Professional Documents

Culture Documents

ACE-VCA Airport Operations Methodology

Uploaded by

Tim Lin0 ratings0% found this document useful (0 votes)

63 views6 pagesACE-VCA Airport Operations Methodology

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentACE-VCA Airport Operations Methodology

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

63 views6 pagesACE-VCA Airport Operations Methodology

Uploaded by

Tim LinACE-VCA Airport Operations Methodology

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

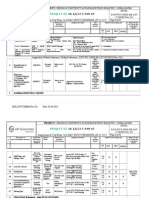

ACE/VCA SPECIFICATION GENERAL AIRPORT WORKS OPERATIONS

Scope: Slab Replacement works including saw cutting, drilling for lifting plates, demolition,

subgrade removal, dowel pin drilling, dowel pin placing, concrete production, placement

and finishing are performed to a minimum VCA/ACE requirement enabling the CTS Rapid Set

Concrete (CTS RSC) the opportunity to perform to its design capability and as per the works

Specification.

Sydney Airport Bay 84/85

Conditions: -

A. ACE/VCA minimum slab thickness for Airport slabs 500mm, Road Pavement slabs

200mm and Lean Mix Concrete Subgrade improvement 100mm.

B. All Volumetric Mixers approved and calibrated prior to any works project beginning.

C. All Aggregates and Sand to comply with AS 1289.1 and tested by NATA Accredited

Laboratory.

D. Concrete testing to be performed by NATA Accredited Laboratory.

E. Subgrade testing to be performed by NATA Accredited Laboratory.

F. All Raw Materials including CTS Rapid Set Cement, Aggregates, Sand and Admixtures

to be pre-loaded in Volumetric Mixers at the Melbourne Airport approved

Holding/Stabling yard.

G. All CTS Rapid Set slab replacement Operators to be Trained, Certified and approved

by CTS.

H. All CTS operations to be under supervision of ACE/VCA personnel.

I. All works to be monitored by APAM Superintendant.

J. ACE/VCA Works Supervisors/Leading Hands may direct duplicate work sections.

K. The weather will be monitored in conjunction with the works Superintendant. Any

delays/cancellations will be jointly agreed as per the specification requirements

L. Slab size, approximately 35m to 40m per slab/shift will be available via a minimum

of 6 x 7m capacity Volumetric Mixers.

M. Tool box meetings will be performed prior to every shift beginning. Appropriate

records will be available.

N. Refer ACE/VCA Programming timeline.

O. Lifting Plate plan to be detailed during drilling operations.

VCA/ACE October 2012 Page 1 of 6

1.0 Saw Cutting and lifting plates drilling: - (see conditions I, K and N)

1.1 Saw Cutting and drilling supervisor to direct operations. (See condition J)

1.2 Saw cutting operations, lifting plate drilling and locating operations are

performed in the scheduled work shifts prior to the slab removal and replacement

process beginning.

1.3 A sawing plan is prepared and adhered to taking into account the length, breadth

and width of the slab to be demolished calculating the mass of each section to be

raised. Note; lifting equipment rating to be considered when designing saw cut

pattern and size of sections for removal.

1.4 Locations of all numbered lifting plates to be recorded on a plan for easy

attachment during lifting process. (See condition O)

Pre-drilling lifting plates Saw cutting

2.0 Demolition / Lifting of slab sections: - (see conditions I, K, M and N)

2.1 Slab removal/replacement Supervisor to direct operations. (See condition J)

2.2 Lifting Equipment including chains, slings and machinery to be rated as per the

appropriate Australian Standard.

2.3 Lifting plates to be located as per plan from drilling operation. (See condition O)

2.4 Removed slabs to be placed into bins / tip trucks for removal to holding yard

(Hub) for disposal to a licensed facility.

Lifting slab sections Attaching Chains prior to lifting

3.0 Subgrade Removal /Compaction / Improvement: - (See conditions A, I, K, M and N)

3.1 Slab removal/replacement Supervisor to direct operations. (See condition J)

3.2 Subgrade to be inspected by APAM Representative for determining the amount

to be removed compacted or improved with CTS Rapid Set Lean Mix. Note: DCP

testing to be performed to determine existing subgrade suitability with results

logged for the site superintendant. (See conditions A and E)

3.3 If excavation of Subgrade material to accommodate new slab depth is required

compaction method of the subgrade as determined by Works Specification.

