Professional Documents

Culture Documents

Simple Dew Point Control With Propane Loop For Chilling (HYSYS V8.6)

Uploaded by

JesusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Simple Dew Point Control With Propane Loop For Chilling (HYSYS V8.6)

Uploaded by

JesusCopyright:

Available Formats

Register of Community

1- Create your Google Account 2- Go to Link

https://accounts.google.com/signup https://plus.google.com/communities/103583759337363889002

Simple Dew Point Control HYSYS v8.6

Steps to set up a simulation in HYSYS v8.6 to model a simple dew point control system consisting of:

Gas chiller

Flash separator

Liquid stabilizer with gas recycle & compression

Product gas compression

Simple propane refrigeration loop

When the simulation is set up the overall PFD should look like the following figure.

Basis

A gas plant is processing 100 MMscfd (dry basis) to produce a spec pipeline gas as well as a pipeline

raw mix liquid product. The following are known conditions for the feedstock and specification for

the products:

The composition of the feed gas is shown in the following table.

The gas enters the plant at 400 psia & 120F.

The gas has a small amount of water, 2 lb water per MMscf dry gas.

The produced pipeline gas should have a gross heating value between 905 to 1050 Btu/scf 1

& a hydrocarbon dew point no higher than 15F.

The produced pipeline gas should be delivered to the pipeline at 1000 psia and no higher

than 120F.

The produced liquids shall be exported via pipeline & stabilized to have a TVP (true vapor

pressure) @ 100F no greater than 103 psia.

A simple propane loop will be used to provide the chilling duty. The condenser will operate

at 120F. The minimum approach temperature within the chiller will be 10F.

1 If the gross heating value spec cannot be achieved set the chilled separator to the lowest reasonable

temperature when using a simple propane chilling loop, -30F.

Rev 1.2 -1- March 13, 2016

Air coolers will be used to cool gases & liquids to 120F.

Component Mol%

N2 0.357

CO2 0.194

C1 80.980

C2 13.238

C3 3.438

i-C4 0.431

n-C4 0.742

i-C5 0.199

n-C5 0.156

n-C6 0.163

n-C7 0.065

n-C8 0.026

n-C9 0.010

Create new simulation file

Start the program from Start, All Programs, Aspen Tech, Process Modeling V8.6, Aspen HYSYS, Aspen

HYSYS V8.6. When the program opens choose the New button.

Define the Components & the Property Models

Specify components, fluid property packages, & crude oil assays

The first step is to add a set of pure chemical species to represent the gas & water phases. With

Component Lists highlighted click on the Add button. From the list of pure components pick: H2O,

Nitrogen, CO2, Methane, Ethane, Propane, i-Butane, n-Butane, i-Pentane, n-Pentane, n-Hexane,

n-Heptane, n-Octane, & n-Nonane.

Rev 1.2 -2- March 13, 2016

The next step is to pick a fluid property package. From the Fluid Packages screen click the Add

button. Choose the Peng-Robinson option and make sure it is associated with Component List 1.

It would be a good idea to save this file. Click the File tab & select Save As. Choose an appropriate

name & location.

Set up & Solve the Flowsheet

Gas Chilling & Separation

When you activate the Simulation & youll see a blank flowsheet. We will want to create a feed

stream & attach it to an LNG Exchanger. The outlet will be attached to a flash separator.

Rev 1.2 -3- March 13, 2016

Ensure that the model Palette is visible. If it is not, press the View tab & click Model Palette.

Place the following items on the flowsheet:

A Material Stream, Dry Feed

A Material Stream, Feed Water

A Mixer, Combine

An LNG Exchanger, Chiller

A 3-Phase Separator, DPC Separator.

Double-click on the Dry Feed stream to open up the entry forms for this stream. Enter the 100

MMscfd flowrate in the Molar Flow box. Note that once you enter the flowrate it changes the units to

lbmole/hr.

Now we need to specify the composition. Select Composition under Worksheet in the left-hand

column. Click the Edit button to bring up a form to enter the composition of this stream. Enter the

values from the table in the Basis section as Mole Fractions. Note that these add up to approximately

100, not 1. Select the Normalize button. Click OK. Now you should see that the form associated with

the stream is in green, meaning that all values for the stream have been calculated.

