Professional Documents

Culture Documents

Reactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design Approach

Uploaded by

Kushagradhi DebnathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reactive Printing and Crease Resistance Finishing of Cotton Fabrics Part I - Study of Influential Factors by An Experimental Design Approach

Uploaded by

Kushagradhi DebnathCopyright:

Available Formats

Volume 7, Issue 1, Spring2011

Reactive Printing and Crease Resistance Finishing of Cotton Fabrics

Part I - Study of Influential Factors by an Experimental Design Approach

Fareha Asim

Department of Textile Engineering

NED University of Engineering & Technology

Karachi, Pakistan

Muzzaffar Mahmood

Department of Mechanical Engineering,

NED University of Engineering & Technology

Karachi, Pakistan

ABSTRACT

Experimental design is a standard statistical technique used to identify key factors and levels that

influence the process. In the present investigation, the factors affecting the combined operation of

reactive printing and crease resistance finishing was designed and analyzed using Design of

Experiment (DOE).The influence of individual factors and their interactions on color yield (k/s)

and Dry Crease Recovery Angle (DCR) has been critically examined using software Design

Expert 7.0.The results showed that apart from the influence of individual factors, the final color

yield and dry crease recovery angle also depended on the interaction effect of the factors. It has

been observed from present analysis that the predicted values are in good agreement with

experimental data, the correlation coefficients were found to 0.9802 & 0.9139

Keywords: DOE, Reactive Printing, Crease Resistance Finishing, k/s, DCR

Introduction refined rather than revolutionized. The same

global pressure that affects all textile

In this age of fuel and energy shortages, it is manufacturing also affects textile printers,

desirable to think of processes and requiring a higher speed and economic

formulations which would result in lowering production method. All these demands mean

fuel and energy consumptions. From time to that textile printers must be able to do right-

time immemorial man has been attempting the-first-time processing, just-in-time

to save time and energy. It is this urge that manufacturing, and a dramatic reduction in

has led the industrial development and has lead time [1-2]. Reports in literature reveal

shaped the technology to the present that simultaneous application of crease

advanced form. recovery finish and reactive dyeing has been

reviewed previously [3-7]. But few studies

Textile printing process remains firmly have been reported on combined reactive

rooted in traditional techniques and printing and crease resistance finishing of

technologies that are continually being cotton fabrics [8]. The present research work

Article Designation: Refereed 1 JTATM

Volume 7, Issue 1, Spring 2011

was undertaken with a view of studying the The reactive dyes used were Drimarine Red

factors influencing the final color yield (k/s) P2B and Drimarine Blue P-3RL. (Clariant).

and dry crease recovery angle (DCR) for Other chemicals used in this study were

combo process of reactive printing and CR commercially available thickener Lamitex

finishing. HP (sodium alginate), sodium bicarbonate,

urea, Reduction Inhibitor (Lyoprint RG) and

Experimental sodium hexa meta phosphate as a

sequestrant.

Materials

Methods

Fabric

Commercially singed, desized, scoured,

Print-finish paste manufacture

bleached and mercerized cotton fabric with

The stock paste was prepared according to

satin weave structure, 40x40s, 130 ends/inch

the following recipe: Urea 150g/kg, Lamitex

x73 picks/inch, and an area density of

HP (4%) 750 g/kg, sodium bi carbonate 30

approximately 136 g/m2 were used in this

g/kg, lyoprint RG 50 gm/kg and sodium

research work.

hexa meta phosphate 5 gm/kg. The stock

paste was adjusted to a constant viscosity of

Chemical and Colorants

65 dPa by adding the necessary amount of

The crease recovery finishing agent used

water. The printing pastes of two different

was Fixapert F-ECO (BASF), based on

levels were prepared with Drimarine P hue

dimethlodihydroxy ethylene urea

and chroma as outlined in Table 1.

(DMDHEU). Magnesium chloride MgCl2

was used to catalyze the CR finishing,

The CR finishing liquor was prepared by

Solusoft MW (Silicon softener), Ceranine-L

using Solusoft MW 20g/l, Ceranine-L 20g/l

(anionic softener) and Invadine PBN

and Invadine PBN 5g/l. the final finish bath

(Wetting Agent).

were prepared with Fixa pert F-ECO and

MgCl2 as outlined in Table 1.

