Professional Documents

Culture Documents

Daewoo Matiz 2000-2013 Heating, Ventilation and Air Conditioner 21-33

Uploaded by

tivilardoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Daewoo Matiz 2000-2013 Heating, Ventilation and Air Conditioner 21-33

Uploaded by

tivilardoCopyright:

Available Formats

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 21

Installation Procedure

1. Install the compressor with the mounting bolts.

Tighten

D Tighten the compressor--to--bracket upper bolt to

20 NSm (15 lb-ft) (1).

D Tighten the compressor--to--bracket lower bolts to

22 NSm (16 lb-ft) (2).

2. Connect the electrical connector.

D18B511B

3. Install the A/C high pressure pipe line to the compres-

sor with the bolt.

Tighten

Tighten the A/C high pressure pipe line bolt to 23 NSm

(17 lb-ft) (3).

4. Install the A/C low pressure pipe line to the compres-

sor with the bolt.

Tighten

Tighten the A/C low pressure pipe line bolt to 23 NSm

(17 lb-ft) (4).

5. Evacuate and charge the system. Refer to Discharg-

D18B512A ing, Adding Oil, Evacuating, and Charging Procedure

for A/C System in this section.

6. Install the A/C belt. Refer to Section 6B, Power Steer-

ing Pump.

7. Install the receiver dryer. Refer to Receiver Dryer

and Dual Cut Switch in this section.

CONDENSER

1. Disconnect the negative battery cable.

2. Remove the front bumper fascia. Refer to Section

9O, Bumpers and Fascias.

3. Discharge and recover the refrigerant. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

cedures for A/C system in this section.

4. Remove the condenser.

D Loosen the condenser pipe--to--compressor pipe

fitting (1).

D Loosen the condenser pipe--to--receiver dryer pipe

fitting (2).

D18B513A

DAEWOO M-150 BL2

7B -- 22 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

D Remove the condenser mounting nuts (3).

D Push the top of the condenser (4).

D Take off the condenser from the lower bracket by

lifting the condenser (5).

D Remove the condenser (6).

D18B514A

Installation Procedure

Important: Discard the removed O--rings.

1. Install the condenser with the nuts.

Tighten

Tighten the condenser mounting nuts to 4 NSm (36 lb-

in).

D18B515B

2. Tighten the fittings and the bolt.

Tighten

D Tighten the condenser pipe--to--compressor pipe

fitting to 23 NSm (17 lb-ft) (1).

D Tighten the condenser pipe--to--receiver dryer pipe

fitting to 14 NSm (10.5 lb-ft) (2).

3. Evacuate and recharge the system. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

cedures for A/C System in this section.

4. Install the front bumper fascia. Refer to Section 9O,

Bumpers and Fascias.

5. Connect the negative battery cable.

D18B516B

A/C HIGH PRESSURE PIPE LINE

(Left--Hand Drive Shown, Right--Hand

Drive Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the front bumper fascia. Refer to Section

9O, Bumpers and Fascias.

3. Discharge and recover the refrigerant. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

cedures for A/C System in this section.

4. Remove the A/C high pressure pipe line between the

compressor and the condenser.

D Remove the bolt securing the high pressure pipe

D108B517

line to the compressor (1).

DAEWOO M-150 BL2

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 23

D Loosen the fitting securing the high pressure pipe

line to the condenser pipe line (2).

D Remove the clamp nut (3).

D18B518A

5. Remove the A/C high pressure pipe line between the

condenser and the receiver dryer.

D Loosen the fitting securing the receiver dryer to the

condenser (1).

D18B519A

D Remove the receiver dryer flange nuts (2).

D108B520

6. Remove the A/C high pressure pipe line between the

receiver dryer and the evaporator.

D Remove the purge control valve. Refer to Section

1F, Engine Controls.

D Remove the bracket nut (1).

D Loosen the fitting (2).

D18B521A

DAEWOO M-150 BL2

7B -- 24 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

Installation Procedure

Important: Discard the removed O--rings.

