Professional Documents

Culture Documents

A4 Small Bore Connection BETA Service and SPEC2014

Uploaded by

Jose BijoyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A4 Small Bore Connection BETA Service and SPEC2014

Uploaded by

Jose BijoyCopyright:

Available Formats

Small Bore Connections (SBC) Assessment and Specification

Evaluation of vibration induced fatigue failure on SBCs for

new projects (design) or existing piping systems

Vibration induced failures on Small Bore Connections (SBCs) are the most common integrity issues for

compressor and pumping systems. A failed piping connection is a high impact problem, and has safety,

environmental, and operational consequences.

BETA Machinery Analysis offers a range of services to manage this integrity/reliability risk, and has conducted

hundreds of successful projects. Appendix 1 contains a summary of the service options, and Appendix 2

contains the specifications/features. For application or support, please contact info@BetaMachinery.com or

call us at +1-403-245-5666.

Available Services for Small Bore Connections (SBC)

1. For new installations (or revamps), there are three levels of service depending on the risk profile of the

unit and customer.

New (Revamped) Compressor or Pump Packages

Service Description Summary Remaining Risks

SBC-D1 Design SBC Review Basic approach: review available drawings Med: Many remaining risks since

and provide best practice resonance is possible (and no field

recommendations. No field measurements. verification/testing)

SBC-D2 Standard SBC Design evaluation of proposed SBC, with Low: Common risks are significantly

Design Assessment recommended changes. Shop and field addressed. A small amount of

testing to verify vibration levels are residual risk remains.

acceptable.

SBC-D3 Comprehensive BETA is directly involved in SBC design to Minimal: Maximum assurance for

SBC Integrity ensure a conservative system that avoids the designed operating system.

Assurance resonances at key frequencies.

Shop and field testing to address steady

state and transient situations.

2. For existing sites, there are two service levels:

Existing Facilities (In Operation)

Service Description Summary Remaining Risks

SBC-F1 Standard SBC Ideal for evaluating SBC integrity and the Low: For standard service, there are

Field associated piping system on the machine system. practical limits to testing all locations.

Assessment Includes impact testing for MNFs, vibration Not all operating conditions checked.

screening, speed sweep, and detailed FEA (if Plant piping (off-skid) SBCs not

required) to resolve problem locations. evaluated.

SBC-F2 Comprehensive For critical applications where more stringent Minimal: Common risks are

SBC Integrity testing is required. Includes transient and steady significantly addressed. A small

Audit state testing, fatigue analysis, and assess pipe amount of residual risk remains.

strain. Can include station piping (away from the

rotating/reciprocating machine).

To mitigate this risk, the owner (or its EC) must specify a SBC vibration study when it orders a new rotating

machine, or to request a field assessment on existing units. See Appendix 1 for service specifications and

options.

Canada | USA | Malaysia | China www.BetaMachinery.com

Beta Machinery Analysis 2

Appendix 1: Service Overview and Features

Evaluation of vibration induced fatigue failure on Small Bore Connections (SBC)

This Appendix outlines the SBC service for new units (design stage), or for assessing vibration on existing

facilities. BETAs services are based on over 40 years of field testing experience and research in SBC and piping

fatigue failure. The scope also includes requirements per Energy Institute Standards, GMRC guidelines, API,

and other vibration standards.

Refer to Appendix 2 for description of each service (specification), and an overview of the remaining integrity

risks.

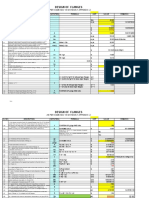

Service Overview

Engineering Shop Field Measurements (Baseline) Report

Detailed Engineering Evaluation

Conclusions, Recommendations

SBC Vibration Survey (including

Transient Vibration Testing and

Risk Assessment Approach

Mainline Vibration Survey

Inspection, Best Practices

Assess Pipe Strain at Key

Impact Testing (MNFs)

(including pulsations

SBC Off-Skid Survey

Engineering Review

Fatigue Analysis

Locations

MNFs)

Service Name

SBC-D1

(Design Stage)

(Design Review)

New Unit

SBC-D2

(Standard

Assessment)

SBC-D3

(Ultra Assurance)

SBC-F1

Existing Unit

(standard field n/a n/a

assessment)

SBC-F2

(Comprehensive n/a n/a

Integrity Audit)

included optional

Small Bore Connections (SBC) Assessment and Specification www.BetaMachinery.com

Beta Machinery Analysis 3

Appendix 2: Specifications for Each Service

Evaluation of vibration induced fatigue failure on Small Bore Connections (SBC)

This Appendix can be used to specify the required service and option (see Appendix 1 for summary). The

description also summarizes the remaining integrity risks.

