Professional Documents

Culture Documents

Oxy. Motor PDF

Uploaded by

JAY PARIKH0 ratings0% found this document useful (0 votes)

23 views4 pagesOriginal Title

oxy. motor..pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views4 pagesOxy. Motor PDF

Uploaded by

JAY PARIKHCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

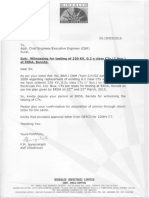

r Bharat Heavy Electricals Limited Bhopal

A.C. Machines Engineering Division

Three Phase Indu‘

n Motor Test Certi

[Customer Praxair for Birla Copper MIC. S.No. 43032A421-11-01

[pes TTF 6542-4p Driven Equip. Compressor DOR From DE ANTICLOGKWISE (UVW-BYR)_6

Volts(V)___Current(A)_Output(Kiv)__Power Factor Spees(RPM) _Frea.(Hz) Duly

47000 470.0 7750 0.89) 1495.0 30.0, St

[Construction

No.of pes 4 Typecf enclosure CACWUPS5) Type of coming ICWSTAE1_ Saif Cooling.Closed circuit

[Typ of Rotor ‘Squirrel Cage Rotor wth SC Rings.

[sot Cooling Act. 2 Sided Cooling gore Water -2285LPM Siping Veniction

Jssiorcomecton Star No.of teminals 6 Rotorcennection Cage No.of Sipaings

lssortraneperts 1A ap 450m Insulalon Cass Sx F(Temp.riseB) RE

INo.otsiprira rushes — nich size Bushiype No. oforichnedere

[Tested According to 19: 325

Fi Insulation Resistance witt ‘SOV DC Slatorwig 17500110, Rotorwag >

[2 High-valtage tests

Stator wag. to frame - Phase to Phase with 232000 AC fort min

Rotor wég to frame - Phase to Phase with VAC for imin

[3 overspeed Test at mpm ie = timesrated speed for = min.

Id Efficiency calculated by summation of losses

Tea] 50%] | Calculated at 20°.

[ouput kw 7750.0 | 5612.6] 3875] [Resistance Of

[Stotor Current | yA 470.0 356.7] 2672]

[Power factor [cose | 0.890 0.38] 0.85] 0.085680

JOnmctosses [Stator [KW 3855] 22.23] 10.68]

lat 75% [Rotor kw 2592] 14221 6.17] o0Bs6Te

[Coro & Friston loss [kW 23.12] 3.12) 63.12]

[Contact toss at slipring [KW | =| = 2.005079,

[adaitionalioss [0.50% _[kiV 375] 22.32 10.79]

Hotatiosses [EP [kW 18638] 141.89] 110.69]

ep [PaEP) few 7036.38] 5064.30] 3036.60]

Efficiency _[PIPS2P | 97.65] 97.52| 97.22]

[Guaranteed Eficiency —_[% 7.30] 97.2 26.

[5H Toad Tex EW[Amps at_ 14020 KV 35.537 177.58

Tooker Ror Tes Short ckt_ current 470.10 A Short Lose 247.60 Kalvos 2607000

Js Resistancethermometers _[wa__7 [2 [3 [@ [s [6 [7 [8 [s wn ]o

Resistance 100. ohmeat_O'C [autres [1 is fer foo _Jo1_los | —[—]—] —[—] =

Bearing temperatures after 300 he. unnng = hein) 4470 NowDieeRd a wane 30S

Bearing ype Sleeve Lubrication Type__Oil Cooling Forcedi10 lnm per Bearing)

[Supprements [Remarks Frermminal Marking

4 Separation of No-Load Lose [Routine Tests. View from MiG Top

2 Annexure 1 Me

: |

: |

NOE

[Proparedby A Varstinay Checked by Date 28.03.2004

DRG. NO. RDM5008/1

IF IN DOUBT ASK

LIMITED

ES.

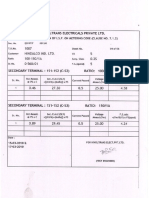

IMPEDANCE VOLTS % , SERIAL NO., YEAR OF MANUFACTURE

WILL BE ENGRAVED AFTER TESTING ANO BEFORE DESPATCH

& ®

save no i

(GByerenee”

MALANPUR

COPPER WOUND TRANSFORMER

TO INDIAN STANDARD 2025-1977

Kwa 7250] TYPE oF COOLING ONAN

VouTs AT .v [11000] FREQUENCY 30 HE

No LOAD. Lv. 433, IMPEDANCE VOLTS. x

HY, GORE AND WINDINGS Kg [7730

Maree Uv[16657—| WEIGHT OF ol Ko | 785

Hass 3 TOTAL WEIGHT Ky [ 4000,

DIAGRAM ORG. NO. [ROWSODB7T) OlL 1 900,

MAKER'S SERIAL No. [M5008 _| YEAR OF MANUFACTURE

[CUSTOMER'S REF KO.

