Professional Documents

Culture Documents

Injection Wafers Simplify Chemical Injection in Pipelines

Uploaded by

Misael RamírezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Injection Wafers Simplify Chemical Injection in Pipelines

Uploaded by

Misael RamírezCopyright:

Available Formats

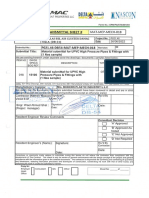

INJECTION WAFER

DATA SHEET (IW SERIES)

Injection Wafers are designed to be installed

between flanges sandwiched between the

pipe flange and a mating flange.

Injection wafers can be used as simplified

injection ports for installing injection quills.

For sludge dewatering applications they can

be used for injecting dilute polymer around

the perimeter of a flow.

Styles Available

Injection wafers are available with:

Threaded ports

Flanged ports

Injection wafers can be provided with:

Full Flange design (including bolt holes)

Ring style design which fits within the

bolt circle of the flange bolts

Simplifies Chemical Injection

Provides a chemically compatible material for

chemical injection or installation of injection

quills.

Ease of Installation

Injection Wafers allow easy installation of

Clockwise from top:

injection points into an existing or new a) Ring style SS injection wafer shown with optional

pipeline. If you can find 2 of play in the threaded injector.

pipeline, a wafer can be installed quickly and b) Full Face PVC injector with (4) NPT ports. For

easily with little downtime. dilute polymer injection into sludge.

c) Custom Full Face injection wafer constructed of

Materials of Construction Kynar with optional multi-hole diffusers for a slurry

Injection Wafers are available in many mixing application.

materials including: d) Ring style SS injection wafer with flanged port.

PVC & CPVC

Stainless Steel

Epoxy Coated Carbon Steel

Other materials such as HDPE and Kynar may be

available

IW SERIES INJECTION WAFERS ARE

DESIGNED FOR INSTALLATION

BETWEEN 150# FLANGES.

Above: A flanged ring style injection wafer constructed

from epoxy coated steel. Shown with dual ports and an

optional multi-hole diffuser for providing maximum

dispersion of a chemical in a pipeline.

1 of 2

www.inyoprocess.com

IW100 Dtd 12-13

You might also like

- Viking Solid Cone Spray NozzleDocument13 pagesViking Solid Cone Spray NozzlebalaNo ratings yet

- ANEXO B ToberaDocument13 pagesANEXO B Toberaernesto garciaNo ratings yet

- Brunswick County Gravity Sewer SpecificationDocument12 pagesBrunswick County Gravity Sewer SpecificationVincent Gabrielle NepomucenoNo ratings yet

- Fiberglass Manholes: Sanitary Sewer LinesDocument10 pagesFiberglass Manholes: Sanitary Sewer LinesshagogalNo ratings yet

- Viking Solid Cone NozzleDocument13 pagesViking Solid Cone NozzleFurkan KadıNo ratings yet

- Division 33 - UtilitiesDocument18 pagesDivision 33 - UtilitiesMisba UddinNo ratings yet

- Design Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeDocument14 pagesDesign Installation Guide For PVC Fittings Laterals For Solid Wall PVC Sewer PipeUnibellNo ratings yet

- Section-220516 Expansion Fittings and Loops For Plumbing Piping Rev 1Document3 pagesSection-220516 Expansion Fittings and Loops For Plumbing Piping Rev 1刘盘石No ratings yet

- 15420Document7 pages15420uddinnadeemNo ratings yet

- Viking NozzlezDocument10 pagesViking NozzlezamardonesNo ratings yet

- Valves - AWWA Valves PDFDocument28 pagesValves - AWWA Valves PDFnilnilen2009No ratings yet

- Floor Gully 1Document93 pagesFloor Gully 1Khaled GameaNo ratings yet

- 33 16 13 - Ground Storage TankDocument6 pages33 16 13 - Ground Storage TankBelford AbuhNo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- DR9919 Dismantling Joints VJ Bro 1018 GB+V1Document16 pagesDR9919 Dismantling Joints VJ Bro 1018 GB+V1Mohamed TarekNo ratings yet

- Vulcan Thread BecoDocument12 pagesVulcan Thread Becos_barrios100% (1)

- CatalogoVCW EN Mai20Document11 pagesCatalogoVCW EN Mai20snri0da9No ratings yet

- Fusible PVC SpecificationsDocument17 pagesFusible PVC Specificationsamir_hayfaNo ratings yet

- Supports, Hangers, Anchors and Sleeves For PlumbingDocument11 pagesSupports, Hangers, Anchors and Sleeves For Plumbingabdullah sahibNo ratings yet

- Model E Spray Nozzles VikingDocument10 pagesModel E Spray Nozzles VikingDeniNo ratings yet