New Unit/Facility Design

SBC-D1: SBC Design Review

This review and shop test provides a basic level of assurance. NOTE: there are remaining vibration risks that can create

integrity failures. This basic review does not include detailed design of SBC, or a visit to the installed site to conduct a

baseline vibration survey. The review requires General Arrangement (GA) and P&ID drawings, isometric drawings, and bill of

materials including weights) during the design phase. Machinery packager to provide advanced notice to BETA to coordinate

shop testing. For more integrity assurance, we recommend SBC-D2 service.

Scope:

- DESIGN PHASE: Review GA and P&ID drawings and provide recommendations for SBC location/orientation. These are

general design recommendations.

- SHOP INSPECTION: Inspect as-built SBC, best practice recommendation based on visual inspection (does not included

detailed measurements).

- Field Testing: not included in this scope. Can be coordinated/purchased by owner at later date.

Remaining Risks: Medium - SBC may be resonant at some operating conditions. Pipe strain due to fabrication, transportation

or installation may be present. Vibrations measurements not conducted during operations.

SBC-D2: Standard SBC Integrity Assessment

This approach provides a very high level of assurance against SBC vibration related failures and includes more thorough

design and testing. During the design phase BETA will evaluate SBC geometry, calculate MNFs, and compare results to

industry guidelines. BETA will collect vibration measurements while the equipment is operating and recommend changes

where needed. This service requires detailed drawings (General Arrangement (GA), P&ID drawings, isometric drawings, and

bill of materials including weights) during the design phase.

Scope: SBC-D1 (above), plus these additional features;

1. DESIGN PHASE:

- Evaluate drawings and compare geometry to established standards;

- Calculate MNFs.

- Recommend changes at locations with high risks.

- Using BETAs performance model, identify the worst case operating conditions (e.g. operating conditions having the highest

dynamic forces (rod loads) and/or pressure pulsations).

2. SHOP TEST: Visual inspection and measure SBC MNFs, document geometries, compare MNF to predictions and guidelines.

This allows time to make piping modifications before the unit is shipped to site.

3. FIELD VIBRATION SURVEY: During Operations

- Survey all SBCs, including PSV piping, to screen vibration amplitudes.

- Identify areas exceeding guideline. Spectral data used to assess vibration frequencies. Pro-rate results based on test

condition vs worst case condition (identified above).

- For areas above guideline, measure relative vibration to obtain a more accurate vibration/stress risk assessment.

- Recommend modifications to reduce integrity risks. Verify recommendations using FEA. Report summarizes vibration

baseline results.

OPTIONs:

- Measure SBCs on the plant or station piping, away from the compressor/pump.

- Measure pulsation and vibration on main piping system.

Note: for contracting purposes, the service maybe separated into two components: Packager scope for items 1 and 2; Owner

scope for 3 (field testing). Alternatively, the entire work could be contracted by owner.

Remaining Risks: Low - This service significantly reduces integrity risk, but does not totally eliminate all risks, such as transient

related vibration, pipe strain, or changes in operating conditions (outside original design).

SBC-D3: Comprehensive SBC Integrity Assurance

For critical installations where maximum reliability/integrity is required, a more stringent design approach and testing is

required. This design approach focuses on designing SBC with higher MNFs to avoid dynamic forces that could cause fatigue

failure. BETA takes a direct role in SPC design, working closely with the owner and its design team.

The service includes SBC-D2 (above), plus these additional features:

1. DESIGN PHASE:

Small Bore Connections (SBC) Assessment and Specification www.BetaMachinery.com

Beta Machinery Analysis 4

- BETA takes a more active role in designing all SBCs in the system, working closely with the owner/EPCs to evaluate and

recommend SBC alternatives. Using a range of design techniques, BETAs approach will ensure more conservative designs.

- The design will include Finite Element Analysis (FEA) of SBCs to accurately predict MNF compared to predicted dynamic

forces. BETA will calculate the allowable vibration for each SBC (for use in field testing and ongoing monitoring programs).

2. SHOP TEST: as above (per SBC-D2)

3. FIELD VIBRATION SURVEY:

- Measure vibration on mainline and SBC. Measure pulsations on main piping system where required.

