Professional Documents

Culture Documents

X Series Roller Cone Drill Bits

Uploaded by

Toth IstvanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X Series Roller Cone Drill Bits

Uploaded by

Toth IstvanCopyright:

Available Formats

Drill Bits

Roller Cone

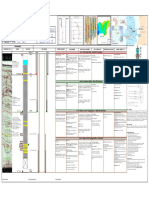

IADC Dull Grading

Cutting Structure

Inner Rows Outer Rows Dull Char. Location Bearings/Seals Gauge Other Dull Char. Reason Pulled

1 2 3 4 5 6 7 8

1 Inner Cutting Structure 3 Dull Characteristics 4 Location 8 Reason Pulled or

Run Terminated

(All inner rows) (Use only cutting structure Roller Cone

related codes) N - Nose Row BHA - Change Bottom

2 Outer Cutting Structure

M - Middle Row Hole Assembly

BC - Broken Cone*

(Gauge row only) G - Gauge Row CM - Condition Mud

BT - Broken Teeth

In columns 1 and 2, a linear A - All Rows CP - Core Point

BU - Balled Up

scale from 0 to 8 is used to DMF - Downhole Motor

CC - Cracked Cone* Cone #

describe the condition of the Failure

CD - Cone Dragged* 1

cutting structure according to DP - Drill Plug

CI - Cone Interference 2

the following: DSF - Drill String Failure

CR - Cored 3

Steel Tooth Bits DST - Drill Stem Test

CT - Chipped Teeth

5 Bearings/Seals DTF - Downhole Tool

A measure of lost tooth height ER - Erosion

due to abrasion and/or dam- Non-Sealed Bearings Failure

FC - Flat Crested Wear

age. A linear scale estimating FM - Formation Change

HC - Heat Checking

bearing life used HP - Hole Problems

0 - No loss of tooth height JD - Junk Damage

0 - No life used HR - Hours on Bit

8 - Total loss of tooth LC - Lost Cone*

8 - All life used, LIH - Left In Hole

height LN - Lost Nozzle

i.e., no bearing life LOG - Run Logs

LT - Lost Teeth

Insert Bits remaining PP - Pump Pressure

NO - No Dull Characteristic

A measure of total cutting PR - Penetration Rate

NR - Not Rerunnable Sealed Bearings

structure reduction due to lost, RIG - Rig Repair

OC - Off Center Wear E - Seals effective

worn and/or broken inserts. TD - Total Depth/

PB - Pinched Bit F - Seals failed Casing Depth

0 - No lost, worn and/or PN - Plugged Nozzle/ N - Not able to grade TQ - Torque

broken inserts Flow Passage

6 Gauge TW - Twist Off

8 - All inserts lost, worn RG - Rounded Gauge

(Measure in fractions of an WC - Weather

and/or broken RR - Rerunnable

inch) Conditions

SD - Shirttail Damage

I - In Gauge WO - Washout - Drill String

SS - Self-Sharpening Wear

TR - Tracking 1 - 1/16 out of gauge * Show cone # or #s

WO - Washed Out 2 - 1/8 out of gauge under location 4. Cone num-

WT - Worn Teeth 4 - 1/4 out of gauge bers are identified as follows:

Cutting Structure Wear 7 Other Dull The number one cone

Characteristics contains the centermost

(Refer to column 3 codes) cutting element.

T4

T3 T5

T2 T6 Cones two and three

follow in a clockwise

T1 T7 orientation as viewed

NEW

looking down at the

T8

cutting structure with

the bit sitting on the pin.

Drill Bits

ROLLER CONE BITS RING GAUGING

Dull Three Cone Bits **

1

1 Obtain a nominal size ring gauge. A nominal ring gauge is one that is

exact in size. For example, a 12-1/4-in. ring gauge is 12-1/4-in. exactly.

2 Rotate all cones so that one of the gauge teeth on each cone is at the

maximum gauge point*. (Remember, soft formation bits with large offsets

have the maximum gauge points on each cone located towards the leading

side of the cone).