Article Designation: Refereed 2 JTATM

Volume 7, Issue 1, Spring 2011

Print-finish Procedure Evaluation of Crease Recovery Angle

The combined process of reactive printing The print-finish fabrics were conditioned (at

and CR finishing was carried out as follows: temperature 251 C and relative humidity

In the first stage the fabric was immersed in 65 1%) before the measurement of easy-

an aqueous solution of CR finish, and then care properties imparted by the CR finish.

squeezed to obtain a 70% wet pickup. The The dry crease recovery angle (DCR) of the

wet fabric was then dried. fabric was measured using AATCC test

method 66-1990, using Shirley Crease

In the second stage the treated fabric was recovery tester. The wider the DCR is, the

printed by the lab scale Rotary Printing higher the crease recovery.

machine (Zimmer). The printed fabric was

again dried. Experiment design

In the third stage, the print-finish fabric was Two-level fractional factorial design was

fixed, and then washed according to used to explore the effect of different factors

washing-off procedure and finally dried. The namely: (i) hue, (ii) chroma, (iii)drying

preparation of finish bath, drying conditions, conditions, (iv) concentration of crease

printing recipe and fixation conditions were resistant, (v) concentration of catalyst, (vi)

employed in accordance with the fixation conditions on the combined reactive

experimental design arrangement as stated printing and crease resistance finishing. A

in Table 1 and 2. 26-1, two-level fractional factorial design of

32 trials with two repetitions were run

Evaluation of fabric properties according to the design matrix as shown in

Table 2. The experiments were performed in

Color yield measurement random order. The results were analyzed-

The printed fabrics were conditioned (at with the Minitab program package software

temperature 251 C and relative humidity (Minitab Inc.). The details of the

65 1%) before color yield measurement experimental design arrangement are shown

with a Tex-Flash spectrophotometer. The in Tables 1 and 2.

condition for measurement was set under

specular excluded with large aperture. The Results and Discussion

fabric was folded twice to ensure opacity.

The color yield (k/s value) was calculated After processing the experimental trials, the

for wavelengths 400-700nm at 20nm k/s and DCR curves of different trials were

intervals within the visible spectrum. The plotted and the sum of k/s and DCR values

k/s was calculated according to Eqn 1: of each trial were calculated with the help

of Minitab software, the dominant factors of

k/s = (1-R)2 / 2R (1) the combined print-finish process were

assessed using pareto charts, main effect

Where, k is the absorption coefficient, s is interactions and interaction plots of the six

the scattering coefficient and R is the different factors.

reflectance of the colored samples. The

higher the k/s value is, the greater the color

yield and dye uptake.

Article Designation: Refereed 3 JTATM

Volume 7, Issue 1, Spring 2011

Pareto Chart of effect to the upper position and the rest of

The dominant factor can be determined the effects, in descending order, to the lower

using a Pareto chart. A Pareto chart is position [9].

specialized version of a histogram that ranks

the categories in the chart from most The Pareto chart of the two response

frequent to least frequent. The construction variables k/s and DCR are shown in Figure

of the Pareto chart places the highest cause 1and 2.

Article Designation: Refereed 4 JTATM

Volume 7, Issue 1, Spring 2011

Main factors interaction plot process. The two dominant factors effecting

From the result shown in Figure 1, the the k/s and DCR is summarized in Table 3.

factors Chroma (B), Hue (A) and Fixation

Conditions (F) respectively were confirmed

as the major factors influencing the final

color yield of combined print-finish process.

The interaction of these factors with other

factors in affecting the final color yield

could be demonstrated in the main factors

interaction plot [9]. It was further confirmed

that increasing the chroma could enhance

the color yield, changing the hue would

change the k/s value depending on the level

of reflectance of the particular color, and

Fixation by means of Hot air could enhance

the color yield of combined print-finish

process. Furthermore, it also interacted with

one of the other factors to influence the final

color yield of combined print-finish process,

i.e. the two dominant factors interacting with

each other would also influence the final Interaction Plot

color yield. Similar to the Pareto plots and the

interaction of the main factors, the

From the result shown in Figure 2, the factor interaction calculations can be displayed

of Fixation Conditions (F) was confirmed graphically to measure the joint effect of

as the major factor influencing the crease two factors for k/s and DCR. The interaction

resistance of combined print-finish process. plots display the average at each of the

It was further confirmed that hot air fixation combinations of the two factors A and B [(-

gives higher DCR values. Furthermore, the ,-);(+,-);(-,+);(+,+)] using the B factor level

interaction of two factors would influence as the horizontal and the average as the

the DCR values of the combined print-finish vertical axis; the averages having the same

Article Designation: Refereed 5 JTATM

Volume 7, Issue 1, Spring 2011

level of A, i.e. [(-,-);(+,-);(-,+);(+,+)] are From the pareto chart Fig 1, Hue was found

joined by a line [9]. The interaction plots of to be the second most frequent factor when

k/s and DCR are shown in Figure 3 and compared with all the other factors for k/s.