VCA/ACE October 2012 Page 2 of 6

3.4 All excavated subgrade material to be taken from site in bin / tip truck and

deposited at the Hub and classified prior to disposal off site to an appropriate

registered facility.

3.5 Subgrade Improvement if required will be with CTS Rapid Set Concrete Lean Mix,

minimum 100mm depth. (See condition A)

3.6 Minimum requirement rework to the existing subgrade by loosening top 100mm

and recompaction.

Levelling subgrade Subgrade removal and compaction

4.0 Dowel Pin Drilling / Placement: - (See conditions I, K, M and N)

4.1 Slab removal/replacement Supervisor to direct operations. (See condition J)

4.2 Spacing () of dowel holes to be located as per Specification.

4.3 Minnich Operator to be fully instructed on locations and drill depths prior to

commencement of drilling.

4.4 Minnich Dowel Pin, minimum 2 Gang Drill, 6 drill steels and 6 drill bits available

as a minimum on site.

4.5 Operator must be fully trained in the equipment use and capable of setting up

the equipment prior to start. (See condition G)

4.6 Drilling operation to be continuous until all holes drilled.

4.7 Placement of Dowel Pins as per specification and to be performed as Dowel hole

drilling is performed.

Dowel hole drilling Completed Dowel pin placement

5.0 CTS Rapid Set Concrete Production /Placement / Finishing: - (See conditions A, I, K,

M and N)

5.1 CTS Rapid Set Concrete Supervisor to direct operations. (See condition J)

5.2 All Volumetric Mixers used on the project will be calibrated prior to

commencement of works at the ACE/VCA facility. (See special condition B)

5.3 All raw materials required for CTS Rapid Set Concrete manufacture will be

organised by the day shift Supervisor and on site in time to enable all necessary

equipment to be ready to move Airside at the scheduled time. (See condition C)

VCA/ACE October 2012 Page 3 of 6

5.4 The quantity of raw materials required for the shift to be on site prior to works

commencement. All loading and priming operations to be completed prior to

Volumetric Mixers moving Airside. (See conditions B, F and C)

5.5 Volumetric Mixers will be set up as per calibration requirements, ready to

produce according to time line requirements. (See conditions B and F)

5.6 All Volumetric Mixers will be loaded and primed (ready to produce) prior to going

airside. (See conditions B, C and F)

5.7 The number of Volumetric Mixers to be used will be dependent on the quantity

of CTS Rapid Set Concrete required for the shift. (See condition L)

5.8 CTS Rapid Set Concrete production will commence after all demolition, subgrade

testing and preparation and dowel pin works are completed with appropriate

approval from the site superintendant as per the works Specification.

5.9 All concrete placing and finishing tools to be prepared and in place prior to CTS

Rapid Set Concrete production. Only VCA certified placing and finishing tools to be

used. Mechanical roller screed to be used in all applications. (See conditions G and

H)

5.10 Concrete crew to be instructed of duties prior to start of Concrete placement

operations. (See conditions G and M)

5.11 CTS Rapid Set Concrete production will be a continuous process until entire slab

area is placed. (See condition L)

5.12 Finishing as per specification will be commenced as initial set of the CTS Rapid

Set Concrete takes place. No attempt to finish after final set is reached to take place.

5.13 Water curing will commence as soon as the CTS Rapid Set Concrete is deemed

ready by the Concrete Supervisor and will be maintained as a minimum until the

curfew period is completed. If required by the Superintendant, the slab area will be

covered as per specification.

5.14 CTS Rapid Set concrete testing will be as per Specification and sampled and

tested according to Australian Standards. (See condition D)

Raw materials on site Volumetric Mixers prepared

Concreting equipment readied Concrete placement

VCA/ACE October 2012 Page 4 of 6

Initial Finishing Final texturing

Final Texturing Water curing

6.0 Site Cleanup and Demobilisation: - (See conditions I, K and N)

6.1 Site cleanup is to be a continuous process throughout the works. All labour will

be instructed in the requirements prior to works commencing. A Vacuum truck will

be part of the equipment on site providing a continuous service. (See conditions J

and M)

6.2 Demobilisation of equipment will occur as soon as equipment is not required on

site.

