Professional Documents

Culture Documents

PV Array Sizing Very Very Important

Uploaded by

Ramesh NaiduCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PV Array Sizing Very Very Important

Uploaded by

Ramesh NaiduCopyright:

Available Formats

SOLAR PV STAND-ALONE SYSTEMS

Good Practice Guide: Small System Sizing

Sizing for Sustainability

Sizing of stand-alone systems requires a fine balance between 33 Educate end-user on system Step 3: Size Battery Bank Example:

cost, energy supply and demand as well as responsible expectations and budget requirements Determine DC system voltage, typically 12 V for small (< 1 kWh)

behavior of operator/end-user 33 Select appropriate, energy-efficient and 24V for intermediate daily loads

components based on load levels Example: 12V system voltage

33 Comply to respective system design Determine the number of days a fully charged battery system can

and product standards supply power without further charging (days of autonomy), typically

3 5 days

Battery Sizing

33 Integrate components into sustainable system

Calculate daily battery capacity demand = total daily energy

33 Thorough training of end-user in operations and

requirement / system voltage * days of autonomy

maintenance is essential for sustainability!

Example: 459Wh/day / 12V x 5 days = 191Ah

Determine depth of discharge (DoD) factor for selected battery,

Step 1: Determine Daily Energy Requirement Example: typically 20 - 80%

List all DC appliances (loads) with their power ratings and daily

Calculate required battery capacity = daily battery capacity

usage

demand / DoD

Calculate average daily energy consumption for each DC Example: 191Ah / 0.75 = 255Ah

appliance: = x x

Select deep discharge batteries, if possible

Total DC energy requirement from battery = sum of Example: 2 x 6V batteries in series with 256Ah capacity

individual DC load energy consumptions

Example: Total DC Energy Requirements = 228 Wh/day

Energy Assessment

List all AC appliances (if applicable) with their power ratings Step 4: Size PV Array Example:

and daily usage Estimate battery charging efficiency (typically 80 90%)

Calculate average daily energy consumption for each AC Estimate soiling factor for installation (typically 0.9 1.0)

appliance: = x x Calculate required charging current from PV array = daily demand on battery

capacity / critical design month insolation / system voltage / battery charging

Sum up total AC load (energy) consumption efficiency / soiling factor: = ////

Determine system wiring losses (typically 5-10% - Example: 459Wh/day / 4.49 psh/day / 12V / 0.90 / 0.95 = 10A

SEIAPI recommends max. 5%) Estimate maximum module temperature & rating reference temperature

Example: Wiring Losses = 5% (typically 25C)

Determine inverter losses for AC loads (typical inverter Calculate required charging voltage from PV array = system voltage -

PV Array Sizing

efficiency: 80-90%) (system voltage x temperature coefficient x (Max.Temperature - Reference

Temperature)): = - ( x x ( - ))

Example: Inverter Efficiency = 85%

Example: 12V-(12V x -0.004 x (60C - 25C)) = 13.7V

Calculate total energy requirement from battery = total DC

Calculate required charging power from PV array = 1.2 x required charging

energy requirement + total AC load energy requirement

voltage from PV array x required charging current from PV array = 1.2 x x

(through inverter): = /(1-) + (/)

Example: 1.2 x 13.7V x 10A = 164 W

Example: Average Daily DC Energy Consumption = 459 Wh/day

Select appropriate PV modules, e.g. for 12 V system voltage

Calculate (round up) number of PV modules in series = required charging

voltage / module rated voltage: = /

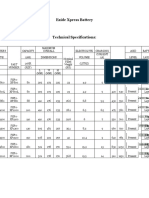

Module nameplate rating:

Step 2: Determine Critical Design Month Example: Example: 13.7 V / 18.3 V = 1 module

