Professional Documents

Culture Documents

MIX Design Related PDF

Uploaded by

indian royalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIX Design Related PDF

Uploaded by

indian royalCopyright:

Available Formats

National Conference on Recent Trends in Engineering & Technology

Testing and Mix Design Method of Self-

Compacting Concrete

Hardik Upadhyay*1, Pankaj Shah*2, Elizabeth George#3

*

PG Students, Dept. of Structure Engg., BVM Engg. College, Gujarat Technological University

Gujarat, India.

1

hpupadhyay88@yahoo.in

2

shah2pankaj@yahoo.com

#

Professor, Dept. of Structure Engg., BVM Engg. College, Gujarat Technological University

Gujarat, India.

3

pmgeorge02@yahoo.com

Abstract Self compacting concrete is a highly flowable, yet A. Basic Principle

stable concrete that can spread readily into place and fill the

The SCC is that which gets compacted due to its self-

formwork without any consolidation and without undergoing any

significant separation. In general, SCC results in reduced weight and is deaerated (no entrapped air) almost completely

construction times and reduced noise pollution. This paper deals while flowing in the form work. In densely reinforced

with the history of SCC development and its basic principle, structural members, it fills completely all the voids and gaps

different testing methods to test high-flowability, resistance and maintains nearly horizontal concrete level after it is

against segregation, and passibility. Different mix design placed. With regard to its composition, SCC consists of the

methods using a variety of materials has been discussed in this same components as conventionally vibrated normal concrete,

paper, as the characteristics of materials and the mix proportion ie, cement, aggregates, water, additives or admixtures.

influences self-compactability to a great extent. However, the high dosage of super-plasticizer used for

reduction of the liquid limit and for better workability, the

KeywordsSelf-compactingconcrete,Mixdesign,Superplasticizer, high powder content as lubricant for the coarse aggregates,

Water-powder ratio, Flowability. as well as the use of viscosity-agents to increase the viscosity

of the concrete have to be taken into account.

I. INTRODUCTION

Superplasticizer enhances deformability and with the

In Japan, in early eighties, premature deterioration of reduction of water/powder segregation resistance is increased.

concrete structures were detected almost everywhere in the High deformability and high segregation resistance is obtained

country. The main cause of the deterioration was recognized by limiting the amount of coarse aggregate. These two

as inadequate compaction. In addition, the gradual reduction properties of mortar and concrete in turn lead to self-

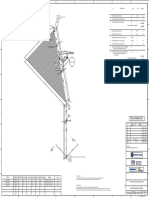

in the number of skilled workers in Japans construction compactability limitation of coarse aggregate content. Figure

industry led to a reduction in the quality of construction work. 1 shows the basic principles for the production of SCC.

As a solution for these social and technical requirements, the

concept of SCC was proposed by Prof Okamura1 at Tokyo

University in 1988. He gave the first prototype of SCC using

materials already in the market. Later studies to develop SCC,

including a fundamental study on the workability of concrete,

were carried out by Ozawa and Maekawa2. SCC has now been

taken up with enthusiasm across Europe and other parts of the

world, in both site and precast concrete work. Practical

application has been backed up by research on its physical and

mechanical characteristics of SCC.Early SCC relied on very

high contents of cementitious paste, the mixes required

specialized and well-controlled placing methods to avoid Fig. 1.Basic principles for production of self-compacting

segregation, but the high contents of cement paste made them concrete3

prone to shrinkage and high heat generation. The overall costs

were very high and applications therefore remained very II. TESTING OF SCC

limited. After series of advancements it is no longer a material At the stage before solidification, self-compacting

consisting of cement, aggregates, water and admixtures. As concrete is required to have three qualities: high-flowability,

already mentioned it is now an engineered material with resistance against segregation and passibility, ie, ability that is

several constituents. necessary to pass the space between reinforcing bars. Other

additional properties, such as, washout resistance and

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

finishability, may be significant and specified for individual

projects/applications. Therefore, it is important to test whether

the concrete is selfcompactable or not and also to evaluate

deformability or viscosity for estimating proper mix

proportioning if the concrete does not have sufficient self-

compactability. The existing procedures for self-compacting

characteristics are those, which measure height differences at

different points under free flow and also resistance against

blocking. The common tests currently used, although not

standardized for assessment of fresh SCC, are described here.