Rev 1.2 -4- March 13, 2016

We want to do the same thing for the water portion of the feed represented by the stream Feed

Water. Double-click on the Feed Water stream to open up the entry forms for this stream. Enter

Rev 1.2 -5- March 13, 2016

200 lb/hr in the Mass Flow box (to represent the 2 lb/MMscf water content). Enter the pressure but

do not enter the temperature.

Select Composition under Worksheet in the left-hand column. Click the Edit button to bring up a

form to enter the composition of this stream. Enter a 1 for the H2O mole fraction. Select the

Normalize button. Click OK. Now you should see that the form associated with the stream is still

yellow because the temperature has not been specified. That is OK, were going to back-calculate

the final condition so that the total feed gas is 120F.

Rev 1.2 -6- March 13, 2016

For most of the unit operations well define connections & create new streams using the operations

Design form. Double-click on Mixer. Define the 2 Inlets as Dry Feed & Feed Water. Define a new

Outlet stream as Total Feed.

Select the Worksheet tab. Note that the flowrate & pressure of the Total Feed stream are calculated.

But we still have to specify some type of temperature information to fully calculate Total Feed.

Specify the temperature as 120F. Note that not only have all properties been calculated for Total

Feed but also the final conditions for Feed Water have been determined. A Mixer is an isenthalpic

operation, so the enthalpy for Feed Water (and hence its temperature & quality) became specified

once we fully specified Total Feed.

Rev 1.2 -7- March 13, 2016

We now want to model the gas side of the Chiller. We could use a Cooler operation, but since well

ultimately want to calculate approach temperatures between the gas & the propane in the chilling

loop an LNG Exchanger is more appropriate. Double-click on Chiller. Specify the 1st Inlet Stream as

Total Feed & define the Outlet Stream as Chilled Gas. For now specify the Pressure Drop as 0. Make

sure that specification for Hot/Cold is Hot.

Rev 1.2 -8- March 13, 2016

We now want to specify the cold separator & determine the properties of the produced gas. Double-

click on DPC Separator. Specify the Inlet as Chilled Gas. Create new streams, Cold Vapor, Cold

Liquid, & Cold Water as the Vapour, Light Liquid, & Heavy Liquid, respectively.

Lets estimate the needed temperature for the cold separator Click on the Worksheet tab &

specify -10F for the temperature of Chilled Gas. Notice that all values are calculated for Chilled

Gas, Cold Liquid, & Cold Vapor.

Rev 1.2 -9- March 13, 2016

Is this temperature for the cold separator appropriate to make spec pipeline gas? The primary

variable that we can control with the temperature is the dew point of the produced gas at the

pipeline conditions. Well look at the P-T diagram for Cold Vapor to get an indication of whether

weve come close to the dew point spec. Up in the ribbon under the Home tab, click on Stream

Analysis & choose Envelope. In the pop-up form choose Cold Vapor as the Object & click OK.

Rev 1.2 - 10 - March 13, 2016

The results in the Design tab show that the Cricondentherm is -2.953F, much colder than it needs to

be to meet the 15F pipeline dew point spec. We could reduce Chiller duty (and ultimately power

required for the propane cooling loop) by allowing this temperature to be higher. Note from the PT

diagram that the dew point at the pipeline inlet pressure, 1000 psia, is about -10F, less than the

cricondentherm. However, since the gas in the pipeline will experience pressures lower than the

inlets 1000 psia, it is more appropriate to use the cricondentherm as the controlling value for this

spec.

For now well use trial-and-error to determine an appropriate temperature for the cold separator.

Note that if we specify the temperature of Chilled Gas as 9.5F we get a cricondentherm of Cold

Vapor of just over 15F.

Rev 1.2 - 11 - March 13, 2016

Rev 1.2 - 12 - March 13, 2016

Have we met the heating value spec? We can determine this from additional properties calculated

for Cold Vapor. Double-click on Cold Vapor & select Properties under the Worksheet in the left-

hand column. Notice that an HHV has been calculated of 1,175 Btu/scf. This is too high & will

require more heavy hydrocarbons be removed.

But before we modify the cold separators operation we will add the liquid stabilizer section.

Liquid Stabilization

The next step is to determine if the produced liquid will make the TVP spec of 103 psia. Double-

click on Cold Liquid & select Properties under the Worksheet heading in the left-hand column. At the

bottom of the list there is an item for True VP at 37.8 C [psia]. The value is 654.9 psia, much higher

than our spec. We can look at the composition to see the problem it has 16% methane. This is

much too high to try to have in a raw mix NGL.