Maximum Power at STC (Pmax) 90W

Find monthly mean solar insolation data in kWh/m^2/day Calculate (round up) number of PV modules in parallel = required charging

or peak sun hours (psh) for installation sites (e.g. NASA current / module rated current: = / Voltage at Pmax (Vmp) 18.3V

website http://eosweb.larc.nasa.gov/sse/) Example: 10 A / 5.04 A = 2 modules Current at Pmax (Imp) 5.04A

Calculate total number of modules in array = number of modules in series x Open circuit voltage (Voc) 22.2V

Divide daily DC energy requirements by available solar number of modules in parallel: = x

Critical Design Month

Short circuit current (Isc) 5.38A

insolation values for different tilt angles: = / Example: 1 x 2 = 2 modules with 180 W total peak power

Note: The factor 1.2 accounts for wiring losses, charge controller loss, PV module overrating and other losses.

The critical design month is the month with the highest ratio

of load to solar insolation. It defines the optimal tilt angle

that results in the smallest array possible Step 5: Size Charge Controller and Inverter Example:

Since lowest irradiation month mostly falls in the winter Look up short circuit current of PV module

Controller Sizing

solstice, the best tilt angle for constant loads is Latitude + Calculate charge controller minimum power current = short circuit current of

15 degree PV module x number of modules in parallel x 1.25: = x x 1.25

Example: Location: Rarotonga, Cook Islands; Latitude : 21 12 Example: 5.38 A x 2 x 1.25 = 13.5 A

South, Longitude: 159 46 West Critical design month is June with Select appropriate charge controller

4.49 psh for 36 tilt angle Calculate inverter minimum power size = power of all AC appliances x

1.25: = x 1.25

Example: 63 W x 1.25 = 78.8 W Note: After correcting for voltage losses due to module

Select appropriate inverter temperature, ensure that voltage input from PV array is

Note: The factor 1.25 is the safety factor for continuous operation within voltage window of charge controller

You might also like

- A Guide To ParallelingDocument3 pagesA Guide To ParallelingBen Wee100% (1)

- 2018 - Impact of IEEE 1547 Standard On Smart Inverters PDFDocument70 pages2018 - Impact of IEEE 1547 Standard On Smart Inverters PDFRamesh Naidu100% (2)

- Enerlin'X FDM128: Ethernet Display For Eight Devices User GuideDocument76 pagesEnerlin'X FDM128: Ethernet Display For Eight Devices User GuideShailesh ChettyNo ratings yet

- DC Control Battery System Protection & CoordinationDocument13 pagesDC Control Battery System Protection & CoordinationvyroreiNo ratings yet

- Practical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsFrom EverandPractical Guide to International Standardization for Electrical Engineers: Impact on Smart Grid and e-Mobility MarketsNo ratings yet

- User Manual - MSIMMA - Rev5 PDFDocument130 pagesUser Manual - MSIMMA - Rev5 PDFiuliiulianNo ratings yet

- 1.4 & 1.5 DEWA Training - PV ModulesDocument57 pages1.4 & 1.5 DEWA Training - PV ModulesMuraryspottyNo ratings yet

- Generator Sizing Guidelines: Total Load RequirementsDocument1 pageGenerator Sizing Guidelines: Total Load Requirementscoolside111No ratings yet

- Backup Supply: Electrical Design and ProtectionDocument30 pagesBackup Supply: Electrical Design and ProtectionVictor SaifiNo ratings yet

- Maximum power supply from Piller UNIBLOCK UBTD Diesel Rotary UPSDocument12 pagesMaximum power supply from Piller UNIBLOCK UBTD Diesel Rotary UPSShajahan KandothNo ratings yet

- System Components and ConfigurationsDocument47 pagesSystem Components and Configurationsathira9satheesanNo ratings yet

- E-23 Shore Connection BoxDocument27 pagesE-23 Shore Connection Boxcengiz kutukcuNo ratings yet

- HCSA-Presales-Smart PV V2.0 Training MaterialDocument239 pagesHCSA-Presales-Smart PV V2.0 Training Materialjesrcontreras1976No ratings yet