Site cleanup Demobilisation of equipment

7.0 Hand over to client: - (See conditions I, K and N)

7.1 Hand over to client will occur as soon as the CTS Rapid Set Concrete is water

cured to the satisfaction of ACE/VCA, Airfield Operations and Airport representative.

VCA/ACE October 2012 Page 5 of 6

Handover

Notes:

All information provided is general ACE/VCA scope for Airport works. Appropriate changes

allowing for Specification details are to be considered when editing document for specific

Airport Project Works.

VCA/ACE October 2012 Page 6 of 6

You might also like

- Ktherm Project Specification FINALDocument26 pagesKtherm Project Specification FINALhenryNo ratings yet

- Section 09260Document60 pagesSection 09260y2kareinNo ratings yet

- Gibe 2 Camp ESIA Draft Report SummaryDocument98 pagesGibe 2 Camp ESIA Draft Report SummaryWeldayNo ratings yet

- Building ManagementDocument16 pagesBuilding ManagementDaltonWongNo ratings yet

- New Airport ReportDocument743 pagesNew Airport Reportrgovindan123No ratings yet

- Preliminary Quality Assurance/Quality Control Plan: Mohawk Solar ProjectDocument4 pagesPreliminary Quality Assurance/Quality Control Plan: Mohawk Solar Project无时差No ratings yet

- Part E - Proceedings Articles Theme 4 - Mechanical, Manufactuirng and Industrial Engineering - FinalDocument196 pagesPart E - Proceedings Articles Theme 4 - Mechanical, Manufactuirng and Industrial Engineering - FinalCEG BangladeshNo ratings yet

- Method Statement For Bored Pile at Rb013: Jalan Air Kuning - Banir (CH 229.424)Document14 pagesMethod Statement For Bored Pile at Rb013: Jalan Air Kuning - Banir (CH 229.424)MAYMODERN STEELNo ratings yet

- Sprinkler Tapping Method of StatementDocument1 pageSprinkler Tapping Method of StatementRaymond ZuYang HngNo ratings yet

- DUR Annual Report EnglishDocument70 pagesDUR Annual Report EnglishAbdullazizMansourNo ratings yet

- Site Investigation Land Survey Installation of BenchmarkDocument17 pagesSite Investigation Land Survey Installation of BenchmarkAnonymous ze9ag1No ratings yet

- 11 - Method of Statement For Stub Angle InstallationDocument10 pages11 - Method of Statement For Stub Angle InstallationiloveumakkahNo ratings yet

- Heathrow Airport Case Study NewDocument9 pagesHeathrow Airport Case Study NewUsama Ahmed100% (1)

- Midal Cables Method StatementDocument13 pagesMidal Cables Method StatementRICHARD FUNUENo ratings yet

- Civil Final 2020Document35 pagesCivil Final 2020Shakil KhanNo ratings yet

- Airport Construction Influencing FactorsDocument4 pagesAirport Construction Influencing FactorsIbrahim AdelNo ratings yet

- 01 50 00 - Construction Facilities and Temporary ControlsDocument23 pages01 50 00 - Construction Facilities and Temporary ControlsshauhramNo ratings yet

- Upgrade Pollution Control Facilities Port Harcourt, Mosimi, Atlas CoveDocument10 pagesUpgrade Pollution Control Facilities Port Harcourt, Mosimi, Atlas Coveajie denzelNo ratings yet

- Approach, Methodology and Work Plan for Ethiopia-Djibouti Railway O&MDocument186 pagesApproach, Methodology and Work Plan for Ethiopia-Djibouti Railway O&MFNo ratings yet

- Development in Mechanical WorkDocument26 pagesDevelopment in Mechanical WorkZameer AhmedNo ratings yet

- EXW-P015-0000-QM-LNT-IT-00066 Rev CADocument4 pagesEXW-P015-0000-QM-LNT-IT-00066 Rev CAbinunalukandamNo ratings yet

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)Document11 pagesMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)MAYMODERN STEELNo ratings yet

- Kingzip Installation GuideDocument44 pagesKingzip Installation GuideBuster73108No ratings yet

- Section 017700 - Closeout ProceduresDocument5 pagesSection 017700 - Closeout ProceduresChase GietterNo ratings yet

- Site Management and OrganizationDocument8 pagesSite Management and OrganizationCarlos Ramos GuerraNo ratings yet

- Method Statement Glass Works Roads - FDocument9 pagesMethod Statement Glass Works Roads - FsolebNo ratings yet