HAL9087

3 Place the ring gauge over the bit and locate it at the maximum gauge point.

4 Pull the ring gauge tight against the gauge points of two cones as shown.

5 Measure the gap between the third cones gauge point and the ring gauge**.

*

6 Multiply this measurement by 2/3 for accuracy. This result is the amount

the bit is under gauge. In the illustration, for example, measurement shows

3/8-in., while the bit is actually 1/4-in. out of gauge. *

7 Report this amount to the nearest 1/16th of an inch.

Sharp Bits

1 When ring gauging a sharp (new) roller cone bit, a nominal ring gauge

may not fit over the cones due to the plus tolerances. Obtain the appropriate

go and no go gauges for each bit size.

2 The go gauge is manufactured to the maximum roller cone bit tolerance

(see API Standard Roller Cone Rock Bit Tolerances) plus its own tolerance

+.003 to -0 inches for clearance.

3 The no go gauge is manufactured to the minimum roller cone bit

tolerance, which is nominal bit diameter, plus its own tolerance +0- to -.003-in.

API Standard Roller Cone Bit Tolerances

Bit Size (IN.) 3-3/8 to 13-3/4 14 to 17-1/2 17-5/8 and Larger

Tolerance +1/32, -0 +1/16, -0 +3/32, -0

2009 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the contract

between Halliburton and the customer that is applicable to the sale. H03086 9/09

www.halliburton.com

You might also like

- Iver Johnson's Arms and Cycle Works 1894 - 1999 - Firearms MFGDocument10 pagesIver Johnson's Arms and Cycle Works 1894 - 1999 - Firearms MFGblowmeasshole1911100% (1)

- Optimal Spacing For Casing Centralizer PDFDocument10 pagesOptimal Spacing For Casing Centralizer PDFimampranadipaNo ratings yet

- Bear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARDocument5 pagesBear - Public - JFEBEAR-TP-M-101 Rev3 Field Inspection of JFEBEARGabriel Ibarra100% (2)

- Toro Tool Joint Identifier PDFDocument9 pagesToro Tool Joint Identifier PDFkrishnsgk100% (1)

- Tric Dull Grade SIIDocument57 pagesTric Dull Grade SIICamila Palacios100% (1)

- Iadc Bit GradingDocument1 pageIadc Bit GradinganarkasisNo ratings yet

- PDC Bit Dull Grading PDFDocument21 pagesPDC Bit Dull Grading PDFmo7ammad_elzawawy100% (1)

- Dull Grading Fixed Cutter BitDocument14 pagesDull Grading Fixed Cutter BitChinyere NkereNo ratings yet

- Bit GradingDocument17 pagesBit GradingnugratamaNo ratings yet

- Rock BitsDocument17 pagesRock Bitssuresh_501No ratings yet

- Drilling ProblemsDocument14 pagesDrilling ProblemsRohith PgNo ratings yet

- Toro Drilling Tools CatalogDocument36 pagesToro Drilling Tools CatalogroicinoNo ratings yet

- 12.25 DT1GJMRS PDFDocument1 page12.25 DT1GJMRS PDFBelen CastroNo ratings yet

- A Presentation ON Drill Bits: Submitted To: Er. Akash Rana (HOD) Petroleum DepttDocument26 pagesA Presentation ON Drill Bits: Submitted To: Er. Akash Rana (HOD) Petroleum DepttJohar marwatNo ratings yet

- Drilling Tools - 1Document269 pagesDrilling Tools - 1berrouiNo ratings yet

- Corpro Coring PresentationDocument80 pagesCorpro Coring PresentationemmanuelNo ratings yet

- Failure Analysis of IEU Drill Pipe Wash OutDocument6 pagesFailure Analysis of IEU Drill Pipe Wash OutDerry RahmaNo ratings yet

- Logan Rotary ShoesDocument1 pageLogan Rotary ShoesCoolProphetNo ratings yet

- 2 - Drill String DesignDocument64 pages2 - Drill String Designqqaassmmm321No ratings yet