- Solar PV Installer (Suryamitra) : Educate Your Mind in The Right DirectionDocument2 pagesSolar PV Installer (Suryamitra) : Educate Your Mind in The Right DirectiondaynongNo ratings yet

- Chapter 1-2 - 3 Phase System To Part 3Document40 pagesChapter 1-2 - 3 Phase System To Part 3Hanis SyafiqNo ratings yet

- Electrical Single Line Diagram GuidanceDocument3 pagesElectrical Single Line Diagram Guidancen73686861No ratings yet

- Protection NotesDocument78 pagesProtection NotesPriya SaxenaNo ratings yet

- Silver Zinc CellDocument5 pagesSilver Zinc CellJoshua De LeonNo ratings yet

- EMC Based LPS For HV SubstationDocument66 pagesEMC Based LPS For HV SubstationDede Rochman100% (1)

- AC Generator Frequency-Power CharacteristicsDocument70 pagesAC Generator Frequency-Power CharacteristicsJohn Patrick CeldaNo ratings yet

- Model Airplane News Magazine. Febraury 2011Document124 pagesModel Airplane News Magazine. Febraury 2011Seymour Allen100% (4)

- UNIBLOCK UBT Rotary UPS provides lower operating costsDocument12 pagesUNIBLOCK UBT Rotary UPS provides lower operating costsap00No ratings yet

- Wind Generator TechnologyDocument56 pagesWind Generator TechnologymedesarrolloNo ratings yet

- Schneider Imverter MannualDocument162 pagesSchneider Imverter MannualPawan RanpiseNo ratings yet

- Technical Manual: Heavy Tractor M1 (Allis-Chalmers HD-10W)Document258 pagesTechnical Manual: Heavy Tractor M1 (Allis-Chalmers HD-10W)VoltaireZeroNo ratings yet

- SEDA Malaysia Grid-Connected PV Design Course ScheduleDocument3 pagesSEDA Malaysia Grid-Connected PV Design Course ScheduleKelly chatingNo ratings yet

- Powin Enclosures Product Manual Rev B01Document51 pagesPowin Enclosures Product Manual Rev B01melihguneriNo ratings yet

- Grid Connected PV Part 2Document31 pagesGrid Connected PV Part 2Ahmed Ousmane BAGRE100% (1)

- Cost-Effective Design of A Hybrid Solar PV-Genset Power Supply System For A Small Rural Community (Zuro-Kpumi) Using HOMERDocument6 pagesCost-Effective Design of A Hybrid Solar PV-Genset Power Supply System For A Small Rural Community (Zuro-Kpumi) Using HOMERInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Voltage Sag-Piller Datacentre Dynamic Dubai Piller PDFDocument54 pagesVoltage Sag-Piller Datacentre Dynamic Dubai Piller PDFNgern KlangNo ratings yet

- PV Testing GuideDocument48 pagesPV Testing GuideHamza EL Hassnaoui100% (1)

- Modbus Gateway: Installation and Operation ManualDocument122 pagesModbus Gateway: Installation and Operation ManualNacho V' ZaletaNo ratings yet

- En TH01!11!2004 Power Factor CorrectionDocument12 pagesEn TH01!11!2004 Power Factor CorrectionSirish SabbellaNo ratings yet

- SG110CXPV Grid-Connected Inverter User ManualDocument101 pagesSG110CXPV Grid-Connected Inverter User ManualAizat AlongNo ratings yet

- Distrubution of PowerDocument175 pagesDistrubution of PowerMuhammadMunirMalikNo ratings yet

- ELENS Online PDF VersionDocument28 pagesELENS Online PDF VersionDaniel PrataNo ratings yet

- 111 - White Paper - Fire-Safety-In-Electric-Vehicle-Parking-GaragesDocument23 pages111 - White Paper - Fire-Safety-In-Electric-Vehicle-Parking-GaragesDmitryNo ratings yet