1. Install the high pressure pipe lines with the bolts, the

nuts, and the fittings.

Tighten

D Tighten the bolt securing the high pressure pipe

line to the compressor to 23 NSm (17 lb-ft) (1).

D Tighten the fitting securing the high pressure pipe

line to the condenser pipe line to 23 NSm (17 lb-ft)

(2).

D Tighten the fitting securing the high pressure pipe

D18B522A

line to the receiver dryer to 14 NSm (10.5 lb-ft) (3).

D Tighten the bracket nut to 5 NSm (44 lb-in) (4).

D Tighten the receiver dryer flange nuts to 14 NSm

(10.5 lb-ft) (5).

D Tighten the nut securing the high pressure pipe line

to the evaporator to 14 NSm (10.5 lb-ft) (6).

D Tighten the bracket nut to 5 NSm (44 lb-in) (7).

2. Install the purge control valve. Refer to Section 1F,

Engine controls.

3. Evacuate and recharge the system. Refer to Dis-

charging, Adding Oil, Evaculating, and Charging Pro-

cedures for A/C System in this section.

4. Install the front bumper fascia. Refer to Section 9O,

D18B523B

Bumpers and Fascias.

5. Connect the negative battery cable.

D18B524A

D18B525B

DAEWOO M-150 BL2

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 25

A/C LOW PRESSURE PIPE LINE

(Left--Hand Drive Shown, Right--Hand

Drive Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Discharge and recover the refrigerant. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

cedures for A/C System in this section.

3. Remove the A/C low pressure pipe line.

D Remove the bolt securing the A/C low pressure

pipe line at the compressor (1).

D108B526

D Remove the bracket nut from shut bar (2).

D18B527A

D Remove the purge control valve. Refer to Section

1F, Engine Controls.

D Loosen the nut securing the A/C low pressure pipe

line at the evaporator (3).

D18B528A

Installation Procedure

Important: Discard the removed O--rings.

1. Install the A/C low pressure pipe line.

Tighten

D Tighten the nut securing the A/C low pressure pipe

line at the evaporator to 14 NSm (10.5 lb-ft) (1).

D18B529B

DAEWOO M-150 BL2

7B -- 26 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

D Tighten the bracket nut to 5 NSm (44 lb-in) (2).

D18B530B

D Tighten the bolt securing the A/C low pressure pipe

line at the compressor to 23 NSm (17 lb-ft) (3).

2. Evacuate and recharge the system. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

cedure for A/C System in this section.

3. Connect the negative battery cable.

D18B531A

EVAPORATOR UNIT AND DRAIN

HOSE

(Left--Hand Drive Shown, Right--Hand

Drive Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Discharge and recover the refrigerant. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

cedures for A/C System in this section.

3. Loosen the high pressure pipe line (receiver dry-

D108B532

er evaporator) nut and the low pressure pipe line

(evaporator compressor) nut.

4. Remove the glove box. Refer to Section 9E, Instru-

mentation/Driver information.

5. Remove the evaporator unit.

D Remove the drain hose (1).

D Disconnect the thermistor connector (2).

D Remove the screws (3).

D Remove the evaporator backward slowly (4).

D108B533

DAEWOO M-150 BL2

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 27

Installation Procedure

1. Install the evaporator evaporator with the screws.

2. Connect the thermistor connector.

3. Install the drain hose.

4. Install the glove box. Refer to Section 9E, Instrumen-

tation / Driver Information.

5. Tighten the high pressure pipe line (receiver dry-

er evaporator) nut and the low pressure pipe line

(evaporator compressor) nut to 14 NSm (10.5 lb-ft).

6. Evacuate and recharge the system. Refer to Dis-

charging, Adding Oil, Evacuating, and Charging Pro-

D18B534A cedures for A/C System in this section.