Figure 4. The interaction effects between this implied that it was another dominant

different factors that affected the final color factor with respect to color yield. The

yield and Crease resistance of combined interaction plots of k/s showed that when the

print-finish fabrics were demonstrated in the Hue red used in the print paste, the color

interaction plots, and the results showed that yield of the printed fabrics was enhanced

different factors interacted with each other. correspondingly Figure 3(a). This is due to

the reason that hue Red gives reflection in

Assessment of the Significant Factors in broader region of spectrum than blue

Combo Process therefore increasing the k/s value.

Influence of Chroma on Combo Process Influence of Fixation Conditions on Combo

Chroma is the concentration of dye. It is a Process

measure of saturation associated with color; Fixation is the most important part of combo

degree of color purity; relative brightness of process, when the fabric is printed and

a hue when compared to another. Color finished through the combo process and

yield of the fabric is associated with the dried, the dye and finishing chemical is not

chroma value of dye. From the Pareto Chart actually transferred into the cloth, and only a

shown in Figure 1, Chroma was located at thin dried film of thickener containing the

the highest frequency when compared with dye and other chemicals were mechanically

all other factors in k/s. This implied that it deposited. The interaction plot of k/s and

was a dominant factor with respect to the DCR Figure 3(a) and 4(a) showed that the

color yield. final color yield and DCR of the combo

process attained the maximum k/s and DCR

The interaction plot of k/s Figure 3(a) at 180C-3min, Hot Air fixation but the

showed that the final color yield of the samples are slightly yellow and pale. The

combo process attained the maximum value reason behind that is the high temperature of

in case of high chroma of Reactive dye. This curing, which aids the concurrent fixation of

is due to the fact that more number of dye reactive dye and CR finish, but at the same

sites is available for covalent bonding in time causes the paling of shade and

high concentration of reactive dyes thus yellowing of fabric due to the scorching of

increasing the color yield of the fabric. cotton fiber. This indicates that Hot Air

Fixation with reduced temperature and

Influence of Hue on Combo Process increased time may be tested in further

Hue is the color of particular dye. Daylight experimental work of combined print-finish

(white light) is made up of numerous waves process to avoid this problem.

or impulses each having different

dimensions or wavelengths. When Assessment of the Significant Interactions

separated, any single wavelength will in Combo Process

produce a specific color impression to the

human eye. When light fall on fabric, the Influence of Hue and Chroma on Combo

dye absorbs certain waves and reflects Process

others, this determines the hue of the dye The interaction of Hue and chroma found to

.The light actually generates the color. What be significant in k/s model. In interaction

we see as color is the reflection of specific plot Figure 3(b) increasing the chroma from

wavelength of light rays from fabric. The 1% to 3% of red hue significantly increases

hue red means the chromophore of the dye the color yield but when compared with blue

reflects only red light and absorbs all other hue the increment is not that much

light. significant as in case of red hue. The reason

Article Designation: Refereed 6 JTATM

Volume 7, Issue 1, Spring 2011

behind this is the fact that blue is more decreased in hot air fixation. Such a drop in

sensitive than red, as its region of reflection color yield with respect to increased amount

is very small as compared to red. of crease resistant is due to an increase in

cross linking of crease resistant in curing

Influence of Chroma and fixation condition condition.

on Combo Process

The interaction of chroma and fixation Influence of Hue and Fixation Conditions on

condition found to be significant in k/s Combo Process

model. The interaction plot figure 3(c) The interaction is found to be significant in

showed at lower level of chroma changing k/s model. Both fixation condition showed

the fixation condition from steaming to same trend Figure 3(b) with respect to hue,

curing increases the color yield of combo irrespective of fixation condition color yield

process but at higher level of chroma this of red is higher than blue as justified earlier,

enhancement of color yield increase whereas in same hue curing provides higher

drastically. Such an increment in color yield color yield as compared to steaming.

is at higher level of chroma is a due to the

lower extent of reactive dye interaction with Influence of Conc. of CR Conc. of Catalyst

CR. on Combo Process

The interaction of Conc. of Crease resistant

Influence of Chroma and Conc. of catalyst and concentration of catalyst found to be

on Combo Process significant and crossed in both k/s and DCR

The interaction of chroma and concentration models Figure 3(e) & 4(e). When

of catalyst has been found to be significant concentration of CR is low, high

and crossed Figure 3(c) in k/s model. At low concentration of catalyst gives high k/s and

level of chroma, the low concentration of DCR, but when concentration of CR

catalyst provide high color yield, however increases the trend reversed. This is due to

when chroma increased to 3% the order the reason that there is a limiting point of

reversed, high concentration of catalyst give catalyst concentration, after which it will

high color yield. This is due to the reason quickly deactivates without performing its

that high level of catalyst of CR quickly task. In case of CR it is added as 15-25 % of

deactivates without accelerating the CR to CR, whereas limiting point is 30g/l. when

the fabric. As less number of CR linkages conc. of CR increases to 200 g/l the 25% of

are being formed with the cotton fiber, so CR is 50g/l which is > 30g/l. so the

more amount of reactive dye being fixed on concentration of catalyst should increased

the fabric thus increasing the k/s. till its limiting point i.e. 30g/l.