- Drilling Workshop BHADocument39 pagesDrilling Workshop BHAOnmmmmNo ratings yet

- NOV Drill Bits New Technologies Helios Cutters and Hybrid FuseTek Bit To Drill Silurian and Ordivician On Rotary ModeDocument27 pagesNOV Drill Bits New Technologies Helios Cutters and Hybrid FuseTek Bit To Drill Silurian and Ordivician On Rotary ModeSlim.BNo ratings yet

- Centralizers & StopCollarsDocument19 pagesCentralizers & StopCollarsSaurabh Parihar100% (1)

- Bha & Drill ColarsDocument6 pagesBha & Drill Colarswasim78622No ratings yet

- Tool Joint Data Assembly Data: Drill Pipe Data TablesDocument5 pagesTool Joint Data Assembly Data: Drill Pipe Data TablesSefa AslanhanNo ratings yet

- Steel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringDocument19 pagesSteel Drill Collars: Quality Control and Ultrasonic Inspection Precision BoringAshba13No ratings yet

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Document16 pagesKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashadNo ratings yet

- Program East Jata # 1Document54 pagesProgram East Jata # 1Dian SikumbangNo ratings yet

- Drilling Tools CatalogDocument96 pagesDrilling Tools CatalogRzvn100% (1)

- ZJ70/4500DB RIG 钻机: Parts ListDocument3 pagesZJ70/4500DB RIG 钻机: Parts Listwaleed100% (1)

- Drilco Spiral Drill Collar PsDocument1 pageDrilco Spiral Drill Collar Psyojan35No ratings yet

- New Drill Pipe DesignDocument9 pagesNew Drill Pipe DesignModebelu EbubeNo ratings yet

- DBS - V2 HalliburtonDocument70 pagesDBS - V2 HalliburtonMohamed Khaled Fadl DahabNo ratings yet

- Formulas y Calculos de PerforacionDocument22 pagesFormulas y Calculos de Perforacionjairaso2950No ratings yet

- BHA Design: ©2011 Best-Drilling-Practices - Tk. All Rights ReservedDocument8 pagesBHA Design: ©2011 Best-Drilling-Practices - Tk. All Rights ReservedRMolina65No ratings yet

- NLOG GS PUB 1975 111220 SodM EOWR LZG-01Document12 pagesNLOG GS PUB 1975 111220 SodM EOWR LZG-01Guiver Suarez V.No ratings yet

- Drill Pipe ChartsDocument11 pagesDrill Pipe ChartsSean PorterNo ratings yet

- Wait and Weight MethodDocument2 pagesWait and Weight MethodMubin Ashraf Sheikh100% (1)

- Cement Plug SidetrackDocument2 pagesCement Plug SidetrackAnilNo ratings yet

- SB Drill CollarDocument51 pagesSB Drill CollarJeff ZhangNo ratings yet

- IADC Bit Types and ClassificationDocument13 pagesIADC Bit Types and ClassificationAnuranjanNo ratings yet

- Mwd-Manual PDFDocument151 pagesMwd-Manual PDFmanu pratap singhNo ratings yet

- Tom Mile Calculation PDFDocument6 pagesTom Mile Calculation PDFBeni N SoloNo ratings yet

- 02IDPT Drill Bits #2Document48 pages02IDPT Drill Bits #2AboZaidNo ratings yet

- Drilling ProblemsDocument38 pagesDrilling Problemskrishnsgk100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- Drill String StandardsDocument27 pagesDrill String StandardsMuhammad Shahrukh100% (2)

- Torque and Drag Class LectureDocument12 pagesTorque and Drag Class Lecturetareq.sefat100% (1)

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Banda East Well Montage 28sept08 A4 SizeDocument1 pageBanda East Well Montage 28sept08 A4 SizeSyed IrtazaNo ratings yet

- Drill StringDocument25 pagesDrill StringsrikantaLeeNo ratings yet

- Stabilizer TypeDocument14 pagesStabilizer TypeAdin PraviMoški PartAdisNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Desgaste de BrocasDocument2 pagesDesgaste de Brocasjuliantobop181No ratings yet

- Introduction To Dull Bit Grading 1Document35 pagesIntroduction To Dull Bit Grading 1ToroboxNo ratings yet