7. Connect the negative battery cable.

DAEWOO M-150 BL2

7B -- 28 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

UNIT REPAIR

EVAPORATOR CORE AND

EXPANSION VALVE

Disassembly Procedure

1. Remove the evaporator unit. Refer to Evaporator

Unit and Drain Hose in this section.

2. Remove the evaporator core and expansion valve.

D Remove the screw (1).

D Remove the clamp (2).

D Remove the screws securing the evaporator case

cover (3).

D Remove the upper evaporator case cover (4).

D Remove the lower evaporator case cover (5).

D Remove the thermistor (6).

D Loosen the fitting and remove the high pressure

pipe line (7).

D Remove the tape (8).

D Remove the evaporator plate seal (9).

D Loosen the fitting and remove the expansion valve

(10).

D18B701A

Assembly Procedure

1. Install the exponsion valve with the fitting.

Tighten

Tighten the high pressure pipe line coupling to 17 NSm

(13 lb-ft) (1).

2. Install the evaporator plate seal.

3. Install the tape.

4. Install the high pressure pipe line with the fitting.

Tighten

Tighten the expansion valve coupling to 22 NSm (16

D18B702A lb-ft) (2).

5. Install the thermistor.

6. Install the screws securing the evaporator case cov-

er.

7. Install the clamp and the screw.

8. Install the evaporator unit. Refer to Evaporator Unit

and Drain Hose in this section.

DAEWOO M-150 BL2

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 29

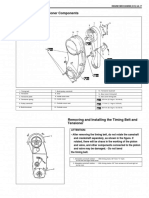

COMPRESSOR OVERHAUL

Tools Required

DW--610--010 Clutch Hub Holding Tool

Disassembly Procedure

1.Remove the compressor. Refer to Compressor in

this section.

2. Remove the clutch drive plate.

D Use the clutch hub holding tool DW--610--010 to

keep the clutch drive plate (1).

D Remove the shaft bolt (2).

D10B703A

3. Remove the compressor pulley.

D Remove the snap ring using a ring pryer (1).

D Remove the pulley (2).

D18B704A

4. Disconnect the wiring harness holder and remove the

electromagnetic clutch.

a. Electromagnetic clutch

D18B705A

Assembly Procedure

1. Connect the wiring harness holder and install the

clutch coil.

2. Install the snap ring and compressor pulley.

3. Use the clutch hub holding tool DW--610--010, install

the clutch drive plate with the shaft bolt.

Tighten

Tighten the shaft bolt to 13 NSm (115 lb-in).

4. Install the compressor. Refer to Compressor in this

section.

D18B706B

DAEWOO M-150 BL2

7B -- 30 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application Unit Description

Compressor -- SP--10.4PK

Receiver--Dryer -- AL R/DRIER

Type -- R--134a System

Refrigerant

Capacity g 500 (RHD : 530)

Type -- RL 244 PAG OIL

Refrigerant Oil in A/C System

Capacity cc 150

A/C Cooling Capacity (Airflow rate 8.7 kg/min) Kcal/h 5,500

Refrigerant Pressure in A/C Sys-

tem(Engine Idle, Fresh Air 30_C Low Pressure Side kPa (psi) 200 (2.9)

(86_F) Ambient Temperature

(86_F),

25_C--35_C (77_F--95_F), Tempera- High Pressure Side kPa (psi) 1,500 (217.5)

ture to Full Cold)

2.45(36.81)

Evaporator Therm- ON

A/C Compressor ON/OFF Condition _C (_F)

istor Temperature

(Refer to Section 1F, Engine Controls OFF

1.0 (34.2)