- Brochure Johnsons Screens® Water Well PVCDocument6 pagesBrochure Johnsons Screens® Water Well PVCMunshenNo ratings yet

- Kenco Chemical Injectors Minimize Corrosive BuildupDocument2 pagesKenco Chemical Injectors Minimize Corrosive BuildupmiltoncNo ratings yet

- 2016-CB - Di Flange-Pipe-SubmittalDocument3 pages2016-CB - Di Flange-Pipe-Submittalsidharth saraswatNo ratings yet

- P021.46 DB54 Mat Mech 001Document115 pagesP021.46 DB54 Mat Mech 001p4p7 projectsNo ratings yet

- Catalogo Staffe 2017Document12 pagesCatalogo Staffe 2017israelNo ratings yet

- Ms01828 Bel Air Cluster Arif Nascon MR Ag&BgDocument118 pagesMs01828 Bel Air Cluster Arif Nascon MR Ag&Bgsasi kNo ratings yet

- Catalog FVCDocument36 pagesCatalog FVCSebastian Xavier MaidanaNo ratings yet

- 01 Appende PDFDocument21 pages01 Appende PDFArun VaithyanathanNo ratings yet

- Danby Panel LokDocument4 pagesDanby Panel LokaffashNo ratings yet

- Permit d08-243 - Segment 3 - Mcdonalds - Restaurant BuildingDocument348 pagesPermit d08-243 - Segment 3 - Mcdonalds - Restaurant BuildingAbdullah.N FAAliNo ratings yet

- Sanitary Works ScheduleDocument4 pagesSanitary Works ScheduleManjunath HrmNo ratings yet

- Section 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC PipeDocument6 pagesSection 02717 - Concrete Sewer Rehabilitation by Machine-Wound PVC Pipefahren_de2015No ratings yet

- E Pipe & Fittings With SampleDocument138 pagesE Pipe & Fittings With Samplep4p7 projectsNo ratings yet

- Catalog LWNDocument36 pagesCatalog LWNPralhadNo ratings yet

- Upvc Pipes - ComplianceDocument6 pagesUpvc Pipes - ComplianceRuby Faith EspinosaNo ratings yet

- BR CiDocument8 pagesBR CiJose MuikeNo ratings yet

- US Pipe - Ductile Iron Pipe Design 2013 PDFDocument26 pagesUS Pipe - Ductile Iron Pipe Design 2013 PDFtylerstearnsNo ratings yet

- Ball Valve PDFDocument9 pagesBall Valve PDFkoushik dasguptaNo ratings yet

- Plumbing Boq of Dominos PizzaDocument8 pagesPlumbing Boq of Dominos PizzaMd. Mominul IslamNo ratings yet

- Csi 2018 Mechanical Division 15Document303 pagesCsi 2018 Mechanical Division 15Taner Demirezen100% (1)

- Kofco Catalouge FlangeDocument96 pagesKofco Catalouge Flangeluft3744100% (4)

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Suggested Specification For Buried Steel Water Transmission Pipe FINALDocument10 pagesSuggested Specification For Buried Steel Water Transmission Pipe FINALA T AlhershNo ratings yet

- Project Standard Specification: Decorative Fountain 15495 - Page 1/7Document7 pagesProject Standard Specification: Decorative Fountain 15495 - Page 1/7adel rihanaNo ratings yet

- PVC Drainage Pipe & FittingsDocument19 pagesPVC Drainage Pipe & FittingsKenneth MooreNo ratings yet

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 pagesFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisNo ratings yet

- IDOT Standard Specs For Storm SewersDocument10 pagesIDOT Standard Specs For Storm Sewerskanagavel muruganNo ratings yet

- Project Report On Double Wall Corrugated (DWC) Hdpe PipesDocument8 pagesProject Report On Double Wall Corrugated (DWC) Hdpe PipesEIRI Board of Consultants and PublishersNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- Dismantling-Joints VJ Bro 0821 Eng+v1Document25 pagesDismantling-Joints VJ Bro 0821 Eng+v1AhmedRamadanNo ratings yet

- Penstocks Catalogue PDFDocument19 pagesPenstocks Catalogue PDFAhmed AbuoelnagaNo ratings yet

- 07/31/20 DESIGN NO. - SECTION 15415 Drainage Part 1 - General 1.01 Description of WorkDocument30 pages07/31/20 DESIGN NO. - SECTION 15415 Drainage Part 1 - General 1.01 Description of WorkJhoNo ratings yet

- CSD Data SheetDocument3 pagesCSD Data SheetDucVikingNo ratings yet

- WincroDocument20 pagesWincromdavies20No ratings yet

- FL - Expansion Fittings and Loops For Plumbing Piping - BudDocument6 pagesFL - Expansion Fittings and Loops For Plumbing Piping - BudAntonius HarrisNo ratings yet