GUARANTEED MAX. TEMP. RISE IN OIL 50,C,0F WOG. 5$C BY RESISTANCE

OVER AN ANBIENT TEMPERATURE OF 45°C.

GREA\

ALL INFORMATION IN THIS COCUMENT

TS CONFIDENTIAL & SHOULO NOT BE

USED WITHOUT PRIOR CONSENT OF

CROMPTON

‘swircn | switch | WH VOLTAGE ACROSS | LOW VOLTAGE ACROSS

Posinion| conmects | wy vw | 20 avo

No. VOUS AMPS” OUTS: AMPS

T |S =s) 180

2_[s —7| 11975 [840

37 — +] 11000 | asa

2 [ee 0795 [ars

3s — $0050 [68:1

2

3

2

mu aw ‘BIL_OF_WINDINGS

‘ p . WA Ly.

7s ace [Ac

z ae a

45} Mess 5 1

oo] >| ee 1 kw

Hy. - 2 i

2NN2D OCW gy

w v

ei Byatt

Law 1 1 1 CONNECTION SYMBOL

lous tz 2 2 WILGT: 1066 /2A, 7.5VA, $5%RE

Lv, GONNEGTION DIAGRAM NET : 300/54, 10VA, C1510.

IMPORTANT

I SCONN: FORMER FROM a

@ BEFORE CHANGING SWITCH POSITION D

140 [70]

160

GENTOL. [MATL : STAINLESS STEEL] THIRD ANGLE PROJECTION

CUSRANTEED (270 ALL DIMENSIONS IN MM

sue! 15 TOLERANCE SPEC._MS-107 Scale

FINSH RATING & DIAGRAM PLT.

INITIALS 1250KVA,_11kV/433V_ (TR-01)

BIRLA COPPER — 1960 LP

RN.

: a GI Crompton)

ste | Greaves

ICUSTONER CONNENTS 29-07 SWALIOR|

ARE. INCORPORATED Ravi [APPD. MALANPUR :

ZONE REVISION DATE | DATE — 2/7172005 ORG. NO. RDM5008/1

BIRLA COPPER, DAHEJ 2

Rev

T-960 LP OXYGEN PLANT ———

Sheet | 4 of 8

ELECTRICAL SYSTEM DESIGN BASIS >

Doc No 2213-EL-BASIS |

[Pate | June 2003

~

KW will be 725 amps only. The full load current of [250 KVA transformer is 1740 amps

on 415V side. Accordingly incomer ACB and busbars are rated for 2000 amperes.

‘The plant will also generate about 300 KW power at 415V through an induetion generator

coupled to the turbine in the cold box. Since the induction generator is used, no special

components for paralleling are required and the induction generator will be provided with

over current and earth fault protection.

Heater Transformer

The plant process includes nitrogen gas heaters and the heating is achieved normally by

means of permanent steam heater. In addition, the plant will be providediwith 2 nos 860

KW electrical heaters. These electrical heaters will mostly function as standby heaters to

the steam heaters and sometimes, will also be operated to supplement steam heaters in

case of any operational problems in the steam heater, such as low steam supply pressure,

ete

‘The standby heater load is isolated from the main auxiliary transformer and is fed from a

dedicated 2500 KVA transformer. The capacity is sufficient to take care of some thyristor

loads in the heater control panel, which may control about 50% of the total heater

capacity.

Single Line Diagrams

Drawings 9-001-00-50 sheets 1 and 2 submitted separately show the single line diagrams

for 11 KV and 415V Power distribution covering the loads enumerated above. The SLD’s

outline the feeders of 11 KV switchgear, 41SV PMCC along with the metering and

protection envisaged.

11 KY Switehgear

The 11 KV panel will be provided with VCB’s having required 40KA/ 3sec short circuit

rating. Incoming, transformer and motor feeders will be protected with numerical type

protection relays (Siemens Type 7SJ series) and the power consumption will be

monitored using Enercon EM3360 meters.

Starting of 11 KV motors and voltage dip

Following factors are considered to keep the voltage dip within acceptable values on the

source side while starting the biggest 7750 KW motors.

a) Motor Locked Rotor (Starting) Current limited to about 470» including tolerance.

b) Motor will be stared at reduced voltage using autotransformer at 75% tap.

Following calculation

ives the voltage dip while starting the 7750 KW motor.

Doc No 2213-EL-BASIS

BIRLA COPPER, DAHEJ ——eerre

‘T-960 LP OXYGEN PLANT

Rev 4

[Shest 5 of8

ELECTRICAL SYSTEM DESIGN BASIS | 5. une 2003)

‘System Minimum short circuit MVA (15 KA) $= 11 X 15 X 1.732 = 285 MVA

Motor full load current 463 amps

Motor Base MVA My = 11 X 0.465 X 1.732 =8.86 MVA

Voltage Dip V. using autotransformer will be

i

T¥S7[M(a+Z yy)

Where,

a= Magnetizing inrush multiplier for auto transformer = 0.2

Z. = Tap position on auto transformer = 0.75

y= Starting Current multiplier = 4.7

Applying the appropriate values,

Voltage Dip while starting 7750 KW motor = 1 / {1 + 285/ [8.86 * (0.2 +0.75°*4.7)}}

1/14(285/25.196)

= 8.11%

The autotransformers will be provided with additional tap at 80% and exact tap will be

selected based on the plant voltage conditions at the time of commissioning.