Influence of Conc. of CR and Fixation Influence of Chroma and Conc. of CR on

Conditions on Combo Process Combo Process

The interaction of concentration of CR and The interaction is found to be significant and

fixation condition found to be significant crossed in DCR model. When chroma of

and interesting in k/s model. In interaction reactive dye is low, high concentration of

plot Figure 3(e) when conc. of CR increases CR gives high DCR Figure 4(c) but as

from 100g/l to 200g/l in steaming mode of concentration of reactive dye increases the

fixation k/s increases. This is due to the fact trend reversed. This is due to the reason that

that cross linking of CR is not favorably reactive dye is highly reactive than CR. At

established in steaming environment instead high concentration of reactive dye it doesnt

the steaming aids the fixation of reactive allow the CR to fix on cotton.

dyes thats why color yield increases.

However In interaction plot Figure 3e when Influence of Drying Conditions and Conc. of

the concentration of crease resistant increase Catalyst on Combo Process

to 200g/l, the color yield of combo process

Article Designation: Refereed 7 JTATM

Volume 7, Issue 1, Spring 2011

The interaction is found to be significant and resistant with the fiber. Thus, an increase in

crossed in DCR model. When drying the dye concentration in the print paste may

condition is low i.e. 60C-7min, high make more dye molecules to be available for

concentration of catalyst gives high DCR, absorption for reaction with the cotton,

whereas when drying condition is high whilst the crease resistant finish will have a

100C-3min, the trend reversed Figure 4(d). less chance to be absorbed and cross-linked

The reason is that catalyst activates with with cotton. Thus, the need for a further

temperature when drying temperature experimental work is evident for fixing

increased to 100C, high concentration of concentration of reactive dyes with a

catalyst activates rapidly and without broader range of crease resistant finish.

performing its task deactivates. The drying

conditions should be optimized at 85C- Acknowledgements

5min.

We wish to express our sincere thanks to

Conclusions Gul Ahmed Textile Mills for providing their

laboratory facilities for this work.

Through an experimental design, it was

found that hue, chroma and fixation References

conditions had major contributions to the

final color yield and dry crease recovery [1] Judi Barton, International dyer, 189,

angle of combined print-finish process. September (2004) 20.

Based on the experimental design study, it

[2] Peter S. Collishaw, Roland Schamberger

was further confirmed that each factor had

and Jurgen Suss - Leonbardt,

an interaction effect with each other among

International dyer 191 October (2006).

them and with other remaining factors such

that the maximum color yield and dry crease [3] Yongchun Dong, Jijun Wang and

recovery angle were the combined effects of Pengfei Liu, Coloration Technology,

these factors. Properties of printed and 117 (2001) 262.

finished cotton fabrics were reasonably [4] Christian Schramm, Sandra Bischof

satisfactory when the treatment conditions Vukusic and Drago Katovic, Coloration

were appropriately adjusted. One important Technology 118 (2002) 244

finding was from this experimental was that

Concentration of Crease Resistant was not [5] M. RAHEEL, C. GUO, G. X. DAI

identified as a significant factor for dry http://www.kotonline.com/english_page

crease recovery angle. It is possible that the s/ana_basliklar/raheel.asp

reactive dye fixation on the cotton fiber [6] Arijit Chakarborty and Chakradhar

competes with the cross linking of crease

Article Designation: Refereed 8 JTATM

Volume 7, Issue 1, Spring 2011

Article Designation: Refereed 9 JTATM

Volume 7, Issue 1, Spring 2011

Article Designation: Refereed 10 JTATM

Volume 7, Issue 1, Spring 2011

You might also like

- Salt Free DyeingDocument18 pagesSalt Free DyeingSakthivel Jegarajan100% (1)

- Multifunctional Finishing of Cotton FabricDocument10 pagesMultifunctional Finishing of Cotton FabricJaime GomezNo ratings yet

- Inkjet Printing of Linen Fabrics Pretreated With Atmospheric Plasma and Various Print PastesDocument6 pagesInkjet Printing of Linen Fabrics Pretreated With Atmospheric Plasma and Various Print Pastesamin sarliNo ratings yet

- Eco-Friendly Dyeing of Viscose Fabric With Reactive DyesDocument13 pagesEco-Friendly Dyeing of Viscose Fabric With Reactive DyesIAEME PublicationNo ratings yet