- Compare vibration to allowable stress limits (per FEA). Pro-rate to worst case operating condition and assess using FEA for

more accurate prevention of fatigue failure (assuming compressor operates within initial operating envelope).

- Assess pipe strain at key locations.

- Measure MNFs to confirm results and identify changes due to shipping, mounting, and installation.

- Measure vibration during transient conditions. Test transients during start-up, shutdown, and due to changes in speed and

operating conditions. Measure the SBC response using multichannel data acquisition system. Assess transients versus fatigue

life (SBC fatigue analysis).

- Recommend changes where required. Test modifications using FEA.

- Detailed report documenting SBC characteristics and results. This information will be the baseline for future monitoring

programs.

OPTION: measure SBCs on the plant or station piping, away from the compressor/pump.

Remaining Risks: Minimal - This service provides maximum assurance to the integrity of SBCs. One risk is that compressor

operates outside the original design envelope, or if changes are made to the system.

Existing Units/Facility (Compressors, Pumps, Piping)

SBC-F1: Standard Field Assessment

This is the ideal approach to manage SBC integrity on existing compressors and pumps. SBCs on off-skid piping or on

remaining facility piping are in F2 (below).

1. PLANNING (Prior to Site Visit):

- Evaluate as-built drawings and photographs to established test points and work plan.

- Identify the range of operating conditions at site.

- Using BETAs compressor and pump performance models, identify the worst case operating conditions (e.g. operating

conditions having the highest dynamic forces and/or pressure pulsations)

- Prepare test plan and coordinate with customers field/reliability team.

2. FIELD VIBRATION SURVEY (BASE-LINE): During Operations

- Survey SBCs at key locations, including PSV piping, to screen vibration amplitudes. Identify areas exceeding guideline.

Spectral data used to assess vibration frequencies. Conduct speed sweep if required to measure vibration across operating

speed range. Pro-rate results based on test condition vs worst case condition (identified above).

- Conduct impact (bump) test to determine MNFs. Ideally this is done during short shut-down. Alternative method for

collecting MNF may be applied if required.

- For larger systems, BETAs multi-channel data acquisition is used to capture transients for operations limited in the amount

of events that can be simulated. This provides more effective testing during speed sweeps or changing operating conditions.

- For areas above guideline, measure relative vibration to obtain more accurate vibration/stress predictions.

- Recommend modifications reduce integrity risks. Verify recommendations using FEA.

- Report summarizes vibration baseline results.

3. OPTIONS: Additional Vibration or Troubleshooting Services

- Measure vibration at other agreed operating conditions.

- Measure vibration on main piping, vessels, skid, foundation, frame, etc. Measure pulsations where required.

- Perform Operating Deflected Shape (ODS) at key locations.

- Troubleshooting support for vibration related problems.

Remaining Risks: Low - This service significantly reduces integrity risk, but does totally eliminate all risks, such as transient

related vibration, pipe strain, or changes in operating conditions that create higher forces or different MNFs.

Small Bore Connections (SBC) Assessment and Specification www.BetaMachinery.com

Beta Machinery Analysis 5

SBC- F2. Comprehensive Integrity Audit

For critical conditions where maximum reliability/integrity is required, a more stringent testing methodology is applied to

evaluate vibrations at different operating conditions, or other locations in the facility. Scope can include transient events

(stop, start, changing conditions).

The service includes SBC-F1 (above), plus these additional features:

- Assess pipe strain at key locations.

- Collect relative vibration data on headers, plant piping, etc (station or facility assessment).

- Evaluate at key conditions.

- Strain gauge measurements as required.

- Measure vibration during transient conditions. Using multichannel data acquisition system, test transients during start-up,

shutdown, and due to changes in speed and operating conditions. Assess transients versus fatigue life (SBC fatigue analysis).

- Recommend changes where required. Test modifications using FEA.

- Detailed report documenting SBC characteristics and results. This information will be the baseline for future monitoring

programs.

Remaining Risks: This service provides maximum assurance to the integrity of SBCs. One risk is that compressor or pump

operates outside the original design envelope, or if changes are made to the system.

