89 pagesLAMPIRAN C Spesifikasi PeralatanRahmaisa HarahapNo ratings yet

- Appendix A: A.1. Three Phase SeparatorDocument48 pagesAppendix A: A.1. Three Phase SeparatorNhaaaeyNo ratings yet

- Design of Industrial Gravity Type Separators For The Hydrocarbons and Heavy Oil-Water SeparationsDocument5 pagesDesign of Industrial Gravity Type Separators For The Hydrocarbons and Heavy Oil-Water SeparationsCandraNo ratings yet

- Air CalculationsDocument4 pagesAir CalculationsSerkan YukselNo ratings yet

- Calculation of Height of The Siphon SystemDocument2 pagesCalculation of Height of The Siphon SystemHsein WangNo ratings yet

- Design Calculation For Gaseous SystemsDocument16 pagesDesign Calculation For Gaseous Systemsshashi ranjanNo ratings yet

- Sizing Calculation - AC214312UJ - R0 PDFDocument1 pageSizing Calculation - AC214312UJ - R0 PDFPavendhan PavNo ratings yet

- Tank FixturesDocument21 pagesTank FixturesASSSSSSSSSSSSNo ratings yet

- 3-Phase Sparator Sizing (Vertical and Horizontal)Document30 pages3-Phase Sparator Sizing (Vertical and Horizontal)WickyNo ratings yet

- Separator design for vapor-liquid mixtureDocument44 pagesSeparator design for vapor-liquid mixtureFadhil KhalidNo ratings yet

- PH ColumnDocument4 pagesPH ColumnAnonymous oVRvsdWzfBNo ratings yet

- ParalDocument9 pagesParalTahirJabbarNo ratings yet

- Three-Phase Separator .: University of KerbalaDocument11 pagesThree-Phase Separator .: University of Kerbalamuhiemin MazinNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Calculation Sheet for Stairs Reinforcement DesignDocument18 pagesCalculation Sheet for Stairs Reinforcement Designsarafan leewan0% (1)

- SP SP VP V PR) : Velocity Pressure Method Calculation SheetDocument6 pagesSP SP VP V PR) : Velocity Pressure Method Calculation SheetAnkit LonareNo ratings yet

- CalculationDocument13 pagesCalculationajit kumarNo ratings yet

- Velocity and Friction Loss Calculation in PipesDocument4 pagesVelocity and Friction Loss Calculation in Pipesmazzam75No ratings yet

- Pressure Safety Valve DatasheetDocument10 pagesPressure Safety Valve DatasheetsithulibraNo ratings yet

- Sizing Sheet for 2-phase separator as per API 12J standardsDocument5 pagesSizing Sheet for 2-phase separator as per API 12J standardsWickyNo ratings yet

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaNo ratings yet

- Separator Design-1Document12 pagesSeparator Design-1vela vanNo ratings yet

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan RamasamyNo ratings yet

- HYSYS PROII Converter - V1.5 PDFDocument28 pagesHYSYS PROII Converter - V1.5 PDFzubair1951No ratings yet

- Air-Cooled Exchanger Design and SizingDocument19 pagesAir-Cooled Exchanger Design and Sizingnafees ahmadNo ratings yet

- Packed Column DesignDocument6 pagesPacked Column Designyamen-691904No ratings yet

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 pagesCalculation of time needed to mix liquids with pitch blade impellershadiNo ratings yet

- Section 19Document97 pagesSection 19rahmat mamuriNo ratings yet

- Waymouth CalculationDocument8 pagesWaymouth CalculationSURJYA TAMULINo ratings yet

- Heat Exchanger Input Correction FactorDocument11 pagesHeat Exchanger Input Correction FactorTrần Tuấn VũNo ratings yet

- Process Calculation For FREYLIT CPI Oil SeparatorDocument4 pagesProcess Calculation For FREYLIT CPI Oil SeparatorRajdeepsinhNo ratings yet

- Unlock Separator SizingDocument42 pagesUnlock Separator SizingmortezasabetiNo ratings yet

- Gas properties and flow calculationsDocument12 pagesGas properties and flow calculationsSergio RodriguezNo ratings yet

- Separator Design: Rev Description Date Prepared by Client ApprovalDocument18 pagesSeparator Design: Rev Description Date Prepared by Client ApprovalUsɱâñ Måâñ100% (1)

- Gas Liquid Separator DesignDocument3 pagesGas Liquid Separator DesignSoheil MoradiNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingNo ratings yet

- Centrifugal Pump FundamentalsDocument140 pagesCentrifugal Pump FundamentalsLizbeth CamachoNo ratings yet