- IJETR031342Document5 pagesIJETR031342erpublicationNo ratings yet

- Imran 2016Document7 pagesImran 2016Awais ImranNo ratings yet

- Dyes and Pigments: Mohammad Nazmul Karim, Muriel Rigout, Stephen G. Yeates, Chris CarrDocument7 pagesDyes and Pigments: Mohammad Nazmul Karim, Muriel Rigout, Stephen G. Yeates, Chris Carrjakariya nugrahaNo ratings yet

- Investigation of Performance Properties of Graphene Coated FabricsDocument6 pagesInvestigation of Performance Properties of Graphene Coated FabricsIjmret JournalNo ratings yet

- A Comparative Studies of Physio Chemical Properties of Linen Yarn Dyed Fabric Dyed With Reactive & Vat DyeDocument7 pagesA Comparative Studies of Physio Chemical Properties of Linen Yarn Dyed Fabric Dyed With Reactive & Vat DyeInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Polydadmac Treatment On Cotton For Improving Printing With Reactive Dye - 50783Document5 pagesPolydadmac Treatment On Cotton For Improving Printing With Reactive Dye - 50783dwidhaNo ratings yet

- A Single Stage Preparatory Process For Woven Cotton Fabric and Its OptimizationDocument13 pagesA Single Stage Preparatory Process For Woven Cotton Fabric and Its OptimizationMaria TitiNo ratings yet

- Effects of Printing With Different Thick PDFDocument6 pagesEffects of Printing With Different Thick PDFAbel AbrhamNo ratings yet

- Process Modification in The Scouring Process of Textile IndustryDocument7 pagesProcess Modification in The Scouring Process of Textile IndustryGizem D.No ratings yet

- Statistical Analysis of Expanded Graphite-Decorated Cobalt Ferrite As Adsorbent For Removal of Congo Red Dye Using Response Surface MethodologyDocument8 pagesStatistical Analysis of Expanded Graphite-Decorated Cobalt Ferrite As Adsorbent For Removal of Congo Red Dye Using Response Surface MethodologyBrahma Hakim Yuanda HutabaratNo ratings yet

- Reactive Dye Printing On Cotton With Natural and Synthetic Thickeners - 23 PDFDocument3 pagesReactive Dye Printing On Cotton With Natural and Synthetic Thickeners - 23 PDFHrishikesh DhawadshikarNo ratings yet

- InkJet Printing PDFDocument9 pagesInkJet Printing PDFNagaraj Goud IreniNo ratings yet

- Reduction Clearing of Simulated Disperse Dyed PLA Fabrics and Their Tensile PropertiesDocument7 pagesReduction Clearing of Simulated Disperse Dyed PLA Fabrics and Their Tensile PropertiesHammad JawaidNo ratings yet

- AATCCpaper 16Document7 pagesAATCCpaper 16Abhay SontakkeNo ratings yet

- 1 s2.0 S1877705814029592 MainDocument7 pages1 s2.0 S1877705814029592 MainFinoana niainaNo ratings yet

- Preparation of Activated Carbon From Date Seeds and Evaluation of It Application A Review PaperDocument7 pagesPreparation of Activated Carbon From Date Seeds and Evaluation of It Application A Review PaperMD RashidNo ratings yet

- 3 - 01 - 11 Salt FreeDocument4 pages3 - 01 - 11 Salt FreeAaria Jayaraj AnishNo ratings yet

- Experimentation and Optimization of Sugar Cane Bagasse (SCB) Dust Reinforced Epoxy Based CompositeDocument10 pagesExperimentation and Optimization of Sugar Cane Bagasse (SCB) Dust Reinforced Epoxy Based CompositeIJAMTESNo ratings yet

- Shin2015Document9 pagesShin2015Riston SinagaNo ratings yet

- Inkjet Printing Effects of Pigment Inks On Silk Fabrics Surface-Modified With O PlasmaDocument7 pagesInkjet Printing Effects of Pigment Inks On Silk Fabrics Surface-Modified With O Plasmaamin sarliNo ratings yet

- Factors Affecting The Functional-And Comfort-Related Properties of Reactive Dyed Cotton KnitsDocument16 pagesFactors Affecting The Functional-And Comfort-Related Properties of Reactive Dyed Cotton KnitsTamer Farouk KhalifaNo ratings yet

- Smart Breathable Fabric: N S. S, M J A K. ADocument17 pagesSmart Breathable Fabric: N S. S, M J A K. AhawNo ratings yet

- 19.05.22 Master Thesis Graphene Group Presentation ValeriuDocument26 pages19.05.22 Master Thesis Graphene Group Presentation ValeriuErickCartman069No ratings yet