System power factor improvement

The induction motors will have about 0.89 power factor at the estimated operating load of

5800 KW (75% of motor rating) as per data guaranteed by the supplier. 2 nos 11 KV, 750

KVAR capacitor banks are considered to get more than the desired 0.9 power factor as

per the calculations below.

Normal motor operating load: S800 KW

Load power factor: 0.89 (75% load) & 0.90 (100% load)

Desired improvement: 0.96 (To take care of negative tolerances)

Capacitor factor

(As per standard tables): 0.221 (0.89 to 0.96) and 0.193 (0.90 to 0.96)

Preferred capacitor rating/motor

5800 X 0.221 = 1282 KVAR

OR

0 X 0.193 = 1496 KVAR

Further the capacitor rating shall be chosen based on the no load (magnetizing) current of

the motor. The motor no load current is about 100 amps and limiting the capacitor current

to about 90% of magnetizing current. the capacitor value shall be around 1700 KVAR.

Accordingly 2 sets of 750 KVAR capacitor banks are chosen per motor and four sets of

capacitor banks will be installed for the two motors. Each capacitor bank will be installed

indoors with load break switch and fuse

You might also like

- Company Logo: Cable Size CalculationDocument7 pagesCompany Logo: Cable Size Calculationahmadgce04No ratings yet

- GRE Word ThesaurusDocument137 pagesGRE Word ThesaurusPhanidhar GubbalaNo ratings yet

- SC CalculationsDocument112 pagesSC CalculationsJAY PARIKHNo ratings yet

- Hindalco Routine Test Report Page No. 4 & 5Document2 pagesHindalco Routine Test Report Page No. 4 & 5JAY PARIKHNo ratings yet

- 220 KV CT TestingDocument4 pages220 KV CT TestingJAY PARIKHNo ratings yet

- GRE Word ThesaurusDocument137 pagesGRE Word ThesaurusPhanidhar GubbalaNo ratings yet

- CEA Battery ManagementDocument112 pagesCEA Battery ManagementJAY PARIKHNo ratings yet

- CT Testing at ERDA & HALOLDocument3 pagesCT Testing at ERDA & HALOLJAY PARIKHNo ratings yet

- Irr - Pa & Id Fan - Boiler 1Document14 pagesIrr - Pa & Id Fan - Boiler 1Jay Rameshbhai ParikhNo ratings yet

- Hindalco DRG PDFDocument3 pagesHindalco DRG PDFJAY PARIKHNo ratings yet

- CT Testing at ERDA & HALOLDocument3 pagesCT Testing at ERDA & HALOLJAY PARIKHNo ratings yet

- 6211391Document2 pages6211391JAY PARIKHNo ratings yet

- 3AH3 Circuit Breaker DetailsDocument28 pages3AH3 Circuit Breaker Details2003vinayNo ratings yet

- CableDocument2 pagesCableJAY PARIKHNo ratings yet

- Hindalco DRG PDFDocument3 pagesHindalco DRG PDFJAY PARIKHNo ratings yet

- WoodwardDocument4 pagesWoodwardKUNALJAYNo ratings yet

- Keeping SafeDocument3 pagesKeeping SafeJay Rameshbhai ParikhNo ratings yet

- CableInstallation PDFDocument8 pagesCableInstallation PDFJAY PARIKHNo ratings yet

- MX3EG1A Automatic Synchronizer Technical ManualDocument38 pagesMX3EG1A Automatic Synchronizer Technical Manualsgshekar30No ratings yet

- Best PracticesDocument28 pagesBest PracticesJAY PARIKHNo ratings yet

- 3AH Catalog PDFDocument75 pages3AH Catalog PDFalsilva2014100% (1)

- 3AH1 Operating InstrDocument29 pages3AH1 Operating InstrJAY PARIKHNo ratings yet

- 011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inDocument1 page011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inJAY PARIKHNo ratings yet

- SynchroniserDocument21 pagesSynchroniserJAY PARIKHNo ratings yet

- Voltage Regulator DECS-100 ManuelDocument81 pagesVoltage Regulator DECS-100 Manuelctsak100% (1)

- 0507BoilerwithComponents PDFDocument1 page0507BoilerwithComponents PDFJAY PARIKHNo ratings yet

- SynchroniserDocument21 pagesSynchroniserJAY PARIKHNo ratings yet

- Boiler DraftDocument22 pagesBoiler DraftJAY PARIKHNo ratings yet

- Procedure For Calculation of Efficiency-1Document7 pagesProcedure For Calculation of Efficiency-1JAY PARIKHNo ratings yet

- Improve Primary Air Heater EfficiencyDocument4 pagesImprove Primary Air Heater EfficiencyJAY PARIKHNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)