- Abstract Book PDFDocument252 pagesAbstract Book PDFPABLO MAURONo ratings yet

- 41 Self ConsumptionDocument2 pages41 Self Consumptioncrico1535No ratings yet

- Windows 8 Pro VL x64 en-US Pre-Activated Aug2013Document2 pagesWindows 8 Pro VL x64 en-US Pre-Activated Aug2013Bunda Emi AchmadNo ratings yet

- Electromagnetic Compatibility of Industrial Networks and FieldbusesDocument38 pagesElectromagnetic Compatibility of Industrial Networks and FieldbusesCarlos ChocobarNo ratings yet

- Terra AC OCPP 1.6 Implementation Overview - v1.5 - ExternalDocument20 pagesTerra AC OCPP 1.6 Implementation Overview - v1.5 - ExternalHenrikNo ratings yet

- Smart power management for solar PV-DG synchronizationDocument8 pagesSmart power management for solar PV-DG synchronizationSunil SinghNo ratings yet

- Elum Energy Monitoring & Control Solutions for Solar Hybrid PlantsDocument17 pagesElum Energy Monitoring & Control Solutions for Solar Hybrid PlantsCyrilColinNo ratings yet

- Nabcep SH Guide 8-5-13Document160 pagesNabcep SH Guide 8-5-13ZeljkoSipcicNo ratings yet

- Synchronizing PDFDocument14 pagesSynchronizing PDFSarath SasidharanNo ratings yet

- Electrical Energy Efficiency (E), Renewable Energies and The Role of The IECDocument31 pagesElectrical Energy Efficiency (E), Renewable Energies and The Role of The IECShailesh PrajapatiNo ratings yet

- WindmillDocument23 pagesWindmillManav KohliNo ratings yet

- Net Metering Guid Lines For ConsumersDocument57 pagesNet Metering Guid Lines For Consumersndm5430No ratings yet

- Generator Interconnection Technical Guide EdmontonDocument64 pagesGenerator Interconnection Technical Guide EdmontonRanieri BenčićNo ratings yet

- I-Gard Grounding PDFDocument42 pagesI-Gard Grounding PDFmoisesramosNo ratings yet

- Grounding, Backfeed Breakers & PV Disconnect 2002Document3 pagesGrounding, Backfeed Breakers & PV Disconnect 2002ronniedakingpouNo ratings yet

- 00 - Presentation 8k SchoolsDocument10 pages00 - Presentation 8k SchoolsImran AshrafNo ratings yet

- Fronius IG2000Document92 pagesFronius IG2000Jimmy F HernandezNo ratings yet

- Report Overview of Flexible Ac Transmission SystemsDocument14 pagesReport Overview of Flexible Ac Transmission SystemsSiddharth Patil100% (1)

- IEEE ELECTRIFICATION Dec 2013Document84 pagesIEEE ELECTRIFICATION Dec 2013constellanaNo ratings yet

- GENERACDocument6 pagesGENERACFabricio PedrielNo ratings yet

- 2HR Intro To PVDocument118 pages2HR Intro To PVVictor JoseNo ratings yet

- Advantages of Bundled Conductors in Transmission LinesDocument5 pagesAdvantages of Bundled Conductors in Transmission Linesf3ziii100% (1)

- An Overview of Batteries For Photovoltaic (PV) Systems: International Journal of Computer Applications November 2013Document6 pagesAn Overview of Batteries For Photovoltaic (PV) Systems: International Journal of Computer Applications November 2013ReparrNo ratings yet

- Active and Reactive Power Injection Strategies For Three-Phase Four-Wire Inverters During Symmetrical/Asymmetrical Voltage SagsDocument9 pagesActive and Reactive Power Injection Strategies For Three-Phase Four-Wire Inverters During Symmetrical/Asymmetrical Voltage SagsRamesh NaiduNo ratings yet