1. Slump Flow Test for Measuring Flowability:

The basic equipment used is the same as for the

conventional Slump test4 (Figure 2). The test method differs

from the conventional one in the way that the concrete sample Fig. 3 V-funnel

placed into the mould has no reinforcement rod and when the

slump cone is removed the sample collapses. The diameter of

the spread of the sample is measured, ie, a horizontal distance 3. L-box Test:

is measured as against the vertical slump measured in the The L-box test method uses a test apparatus

conventional test. While measuring the diameter of the spread, comprising a vertical section and a horizontal trough into

the time that the sample takes to reach a diameter of 500 mm which the concrete is allowed to flow on the release of a trap

(T50) is also sometimes measured. The Slump Flow test can door from the vertical section passing through reinforcing bars

give an indication about the filling ability of SCC and an placed at the intersection of the two areas of the apparatus

experienced operator can also detect an extreme susceptibility (Figure 4)6. The concrete ends of the apparatus H1 and H2

of the mix to segregation. However, this information cannot measure the height of the concrete at both ends. The L-box

be obtained from numerical results alone, a substantial test can give an indication as to the filling ability and passing

previous experience in using the test and carrying out ability.

construction in SCC is essential.

Fig. 4 L-box test

TABLE.I RECOMMENDED LIMITS FOR DIFFERENT FRESH

Fig. 2 Slump flow test PROPERTIES OF SCC BY EFNARC

Typical range of

2. V-funnel Test: Sr values

The V-funnel test was developed in Japan and used Method Unit

No

by Ozawa, et al 5. The equipment consists of a V-shaped Min. Max.

funnel, shown in Figure 3. The funnel is filled with concrete Slump flow by abram's

and the time taken by it to flow through the apparatus 1 cone Mm 650 800

measured. This test gives account of the filling capacity 2 T50cm Slump flow Sec 2 5

(flowability). The inverted cone shape shows any possibility

3 V-Funnel Sec 6 12

of the concrete to block is reflected in the result.

4 T5 minutes V-Funnel Sec 0 3

5 L-Box h2/h1 0.8 1

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

III. MIX-DESIGN cost and much improvement in working conditions as it

The Japanese concept for design of SCC is based on a reduces noise pollution.

method proposed by Okamura and Ozawa7. The authors have

proposed a simple mix-proportioning system assuming REFERENCE

general supply from ready-mixed concrete plants. The coarse

[1] H Okamura and M Ouchi. Self-compacting Concrete.

and fine aggregate contents are fixed so that self- Development, Present use and Future. Proceedingd of the First

compactability can be achieved easily by adjusting the water International RILEM Symposium on Self-Compacting Concrete.

to powder volume ratio and superplasticizer dosage only. The Sweden, Proc 7, 1999, pp 3-14.

mixed design as proposed is: [2] K Ozawa, M Kunishima, K Maekawa and K Ozawa. Development of

High Performance Concrete Based on Durability Design of Concrete

Coarse aggregate content is fixed at 50% of the solid Structures. Proceeding of East-Asai and Pacific Conference on

volume; Structural Engineering and Construction (EASEC-2), vol 1, January

Fine aggregate content is fixed at 40% of the mortar volume; 1989, pp 445-450.

Water-powder ratio in volume is assumed as 0.9 to 1.0 [3] F Dehn, K Holschemacher, K and D Weibe. Self-Compacting

Concrete (SCC) Time Development of the Material Properties and

depending on the properties of the powder; and the Bond Behaviour. LACER No 5, 2000, pp 115-124.

Superplasticizer dosage and the final water-powder ratio are [4] Specification and Guidelines for Self-Compacting Concrete.

determined so as to ensure the self-compactability. EFNARC, Association House, 99 West Street, Farnham, Surrey GU9

The value of water to powder volume ratio (Vw/Vp) 7EN, UK, February 2002.