Small Bore Connections (SBC) Assessment and Specification www.BetaMachinery.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Bolting Equipment of Flange JointsDocument22 pagesBolting Equipment of Flange JointsJose BijoyNo ratings yet

- FSA Gasket Handbook - June 2017Document138 pagesFSA Gasket Handbook - June 2017Dijin MaroliNo ratings yet

- Design of Flanges - 12 600# CalculationsDocument5 pagesDesign of Flanges - 12 600# CalculationsJose BijoyNo ratings yet

- Pressure Equivalent CalculationDocument1 pagePressure Equivalent CalculationJose BijoyNo ratings yet

- Bro Spiral WoundDocument52 pagesBro Spiral WoundBruno SantosNo ratings yet

- AOGV Presentation Nov 2018Document25 pagesAOGV Presentation Nov 2018Jose BijoyNo ratings yet

- Introduction To Vibration Problems at Compressor Stations PDFDocument20 pagesIntroduction To Vibration Problems at Compressor Stations PDFJose Bijoy100% (1)

- Marine Breakaway Couplings Information PaperDocument20 pagesMarine Breakaway Couplings Information Paperjamolina9093100% (5)

- BP Ground Flare Control System PR OG1 0409ADocument1 pageBP Ground Flare Control System PR OG1 0409AJose BijoyNo ratings yet

- Process Safety Leading and Lagging Metrics - CCPS - 2011Document44 pagesProcess Safety Leading and Lagging Metrics - CCPS - 2011Haribo1962No ratings yet

- Statement - Public Hearing - Process Safety Performance IndicatorsDocument28 pagesStatement - Public Hearing - Process Safety Performance IndicatorsJose BijoyNo ratings yet

- Small-Bore Connections (SBC) Assessment - BETA Machinery AnalysisDocument7 pagesSmall-Bore Connections (SBC) Assessment - BETA Machinery AnalysisJose BijoyNo ratings yet

- Marine Breakaway Couplings Information PaperDocument20 pagesMarine Breakaway Couplings Information Paperjamolina9093100% (5)

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFDocument4 pagesA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyNo ratings yet

- Small Bore Fittings - Your Hidden Risk - SVT Articles - SVT Engineering ConsultantsDocument4 pagesSmall Bore Fittings - Your Hidden Risk - SVT Articles - SVT Engineering ConsultantsJose BijoyNo ratings yet

- Applyingtheenergyinstituteandprcipaper GMC 140625101214 Phpapp01Document29 pagesApplyingtheenergyinstituteandprcipaper GMC 140625101214 Phpapp01Jose BijoyNo ratings yet

- Small Bore Tubing Sample Pages PDFDocument8 pagesSmall Bore Tubing Sample Pages PDFJose BijoyNo ratings yet

- Small-Bore Connections (SBC) Assessment - BETA Machinery AnalysisDocument7 pagesSmall-Bore Connections (SBC) Assessment - BETA Machinery AnalysisJose BijoyNo ratings yet

- Small Bore Tubing Sample PagesDocument8 pagesSmall Bore Tubing Sample PagesJose BijoyNo ratings yet

- Vibration Integrity PrimerDocument2 pagesVibration Integrity PrimerJose BijoyNo ratings yet

- A4 SPEC Pumping Systems 201507 PDFDocument5 pagesA4 SPEC Pumping Systems 201507 PDFJose BijoyNo ratings yet

- Small Bore Tubing Sample PagesDocument8 pagesSmall Bore Tubing Sample PagesJose BijoyNo ratings yet

- A4 SPEC Pumping Systems 201507 PDFDocument5 pagesA4 SPEC Pumping Systems 201507 PDFJose BijoyNo ratings yet

- Training Courses - BETA Machinery AnalysisDocument8 pagesTraining Courses - BETA Machinery AnalysisJose BijoyNo ratings yet

- Specifications - BETA Machinery AnalysisDocument2 pagesSpecifications - BETA Machinery AnalysisJose BijoyNo ratings yet

- A4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFDocument4 pagesA4 SPEC Surge Control Dynamics FIV AIV Station2014 PDFJose BijoyNo ratings yet

- Flow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureDocument6 pagesFlow-Induced Pulsations in Pipe Systems With Closed Side Branches: Study of The Effectiveness of Detuning As Remedial MeasureJose BijoyNo ratings yet

- Vibration Integrity PrimerDocument2 pagesVibration Integrity PrimerJose BijoyNo ratings yet

- Vibration Induced Failure Avoidance and Management Around Vendor PackagesDocument24 pagesVibration Induced Failure Avoidance and Management Around Vendor PackagesJose Bijoy100% (1)