About the A/C Compressor ON/OFF

Condition According to Engine Oper- 205--245 300--400

ating Status) Dual Cut Switch ON

kPa

Pressure OFF

180--220 240--280

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb-Ft Lb-In

Compressor Upper Bracket Bolts 20 15 --

Compressor Front Head-to-Rear Head Through-Bolt 22 16 --

High Pressure Pipe Line (Compressor Condenser) Bolt 23 17 --

High Pressure Pipe Line (Compressor Condenser) Fitting 23 17 --

High Pressure Pipe Line (Compressor Condenser) Clamp Nut 5 -- 44

Receiver--Dryer Flange Nut 14 10.5 --

High Pressure Pipe Line (Condenser Receiver--Dryer) Fitting Nut 14 10.5 --

High Pressure Pipe Line (Receiver--Dryer Evaporator) Fitting Nut 14 10.5 --

High Pressure Pipe Line(Receiver--Dryer Evaporator) Clamp Nut 5 -- 44

Low Pressure Pipe Line (Evaporator Compressor) Fitting Nut 14 10.5 --

Low Pressure Pipe Line (Evaporator Compressor) Clamp Nut 5 -- 44

Low Pressure Pipe Line(EvaporatorCompressor) Compressor Bolt 23 17 --

Dual Cut Switch 13 -- 115

Receive--Dryer Bracket--to--Body Bolts 5 -- 44

Receive--Dryer Bracket Bolt 5 -- 44

Expansion Valve Coupling (Receiver--Dryer Expansion Valve) 17 13 --

Expansion Valve Coupling (Expansion Valve Evaporator) 22 16 --

Compressor Shaft Bolt 13 -- 115

Condenser Mounting Nuts 4 -- 36

DAEWOO M-150 BL2

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 31

SPECIAL TOOLS AND EQUIPMENT

SPECIAL TOOLS TABLE

DW--610--010

Clutch Hub

Holding Tool

D108B101

DAEWOO M-150 BL2

7B -- 32 MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM

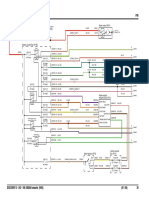

SCHEMATIC AND ROUTING DIAGRAMS

A/C DIAGRAMS

D18B201B

DAEWOO M-150 BL2

MANUAL CONTROL HEATING, VENTILATION, AND AIR CONDITIONING SYSTEM 7B -- 33

A/C AIRFLOW

(Left--Hand Drive Shown, Right--Hand Drive Similar)

D108B202

A/C SYSTEM

(Left--Hand Drive Shown, Right--Hand Drive Similar)

D18B203A

DAEWOO M-150 BL2

You might also like

- 2 2az Fe+coolingDocument36 pages2 2az Fe+coolingfredypezNo ratings yet

- Daewoo Service Manual Cooling MatizDocument4 pagesDaewoo Service Manual Cooling Matizjulio797100% (1)

- DTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance ProblemDocument2 pagesDTC P0121 Throttle / Pedal Position Sensor / Switch "A" Circuit Range / Performance Problempeter_nicks5441No ratings yet

- 2014 D4CB (A2) Schematic Diagrams Body Electrical System Immobilizer System Schematic DiagramsDocument1 page2014 D4CB (A2) Schematic Diagrams Body Electrical System Immobilizer System Schematic DiagramsMarcioMartinhoFerreiraNo ratings yet

- Isuzu vehicle pinouts and OBD compatibility from 1996-presentDocument3 pagesIsuzu vehicle pinouts and OBD compatibility from 1996-presentEdwinAyalaNo ratings yet

- Manual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFDocument148 pagesManual Calefaccion y A.Acondicionado Chevrolet Captiva 2006-10 PDFskpppNo ratings yet

- Key Features Key Specifications: 4 X 2 Cab ChassisDocument4 pagesKey Features Key Specifications: 4 X 2 Cab ChassispendiNo ratings yet

- Lexus GsicDocument1 pageLexus GsicdvalodiaNo ratings yet

- Isuzu Engine - 4he1-Tc (Valve Adjustment) PDFDocument3 pagesIsuzu Engine - 4he1-Tc (Valve Adjustment) PDFTadas P100% (3)

- Công Ty Cổ Phần Obdvietnam TỔNG ĐÀI HỖ TRỢ: 02871.088.881Document2 pagesCông Ty Cổ Phần Obdvietnam TỔNG ĐÀI HỖ TRỢ: 02871.088.881ANH LÊNo ratings yet