- Effects of Peroxide and Gamma Radiation PDFDocument10 pagesEffects of Peroxide and Gamma Radiation PDFFocuNo ratings yet

- ONE BATH and Two BathDocument11 pagesONE BATH and Two Bathwman6914No ratings yet

- 06 - 05 - 10 Characteristics of Knitted Fabrics After Enzyme TreatmentDocument10 pages06 - 05 - 10 Characteristics of Knitted Fabrics After Enzyme Treatmentleosun halariNo ratings yet

- Effects of Warp-Weft Density Variation & Fabric Porosity of Cotton Fabrics On Their Colour in Reactive DyeingDocument5 pagesEffects of Warp-Weft Density Variation & Fabric Porosity of Cotton Fabrics On Their Colour in Reactive DyeingRezaul Karim TutulNo ratings yet

- Enhancing Textile Ink-Jet Printing With Chitosan: Cwmyuen, Skaku, Cwkan AndpsrchoiDocument4 pagesEnhancing Textile Ink-Jet Printing With Chitosan: Cwmyuen, Skaku, Cwkan Andpsrchoiamin sarliNo ratings yet

- Dyeing of Cotton Fabric With Pigment ColourDocument15 pagesDyeing of Cotton Fabric With Pigment ColourHemant SinglaNo ratings yet

- Jurnal Kertas Dari Pelepah PisangDocument11 pagesJurnal Kertas Dari Pelepah PisangYogi IrawanNo ratings yet

- Artigo Isap FinalDocument8 pagesArtigo Isap FinalJorge Luiz Oliveira Lucas JuniorNo ratings yet

- Preparation of Electrospun Affinity Membrane and Cross Flow System For Dynamic Removal of Anionic Dye From Colored WastewaterDocument13 pagesPreparation of Electrospun Affinity Membrane and Cross Flow System For Dynamic Removal of Anionic Dye From Colored WastewaterManu SharmaNo ratings yet

- Cat IonizerDocument6 pagesCat IonizerAnonymous 5HRD46hNo ratings yet

- Surfaces and Interfaces: SciencedirectDocument9 pagesSurfaces and Interfaces: SciencedirectygNo ratings yet

- Salt and Alkali Free Reactive Dyeing On Cotton Fabric (Part-2) - Textile LearnerDocument15 pagesSalt and Alkali Free Reactive Dyeing On Cotton Fabric (Part-2) - Textile LearnerAnas ZidaneNo ratings yet

- Efficiency of Plasma Onto Denim Faded GarmentsDocument7 pagesEfficiency of Plasma Onto Denim Faded GarmentsijsretNo ratings yet

- Study Nanocomposites by AFM TechniqueDocument43 pagesStudy Nanocomposites by AFM TechniqueHong Nguyen 눈 꽃No ratings yet

- MATERIALDocument260 pagesMATERIALVERMADEENNo ratings yet

- The Influence of Pigment Volume Concentration (PVC)Document6 pagesThe Influence of Pigment Volume Concentration (PVC)chemsiton100% (1)

- 2008 - A Membrane-Based Co-Treatment Strategy For The Recovery of Print - and Beck-Dyeing Textile EffluentsDocument8 pages2008 - A Membrane-Based Co-Treatment Strategy For The Recovery of Print - and Beck-Dyeing Textile EffluentsClaudio CastroNo ratings yet

- Coloration Technology - 2009 - Clark - Modified 2 4 Difluoro 5 Chloro Pyrimidine Dyes and Their Application in Ink JetDocument7 pagesColoration Technology - 2009 - Clark - Modified 2 4 Difluoro 5 Chloro Pyrimidine Dyes and Their Application in Ink JetGhatas AwadNo ratings yet

- Micromachines 11 00104Document14 pagesMicromachines 11 00104Gorkem GorkemNo ratings yet

- 14.isca RJCS 2012 171Document11 pages14.isca RJCS 2012 171Ahmad SamerNo ratings yet

- Foundations of Textiles II Lab Manual 2022Document19 pagesFoundations of Textiles II Lab Manual 2022viovio7012No ratings yet

- Diffusion of Plasticizer in A Solid Propellant Based On Hydroxyl Terminated PolybutadieneDocument5 pagesDiffusion of Plasticizer in A Solid Propellant Based On Hydroxyl Terminated PolybutadieneJohnny Di SantoNo ratings yet

- Laser Surface Preparation For Adhesive Bonding of Aerospace Structural CompositesDocument8 pagesLaser Surface Preparation For Adhesive Bonding of Aerospace Structural CompositesManojmsvssc KaravoorNo ratings yet