[5] K Ozawa, N Sakata and H Okamura. Evaluation of Self-

is optimized by mortar flow test and Mortar Funnel Test. Compactibility of Fresh Concrete Using the Funnel Test. Concrete

Takada8 considered the slump flow value of 65030 mm and Library of JSCE, vol 25, June 1995, pp 59-75. March 2-3, 1993, pp

the V-funnel time of 112 s as adequate value for the 183-190.

workable SCC. Further to increase the viscosity and thereby [6] Petersson, P Billberg and B K Van. A Model for Self-compacting

Concrete. Proceedings of International RILEM Conference on

reduce the deformity an organic stabilizer welan gum9 was Production Methods and Workability of Concrete, edited by P J M

used. In organic stabilizer, there is a polymer formation of 3- Bartos, et al, Chapman & Hall/E & FN Spon, Paisley, 1996, pp 483-

dimensional framework which increases the viscosity and 490.

water adsorption. [7] H Okamura and K Ozawa. Mix Design for Self-Compacting

Concrete. Concrete Library of JSCE, no 25, June 1995, pp 107-120.

[8] K Takada, G I Pelova and J C W Walraven. Influence of Chemical

IV. FUTURE OF SELF-COMPACTING CONCRETE Admixtures and Mixing on the Mix Proportion of General Purpose

Since the development of the prototype of SCC in 1988, its Self-Compacting Concrete. International Congress Creating with

use in actual structures has gradually increased worldwide. Concrete, University of Dundee, UK, September 6-10, 1999.

[9] N Sakata, K Maruyama and K Minami. Basic Properties and Effects

SCC addresses many environmental issues; the main ones are of Welan Gum on Self-consolidating Concrete. Proceedings of the

reduction in noise level in the factory as well as on site, International RILEM Conference on Production Methods and

reduction in personal injuries from noise and manual Workability of Concrete, edited by P J M Bartos, D L Marrs and D J

handling, reduction in electricity usage and reduction in the Cleland, E & FN Spon, Paisley, Scotland, June 3-5, 1996, pp 237-253.

overall maintenance costs of vibration equipment. A typical

application example of SCC is the two anchorages of Akashi-

Kaikyo (Straits) Bridge opened in April 1998, a suspension

bridge with the longest span (1991 m) in the world. The SCC

provides tangible opportunities to both designer and

contractor. It also has a future in the precast industry

providing durable concrete at a lower cost due to lower initial

investments of vibrating facilities and lower recurring costs

due to faster reusage of moulds. It improves the working

environment at plants and sites by eliminating noise of

vibration; it is possible for concrete product plants to be

located in the urban area.

V. CONCLUSION

Considering the economy and the durability of

conventional concrete structures, it is observed that the quality

and the density of the concrete, as well as the compaction of

the concrete are main parameters that cause deterioration. For

this, SCC offers new possibilities and prospects. For this, SCC

offers new possibilities and prospects. It can be a boon

considering improvement in concrete quality, significant

advances towards automation and concrete construction

processes, shortened construction time, lower construction

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

National Conference on Recent Trends in Engineering & Technology

13-14 May 2011 B.V.M. Engineering College, V.V.Nagar,Gujarat,India

You might also like

- Makinde Et AlDocument200 pagesMakinde Et Alindian royalNo ratings yet

- IGBC Green Interiors Ratings SystemDocument108 pagesIGBC Green Interiors Ratings SystempallabdgNo ratings yet

- Standardization of Construction Demolition Waste Aggregate: Explore VIP MembershipDocument12 pagesStandardization of Construction Demolition Waste Aggregate: Explore VIP Membershipindian royalNo ratings yet

- Sample Cover LetterDocument1 pageSample Cover Letteryarrha100% (3)

- AJE Journal Cover Letter TemplateDocument1 pageAJE Journal Cover Letter TemplatehimagirisaiNo ratings yet