Rev 1.2 - 13 - March 13, 2016

We can process the high-pressure liquid in a low pressure stripping column to remove these light

ends. Lets add two more units:

A Control Valve, VLV-001

A Reboiled Absorber, Stabilizer.

Double-click on VLV-100. Specify the Inlet as Cold Liquid and define a new stream Flashed Liquid

as the Outlet.

Lets define the stabilizing column as a 10-stage column with a kettle reboiler. Double-click on

Stabilizer. Set the Top Stage Inlet feed as Flashed Liquid. Define new streams Recovered Gas for

the Ovhd Vapour Outlet and Stabilized Liquid for the Bottoms Liquid Outlet. Define the stream

Q-Reboiler for the Reboiler Energy Stream. Set the # Stages as 10. Press the Next> button to

continue the definition for this tower.

Rev 1.2 - 14 - March 13, 2016

Accept the default Once-Through reboiler configuration. This will model a kettle reboiler. Press the

Next > button to continue the towers definition.

Lets look running the tower at 200 psia. Specify 200 for both Top Stage Pressure & the Reboiler

Pressure. Press the Next > button to continue the towers definition.

Were able to specify temperatures on this next form. Ultimately we will want to run the reboiler in

such as way as to produce a liquid with a 103 psia vapor pressure at 100F. If we were running the

tower at 103 psia then we could set the reboiler temperature as 100F. However, since were

running the tower at a higher pressure the reboiler temperature must be higher; for now lets set an

estimate of 200F. Press the Next > button to continue the towers definition.

Rev 1.2 - 15 - March 13, 2016

We will not have to specify a boil-up ratio since were going to use a TVP spec on the reboiler. Leave

this blank & press Done

The tower does not run automatically because the specifications have not been fully defined. Select

Specs Summary item in the left-hand column. Notice that the default spec on the column is to

produce an overhead product rate (whose value has not been specified). But this is not how we

want to run this column. Before we enter the true spec click on the Active box for Ovhd Prod Rate to

turn it off.

Rev 1.2 - 16 - March 13, 2016

Lets add the reboiler temperature as the operating spec. Select Specs item in the left-hand column.

Press the Add button for column specifications. On the list select Column Temperature & press Add

Spec(s) Select Reboiler as the Stage & enter 200 for the Spec Value. Close this form.

Even though we have fully specified the tower the feed coming from VLV-100 has not been fully

specified, so the tower will not run. Go to the Worksheet tab and enter 200 for the pressure of

Flashed Liquid. Now that this feed is fully specified the tower will quickly calculate & converge.

Rev 1.2 - 17 - March 13, 2016

How close are we to creating a stabilized liquid with the correct TVP? Lets create a new spec for

this but dont make it active; we can then see how close we are. Select the Design tab and then the

Specs item in the left-hand column. Press the Add button for column specifications. On the list select

Column Stream Property Spec near the bottom of the list & press Add Spec(s) Select the Stabilized

Liquid @COL1. Youll have to go to another form to actually pick the type of stream property. Click

the Select Property button. On the next form select the tree structure under Standard & choose True

VP @ 37.8 C; press Select. Enter the value 103. Close this form.

Rev 1.2 - 18 - March 13, 2016

Now lets go back to the Design tab & Specs selection. Highlight the Stream Property Spec & you can

see that the calculated TVP is actually 67.85 psia, lower than the desired 103 psia. Well have to

decrease the temperature in the reboiler.

Select the Active check box; now the tower becomes unconverged (because we have overspecified

the unit with both the TVP spec & the reboiler temperature spec). Select the Temperature column

specification & uncheck its Active checkbox. Now the tower will converge again, now with a reboiler

temperature of 166.4F.

Rev 1.2 - 19 - March 13, 2016

What does the stabilized liquid look like? Double-click on Stabilized Liquid & select Composition

under the Worksheet tab. Note that there is essentially no methane & very little ethane all of this

material has been stripped out into the overhead vapor stream.

