Professional Documents

Culture Documents

Drill Collar Performance Sheet

Uploaded by

Инженер Луис А. ГарсиаOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drill Collar Performance Sheet

Uploaded by

Инженер Луис А. ГарсиаCopyright:

Available Formats

Drill Collar Performance Sheet

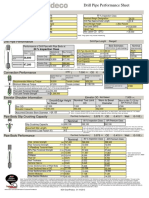

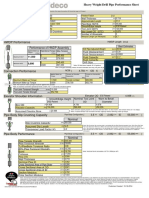

www.NOV.com/GrantPrideco Phone: +1 (281) 878-8000

Drill Collar Configuration

Connection 6-5/8 API Reg

Drill Collar OD 8.000 (in)

Drill Collar ID (in) 2.813 Connection ID (in) 2.813

Min Yield Strength (SMYS) (psi) 100,000 Bevel Diameter (in) 7.516

Wall Thickness (in) 2.594

Approximate Length (ft) 31.5

BSR (Bending Strength Ratio) 2.6

Friction Factor 1.0

Connection Performance 6-5/8 API Reg ( 8.000 (in) OD X 2.813 (in) ID ) 100,000 (psi)

Applied Make-up Tension at Shoulder Tension at Connection

Torque Separation Yield

Tool Joint Dimensions

(ft-lbs) (lbs) (lbs) Balanced OD (in) 7.689

Maximum Make-up Torque 58,700 Tensile Limited 1,253,900

Minimum Make-up Torque 53,300 Tensile Limited 1,508,000

Tool Joint Torsional Strength (ft-lbs) 85,400

Tool Joint Tensile Strength (lbs) 1,816,200

Drill Collar Properties Drill Collar Length 31.5 (ft)

Best Estimates

Adjusted Weight (lbs/ft) 149.76

Fluid Displacement (gal/ft) 2.29

Fluid Displacement (Bbls/ft) 0.0545

Fluid Capacity (gal/ft) 0.32

Fluid Capacity (Bbls/ft) 0.0077

Drift Size (in) 2.688

Note: Oil field barrel equals 42 US gallons.

Note: Drill Collar assembly values are best estimates and may vary due to length.

Drill Collar Body Properties Drill Collar Configuration ( 8.000 (in) OD X 2.813 (in) ID )

Nominal

Calculated plain end weight (lbs/ft) 149.762

Cross Sectional Area of Pipe Body (in^2) 44.053

Cross Sectional Area of OD (in^2) 50.265

Cross Sectional Area of ID (in^2) 6.213

Section Modulus (in^3) 49.498

Polar Section Modulus (in^3) 98.995

Moment of inertia drill collar body (in^4) 197.99

Polar moment of inertia drill collar body (in^4) 395.98

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill collar properties are calculated based on uniform OD and wall thickness. No safety factor is applied. It is the responsibility of the customer and the end user to determine the appropriate

performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool

joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback Customer Created 06-18-2014

You might also like

- Drill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUDocument9 pagesDrill-Pipe PipeBody at 80%, 5.875in, 0.361wall, IEUFernando Ruiz ArroyoNo ratings yet

- 1 - Drill String & BHA Components - Review - D1 - D2Document27 pages1 - Drill String & BHA Components - Review - D1 - D2علي سعيد سعودNo ratings yet

- Casing Drive System STD PDFDocument2 pagesCasing Drive System STD PDFcristian sanchezNo ratings yet

- 41000e Casing Drive SystemDocument4 pages41000e Casing Drive SystemjulioramcaNo ratings yet

- Stuck Point WorksheetDocument5 pagesStuck Point Worksheetjose perozoNo ratings yet

- Basic of Drillpipe Tensile Capacity and Its Calculation PDFDocument5 pagesBasic of Drillpipe Tensile Capacity and Its Calculation PDFMokr AchourNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Varel Mining CatalogDocument24 pagesVarel Mining CatalogEmerson Phocco Yauli100% (1)

- Final Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Document21 pagesFinal Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Casing TallyDocument6 pagesCasing TallyAngga BayuNo ratings yet

- 00087167Document11 pages00087167JohnSmith100% (1)

- Thread CompoundDocument5 pagesThread CompoundJas SumNo ratings yet

- Var-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFDocument12 pagesVar-3704 - Performanceupdates-Me - Brochure-V1.0sm - ROP DATA PDFamir_hayfaNo ratings yet

- Drilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Document1 pageDrilling Application: Hole Diameter, In? Mud WT? Hole Diameter, In? Mud WT?Abdul Hameed OmarNo ratings yet

- Rotating Control Device: SperrydrillingservicesDocument4 pagesRotating Control Device: SperrydrillingservicesSlim.B100% (1)