- IGBC Green Interiors Ratings SystemDocument108 pagesIGBC Green Interiors Ratings SystempallabdgNo ratings yet

- Effect of Rooftop Mounted TelecommunicatDocument6 pagesEffect of Rooftop Mounted Telecommunicatindian royalNo ratings yet

- Provision For Fixing of Solar Panels in Residential BuildingsDocument3 pagesProvision For Fixing of Solar Panels in Residential Buildingsindian royalNo ratings yet

- International Journal of Structural Engineering and AnalysisDocument2 pagesInternational Journal of Structural Engineering and Analysisindian royalNo ratings yet

- IGBC Green Homes Rating System Ver 3.0Document179 pagesIGBC Green Homes Rating System Ver 3.0indian royalNo ratings yet

- General Guidelines - R2 - 19.4.2020Document3 pagesGeneral Guidelines - R2 - 19.4.2020Anonymous Qm0zbNkNo ratings yet

- CE 751 Urban Transportation System PlanningDocument1 pageCE 751 Urban Transportation System Planningindian royalNo ratings yet

- IGBC - AP Practice Paper - 1Document38 pagesIGBC - AP Practice Paper - 1Anonymous Qm0zbNk50% (2)

- Self-Immunity Boosters - Vitamin SupplementsDocument2 pagesSelf-Immunity Boosters - Vitamin Supplementsindian royalNo ratings yet

- IGBC Green Homes Rating System Ver 3.0Document179 pagesIGBC Green Homes Rating System Ver 3.0indian royalNo ratings yet

- OECD Work On: Sustainable DevelopmentDocument84 pagesOECD Work On: Sustainable DevelopmentAnmol SahuNo ratings yet

- Trip Models PDFDocument6 pagesTrip Models PDFAravind B PatilNo ratings yet

- Design, Analysis and Comparison of Underground Rectangular Water Tank by Using STAAD Provi8 SoftwareDocument6 pagesDesign, Analysis and Comparison of Underground Rectangular Water Tank by Using STAAD Provi8 SoftwareNitin shepurNo ratings yet

- Green Building Rating System in India An PDFDocument8 pagesGreen Building Rating System in India An PDFindian royalNo ratings yet

- 247081ce PDFDocument138 pages247081ce PDFMahipal ReddyNo ratings yet

- Renewable Energy SourcesDocument61 pagesRenewable Energy SourcesPiyush AgarawalNo ratings yet

- A Comparative Study of Rating Systems in PDFDocument3 pagesA Comparative Study of Rating Systems in PDFindian royalNo ratings yet

- MBBL - Model Building Bylaws 2016Document268 pagesMBBL - Model Building Bylaws 2016RAJEEV JHANo ratings yet

- 4.sustainable Special Supp - August16ly - 15Document6 pages4.sustainable Special Supp - August16ly - 15indian royalNo ratings yet

- PDF Application TipsDocument2 pagesPDF Application Tipsindian royalNo ratings yet

- Germany Guideline SB PDFDocument123 pagesGermany Guideline SB PDFFrancisco Bustos-GonzálezNo ratings yet

- Energy saving in buildings using green materialsDocument18 pagesEnergy saving in buildings using green materialsindian royalNo ratings yet

- 3-CF CH 004 Sustainable Design PDFDocument9 pages3-CF CH 004 Sustainable Design PDFindian royalNo ratings yet

- Design of A Sustainable Building A Conceptual FrameworkDocument27 pagesDesign of A Sustainable Building A Conceptual FrameworkKaram Mustafa Alobaidy100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- SI 2013 - 45 CBA - Construction Industry2Document117 pagesSI 2013 - 45 CBA - Construction Industry2chrissy zee1No ratings yet

- 22 - 1507375959 - Waterproofingwale BOQ For Building StructureDocument3 pages22 - 1507375959 - Waterproofingwale BOQ For Building StructuremohnishNo ratings yet

- September 2016 - BNRDocument34 pagesSeptember 2016 - BNRMae Ann GonzalesNo ratings yet