Lets look at how much has been stripped out. Double-click on Recovered Gas. Select Composition

under the Worksheet tab. Notice that this gas has very high concentrations of methane & ethane. But

could this be directly produced as pipeline gas? Select Properties. Note that the HHV is too high,

1449 Btu/scf.

Rev 1.2 - 20 - March 13, 2016

Recycle of Recovered Gas

One might ask we didnt include a condenser on the stabilizer column. We can effectively get this

effect by reconfiguring the process to recycle the recovered gas from the stabilizing column

upstream of the chiller & cold separator. However, since the recovered gas is produced at a lower

pressure it must be compressed to a higher pressure consistent with the original feed gas.

Rev 1.2 - 21 - March 13, 2016

Lets add three units:

A Compressor, Recycle Gas Compressor

A Mixer, Recycle Mixer.

A Recycle, RCY-1.

Note that some of the items have been flipped on the PFD shown above. This was done by selecting

the item on the Flowsheet, selecting Flowsheet/Modify in the ribbon, & then selecting Flip

Horizontal.

Double-click Recycle Gas Compressor. Set the Inlet as the Recovered Gas stream. Create an Outlet

stream HP Recycle Gas & a work Energy stream W-Recycle Compressor. Select the Worksheet tab.

Set the outlet pressure of the HP Recycle Gas to 400 psia. Note the calculations are completed using

the default adiabatic efficiency, 75%, and gives an outlet temperature of 225F.

Rev 1.2 - 22 - March 13, 2016

Now lets combine the HP Recycle Gas with the Total Feed & introduce it into the Chiller. Double-

click on Chiller & delete Total Feed as an Inlet Stream. Instead, create a new stream, Process Feed,

as the Inlet Stream.

Double-click on RCY-1. Select HP Recycle Gas as the Inlet. Create a stream Recycled Gas as the

Outlet.

Double-click on the Mixer Recycle Mixer. Select Process Feed as the Outlet. For now, only select

Total Feed as the Inlet.

Rev 1.2 - 23 - March 13, 2016

At this point the simulation has converged but without the Recycled Gas being mixed with the fresh

feed. But the stream has been initialized and the recycle calculation can proceed. Now, double-click

on Recycle Mixer & add Recycled Gas as the second Inlet stream. Now the simulation should

converge including this recycle back to the fresh feed.

How has adding the recycle gas affected the final results? There is not a great deal of Recycled Gas

being mixed with the fresh feed so the composition of the Cold Vapor does not change by much. The

cricondentherm increases only slightly to 15.07F.

The produced gas also still has a higher heating value that is too high, 1176 Btu/scf. We can try to

decrease the HHV by reducing the temperature of the Chilled Gas. Lets lower this temperature to

the lowest limit reasonable for a simple propane chilling loop, -30F. Reducing this temperature

does shift more of the heavy ends out of the produced gas & the HHV is lower. However, the HHV of

Chilled Gas is still too high, 1145 Btu/scf. Unfortunately this is pretty much the best we can do when

using a chilled single-stage flash separation unit.

Prevention of Freezing in DPC Separator

Even though there is not a great deal of water in the fresh feed there will still be water drop-out &

potential freezing in the DPC Separator. The typical technique is to inject a high concentration of

ethylene glycol (EG) upstream of the Chiller to prevent ice or hydrate formation.

Rev 1.2 - 24 - March 13, 2016

Return to the Properties section. Select Component List -1 to view the active component list. Use the

search term glycol. Select EGlycol from the databank list & press Add. The component EGlycol will

be placed at the bottom of the list.

Return to the Simulation section. Lets add a stream for the ethylene glycol, EG, into the Recycle

Mixer. Double-click on the stream EG. Select Composition & set it to 85 wt% ethylene glycol & 15

wt% water. Select Conditions; set the pressure to 400 psia & its temperature to 120F (typical for

air cooling after regenerating in a small packed column). For now set the mass flow rate to 370

lb/hr (this should make the Cold Water stream about 55 wt% glycol).

Rev 1.2 - 25 - March 13, 2016

Nearly all of the glycol will be part of the Cold Water stream. This stream will be about 55 wt%

glycol. Is this enough to protect from freezing? We can check the hydrate formation temperature for

the Cold Water stream to determine if weve added enough glycol (the hydrate calculation will also

determine ice conditions, too). Right-click on the Cold Water stream & choose Create Stream

Analysis, Hydrate Formation. Click on the Design tab & select Connections. Note that solids will

form at these conditions. You can get more information form the Performance tab. The freezing

point temperature for this stream is -8.2F. So, we do not have enough glycol added to provide

protection from solid formation.