- Method Statement Installation of Air Handling UntDocument6 pagesMethod Statement Installation of Air Handling UntkouarNo ratings yet

- Airport Engineering 3 TaxiwayDocument17 pagesAirport Engineering 3 Taxiwayraghav VarmaNo ratings yet

- Contract No: Ocm-471: Delhi Metro Rail Corporation LTDDocument9 pagesContract No: Ocm-471: Delhi Metro Rail Corporation LTDprakash iyerNo ratings yet

- Ms Block WorksDocument3 pagesMs Block WorksjaladeepNo ratings yet

- KHNKJH NCP 30 1Document31 pagesKHNKJH NCP 30 1djsouravNo ratings yet

- Aberra Bekele ThesisDocument147 pagesAberra Bekele Thesisdanielalemayehu100% (2)

- Unops PDFDocument5 pagesUnops PDFlay86No ratings yet

- Modern Concrete Formwork SystemsDocument16 pagesModern Concrete Formwork SystemsABHIJEET DHOBALENo ratings yet

- Safe bikes - Operators wearing helmetsDocument6 pagesSafe bikes - Operators wearing helmetsZeljkoNo ratings yet

- PMC - POS Split Scope of WorkDocument10 pagesPMC - POS Split Scope of Workgigiphi100% (1)

- Quality Assurance and Quality Control PlanDocument6 pagesQuality Assurance and Quality Control PlanTia KurniawatiNo ratings yet

- Bedding & Back Filling SpecificationDocument3 pagesBedding & Back Filling SpecificationMohammed Asimuddin Farooqui100% (1)

- P4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCDocument19 pagesP4586-CPC-WEC-PJ-MS-0004 Method Statement For Installation of HDPE Work Apron ABCLahiru IndrajithNo ratings yet

- Noi Bai International Airport Terminal 2 ConstructionDocument2 pagesNoi Bai International Airport Terminal 2 ConstructionManh TuNo ratings yet

- As-Built Draughting Method StatementDocument6 pagesAs-Built Draughting Method StatementMichaelChiwuezeNo ratings yet

- Fcu Method StatementDocument3 pagesFcu Method StatementBalajiNo ratings yet

- TEC-312319 - MET-DoR-004 (Method Statement For Dewatering Works For A 6 Mts Basement) (K)Document9 pagesTEC-312319 - MET-DoR-004 (Method Statement For Dewatering Works For A 6 Mts Basement) (K)Hebatallah Reda El-desouqiNo ratings yet

- Annex 10, V-I, Radio Nav Aids, Amendment 84 of Nov 19, 2009Document184 pagesAnnex 10, V-I, Radio Nav Aids, Amendment 84 of Nov 19, 2009b2v4No ratings yet

- Construction Contract Administration Manual (CAH)Document232 pagesConstruction Contract Administration Manual (CAH)waqas aliNo ratings yet

- 006-Sample Method Statement Structure New WorksDocument4 pages006-Sample Method Statement Structure New WorksS.C.Satish ChanderNo ratings yet

- 2022 Airport Terminal Program Final SelectionsDocument8 pages2022 Airport Terminal Program Final SelectionsClickon DetroitNo ratings yet

- Checklist For PCCDocument4 pagesChecklist For PCCSR BuildersNo ratings yet

- Award of ContractDocument3 pagesAward of ContractVikramSinghNo ratings yet

- 3 BConstruction Stormwater Erosion Control PlansDocument4 pages3 BConstruction Stormwater Erosion Control Plans许爱文No ratings yet

- MS - Raft PouringDocument14 pagesMS - Raft PouringAby ThykkodathuNo ratings yet

- AIRPORT PLANNING AND DESIGN: A HISTORY OF AVIATION AND AIRPORT DEVELOPMENTDocument26 pagesAIRPORT PLANNING AND DESIGN: A HISTORY OF AVIATION AND AIRPORT DEVELOPMENTPradeepta DeyNo ratings yet

- Partial TOPDocument3 pagesPartial TOPMuthuNo ratings yet

- Method Statement - Installation CCTVDocument1 pageMethod Statement - Installation CCTVMuhammad SyadhamNo ratings yet

- Qcs 2010 Section 21 Part 1 General Provisions For Electrical InstallaDocument15 pagesQcs 2010 Section 21 Part 1 General Provisions For Electrical Installabryanpastor106100% (1)