- Down HoleDocument14 pagesDown HoleGhinet Teodor-ioanNo ratings yet

- Drilling Levels 3 and 4 Syllabus PDFDocument35 pagesDrilling Levels 3 and 4 Syllabus PDFGOKUL PRASADNo ratings yet

- 1 - Hydra Jar - Technical DataDocument3 pages1 - Hydra Jar - Technical DataJoseMi Vacaflor IllanesNo ratings yet

- Tech/drilling/Casing Design ExDocument43 pagesTech/drilling/Casing Design ExSohaib RashidNo ratings yet

- PZ-9 FlyerDocument2 pagesPZ-9 FlyerChris KNo ratings yet

- Volant Crti and CrteDocument4 pagesVolant Crti and CrteSudish Bhat100% (2)

- Analisis Penggunaan Bit For ChevronDocument15 pagesAnalisis Penggunaan Bit For Chevronfaishal hafizhNo ratings yet

- 02IDPT Drill Bits #2Document48 pages02IDPT Drill Bits #2AboZaidNo ratings yet

- Mill Washover ShoesDocument2 pagesMill Washover ShoesEdwin MP100% (1)

- Drill String DesignDocument1 pageDrill String DesignmalikshababNo ratings yet

- SPE Rig SelectionDocument8 pagesSPE Rig SelectionEyoma EtimNo ratings yet

- 575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFDocument8 pages575 Venturi Jet Basket Mini Tech Brief Ver 3 PDFJhonathan MirandaNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Jfebear BrochureDocument12 pagesJfebear BrochurebabuNo ratings yet

- III. Basic CalculationDocument14 pagesIII. Basic Calculationdidin kenyalNo ratings yet

- Wedge 563 Brochure OKDocument32 pagesWedge 563 Brochure OKNico Pan100% (1)

- Well Control Euqations Drilling Formulas 2016Document12 pagesWell Control Euqations Drilling Formulas 2016Cristian BarbuceanuNo ratings yet

- Understanding IU, EU and IEU Drill Pipe UpsetsDocument2 pagesUnderstanding IU, EU and IEU Drill Pipe Upsetsmadonnite3781No ratings yet

- Chap EDocument44 pagesChap ERANJITH K PNo ratings yet

- W5D2 - DE - Introduction To Well Trajectory PlanningDocument54 pagesW5D2 - DE - Introduction To Well Trajectory PlanningFernandoNo ratings yet

- Rig Move Brochure: Parker Drilling CompanyDocument39 pagesRig Move Brochure: Parker Drilling CompanyJonathan CustodioNo ratings yet

- IADC Vol-1 08 Directional DrillingDocument35 pagesIADC Vol-1 08 Directional Drillingballa bammouneNo ratings yet

- Guide to Drill Bit Selection, Design Factors & GradingDocument54 pagesGuide to Drill Bit Selection, Design Factors & GradingHamis RamadhaniNo ratings yet

- Make-up torque values and dope quantities for tubing and casingDocument9 pagesMake-up torque values and dope quantities for tubing and casingKhaledFekairNo ratings yet

- Bit Hydraulics OptimizationDocument23 pagesBit Hydraulics OptimizationAhmed Ali AlsubaihNo ratings yet

- API-55-165 Use of Stabilizers in Controlling Hole DeviationDocument18 pagesAPI-55-165 Use of Stabilizers in Controlling Hole Deviationdrilling moneytreeNo ratings yet

- 7in 29ppf 13Cr-80 JFE BearDocument1 page7in 29ppf 13Cr-80 JFE BearYeit HauNo ratings yet

- 12-BT-0092 Impreg Dull Grade BookDocument52 pages12-BT-0092 Impreg Dull Grade BookFredy Farell OrtegaNo ratings yet

- BHA Components Rupo CDocument1 pageBHA Components Rupo CJimmy JohnsNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Hydril 513™Document4 pagesHydril 513™renatoNo ratings yet

- 21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Document28 pages21 1/4 - 2,000 Ram Blowout Preventer Operation Manual Hydraulic Wedge Lock 2FZ54-14 FZ54-14Mehdi SoltaniNo ratings yet

- Tric Dull Grade SIIDocument57 pagesTric Dull Grade SIICamila Palacios100% (1)

- Trip Sheet For RigDocument1 pageTrip Sheet For Rigankurume1984100% (1)

- Drilling Contract Types and Their EffectsDocument206 pagesDrilling Contract Types and Their EffectsMohammed Zubair AhmedNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- Aluminum Alloy Drill PipeDocument20 pagesAluminum Alloy Drill PipeMark Garrett100% (1)