- Horizontal Three Phase Separator Sizing CalculationDocument3 pagesHorizontal Three Phase Separator Sizing CalculationDazzy 265No ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- CentrifugalCompressorPower SI UnitsDocument4 pagesCentrifugalCompressorPower SI UnitsReza GhanavatiNo ratings yet

- Calculation Sheet For Make - Up Water Tank: #Value!Document4 pagesCalculation Sheet For Make - Up Water Tank: #Value!thanh_79No ratings yet

- Fdocuments - in Separator Sizing SpreadsheetDocument31 pagesFdocuments - in Separator Sizing SpreadsheetGabrielito PachacamaNo ratings yet

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNo ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- Control Valve Technical Specification Sheet Globe Service: GasDocument1 pageControl Valve Technical Specification Sheet Globe Service: Gassiddhesh_guessNo ratings yet

- Dykewall CalculationDocument4 pagesDykewall CalculationVipul GandhiNo ratings yet

- Horizontal SeparatorDocument64 pagesHorizontal SeparatorKathleen RoldanNo ratings yet

- Cvts - Tag No. Mpt-tv-4161Document2 pagesCvts - Tag No. Mpt-tv-4161biswasdipankar05No ratings yet

- Wastewater Treatment Plant Design PDFDocument68 pagesWastewater Treatment Plant Design PDFmostafa1alaahobaNo ratings yet

- R-Pump Cal Sheet2Document3 pagesR-Pump Cal Sheet2ggdgdfgdfgdfgdgddddNo ratings yet

- 3-Phase Separator Sheet (GPSA)Document12 pages3-Phase Separator Sheet (GPSA)WickyNo ratings yet

- Unit conversion program for engineering processesDocument9 pagesUnit conversion program for engineering processesAnubhav KhandelwalNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Doc. No. 01 - 42 10 002 - OCSDocument36 pagesDoc. No. 01 - 42 10 002 - OCSHerlambang sNo ratings yet

- Concentric Tube Heat ExchangerDocument10 pagesConcentric Tube Heat Exchangeramirhazwan93% (14)

- Concentric Tube Heat ExchangerDocument10 pagesConcentric Tube Heat ExchangerSharifah Zulaikha BenYahyaNo ratings yet

- Cooling Tower Refrigeration CapacityDocument28 pagesCooling Tower Refrigeration Capacityboj VillanuevaNo ratings yet

- IPC TM 650 Water AbsorptionDocument1 pageIPC TM 650 Water AbsorptionamandaNo ratings yet

- IPC TM 650 Water AbsorptionDocument1 pageIPC TM 650 Water AbsorptionamandaNo ratings yet

- IPC TM 650 Water AbsorptionDocument1 pageIPC TM 650 Water AbsorptionamandaNo ratings yet

- 1 20 IntroDocument20 pages1 20 IntroamandaNo ratings yet

- Tranquilan 2012Document1 pageTranquilan 2012amandaNo ratings yet

- Tranquil An A Ran Ill A 2012Document1 pageTranquil An A Ran Ill A 2012amandaNo ratings yet

- Sintesis Dan Karakterisasi CMC (Carboxymethyl Cellulose) Yang Dihasilkan Dari Selulosa Jerami PadiDocument10 pagesSintesis Dan Karakterisasi CMC (Carboxymethyl Cellulose) Yang Dihasilkan Dari Selulosa Jerami PadiamandaNo ratings yet

- Structure and Written Expression Practice Questions with Reading Comprehension PassagesDocument4 pagesStructure and Written Expression Practice Questions with Reading Comprehension Passagesamanda100% (1)

- Density Separator SPSS1042EN 01Document2 pagesDensity Separator SPSS1042EN 01amandaNo ratings yet

- Designing an Acetone-Water Distillation ColumnDocument23 pagesDesigning an Acetone-Water Distillation ColumnamandaNo ratings yet

- HPGEDocument2 pagesHPGEamandaNo ratings yet

- Matlab Guide BookDocument26 pagesMatlab Guide BookKingchemNo ratings yet

- Shell and tube reactor design optimizationDocument4 pagesShell and tube reactor design optimizationamandaNo ratings yet

- Table 7Document18 pagesTable 7amandaNo ratings yet

- Modeling Chemical Processes Using MATLAB: Exercise Problems 7th EditionDocument64 pagesModeling Chemical Processes Using MATLAB: Exercise Problems 7th EditionamandaNo ratings yet

- Taco Hydraulic SeparatorDocument4 pagesTaco Hydraulic SeparatoramandaNo ratings yet

- 06 Gamma SpectrometryDocument60 pages06 Gamma SpectrometryamandaNo ratings yet

- HPGEDocument2 pagesHPGEamandaNo ratings yet

- 10 1 1 573 6854Document5 pages10 1 1 573 6854amandaNo ratings yet

- Removal of Phenol and Surfactant From Landfill Leachate by Coagulation-Flocculation ProcessDocument13 pagesRemoval of Phenol and Surfactant From Landfill Leachate by Coagulation-Flocculation ProcessamandaNo ratings yet