- Delphi SystemDocument5 pagesDelphi SystemPhilip Peter Hanssen100% (1)

- Mustan 05-09 AutomaticDocument6 pagesMustan 05-09 AutomaticJohn MooreNo ratings yet

- 2020 D6CC Schematic Diagrams Heating, Ventilation, Air Conditioning A/C Control System (Manual) Schematic DiagramsDocument3 pages2020 D6CC Schematic Diagrams Heating, Ventilation, Air Conditioning A/C Control System (Manual) Schematic DiagramsQuốc Phú ĐinhNo ratings yet

- Circ Electrico Eps-EtiosDocument4 pagesCirc Electrico Eps-EtiosAngel RodríguezNo ratings yet

- VSA DTC Troubleshooting: 83-11Document2 pagesVSA DTC Troubleshooting: 83-11Ali100% (1)

- How to Optimize Your Website for Search EnginesDocument49 pagesHow to Optimize Your Website for Search EnginestfphoenixNo ratings yet

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelAdedeji OluwatobilobaNo ratings yet

- PDF Isuzu Truck Fault Codes List PDF - CompressDocument1 pagePDF Isuzu Truck Fault Codes List PDF - CompressRodrigo Almanza NNo ratings yet

- Hino 700 Suspension HendricsonDocument20 pagesHino 700 Suspension HendricsonJoki MarzukiNo ratings yet

- Suzuki APV Service ManualDocument7 pagesSuzuki APV Service ManualdhgdfgNo ratings yet

- The Factory Boost Jets NAVARA D40Document7 pagesThe Factory Boost Jets NAVARA D40Icram Ibrahimo100% (1)

- Connection of The STAG-300Document1 pageConnection of The STAG-300Anonymous IkfTLYBNo ratings yet

- 1KD EduDocument5 pages1KD EduMakokha Mumelo100% (1)

- Home Dercomaster Public HTML Online Media Image CL GREATTEC Apoyo Modelos GWM Camionetas WINGLE 3-5 Wingle 3-5 Service Manual After 2012 E PDFDocument219 pagesHome Dercomaster Public HTML Online Media Image CL GREATTEC Apoyo Modelos GWM Camionetas WINGLE 3-5 Wingle 3-5 Service Manual After 2012 E PDFAlejandro Mario Cerda Ruiz33% (3)

- Clutch Hino 5.5Document5 pagesClutch Hino 5.5Yeam_90No ratings yet

- Engine 1Document278 pagesEngine 1RodrigoNo ratings yet

- Schematy Daewoo Nubira All Models PDFDocument97 pagesSchematy Daewoo Nubira All Models PDF8014000% (1)

- 520 Fuse Box in The Engine CompartmentDocument4 pages520 Fuse Box in The Engine CompartmentPatricio ValenciaNo ratings yet

- S7-Lxje05a 4Document563 pagesS7-Lxje05a 4Andres GomezNo ratings yet

- Mitsubishi DelicaDocument104 pagesMitsubishi DelicaGabriel BalcazarNo ratings yet

- Removal: 2Tr-Fe Engine Mechanical - Timing ChainDocument15 pagesRemoval: 2Tr-Fe Engine Mechanical - Timing ChainNacho Akiba-keiNo ratings yet

- Toyota L 2l 2l T Engine Workshop Service Repair ManualDocument228 pagesToyota L 2l 2l T Engine Workshop Service Repair ManualHaji Rashid100% (1)

- Mazda 6 2014 OBD2 PinDocument2 pagesMazda 6 2014 OBD2 Pinoak2147No ratings yet

- Mazda 5 ABSDocument77 pagesMazda 5 ABSWilder LopezNo ratings yet

- Webasto Peugeot 208Document36 pagesWebasto Peugeot 208Sorin Daniel CostinasNo ratings yet

- DTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionDocument1 pageDTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionWillian Jane100% (1)