Rev 1.2 - 26 - March 13, 2016

Lets manually add more EG to bring the hydrate formation temperature down to -40F (colder than

the actual DPC Separator conditions but will match what will be the coldest temperature of the

refrigerant in the Chiller). Making manual adjustments to the flowrate of EG shows that you need to

add 2285 lb/hr of the 85 wt% glycol solution to provide protection from solid formation down

to -40F. Note that the glycol concentration in Cold Water will be 78 wt%.

Rev 1.2 - 27 - March 13, 2016

Propane Refrigeration Loop

We need to add a refrigeration loop to be able to cool the feed & recycle gases to the DPC Separator

temperature. Add the following equipment to the flowsheet:

A Compressor, C3 Compressor

A Cooler, C3 Condenser.

A Control Valve, C3 Valve.

Lets create the streams for the refrigeration loop starting at the Chiller. Double-click on Chiller.

Create new inlet & outlet streams Refrig Liquid & Refrig Vapor, respectively. Make sure that these

streams are associated with the Cold side. Specify a zero pressure drop. Under the Worksheet tab

specify the conditions for the outlet stream Refrig Vapor (1 vapor fraction & -40F).

Rev 1.2 - 28 - March 13, 2016

Double-click on the stream Refrig Vapor. Set the composition to 100% propane. (The temperature

& the vapor fraction should already have been set to -40F & 1, respectively).

Rev 1.2 - 29 - March 13, 2016

Next lets connect the cold liquid to the let-down valve. Double-click on C3 Valve. Set the Outlet as

Refrig Liquid. Create a new stream Condensed Liquid as the Inlet. Select the Worksheet tab; set the

temperature of Condensed Liquid to 120F & the Vapour / Phase Fraction to 0 (i.e., saturated

liquid). Note that the flowrate can now be calculated (276,972 lb/hr) to ensure an energy balance in

Chiller.

Rev 1.2 - 30 - March 13, 2016

Now lets complete the refrigeration loop. Double-click on C3 Compressor. Select Refrig Vapor as

the Inlet & create HP Vapor as the Outlet; create W-C3 Compressor as the Energy stream.

Double-click on C3 Condenser. Select HP Vapor as the Inlet & Condensed Liquid as the Outlet;

create Q-C3 Condenser as the Energy stream. Under Parameters set the Delta P as 0. Now the

refrigeration loop calculations are completed.

Product Compression

The final step is to add compression for the final product gas. Add to the flowsheet the unit:

A Compressor, Product Gas Compressor

Rev 1.2 - 31 - March 13, 2016

Double-click on Product Gas Compressor. Select Cold Vapor as the Inlet & create HP Product Gas

as the Outlet; create W-Product Compressor as the Energy stream. Select the Worksheet tab; set

the outlet pressure as 1000 psia. Note that outlet temperature is less than 120F, so a final cooler is

not needed to be able to introduce this gas into the pipeline.

Optimizing Process

The basic process has now been set up. Note that there are three major power users:

Product Gas Compressor 4,027 hp

Recycle Gas Compressor 111 hp

Refrigeration Compressor 7,982 hp

In addition there are two major heat users:

Stabilizers reboiler 3.293 MMBtu/hr

Reboiler to regenerate the ethylene glycol (not included in this simulation).

The major step for optimization is to recover the refrigeration from the cold streams from the DPC

Separator. By doing so there would be less refrigeration duty needed, reducing the power

requirement for the C3 Compressor. Also, by warming the Cold Liquid before going to the

Stabilizer the amount of reboiler duty will also be reduced.

As an example, if we send the Cold Vapor to the Chiller to recover some its refrigeration (heating to

-14F so that the outlet of the Product Gas Compressor is limited to 120F) then we reduce the

power to the C3 Compressor (7,327 hp) but increase the power to the Product Gas Compressor

(4,275 hp). Overall the power needed for these two compressors decreases by 3.4%.