- Checklist For Pre-PourDocument1 pageChecklist For Pre-PourMin Min SoeNo ratings yet

- Sample - Macau International Airport PDFDocument104 pagesSample - Macau International Airport PDFChin Xue KeiNo ratings yet

- Method Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Document32 pagesMethod Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Imranuddin SyedNo ratings yet

- Method Statement For PILINGDocument7 pagesMethod Statement For PILINGcworld86% (7)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- 20180313-142007-6767-745-Kaushlendra Kumar VermaDocument18 pages20180313-142007-6767-745-Kaushlendra Kumar VermaTim LinNo ratings yet

- 2014 (NCPTC) Performance History of Concrete Overlays in The United StatesDocument30 pages2014 (NCPTC) Performance History of Concrete Overlays in The United StatesTim LinNo ratings yet

- 666 Sucess For Concrete Overlays - InterlayerDocument4 pages666 Sucess For Concrete Overlays - InterlayerTim LinNo ratings yet

- DMG - 33 Reflection Cracking On Airfield Pavements - A Design Guide For Assessment, Treatment Selection and Future MinimisationDocument35 pagesDMG - 33 Reflection Cracking On Airfield Pavements - A Design Guide For Assessment, Treatment Selection and Future MinimisationTim LinNo ratings yet

- Proposed Specification for Airfield Concrete Pavement ConstructionDocument18 pagesProposed Specification for Airfield Concrete Pavement ConstructionTim LinNo ratings yet

- 2006 Investigation of Hot Mix Asphalt Surfaced Pavements Skid Resistance in Maryland State Hightway Network SystemDocument15 pages2006 Investigation of Hot Mix Asphalt Surfaced Pavements Skid Resistance in Maryland State Hightway Network SystemTim LinNo ratings yet

- Why Slabs Curl - Part1Document6 pagesWhy Slabs Curl - Part1Tim LinNo ratings yet

- 1997 Bonded Concrete Overlay Project Selection, Design and Construction PDFDocument89 pages1997 Bonded Concrete Overlay Project Selection, Design and Construction PDFTim LinNo ratings yet

- Use of DCP & DeflectometerDocument244 pagesUse of DCP & DeflectometerSalvatory LyakurwaNo ratings yet

- 0 - 4398 - 2 Techniques and Procedures For Bonded Concrete OverlaysDocument225 pages0 - 4398 - 2 Techniques and Procedures For Bonded Concrete OverlaysTim LinNo ratings yet

- Quality Assurance For Rapid Airfield ConstructionDocument123 pagesQuality Assurance For Rapid Airfield ConstructionTim LinNo ratings yet

- Portland Cement Concrete Paving InspectionDocument139 pagesPortland Cement Concrete Paving InspectionTim Lin100% (1)

- Best Practices of Concrete Pavement TransitionDocument91 pagesBest Practices of Concrete Pavement Transitionhastoutomo100% (1)

- Quality Assurance For Rapid Airfield ConstructionDocument123 pagesQuality Assurance For Rapid Airfield ConstructionTim LinNo ratings yet

- Why Slabs Curl - Part2Document6 pagesWhy Slabs Curl - Part2Tim LinNo ratings yet

- Atr 021 eDocument165 pagesAtr 021 eMuhammad Azeem Khan100% (1)

- Airport Manager's Guide For The Maintenance of Asphalt Pavements of General Aviation AirportsDocument79 pagesAirport Manager's Guide For The Maintenance of Asphalt Pavements of General Aviation AirportsarklinNo ratings yet

- 39Document16 pages39hiyeonNo ratings yet

- Analysis of The Structural Bearing Capacity of An Airport Using Rudimentary Test Results As Input Into The SAMDMDocument15 pagesAnalysis of The Structural Bearing Capacity of An Airport Using Rudimentary Test Results As Input Into The SAMDMTim Lin100% (1)

- Design Practice To Prevent Floor VibrationsDocument28 pagesDesign Practice To Prevent Floor VibrationsVincent TengNo ratings yet

- Design Guide For Floor Vibrations: Long Carbon Europe Sections and Merchant BarsDocument56 pagesDesign Guide For Floor Vibrations: Long Carbon Europe Sections and Merchant Barsgdug27No ratings yet