- Chittibabu PaprDocument12 pagesChittibabu PaprRamesh NaiduNo ratings yet

- Short-Circuit Analysis Models For Unbalanced Inverter-Based Distributed Generation Sources and LoadsDocument11 pagesShort-Circuit Analysis Models For Unbalanced Inverter-Based Distributed Generation Sources and LoadsRamesh NaiduNo ratings yet

- Three-Phase PLL For Grid-Connected Power Converters Under Both Amplitude and Phase Unbalanced ConditionsDocument10 pagesThree-Phase PLL For Grid-Connected Power Converters Under Both Amplitude and Phase Unbalanced ConditionsRamesh NaiduNo ratings yet

- NIT Meghalaya Academic Calendar 2016-17Document1 pageNIT Meghalaya Academic Calendar 2016-17Ramesh NaiduNo ratings yet

- Power Converters and Power System VVIPDocument12 pagesPower Converters and Power System VVIPRamesh NaiduNo ratings yet

- Presentation On DC MicrogridDocument9 pagesPresentation On DC MicrogridRamesh NaiduNo ratings yet

- Reactive Power Control of Three-Phase Grid-Connected PV System During Grid Faults Using Takagi-Sugeno-Kang Probabilistic Fuzzy Neural Network ControlDocument13 pagesReactive Power Control of Three-Phase Grid-Connected PV System During Grid Faults Using Takagi-Sugeno-Kang Probabilistic Fuzzy Neural Network ControlRamesh NaiduNo ratings yet

- Fault Analysis For Distribution Networks With Current-Controlled Three-Phase Inverter-Interfaced Distributed GeneratorsDocument11 pagesFault Analysis For Distribution Networks With Current-Controlled Three-Phase Inverter-Interfaced Distributed GeneratorsRamesh NaiduNo ratings yet

- Adjustable DC Link Voltage of PV ArrayDocument10 pagesAdjustable DC Link Voltage of PV ArrayRamesh NaiduNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentRamesh NaiduNo ratings yet

- DC Microgrid Nov 30Document9 pagesDC Microgrid Nov 30Ramesh NaiduNo ratings yet

- MPC DC DC Converters PDFDocument66 pagesMPC DC DC Converters PDFRamesh NaiduNo ratings yet

- Protection of Buried CableDocument4 pagesProtection of Buried CableRamesh NaiduNo ratings yet

- Resilient DC MicrogridDocument16 pagesResilient DC MicrogridRamesh NaiduNo ratings yet

- Efficient three-phase load flow method for unbalanced distribution systemsDocument19 pagesEfficient three-phase load flow method for unbalanced distribution systemsRamesh NaiduNo ratings yet

- Stochastic Model Predictive Control Method For Microgrid ManagementDocument7 pagesStochastic Model Predictive Control Method For Microgrid ManagementRamesh NaiduNo ratings yet

- Ieee 30Document2 pagesIeee 30Ramesh NaiduNo ratings yet

- Exp 2 ReportDocument11 pagesExp 2 ReportRamesh NaiduNo ratings yet

- Sysgen UserDocument424 pagesSysgen Uservicky_ani1986No ratings yet

- ScopeDocument1 pageScopeRamesh NaiduNo ratings yet

- Perceptron OutputsDocument3 pagesPerceptron OutputsRamesh NaiduNo ratings yet

- 1) Affidavit by Parent/GuardianDocument3 pages1) Affidavit by Parent/GuardianRamesh NaiduNo ratings yet

- List of Student Personal Details For ERP Profile: TH THDocument2 pagesList of Student Personal Details For ERP Profile: TH THRamesh NaiduNo ratings yet

- Mesh MenuDocument7 pagesMesh MenuRamesh NaiduNo ratings yet

- JNTU Kakinada EEE SyllabusDocument85 pagesJNTU Kakinada EEE SyllabusRajesh Kumar MamidiNo ratings yet

- Ansys Maxwell Brochure 14.0Document8 pagesAnsys Maxwell Brochure 14.0Ramesh NaiduNo ratings yet