- Viking K25 ESFRDocument16 pagesViking K25 ESFRnsantos102415No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Handbook of PVC Pipe Design and Construction: (First Industrial Press Edition)From EverandHandbook of PVC Pipe Design and Construction: (First Industrial Press Edition)No ratings yet

- Steam Tracing: Design GuideDocument17 pagesSteam Tracing: Design GuidevladimirNo ratings yet

- Booster-Air Ejector-Liquid Ring Info SheetDocument2 pagesBooster-Air Ejector-Liquid Ring Info SheetMisael RamírezNo ratings yet

- Booster-Air Ejector-Liquid Ring Info SheetDocument2 pagesBooster-Air Ejector-Liquid Ring Info SheetMisael RamírezNo ratings yet

- Beam DeflectionDocument5 pagesBeam DeflectionChinna ValleNo ratings yet

- RecentDocument28 pagesRecentelectroquimicaNo ratings yet

- sp3d ToolkitDocument45 pagessp3d ToolkitMisael RamírezNo ratings yet

- Coco SoftwareDocument22 pagesCoco SoftwareMisael RamírezNo ratings yet

- NEMO® C.Pro®: Pumps & SystemsDocument4 pagesNEMO® C.Pro®: Pumps & SystemsMisael RamírezNo ratings yet

- MATLAB ODE Suite for Solving Ordinary Differential EquationsDocument35 pagesMATLAB ODE Suite for Solving Ordinary Differential EquationsMisael RamírezNo ratings yet

- Npa 305Document20 pagesNpa 305Misael RamírezNo ratings yet

- Nemo NM Mini Metering PumpsDocument6 pagesNemo NM Mini Metering PumpsMisael RamírezNo ratings yet

- PipeSchedulerev2 PDFDocument1 pagePipeSchedulerev2 PDFMisael RamírezNo ratings yet

- Journal For HydrologyDocument21 pagesJournal For HydrologyMisael RamírezNo ratings yet

- Manual Del Conductor CompletoDocument30 pagesManual Del Conductor CompletoMisael RamírezNo ratings yet

- Case 14 Chlorine CondensingDocument10 pagesCase 14 Chlorine CondensingMisael RamírezNo ratings yet

- Samper 2006 Physics and Chemistry of The Earth, Parts ABCDocument9 pagesSamper 2006 Physics and Chemistry of The Earth, Parts ABCMisael RamírezNo ratings yet

- Coeficientes de Dilución InfinitaDocument7 pagesCoeficientes de Dilución InfinitaMisael RamírezNo ratings yet

- The Visual L Tex Faq: 1 Magna CondimentumDocument30 pagesThe Visual L Tex Faq: 1 Magna CondimentumpcusinuNo ratings yet

- Samper 2008 Journal of Contaminant HydrologyDocument13 pagesSamper 2008 Journal of Contaminant HydrologyMisael RamírezNo ratings yet

- Yang 2007 Journal of Contaminant HydrologyDocument19 pagesYang 2007 Journal of Contaminant HydrologyMisael RamírezNo ratings yet

- Use of Numerical Groundwater Modelling For Mine Dewatering PDFDocument10 pagesUse of Numerical Groundwater Modelling For Mine Dewatering PDFMisael RamírezNo ratings yet

- Design standards for low-clearance vehiclesDocument10 pagesDesign standards for low-clearance vehiclesMisael RamírezNo ratings yet

- Tutorial1gwwm GrassDocument24 pagesTutorial1gwwm GrassMisael RamírezNo ratings yet

- Samper 2008 Applied-GeochemistryDocument16 pagesSamper 2008 Applied-GeochemistryMisael RamírezNo ratings yet

- Simulating Underground Mine InflowsDocument5 pagesSimulating Underground Mine InflowsMisael RamírezNo ratings yet

- Renard PDFDocument12 pagesRenard PDFMisael RamírezNo ratings yet

- Samper 2008 Physics and Chemistry of The Earth, Parts ABCDocument11 pagesSamper 2008 Physics and Chemistry of The Earth, Parts ABCMisael RamírezNo ratings yet

- Parameter Identification in Groundwater Flow and Transport With The New Front Limitation AlgorithmDocument9 pagesParameter Identification in Groundwater Flow and Transport With The New Front Limitation AlgorithmMisael RamírezNo ratings yet

- RenardDocument13 pagesRenardMisael RamírezNo ratings yet

- Coeficientes de Dilución InfinitaDocument7 pagesCoeficientes de Dilución InfinitaMisael RamírezNo ratings yet