- Dull Grading TriDocument15 pagesDull Grading TriCamilo SanchezNo ratings yet

- Iadc Bit GradingDocument1 pageIadc Bit GradingBilly WilsonNo ratings yet

- IADC Dull Bit GradingDocument1 pageIADC Dull Bit Gradinghmmbagodden100% (1)

- Forensic Ballistics (Weebly)Document17 pagesForensic Ballistics (Weebly)Randal's CaseNo ratings yet

- Suppressor Engineering 101Document6 pagesSuppressor Engineering 101Irma Knutt83% (6)

- The Real Benefits of Barrel FlutingDocument9 pagesThe Real Benefits of Barrel Flutingblowmeasshole1911No ratings yet

- Tri Star CatalogDocument7 pagesTri Star CatalogMarcelo M. GattiNo ratings yet

- PCP Air Rifles 2011Document15 pagesPCP Air Rifles 2011Rafael Baptista AlvesNo ratings yet

- Disclosure To Promote The Right To InformationDocument25 pagesDisclosure To Promote The Right To InformationztmpNo ratings yet

- Gun ComponentsDocument2 pagesGun ComponentsRomica SibisanNo ratings yet

- 2010 Browning CatalogDocument246 pages2010 Browning CatalogMario LopezNo ratings yet

- Bullet Design & PerformanceDocument12 pagesBullet Design & Performancej40bigzNo ratings yet

- Astm 510Document7 pagesAstm 510Arnold Bohorquez Acevedo100% (1)

- Merkel Sidebyside PDFDocument36 pagesMerkel Sidebyside PDFdannyjan5080No ratings yet

- About BuckshotDocument12 pagesAbout BuckshotpitasignupNo ratings yet

- Is Iso 6621 2 2003Document35 pagesIs Iso 6621 2 2003Selvaraji MuthuNo ratings yet

- Thickness GaugeDocument9 pagesThickness GaugeDGWNo ratings yet

- Ballistics ChartsDocument4 pagesBallistics ChartsMartin J.No ratings yet

- Applied Mechanics PDFDocument348 pagesApplied Mechanics PDFabdukadir442100% (1)

- This Page Is Basically An Illustrated Glossary of Cartridge Types. I Hope It Answers A Few Basic QuestionsDocument54 pagesThis Page Is Basically An Illustrated Glossary of Cartridge Types. I Hope It Answers A Few Basic QuestionsÁdám MajorNo ratings yet

- Pipe ScheduleDocument2 pagesPipe Scheduleriz2010No ratings yet

- Manual Horus ATrag-V36Document33 pagesManual Horus ATrag-V36Rodrigo Morales MorenoNo ratings yet

- Home Defender - Spring 2015Document132 pagesHome Defender - Spring 2015Seth Calkins100% (6)

- Ballistics GlossaryDocument9 pagesBallistics GlossaryAlfredo Dib100% (1)

- Wszystkie Kalibry BroniDocument8 pagesWszystkie Kalibry BroniandrzejzbagienNo ratings yet

- Hornady 2017 Product CatalogDocument132 pagesHornady 2017 Product CatalogPeter DavidsonNo ratings yet

- 2014-05-22 - Moneysaver - Lewis-Clark EditionDocument20 pages2014-05-22 - Moneysaver - Lewis-Clark EditionDavid ArndtNo ratings yet

- Building A Survival BatteryDocument12 pagesBuilding A Survival BatteryMax DemasiNo ratings yet

- Browning Hunting and Shooting 2011Document148 pagesBrowning Hunting and Shooting 2011Mario LopezNo ratings yet

- Winchester Select Over and Under Shotgun Owner's ManualDocument34 pagesWinchester Select Over and Under Shotgun Owner's Manualcarlosfanjul1No ratings yet

- 2013 Browning CatalogDocument292 pages2013 Browning CatalogMiljan MileticNo ratings yet

- .45-70 at Two Miles: The Sandy Hook Tests of 1879: by W. John FarquharsonDocument5 pages.45-70 at Two Miles: The Sandy Hook Tests of 1879: by W. John Farquharsonherciomoyses9420100% (1)