- OMNI Roller ReamerDocument2 pagesOMNI Roller ReamerCaptain NematollahiNo ratings yet

- Drilling Spool SpecsDocument2 pagesDrilling Spool SpecsCarlos Sarmiento CalderónNo ratings yet

- HC606 Drill Bit ManualDocument1 pageHC606 Drill Bit ManualMahdy BasimNo ratings yet

- Drill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)Document1 pageDrill Collar, 4.5 IF (6.500 X 2.813) 110,000 (Psi)juan moralesNo ratings yet

- No. 3Document1 pageNo. 3Luis Alberto García CórdovaNo ratings yet

- Drill-Pipe Performance SheetDocument8 pagesDrill-Pipe Performance SheetrahulNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- B Borehole Drilling-GEOT026 4Document1 pageB Borehole Drilling-GEOT026 4Инженер Луис А. ГарсиаNo ratings yet

- Player Prefs 1Document6 pagesPlayer Prefs 1Prabhat VishwasNo ratings yet

- Drilling An Oil Well From Surface Drilling To CompletionDocument9 pagesDrilling An Oil Well From Surface Drilling To CompletionИнженер Луис А. ГарсиаNo ratings yet

- Second Conditional Quiz.Document2 pagesSecond Conditional Quiz.Инженер Луис А. ГарсиаNo ratings yet

- Possessive CaseDocument1 pagePossessive CaseИнженер Луис А. ГарсиаNo ratings yet

- Directional Drilling NoDocument4 pagesDirectional Drilling NoИнженер Луис А. ГарсиаNo ratings yet

- Top Drive Solutions d392001277 MKT 001Document12 pagesTop Drive Solutions d392001277 MKT 001JINDAL100% (2)

- What Will You Do About Your Homework?Document3 pagesWhat Will You Do About Your Homework?Инженер Луис А. ГарсиаNo ratings yet

- Time ContrastDocument2 pagesTime ContrastИнженер Луис А. ГарсиаNo ratings yet

- Future: Will Verb (Base Form)Document4 pagesFuture: Will Verb (Base Form)Инженер Луис А. ГарсиаNo ratings yet

- How To Form "Be Going To" Sentences: Subject Statement NegativeDocument2 pagesHow To Form "Be Going To" Sentences: Subject Statement NegativeИнженер Луис А. ГарсиаNo ratings yet

- Comparison (3) - As... As/than: David EricDocument1 pageComparison (3) - As... As/than: David EricИнженер Луис А. ГарсиаNo ratings yet

- Regular Comparatives and SuperlativesDocument2 pagesRegular Comparatives and SuperlativesValter Pinheiro LimaNo ratings yet

- 15 Fun Activities To Practice Will For PredictionsDocument3 pages15 Fun Activities To Practice Will For PredictionsSonsaku HakufuNo ratings yet

- Regular Comparatives and SuperlativesDocument2 pagesRegular Comparatives and SuperlativesValter Pinheiro LimaNo ratings yet

- 15 Fun Activities To Practice Will For PredictionsDocument3 pages15 Fun Activities To Practice Will For PredictionsSonsaku HakufuNo ratings yet

- Funny StoriesDocument8 pagesFunny StoriesИнженер Луис А. ГарсиаNo ratings yet

- Universidad Politecnica Del Golfo de Mexico Evidencia de Conocimiento 1 Aplicación de Evaluacion Fecha 26 de Noviembre de 2008Document3 pagesUniversidad Politecnica Del Golfo de Mexico Evidencia de Conocimiento 1 Aplicación de Evaluacion Fecha 26 de Noviembre de 2008Инженер Луис А. ГарсиаNo ratings yet

- Expressing Yourself 3Document1 pageExpressing Yourself 3Onufriiciuc Raluca100% (1)

- Subject + Will + 1: 1 2 3 Go Went Gone Affirmative Negative InterrogativeDocument6 pagesSubject + Will + 1: 1 2 3 Go Went Gone Affirmative Negative InterrogativeИнженер Луис А. ГарсиаNo ratings yet

- African Lion (Reading)Document2 pagesAfrican Lion (Reading)Инженер Луис А. ГарсиаNo ratings yet

- Community Landmarks: Directions: Try To Write at Least Two Activities of Each Community LandmarkDocument2 pagesCommunity Landmarks: Directions: Try To Write at Least Two Activities of Each Community LandmarkLaura CosteiuNo ratings yet

- Likes and Dislikes worksheetDocument1 pageLikes and Dislikes worksheetИнженер Луис А. Гарсиа100% (1)

- List of Comparatives and SuperlativeDocument7 pagesList of Comparatives and SuperlativeInga JurjuNo ratings yet