- Experimental Evaluation and Simulation of Volumetric Shrinkage and Warpage On Polymeric Composite Reinforced With Short Natural FibersDocument7 pagesExperimental Evaluation and Simulation of Volumetric Shrinkage and Warpage On Polymeric Composite Reinforced With Short Natural FibersClynoesNo ratings yet

- 18-Recycling of Fly Ash For Development of Value Added ProductsDocument9 pages18-Recycling of Fly Ash For Development of Value Added ProductsAli SherNo ratings yet

- Advanced Approach For Trichromy FormulatDocument9 pagesAdvanced Approach For Trichromy FormulatSajjad Haider ShiraziNo ratings yet

- Verma 2018Document8 pagesVerma 2018Tri Muhammad EkoNo ratings yet

- Effect of Parafin Wax On MixingDocument11 pagesEffect of Parafin Wax On MixingHriday BhowmikNo ratings yet

- Coatings 13 01129Document11 pagesCoatings 13 01129shivangi saxenaNo ratings yet

- Paper 1Document9 pagesPaper 1Jǝ Ǝʌan M CNo ratings yet

- Thermodynamic and Kinetic Parameters of Polyester Dyeing With Disperse Blue 56 Using Bio-Based Auxiliaries and Co-Solvent MicroemulsionDocument14 pagesThermodynamic and Kinetic Parameters of Polyester Dyeing With Disperse Blue 56 Using Bio-Based Auxiliaries and Co-Solvent MicroemulsionAmi SaNo ratings yet

- Handbook of Renewable Materials for Coloration and FinishingFrom EverandHandbook of Renewable Materials for Coloration and FinishingMohd YusufNo ratings yet

- Catalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationDocument21 pagesCatalyzation of Alkaline Hydrolysis of Polyester by Oxidizing Agents For Surface ModificationKushagradhi DebnathNo ratings yet

- UNIQEMA HypermerPolymericSurfactantsDocument2 pagesUNIQEMA HypermerPolymericSurfactantsKushagradhi DebnathNo ratings yet

- Barco Projection SystemDocument7 pagesBarco Projection SystemKushagradhi DebnathNo ratings yet

- The Impact of 'Zero' Coming Into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurDocument23 pagesThe Impact of 'Zero' Coming Into Fashion: Zero Liquid Discharge Uptake and Socio-Technical Transitions in TirupurKushagradhi DebnathNo ratings yet

- British BS 5867 Part 2 Type B and C PDFDocument1 pageBritish BS 5867 Part 2 Type B and C PDFKushagradhi Debnath100% (1)

- ISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterDocument1 pageISO 105-E01:2013 Textiles - Tests For Colour Fastness - Part E01: Colour Fastness To WaterKushagradhi DebnathNo ratings yet

- Hydrosulfite Types: Technical InformationDocument8 pagesHydrosulfite Types: Technical InformationKushagradhi DebnathNo ratings yet

- Taiwan K.K. Corp: Technical Data SheetDocument2 pagesTaiwan K.K. Corp: Technical Data SheetKushagradhi DebnathNo ratings yet

- The+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Document1 pageThe+Sequestering+Properties+of+Copolymer+Containing+Acrylic+Acid+Derivatives 최민배 (공개)Kushagradhi DebnathNo ratings yet

- Chemours Capstone For Textiles K25183-1Document1 pageChemours Capstone For Textiles K25183-1Kushagradhi DebnathNo ratings yet

- Synthesis and Application of Cationic SoDocument5 pagesSynthesis and Application of Cationic SoKushagradhi DebnathNo ratings yet

- No Vo GADocument2 pagesNo Vo GAlongthNo ratings yet

- Calculation of Dyeing Recipe Calculation For Dyeing LabDocument3 pagesCalculation of Dyeing Recipe Calculation For Dyeing LabKushagradhi DebnathNo ratings yet

- GOTS 3.0-4.0 Positive List 1Document8 pagesGOTS 3.0-4.0 Positive List 1Kushagradhi DebnathNo ratings yet

- Evaluation of DetergentsDocument14 pagesEvaluation of DetergentsKushagradhi DebnathNo ratings yet

- Basosoft N-Ap: Technical InformationDocument7 pagesBasosoft N-Ap: Technical InformationKushagradhi DebnathNo ratings yet

- Process Chemicals ViswaatDocument6 pagesProcess Chemicals ViswaatKushagradhi DebnathNo ratings yet

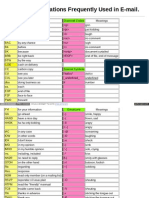

- A List of Abbreviations Frequently Used in E-Mail.: ItalicsDocument3 pagesA List of Abbreviations Frequently Used in E-Mail.: ItalicsKushagradhi DebnathNo ratings yet