Rev 1.2 - 32 - March 13, 2016

You might also like

- Acid Gas Sweetening Simulation SetupDocument16 pagesAcid Gas Sweetening Simulation Setupome solNo ratings yet

- AspenHYSYSRefiningV7 2 OpsDocument478 pagesAspenHYSYSRefiningV7 2 Opsnguyennha1211100% (1)

- ASPEN Hysys Steam Table TutorialDocument6 pagesASPEN Hysys Steam Table TutorialdeltaoperativNo ratings yet

- UniSim Design Tutorial 2Document63 pagesUniSim Design Tutorial 2solo66No ratings yet

- Pressure Safety Valves: Selection, Sizing & Design in 40 CharactersDocument19 pagesPressure Safety Valves: Selection, Sizing & Design in 40 CharactersAbdulAbdulNo ratings yet

- Natural Gas Processing Principles and Technology Part-II - DR YoungerDocument448 pagesNatural Gas Processing Principles and Technology Part-II - DR YoungerBakhtiyar Suleimenov100% (2)

- Enhanced NGL Recovery ProcessDocument5 pagesEnhanced NGL Recovery ProcessEdgar HuancaNo ratings yet

- Rules of Dynamic SimulationDocument1 pageRules of Dynamic SimulationImtihan KomahateeNo ratings yet

- PRO-II Thermodynamic Model SelectionDocument79 pagesPRO-II Thermodynamic Model Selectionchemsac2100% (1)

- Refrigeration & Liquefaction: J. G. Weisend IIDocument36 pagesRefrigeration & Liquefaction: J. G. Weisend IIsyafiqNo ratings yet

- 08 - Column Pressure ReliefDocument10 pages08 - Column Pressure ReliefjeedanNo ratings yet

- Water Dewpoint Calculation of Natural GasDocument5 pagesWater Dewpoint Calculation of Natural GasSrinivas BobbyNo ratings yet

- Gas Treating Technologies and ServicesDocument16 pagesGas Treating Technologies and Services13201940No ratings yet

- Air Cooler Design With Aspen EDR PDFDocument26 pagesAir Cooler Design With Aspen EDR PDFNicandroGonzales0% (1)

- Engineering 0016 General Process Design RequirementsDocument51 pagesEngineering 0016 General Process Design Requirementsmarin cristianNo ratings yet

- Size Depressurization and Relief Devices For Pressurized Segments Exposed To FireDocument8 pagesSize Depressurization and Relief Devices For Pressurized Segments Exposed To Fireromdhan88No ratings yet

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsNo ratings yet

- Conceptual Process Design Suite: TutorialsDocument111 pagesConceptual Process Design Suite: TutorialsDoccon PT SynergyNo ratings yet

- Flaresim Getting StartedDocument116 pagesFlaresim Getting Startedfiqry DarwansyahNo ratings yet

- Interview Questions For Chemical EngineeringDocument6 pagesInterview Questions For Chemical EngineeringNikunj PatelNo ratings yet

- Dynamic simulation of natural gas sweetening processDocument6 pagesDynamic simulation of natural gas sweetening processRebwar Nori JanNo ratings yet

- JEWEL T Hydrocarbon Dew Point ControlDocument2 pagesJEWEL T Hydrocarbon Dew Point ControljojeecaresNo ratings yet

- Gas Sweetening-Part 1: Comparison of Amines - Campbell Tip of The MonthDocument8 pagesGas Sweetening-Part 1: Comparison of Amines - Campbell Tip of The MonthAmit YadavNo ratings yet

- Risk Assessment of A Post-Combustion and Amine-Based CO2 Capture Ready ProcessDocument7 pagesRisk Assessment of A Post-Combustion and Amine-Based CO2 Capture Ready Processscm996No ratings yet

- Aspen Plus Lesson 1 PDFDocument12 pagesAspen Plus Lesson 1 PDFsamandondonNo ratings yet

- 08a PDFDocument36 pages08a PDFProcess EngineerNo ratings yet

- Jump Start - Multiple Valve Analysis in Aspen HYSYS and Aspen Plus - TempDocument16 pagesJump Start - Multiple Valve Analysis in Aspen HYSYS and Aspen Plus - TempphantanthanhNo ratings yet

- Basics of Reforming, Shapes and Carbon WSVDocument28 pagesBasics of Reforming, Shapes and Carbon WSVMuhammad NaeemNo ratings yet

- Tray Distillation ColumnsDocument27 pagesTray Distillation ColumnsRajeshkumar Elango0% (1)

- Getting Started Modeling Petroleum Processes PDFDocument106 pagesGetting Started Modeling Petroleum Processes PDFMygroup 5544No ratings yet

- What Is The Static Pressure and The Total Pressure in Aspen Flarent?Document3 pagesWhat Is The Static Pressure and The Total Pressure in Aspen Flarent?snikraftar1406100% (1)