- Training Courses - BETA Machinery AnalysisDocument8 pagesTraining Courses - BETA Machinery AnalysisJose BijoyNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BridgeDocument20 pagesBridgebewketNo ratings yet

- 2nd Final 2020Document7 pages2nd Final 2020Mira VeranoNo ratings yet

- PCS0316H tcm29-2720Document39 pagesPCS0316H tcm29-2720syailendra dyanNo ratings yet

- Alia APT3000 Pressure TransmitterDocument2 pagesAlia APT3000 Pressure TransmitterRexCrazyMindNo ratings yet

- Diploma - Mech - Engg (III, IV, V, VI SEM)Document39 pagesDiploma - Mech - Engg (III, IV, V, VI SEM)Dev GuptaNo ratings yet

- Chemical Bonding: Session - 1 AIMDocument100 pagesChemical Bonding: Session - 1 AIMMOHAMMED RASHIDNo ratings yet

- Cognizance Ias: JPSC Mains Answer Writing TestDocument7 pagesCognizance Ias: JPSC Mains Answer Writing TestAnshu RNo ratings yet

- Observing Microorganisms Through A MicroscopeSV PDFDocument3 pagesObserving Microorganisms Through A MicroscopeSV PDFFelipe Andrés JorqueraNo ratings yet

- Indian Standard: Methods of Test For CablesDocument3 pagesIndian Standard: Methods of Test For CablesVatsalNo ratings yet

- A Slurry Consolidation Approach To Reconstitute Low-Plasticity Silt Specimens For Laboratory Triaxial TestingDocument9 pagesA Slurry Consolidation Approach To Reconstitute Low-Plasticity Silt Specimens For Laboratory Triaxial TestingFrancyNo ratings yet

- NORSOK Structural Steel Fabrication M-101Document67 pagesNORSOK Structural Steel Fabrication M-101Agnes Chong80% (5)

- BRECO ComponentsDocument43 pagesBRECO ComponentsDobrica PetrovicNo ratings yet

- First Portion 1Document58 pagesFirst Portion 1Yeabsira Gashaw AregaNo ratings yet

- PU523 TDS - TremcoDocument2 pagesPU523 TDS - TremcoZerina MoralesNo ratings yet

- Anchor InstallationDocument12 pagesAnchor InstallationSundara SubramaniyanNo ratings yet

- CCW - Cooling Water Treatment ProgramsDocument43 pagesCCW - Cooling Water Treatment Programszerocool86No ratings yet

- Final Tower Analysis Report SST 65 M - SoeDocument99 pagesFinal Tower Analysis Report SST 65 M - SoeErpanBeanTarpoNo ratings yet

- Square Wave SimulinkDocument10 pagesSquare Wave SimulinkEysha qureshiNo ratings yet

- Chemistry and Association of Vanadium Compounds in Heavy Oil and Bitumen, and Implications For Their Selective RemovalDocument14 pagesChemistry and Association of Vanadium Compounds in Heavy Oil and Bitumen, and Implications For Their Selective RemovalMelNo ratings yet

- Interpretation of DSC Curves in Polymer Analysis 2000 - ToledoDocument0 pagesInterpretation of DSC Curves in Polymer Analysis 2000 - ToledoyrecoverNo ratings yet

- Lecture 4Document60 pagesLecture 4Shahzaib HaiderNo ratings yet

- Sista Foam SpecificationDocument1 pageSista Foam SpecificationFrancois-No ratings yet

- Fluid Mechanics HydraulicsDocument420 pagesFluid Mechanics Hydraulicsanonymousdi3noNo ratings yet

- 9702 w22 Ms 42 PDFDocument16 pages9702 w22 Ms 42 PDFsangdeepNo ratings yet

- Introduction To Highway Pavement-1Document60 pagesIntroduction To Highway Pavement-1Sagni Oo ChambNo ratings yet

- Sauli PrinciplesDocument35 pagesSauli PrinciplesSeb TegNo ratings yet

- Oceanography For General Studies UPSC Civil Services Exam: Short Notes PDFDocument71 pagesOceanography For General Studies UPSC Civil Services Exam: Short Notes PDFHari ShankarNo ratings yet

- Lec 22 PDFDocument2 pagesLec 22 PDFabdulzahraNo ratings yet

- Contoh Turbin Gas 1Document5 pagesContoh Turbin Gas 1Alfan FathNo ratings yet

- SADT HT-225A User Manual PDFDocument20 pagesSADT HT-225A User Manual PDFDayane GomesNo ratings yet