- Problems and Aspects of Natural DyesDocument8 pagesProblems and Aspects of Natural DyesKushagradhi Debnath100% (1)

- HeiQ Product Range 2014-03-25Document37 pagesHeiQ Product Range 2014-03-25Kushagradhi Debnath100% (1)

- Phosphate EstersDocument4 pagesPhosphate EstersKushagradhi DebnathNo ratings yet

- Dwarkesh Enterprise: Properties of GREEN, VIOLET & BLUE PigmentsDocument1 pageDwarkesh Enterprise: Properties of GREEN, VIOLET & BLUE PigmentsKushagradhi DebnathNo ratings yet

- Project Title: Hotel Management Software Project: PurposeDocument3 pagesProject Title: Hotel Management Software Project: PurposesuryaNo ratings yet

- Gate Ee 1991Document7 pagesGate Ee 1991Bhavani Chandra UniqueNo ratings yet

- Key Features Boilermaker Proven, Legendary ReliabilityDocument2 pagesKey Features Boilermaker Proven, Legendary ReliabilityManuel Cantoral CortazarNo ratings yet

- Advanced Techniques in Power System Protective Relaying PDFDocument332 pagesAdvanced Techniques in Power System Protective Relaying PDFshashikant yadavNo ratings yet

- EN 61000 3-2 GuideDocument19 pagesEN 61000 3-2 Guideyunus emre KılınçNo ratings yet

- Speaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadDocument38 pagesSpeaker Bio - : Anupam Shil Is Working With STP Limited As SBU HeadRainakNo ratings yet

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocument18 pagesToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiNo ratings yet

- SAX Brochure - Web ReadyDocument4 pagesSAX Brochure - Web ReadyEng-Ahmad Abo-AledousNo ratings yet

- IMDSDocument13 pagesIMDSJohn OoNo ratings yet

- Citrix Xenserver ® 6.0.2 Emergency Network Reset: Published Wednesday, 29 February 2012 1.0 EditionDocument6 pagesCitrix Xenserver ® 6.0.2 Emergency Network Reset: Published Wednesday, 29 February 2012 1.0 EditionJuan CarlosNo ratings yet

- 101.S-4501 Steamer Cyclone Cleaning ProcedureDocument6 pages101.S-4501 Steamer Cyclone Cleaning ProcedureTRONGKIMNo ratings yet

- AY 2015-16cvbbnjDocument245 pagesAY 2015-16cvbbnjSyed Abdul AzizNo ratings yet

- Griet DSP ProgramsDocument14 pagesGriet DSP ProgramsJaipaul CheernamNo ratings yet

- Practical Considerations For The Use of A Howland Current SourceDocument4 pagesPractical Considerations For The Use of A Howland Current SourceRamiShaabannnnNo ratings yet

- PDFDocument255 pagesPDFwrite2arshad_mNo ratings yet

- Precision r5500 Service Manual en UsDocument104 pagesPrecision r5500 Service Manual en UsJonDyson32No ratings yet

- 2015 VGP Checklist - Rev0Document9 pages2015 VGP Checklist - Rev0Takis RappasNo ratings yet

- Oracle Exadata Technical Series: Smart ScanDocument59 pagesOracle Exadata Technical Series: Smart ScanVishnusivathej PotukanumaNo ratings yet

- Powerware 5110 UPS User's ManualDocument14 pagesPowerware 5110 UPS User's ManualjulbfuNo ratings yet

- 9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PDocument6 pages9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PttussenoNo ratings yet

- Banda Hoja de DatosDocument1 pageBanda Hoja de DatosSergio Guevara MenaNo ratings yet

- Uponor Dop Klett CPR 20 Ic 251 V 001Document3 pagesUponor Dop Klett CPR 20 Ic 251 V 001jamppajoo2No ratings yet

- CSC 263Document108 pagesCSC 263osecaloNo ratings yet

- Basic Electronics - AC - DC PDFDocument20 pagesBasic Electronics - AC - DC PDFRowena ResurreccionNo ratings yet

- Home,: A Solace To Which A Journey Is Never Too Long..Document25 pagesHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyNo ratings yet

- ThaiREC Checklist-Barge Inspection Questionnaire GasDocument18 pagesThaiREC Checklist-Barge Inspection Questionnaire Gasเปีย วันชัย สวนทอง100% (1)

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationDocument3 pagesPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesNo ratings yet

- Know It BrochureDocument8 pagesKnow It BrochureSonali SinhaNo ratings yet

- M S 1 1 - M S E 1 1: Hydraulic MotorsDocument36 pagesM S 1 1 - M S E 1 1: Hydraulic MotorsmehmetNo ratings yet

- Data SheetDocument2 pagesData SheetAsalamEilujNo ratings yet