- Flare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaDocument10 pagesFlare Systems-Conclusion Safety, Noise, and Emissions Elements Round Out FlaJR RomanNo ratings yet

- Chemical Engineering 422 Simulation With Hysys: NotesDocument9 pagesChemical Engineering 422 Simulation With Hysys: NotesNoor Ul HaqNo ratings yet

- Unisim Tutorial - Methanol ProductionDocument77 pagesUnisim Tutorial - Methanol ProductionR-wah LarounetteNo ratings yet

- 1.3.9 Rating Heat ExchangerDocument18 pages1.3.9 Rating Heat ExchangerMelva NainggolanNo ratings yet

- De Ethanizer ColumnDocument24 pagesDe Ethanizer Columnrohit agrawalNo ratings yet

- UniSim design tutorial for methanol processDocument92 pagesUniSim design tutorial for methanol processsolo660% (1)

- DespresurizaciónDocument3 pagesDespresurizaciónmatrix69No ratings yet

- Article PSV Specific HeatDocument6 pagesArticle PSV Specific Heatprq123No ratings yet

- Case Histories of Amine Plant Equipment Corrosion Problems - Part 2Document4 pagesCase Histories of Amine Plant Equipment Corrosion Problems - Part 2jdgh1986No ratings yet

- Adv 8 1Document10 pagesAdv 8 1Micu Ionut BogdanNo ratings yet

- Controlled and Non-Controlled Type DepressuringDocument12 pagesControlled and Non-Controlled Type Depressuringgrimdorlf100% (1)

- Fluid Package EOSDocument12 pagesFluid Package EOSdani2611No ratings yet

- DynamicModel7 3 PDFDocument224 pagesDynamicModel7 3 PDFArcangelo Di TanoNo ratings yet

- Hot Oil System Control PhilosophyDocument3 pagesHot Oil System Control PhilosophyRiyadh SalehNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Energy and Process Optimization for the Process IndustriesFrom EverandEnergy and Process Optimization for the Process IndustriesNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- Vapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodFrom EverandVapor-Liquid Equilibria Using Unifac: A Group-Contribution MethodNo ratings yet

- Simple Dew Point Control HYSYS v10 - Rev2.2 PDFDocument41 pagesSimple Dew Point Control HYSYS v10 - Rev2.2 PDFlaura jaimesNo ratings yet

- Simple Dew Point Control in HYSYSDocument35 pagesSimple Dew Point Control in HYSYSdigeca100% (1)

- C 03 RefrigeratedGasPlantDocument20 pagesC 03 RefrigeratedGasPlantShariq KhanNo ratings yet

- Process Modelling and System Dynamic Project 1 Gas Processing SimulationDocument14 pagesProcess Modelling and System Dynamic Project 1 Gas Processing SimulationHusaini ZaidanNo ratings yet

- Bombas Sea MetricsDocument6 pagesBombas Sea MetricsJesusNo ratings yet

- Selection of Centrifugal Pumping EquipmentDocument11 pagesSelection of Centrifugal Pumping Equipmentshahzad32552372No ratings yet

- STD Assay PDFDocument27 pagesSTD Assay PDFJesusNo ratings yet

- StrainersDocument12 pagesStrainersbakhtyar21No ratings yet

- William HazensDocument1 pageWilliam HazensJesusNo ratings yet

- Devoe - Thermodynamics and Chemistry 2e (2012) - Small Page SizeDocument533 pagesDevoe - Thermodynamics and Chemistry 2e (2012) - Small Page SizeJordy Lam50% (2)

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- AspenPIPESYSV7 3 TutorialDocument64 pagesAspenPIPESYSV7 3 Tutorialjimbob8888No ratings yet

- Gama Bombas de Calor Waterkotte 2012 EDocument8 pagesGama Bombas de Calor Waterkotte 2012 ELuis Campos GonzalezNo ratings yet

- Soal Nomor 18Document2 pagesSoal Nomor 18Mawaddah Nur TambakNo ratings yet

- City Multi DataBook Indoor Units MEES19K057Document64 pagesCity Multi DataBook Indoor Units MEES19K057Rafael GomesNo ratings yet

- Tekmar Thermostat 557 p9335 03Document2 pagesTekmar Thermostat 557 p9335 03api-221502147No ratings yet