- JNTU Kakinada MECH Syllabus Book 4th YearDocument90 pagesJNTU Kakinada MECH Syllabus Book 4th Yearrao253No ratings yet

- GNB MP Overview enDocument16 pagesGNB MP Overview enMohamed MahgoubNo ratings yet

- 2016 OWIKIT CatalogDocument12 pages2016 OWIKIT CatalogOwi DanielNo ratings yet

- Renewable Energy Charging Parameters: Monobloc 2-Volt CellsDocument4 pagesRenewable Energy Charging Parameters: Monobloc 2-Volt CellsarunghandwalNo ratings yet

- Andis BGR ManualDocument24 pagesAndis BGR ManualRebeca BookerNo ratings yet

- Lenovo Z370Z470Z570 Hardware Maintenance Manual V1.0Document120 pagesLenovo Z370Z470Z570 Hardware Maintenance Manual V1.0Anna Lissa PilapilNo ratings yet

- Exide Xpress BatteryDocument1 pageExide Xpress BatteryPisupati_1234No ratings yet

- Flexenclosure ESite BrochureDocument5 pagesFlexenclosure ESite Brochureteju2812No ratings yet

- Integrity TestingDocument0 pagesIntegrity Testingjesus_hfNo ratings yet

- Electrical Characteristics Performance Portable Solar ChargerDocument2 pagesElectrical Characteristics Performance Portable Solar ChargerAlan OsborneNo ratings yet

- GILIANDocument1 pageGILIANINSTRUMENTACION INGENIEROSNo ratings yet

- MPPT Power PsocDocument14 pagesMPPT Power PsocgubiliNo ratings yet

- Guia de Instalacion Panel 1057 1058Document108 pagesGuia de Instalacion Panel 1057 1058Amy ThompsonNo ratings yet

- IM34M06P15-01E UsDocument708 pagesIM34M06P15-01E UsLovelySinghNo ratings yet

- Aerospace SystemsDocument228 pagesAerospace SystemskgrhoadsNo ratings yet

- Procedure To Recover Deeply Discharged OdysseyDocument2 pagesProcedure To Recover Deeply Discharged OdysseyBasman GeorgeNo ratings yet

- 8 930Document3 pages8 930J100% (1)

- Unit 3 ElectrochemistryDocument14 pagesUnit 3 ElectrochemistrySuresh Dasaraddi100% (1)

- FCPS 24S6 Datasheet - Eeworld.com - CNDocument4 pagesFCPS 24S6 Datasheet - Eeworld.com - CNDiana C. Parrado MartínezNo ratings yet

- GPMR 72 P (72X72) Operation: (12 and 24vcc)Document3 pagesGPMR 72 P (72X72) Operation: (12 and 24vcc)carlosmarciosfreitas50% (2)

- Diesel Generator Set General Preventive Maintenance ProgramsDocument2 pagesDiesel Generator Set General Preventive Maintenance ProgramsRaghav GhateNo ratings yet

- P15xHMx ESMDocument116 pagesP15xHMx ESMJunhee RaNo ratings yet

- Specifications Infusion Pump Te112Document2 pagesSpecifications Infusion Pump Te112puskesmas100% (2)

- Pinger Operation BrochureDocument2 pagesPinger Operation Brochurejosephrithin_9353927No ratings yet

- Amity University Rajasthan: Project Synopsis Project Supervisor: Supervisor SignatureDocument3 pagesAmity University Rajasthan: Project Synopsis Project Supervisor: Supervisor SignatureAsha678No ratings yet

- SIMEX Subglottic Broschuere en 002Document7 pagesSIMEX Subglottic Broschuere en 002Waeil MakkiNo ratings yet

- Magellan Cyclo 315/505 User's ManualDocument39 pagesMagellan Cyclo 315/505 User's ManualSergio VillasecaNo ratings yet

- Lead Acid BatteryDocument8 pagesLead Acid BatteryRavinder SinghNo ratings yet