- Annexure-I List of Acceptable Combinations of Coating MaterialsDocument2 pagesAnnexure-I List of Acceptable Combinations of Coating MaterialsVidyut UjalaNo ratings yet

- A. Steps For A Drawing ReviewDocument24 pagesA. Steps For A Drawing ReviewAkdas ArmanNo ratings yet

- Super Final MH ESTIMATEDocument214 pagesSuper Final MH ESTIMATEIshor ThapaNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerAli RazaNo ratings yet

- Sump Discharge Piping - ISOMETRIC DrawingDocument9 pagesSump Discharge Piping - ISOMETRIC DrawingIlham KelanaNo ratings yet

- Grouting Work and Jet-Grouting - ENDocument92 pagesGrouting Work and Jet-Grouting - ENLucki Yohan GunawanNo ratings yet

- Damage Mechanism and NDTDocument1 pageDamage Mechanism and NDTNurul AinNo ratings yet

- Shell Mold Casting Manufacture Complex Parts Thin SectionsDocument7 pagesShell Mold Casting Manufacture Complex Parts Thin Sectionsneel gajNo ratings yet

- Concrete: Pass/Fail Check List - Civil MaterialsDocument1 pageConcrete: Pass/Fail Check List - Civil Materialsankur100% (1)

- Vbs Pg κ ΜετρικάDocument76 pagesVbs Pg κ ΜετρικάkosthsNo ratings yet

- 7B Microstructure of Iron Carbon AlloysDocument14 pages7B Microstructure of Iron Carbon AlloysAhmed AliNo ratings yet

- Trcking Sheet Drawing Update by 13-6-2023Document4 pagesTrcking Sheet Drawing Update by 13-6-2023Hossam H. HamedNo ratings yet

- Item No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkDocument5 pagesItem No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkGautham GautiNo ratings yet

- Control Valve ErosionDocument4 pagesControl Valve ErosionIbrahim HomosNo ratings yet

- Module 6 (Materials & Hardware) SubModule 6.3 (Aircraft MatDocument57 pagesModule 6 (Materials & Hardware) SubModule 6.3 (Aircraft MatInterogator5No ratings yet

- GGBS in Soil StabilisationDocument15 pagesGGBS in Soil Stabilisationkmadan_111No ratings yet

- Grinding Machine All PDFDocument90 pagesGrinding Machine All PDFRohit Ghulanavar100% (2)

- Yoder Brochure 2018Document12 pagesYoder Brochure 2018James Allen Roberts Sr.No ratings yet

- Const Estimate Made Easy by Engr Cajilla V0 99Document25 pagesConst Estimate Made Easy by Engr Cajilla V0 99Al Patrick Dela CalzadaNo ratings yet

- Drilling Speeds and FeedsDocument1 pageDrilling Speeds and FeedsLe Hoang HiepNo ratings yet

- 2009FDocument26 pages2009FdaimaheshNo ratings yet

- RPS Support CatalogueDocument49 pagesRPS Support Catalogueravivarmadatla2011No ratings yet

- Synthetic Fibres and Plastics - Class 8 - NCERT Exercise Questions - PANTOMATHDocument3 pagesSynthetic Fibres and Plastics - Class 8 - NCERT Exercise Questions - PANTOMATHsourav9823No ratings yet

- Pavementdesign PDFDocument95 pagesPavementdesign PDFอัชวิน เจริญสินNo ratings yet

- Water Distribution Piping Materials & InstallationDocument1 pageWater Distribution Piping Materials & InstallationEslam ElsayedNo ratings yet

- 59-69p-BUILDING ON EPS GEOFOAM IN THE 'LOW-LANDS' EXPERIENCES IN THE NETHERLANDSDocument11 pages59-69p-BUILDING ON EPS GEOFOAM IN THE 'LOW-LANDS' EXPERIENCES IN THE NETHERLANDSVa Ni SkyNo ratings yet

- BOQ and specifications for Med United pharmacy and lab interiorsDocument4 pagesBOQ and specifications for Med United pharmacy and lab interiorskuffainNo ratings yet