- Food DislikesDocument1 pageFood DislikesИнженер Луис А. ГарсиаNo ratings yet

- Datum I VremeDocument1 pageDatum I VremeEli PanovaNo ratings yet

- Expressing Likes and DislikesDocument2 pagesExpressing Likes and DislikesИнженер Луис А. ГарсиаNo ratings yet

- Would, Would Like, Would Love Completion ActivityDocument1 pageWould, Would Like, Would Love Completion ActivitySonja KostoskaNo ratings yet

- Personal Information PDFDocument1 pagePersonal Information PDFИнженер Луис А. ГарсиаNo ratings yet

- Past Continuous ExerciseDocument2 pagesPast Continuous ExerciseИнженер Луис А. ГарсиаNo ratings yet

- Drag Force in Flow Over A BodyDocument11 pagesDrag Force in Flow Over A Bodyamin67% (3)

- Error & Measurement Sheet 2Document2 pagesError & Measurement Sheet 2prayag527No ratings yet

- Trends in Industrial Gear OilDocument8 pagesTrends in Industrial Gear OilM.TayyabNo ratings yet

- UmbraDocument3 pagesUmbramaplecookieNo ratings yet

- Easy Way To Determine R, S ConfigurationDocument11 pagesEasy Way To Determine R, S ConfigurationHimNo ratings yet

- Andersen 2009Document23 pagesAndersen 2009Lucas MartinsNo ratings yet

- Combined GearboxDocument8 pagesCombined Gearboxkats2404No ratings yet

- Seismic Evaluation and Retrofit of DeterDocument195 pagesSeismic Evaluation and Retrofit of DeternoijpNo ratings yet

- State FunctionDocument15 pagesState FunctionmelprvnNo ratings yet

- Inclined StressDocument28 pagesInclined StressAli El-Gazzar100% (1)

- MSE WallDocument418 pagesMSE WallC.y. ChiuNo ratings yet

- Daylight Factor: Prasented byDocument8 pagesDaylight Factor: Prasented byDebayan dasNo ratings yet

- Article # 22C - Predicting Timing of Marriage Event Using Sudarshana Chakra DasaDocument31 pagesArticle # 22C - Predicting Timing of Marriage Event Using Sudarshana Chakra DasaSastry Karra100% (4)

- (1966) Basic Facts Concerning Shear Failure PDFDocument37 pages(1966) Basic Facts Concerning Shear Failure PDFMohammad AshrafyNo ratings yet

- 3 CrystalDocument50 pages3 CrystalDhaffer Al-MezhanyNo ratings yet

- Chem XI CH 1 Test 1 BDocument2 pagesChem XI CH 1 Test 1 BAnonymous AvNQhky1No ratings yet

- Lab 3 X Term.Document9 pagesLab 3 X Term.LINDER ARCE INGANo ratings yet

- TOEFLDocument6 pagesTOEFLYou Suf50% (2)

- Daftar PustakaDocument6 pagesDaftar PustakavitawidNo ratings yet

- Heat Equation Fourier Series SolutionDocument20 pagesHeat Equation Fourier Series SolutionSwen Moreno RosalesNo ratings yet

- Downhole Seismic Testing: Standard Test Methods ForDocument11 pagesDownhole Seismic Testing: Standard Test Methods ForRubén Darío Rodari100% (1)

- PDE Solutions Manual Fourier Series BVP 2nd EdDocument5 pagesPDE Solutions Manual Fourier Series BVP 2nd EdJames Hobbs50% (2)

- Refining Precious Metals Wastes by CM. HokeDocument369 pagesRefining Precious Metals Wastes by CM. HokeadamdwaldropNo ratings yet

- Lecture Notes 7 - 203 OpticsDocument33 pagesLecture Notes 7 - 203 OpticsGramoz Cubreli100% (1)

- Practice Test 1Document6 pagesPractice Test 1Thuc TranNo ratings yet

- Design of Steel Beam in Torsion PDFDocument148 pagesDesign of Steel Beam in Torsion PDFdaeealiNo ratings yet

- Probability Examples of Discrete Probability DistributionDocument25 pagesProbability Examples of Discrete Probability DistributionSehzadNo ratings yet

- IB Questionbank Mathematical Studies 3rd Edition 1Document9 pagesIB Questionbank Mathematical Studies 3rd Edition 1KatherineNo ratings yet

- Finite Element Method Chapter 4 - The DSMDocument17 pagesFinite Element Method Chapter 4 - The DSMsteven_gogNo ratings yet

- Chapter 19: TEMPERATURE, HEAT, and The First Law of ThermodynamicsDocument18 pagesChapter 19: TEMPERATURE, HEAT, and The First Law of ThermodynamicsWahyu RiyandiNo ratings yet