- Система управления двигателемDocument3 pagesСистема управления двигателемEdik Bonifacio MamaniNo ratings yet

- Volta 1.2 Instructions PDFDocument10 pagesVolta 1.2 Instructions PDFMick BurnsNo ratings yet

- Corolla 4AfE 1 6 Ecu Pinout PDFDocument1 pageCorolla 4AfE 1 6 Ecu Pinout PDFWander Sarante100% (1)

- APP Sensor DiagnosisDocument9 pagesAPP Sensor DiagnosisAndres AriasNo ratings yet

- Electronic Engine ControlsDocument6 pagesElectronic Engine ControlstuningNo ratings yet

- Holden Alloytec Camshaft TimingDocument9 pagesHolden Alloytec Camshaft Timingducatiss900No ratings yet

- Tomihawk Tools CatalogueDocument60 pagesTomihawk Tools CatalogueRosília DomingosNo ratings yet

- FAW CA4GA5 Engine Maintenance ManualDocument135 pagesFAW CA4GA5 Engine Maintenance ManualjamesNo ratings yet

- Galant ECU PinOutDocument1 pageGalant ECU PinOuthakyNo ratings yet

- 5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)Document8 pages5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)MyBriggsNo ratings yet

- Zd30 ecu pinouts guideDocument10 pagesZd30 ecu pinouts guideKinaryoNo ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- Isuzu Obd IIDocument1 pageIsuzu Obd IISaid TouhamiNo ratings yet

- RPM Tech LM220 Snow Blower BrochureDocument4 pagesRPM Tech LM220 Snow Blower BrochurePhil B.No ratings yet

- Matiz Service Manual Section IndexDocument105 pagesMatiz Service Manual Section IndexBrenda Cruces100% (2)

- FT Kinglong XMQ6520 Gasoline En-01-2015Document4 pagesFT Kinglong XMQ6520 Gasoline En-01-2015Teddy Khant0% (1)

- Group62-3 Aire AcondicionadoDocument9 pagesGroup62-3 Aire AcondicionadoKonax Lihysd MandeNo ratings yet

- Ac 24Document2 pagesAc 24Tung NguyenNo ratings yet

- Typical Install: InstructionsDocument9 pagesTypical Install: InstructionsPrzemysław OstałowskiNo ratings yet

- Civic 1996 2000 D16Y5 D16D8 B16A2Document176 pagesCivic 1996 2000 D16Y5 D16D8 B16A2Juan David RamirezNo ratings yet

- Overhaul: Heater & Air ConditionerDocument4 pagesOverhaul: Heater & Air ConditionerIcaro FerreiraNo ratings yet

- Overhaul: Heater & Air ConditionerDocument4 pagesOverhaul: Heater & Air ConditionerCoco LinoNo ratings yet

- RemoDocument1 pageRemoMansur KhanNo ratings yet

- Engine CoolingDocument5 pagesEngine CoolingEl OhmimetroNo ratings yet

- ReadMe PDFDocument10 pagesReadMe PDFtivilardoNo ratings yet

- ReadMe PDFDocument10 pagesReadMe PDFtivilardoNo ratings yet

- ReadMe PDFDocument10 pagesReadMe PDFtivilardoNo ratings yet

- Read Me PDFDocument1 pageRead Me PDFtivilardoNo ratings yet

- Manual de Aplicacion - 2014Document10 pagesManual de Aplicacion - 2014tivilardoNo ratings yet

- Gate Questions Bank ME HMTDocument4 pagesGate Questions Bank ME HMTTaanzNo ratings yet

- Chem 2BLabManual201303Document121 pagesChem 2BLabManual201303Naveen KamatNo ratings yet

- #10 - Energy Balance - 01 (Rev01)Document48 pages#10 - Energy Balance - 01 (Rev01)Valentino LunardiNo ratings yet

- PHPP2007 English DemoDocument57 pagesPHPP2007 English DemoSrinivas SukhavasiNo ratings yet