- Automotive Air Conditioning ThesisDocument8 pagesAutomotive Air Conditioning Thesiscindyturnertorrance100% (2)

- Piping General Arrangement Cooling Tower Water System AreaDocument1 pagePiping General Arrangement Cooling Tower Water System AreaajmainNo ratings yet

- 160.67-PR1 - Advances in Steam Cooling ASHRAEDocument4 pages160.67-PR1 - Advances in Steam Cooling ASHRAEGustavo Oliveira SilvaNo ratings yet

- Completion in Airconditioning and Ventilation System: DBT 44°CDocument6 pagesCompletion in Airconditioning and Ventilation System: DBT 44°CJay Mark CayonteNo ratings yet

- Research Paper On Magnetic Refrigeration Sourabh SInghDocument9 pagesResearch Paper On Magnetic Refrigeration Sourabh SInghersourabh75% (4)

- Training COMMERCIAL REFRIGERATION Cold Controls PDFDocument4 pagesTraining COMMERCIAL REFRIGERATION Cold Controls PDFFranco TadayNo ratings yet

- Alhaji Massoud Juma - Thermo AssignmentDocument12 pagesAlhaji Massoud Juma - Thermo AssignmentAlhaj MassoudNo ratings yet

- 38P Condensing Units - 60Hz: 38P 18K-24K 38P 36K-60KDocument20 pages38P Condensing Units - 60Hz: 38P 18K-24K 38P 36K-60KYousefNo ratings yet

- Danfoss 2020 Refrigerantes Actuales y FuturoDocument24 pagesDanfoss 2020 Refrigerantes Actuales y FuturoArturo VelascoNo ratings yet

- 1.fcu Schedule (Basement-1 & 2)Document2 pages1.fcu Schedule (Basement-1 & 2)shahid asgharNo ratings yet

- Spesifikasi Teknis SiroDocument5 pagesSpesifikasi Teknis SiroIPIN Hi. PAYONo ratings yet

- Vapor Power Cycle Lecture 3Document14 pagesVapor Power Cycle Lecture 3Zain Ul AbideenNo ratings yet

- Chiller Plant Design GuideDocument24 pagesChiller Plant Design GuideNeal JohnsonNo ratings yet

- M Air-Cooled Chiller - Scroll TCIDocument20 pagesM Air-Cooled Chiller - Scroll TCIstetams.cervantesNo ratings yet

- 5.2 CLIVET Air Cooled Inv-Screw ChillerDocument17 pages5.2 CLIVET Air Cooled Inv-Screw Chillerremigius yudhiNo ratings yet

- Boiler Lit-Up PDFDocument2 pagesBoiler Lit-Up PDFHoncho Abhi Sinha100% (1)

- TE5 TE55 Expansion ValveDocument24 pagesTE5 TE55 Expansion ValveIvan KurniadiNo ratings yet

- Defrosting Industrial Refrigeration Evaporators Reindl Jekel August 2009Document13 pagesDefrosting Industrial Refrigeration Evaporators Reindl Jekel August 2009RASHEED YUSUFNo ratings yet

- 2020 Full Catalogue - HitachiDocument221 pages2020 Full Catalogue - HitachiIsmael Perez100% (1)

- Homework: Chapter 11 Refrigeration CyclesDocument1 pageHomework: Chapter 11 Refrigeration CyclesanikfaisalNo ratings yet

- Horizontal Type Chilled Water Fan Coil UnitDocument35 pagesHorizontal Type Chilled Water Fan Coil UnitTuấn NguyễnNo ratings yet

- SB Multiv S Arun038gss4!11!15Document2 pagesSB Multiv S Arun038gss4!11!15Anonymous 73gEYyEtLNo ratings yet

- Ceiling Mounted Duct Type FXMQ20-140PVE 50/60HzDocument65 pagesCeiling Mounted Duct Type FXMQ20-140PVE 50/60HzTi TiNo ratings yet

- York VRF Units ChinaDocument37 pagesYork VRF Units ChinaDANISH100% (2)

- TM Screw Compressor Fluid Archive EDocument581 pagesTM Screw Compressor Fluid Archive EOliver FrereNo ratings yet

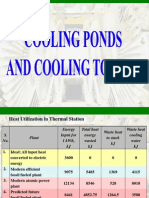

- Cooling Ponds and Cooling TowersDocument31 pagesCooling Ponds and Cooling Towersphanendra2No ratings yet