- TADO Smart Thermostat ManualDocument16 pagesTADO Smart Thermostat ManualMark WillisNo ratings yet

- Bangladesh National Building Code 2012 Part 07 - Construction Practices and SafetyDocument83 pagesBangladesh National Building Code 2012 Part 07 - Construction Practices and SafetyPranoy Barua100% (3)

- (UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Document33 pages(UNISIM (BEHAS) - Introduction To Aerospace) EAS105 - Lab4Mohd Ashraf Mohd IsmailNo ratings yet

- Data SheetDocument15 pagesData SheetLucian Sorin BortosuNo ratings yet

- SF 9 - ES Learners Progress Report CardDocument3 pagesSF 9 - ES Learners Progress Report Cardroxanne50% (2)

- Environmental Monitoring Plans For Decommissioning of Nuclear FacilitiesDocument9 pagesEnvironmental Monitoring Plans For Decommissioning of Nuclear FacilitiesEric GozzerNo ratings yet

- Filipino Nurses' Deep Faith and Cultural Attitudes in HealthcareDocument41 pagesFilipino Nurses' Deep Faith and Cultural Attitudes in HealthcareKeziah Marie Chua Santa-AnaNo ratings yet

- JSS20-48 Single Time Control Digital Display Time Relay: Page 1 / 2Document2 pagesJSS20-48 Single Time Control Digital Display Time Relay: Page 1 / 2FranciscoNo ratings yet

- Monica Stelly Resume 2017Document2 pagesMonica Stelly Resume 2017api-355097199No ratings yet

- Explorations in PersonalityDocument802 pagesExplorations in Personalitypolz2007100% (8)

- 7220 Instrucciones de Intalacion PDFDocument2 pages7220 Instrucciones de Intalacion PDFAttackDenied123No ratings yet

- Calcul BADocument15 pagesCalcul BAHanane BenGamraNo ratings yet

- Recent Developments in Carbapenems: ReviewDocument16 pagesRecent Developments in Carbapenems: ReviewFrancielleNo ratings yet

- Ethylene Glycol PDFDocument2 pagesEthylene Glycol PDFAngela0% (1)

- 5 Ethiopian - National - Healthcare - Quality - and - Safety - Strategy - Final - Draft-July122021Document86 pages5 Ethiopian - National - Healthcare - Quality - and - Safety - Strategy - Final - Draft-July122021Kemal MahmoudNo ratings yet

- Non Ferrous AlloysDocument45 pagesNon Ferrous AlloysDeepak NegiNo ratings yet

- Body Language - Julius FastDocument30 pagesBody Language - Julius FastPat Kifrynski100% (1)

- Electro BladeDocument2 pagesElectro Bladeapi-19808945No ratings yet

- Prof. J.L. HumarOffice: HP 3051Phone: 613-520-2600 ext. 3051Email: jhumar@cmail.carleton.caOffice Hours: Tuesdays and Thursdays, 2:00-3:00 pmDocument2 pagesProf. J.L. HumarOffice: HP 3051Phone: 613-520-2600 ext. 3051Email: jhumar@cmail.carleton.caOffice Hours: Tuesdays and Thursdays, 2:00-3:00 pmBhind NijjarNo ratings yet

- The Benefit of Power Posing Before A High-Stakes Social EvaluationDocument20 pagesThe Benefit of Power Posing Before A High-Stakes Social EvaluationpaolaNo ratings yet

- We Get Results!: Spring FlingDocument35 pagesWe Get Results!: Spring FlingThe WorldNo ratings yet

- Manufacturing ProcessDocument6 pagesManufacturing Processbro nawalibmatNo ratings yet

- Red Velvet Cake RecipeDocument6 pagesRed Velvet Cake RecipeRuminto SubektiNo ratings yet

- RRL CapstoneDocument3 pagesRRL CapstoneMatthew Dane SitoNo ratings yet

- Handout2 Fischer CarbeneDocument5 pagesHandout2 Fischer CarbeneMuhammad ShimaNo ratings yet

- WasdabDocument13 pagesWasdabfakhri84No ratings yet

- Rules of SungazingDocument2 pagesRules of SungazingaustralexdiNo ratings yet

- 30 Natural Ways To Help Treat Polycystic Ovary SyndromeDocument12 pages30 Natural Ways To Help Treat Polycystic Ovary SyndromeArun AchalamNo ratings yet

- Screening Criteria For Application of EOR Processes in Offshore FieldsDocument7 pagesScreening Criteria For Application of EOR Processes in Offshore FieldsSajad FalahNo ratings yet

- CPRMSE GuidelinesDocument2 pagesCPRMSE GuidelinesDeepak KumarNo ratings yet