- Gas Laws: Boyle's, Charles', Gay-Lussac's and CombinedDocument5 pagesGas Laws: Boyle's, Charles', Gay-Lussac's and Combinedcj lequinNo ratings yet

- Guide to Cascade Refrigeration SystemsDocument11 pagesGuide to Cascade Refrigeration SystemsJashandeep SinghNo ratings yet

- Non Isothermal Reactors: Prepared byDocument9 pagesNon Isothermal Reactors: Prepared byاحمد حمید کارسول عزیزNo ratings yet

- Fundamentals of Thermodynamics and Heat TransferDocument4 pagesFundamentals of Thermodynamics and Heat Transferविशाल पुडासैनीNo ratings yet

- Elcometer 116 Sling Psychrometer Product Data SheetDocument1 pageElcometer 116 Sling Psychrometer Product Data SheethetpinNo ratings yet

- Glucose Syrup Three-Effect Evaporation System: 1. Background & DescriptionDocument2 pagesGlucose Syrup Three-Effect Evaporation System: 1. Background & DescriptionRushikesh uNo ratings yet

- CASE TEACHING NOTES FOR A FRIDGE IN SPACEDocument3 pagesCASE TEACHING NOTES FOR A FRIDGE IN SPACEValter César MontanherNo ratings yet

- Technical ReferenceDocument120 pagesTechnical ReferenceSimone RizzoNo ratings yet

- Montevecchi2018heat Accumulation Prevention in Wire-Arc-Additive-Manufacturing Using Air JetDocument9 pagesMontevecchi2018heat Accumulation Prevention in Wire-Arc-Additive-Manufacturing Using Air JetGustavo de CastroNo ratings yet

- KNC 4383 Natural Gas - Lecture 2Document62 pagesKNC 4383 Natural Gas - Lecture 2Kunashiny RamashNo ratings yet

- Gasesous State PuuchoDocument78 pagesGasesous State PuuchoNdbbdh bdbdbNo ratings yet

- Conduction HMTDocument43 pagesConduction HMTbalakaleesNo ratings yet

- Reynolds Analogy Pandtl and Chilton Coulbourn AnalogyDocument5 pagesReynolds Analogy Pandtl and Chilton Coulbourn Analogykartik521No ratings yet

- MSCDocument12 pagesMSCJayanath Nuwan SameeraNo ratings yet

- SA 17 19 XI Physics Unit-3 Section-ADocument30 pagesSA 17 19 XI Physics Unit-3 Section-AAnkit GargNo ratings yet

- Physics 253 Problem Set 6 entropy mixing gasesDocument1 pagePhysics 253 Problem Set 6 entropy mixing gasesGary TomNo ratings yet

- Unit - 1-Rayleigh and Fanno FlowDocument86 pagesUnit - 1-Rayleigh and Fanno Flowmebrahtu100% (4)

- Refrigeration Dryers TG - TI Series: Flow Rate 30.8 To 90 M /minDocument7 pagesRefrigeration Dryers TG - TI Series: Flow Rate 30.8 To 90 M /minSergey SofferNo ratings yet

- Module-2: SolidificationDocument16 pagesModule-2: SolidificationSachin AgnihotriNo ratings yet

- Atkins' Physical Chemistry: Peter Atkins - Julio de PaulaDocument36 pagesAtkins' Physical Chemistry: Peter Atkins - Julio de PaulaIvy JoyceNo ratings yet

- Physics Thermodynamics and MolDocument151 pagesPhysics Thermodynamics and MolSuzaki KurushiNo ratings yet

- 3030 eDocument58 pages3030 ecesar luis gonzalez rodriguezNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- A2 Ideal Gases QuestionsDocument60 pagesA2 Ideal Gases QuestionsmandoolalaNo ratings yet

- ICSE Class 8 Physics Selina Solution Chapter 6 Heat TransferDocument6 pagesICSE Class 8 Physics Selina Solution Chapter 6 Heat Transfersavithas19794153No ratings yet