- Characteristics Integrated Gamma Ray Spectrometer Using Germanium Detectors Fixed Mobile Measurement SystemsDocument7 pagesCharacteristics Integrated Gamma Ray Spectrometer Using Germanium Detectors Fixed Mobile Measurement SystemsamandaNo ratings yet

- Balancing Load and Power (The Function and Operating Principle of Hydraulic Separators) enDocument16 pagesBalancing Load and Power (The Function and Operating Principle of Hydraulic Separators) enamandaNo ratings yet

- Seawater Filtration and Desalination PrototypeDocument35 pagesSeawater Filtration and Desalination PrototypeDiana Mae JavierNo ratings yet

- Unit Price For Retrofitting WorksDocument2 pagesUnit Price For Retrofitting Workslaxmi29No ratings yet

- Framini 2021Document56 pagesFramini 2021saad tadaoutNo ratings yet

- NEP 2020 highlights for EEDocument65 pagesNEP 2020 highlights for EENidul SinhaNo ratings yet

- Finite Element Modeling and Simulation For BendingDocument5 pagesFinite Element Modeling and Simulation For BendingAnand RasNo ratings yet

- Limits and Fits HandoutDocument6 pagesLimits and Fits HandoutdrthuhanNo ratings yet

- AEC Profile 2023Document20 pagesAEC Profile 2023Aosaf FarooquiaNo ratings yet

- 7th SEM Course Plan 2021 22Document69 pages7th SEM Course Plan 2021 22TriGo EVNo ratings yet

- Perfiles y AngulosDocument2 pagesPerfiles y AngulosAlejandro Isaac López RamírezNo ratings yet

- JAPLAN DIAGNOSTIC JD - General Manager Engineering and Buisness DevelopmentDocument3 pagesJAPLAN DIAGNOSTIC JD - General Manager Engineering and Buisness Developmentkanishka112No ratings yet

- Analysis of Shear Wall Thicknesses and Opening EffectsDocument7 pagesAnalysis of Shear Wall Thicknesses and Opening EffectsBadr AmmarNo ratings yet

- Record Note and Bonafide CertificateDocument6 pagesRecord Note and Bonafide CertificateHari Suriya 520No ratings yet

- 101 Approved NCEC Ncec SeptDocument9 pages101 Approved NCEC Ncec SeptLLOYD LloydNo ratings yet

- Civil Structural Permit FrontDocument1 pageCivil Structural Permit FrontAndrea Mae SanchezNo ratings yet

- Factors Affecting Pavement DesignDocument3 pagesFactors Affecting Pavement DesignEng Abdikarim Walhad0% (1)

- Scope and Aims of Engineering EthicsDocument5 pagesScope and Aims of Engineering EthicsSamir ParekhNo ratings yet

- Wall PDFDocument87 pagesWall PDFEmil SánchezNo ratings yet

- Amirrul Aiman Bin Muhammad: Career ObjectiveDocument1 pageAmirrul Aiman Bin Muhammad: Career ObjectiveAmirrul AimanNo ratings yet

- WSIB Quality ImprovementDocument1 pageWSIB Quality ImprovementSelvaraj RangasamyNo ratings yet

- Lecture 2 Engineering EconomicsDocument30 pagesLecture 2 Engineering Economicsahmer100% (1)

- Importance of Learning English For Cse StudentsDocument4 pagesImportance of Learning English For Cse Studentspavel7747No ratings yet

- Introduction to Marine TechnologyDocument32 pagesIntroduction to Marine TechnologyFairuzNo ratings yet

- Energy Auditor What Is An Energy Auditor? (Amel)Document2 pagesEnergy Auditor What Is An Energy Auditor? (Amel)nadzertss4No ratings yet

- Method Statement GSSDocument4 pagesMethod Statement GSSkannanrk1984No ratings yet

- Test Management - Test PlanDocument15 pagesTest Management - Test PlanAnil NagNo ratings yet

- Y.B. Patil Polytechnic College BrochureDocument6 pagesY.B. Patil Polytechnic College BrochureY. B. Patil Polytechnic CollegeNo ratings yet

- Thesis Topics For Electronics and Communication EngineeringDocument4 pagesThesis Topics For Electronics and Communication Engineeringrebeccabuonocambridge100% (2)

- BasementDocument10 pagesBasementNikita ShethNo ratings yet

- Difference Between APQP and PPAPDocument2 pagesDifference Between APQP and PPAPshankarNo ratings yet

- Detailed Cost EstimateDocument69 pagesDetailed Cost EstimateJames PiñolNo ratings yet