- 747-8 Pavement Loading 2009Document10 pages747-8 Pavement Loading 2009Tim LinNo ratings yet

- Studies On Correlation Between Flexural Strength and Compressive Strength of ConcreteDocument6 pagesStudies On Correlation Between Flexural Strength and Compressive Strength of ConcreteTim Lin50% (2)

- Minimizing Floor Vibration by Design and RetrofitDocument0 pagesMinimizing Floor Vibration by Design and RetrofitCrosman StefanNo ratings yet

- Airfield Pavement Rehabilitation PDFDocument114 pagesAirfield Pavement Rehabilitation PDFTim LinNo ratings yet

- Guidelines For Evaluation of Highway Pavements For RehabilitationDocument23 pagesGuidelines For Evaluation of Highway Pavements For RehabilitationTim LinNo ratings yet

- TP-2009-190 Evaluation Methods For Longitudinal Evenness of Runway PavementsDocument23 pagesTP-2009-190 Evaluation Methods For Longitudinal Evenness of Runway PavementsTim LinNo ratings yet

- Alacpa10-P23 Runway Grooving and Surface Friction 2013 PDFDocument99 pagesAlacpa10-P23 Runway Grooving and Surface Friction 2013 PDFTim LinNo ratings yet

- 2103-14335-1-PB Effect of Aicraft Wheel Load and Configuration On Runway DamagesDocument10 pages2103-14335-1-PB Effect of Aicraft Wheel Load and Configuration On Runway DamagesTim LinNo ratings yet

- Airfield Pavement RehabilitationDocument114 pagesAirfield Pavement RehabilitationTim LinNo ratings yet

- Touareg VWDocument6 pagesTouareg VWMeor Amri67% (3)

- Logistics: Assessing Causes of Driver Job Dissatisfaction in The Flatbed Motor Carrier IndustryDocument15 pagesLogistics: Assessing Causes of Driver Job Dissatisfaction in The Flatbed Motor Carrier IndustryVanco AdziskiNo ratings yet

- Granular Sub Base-GsbDocument4 pagesGranular Sub Base-GsbCheng EngiNo ratings yet

- Analysis of Recent Bridge Failures in The United States: Kumalasari Wardhana and Fabian C. Hadipriono, P.E., F.ASCEDocument7 pagesAnalysis of Recent Bridge Failures in The United States: Kumalasari Wardhana and Fabian C. Hadipriono, P.E., F.ASCEMohamed YasserNo ratings yet

- Slides. Rear Axle RTS2370A. TextoDocument16 pagesSlides. Rear Axle RTS2370A. TextoJorge Ricce YngaNo ratings yet

- Airport MarkingsDocument32 pagesAirport MarkingsMD WAHID ANSARINo ratings yet

- Updated Checklist of HYWA, ROLLERDocument2 pagesUpdated Checklist of HYWA, ROLLERparthaNo ratings yet

- Ram 2013 Isb PDFDocument2 pagesRam 2013 Isb PDFRobert Anderson100% (1)

- Feasibility Analysis: Heritage Walk & Adventure Trail, Warangal, TelanganaDocument32 pagesFeasibility Analysis: Heritage Walk & Adventure Trail, Warangal, Telanganakarthik1216No ratings yet

- Union of India Driving License: Issuing Authority: ASST - RTO, JAUNPURDocument1 pageUnion of India Driving License: Issuing Authority: ASST - RTO, JAUNPURRAMESH YADAVNo ratings yet

- Where To Go Camping GuideDocument20 pagesWhere To Go Camping GuideaasufiNo ratings yet

- 4 Wheeler Safety RulesDocument2 pages4 Wheeler Safety Rulessudam kumar rautNo ratings yet

- GW Wingle (All) SpecsDocument5 pagesGW Wingle (All) SpecsNorberto PattNo ratings yet

- MercedesDocument334 pagesMercedesAnonymous as5qbwfe100% (1)

- Evaluation of Rapid Repair of Concrete Pavements Using Precast Concrete Technology A Sustainable and Cost-Effective SolutionDocument22 pagesEvaluation of Rapid Repair of Concrete Pavements Using Precast Concrete Technology A Sustainable and Cost-Effective SolutionIrvebry AyuNo ratings yet

- RTSM V1 Uniform Traffic Control DeviceDocument881 pagesRTSM V1 Uniform Traffic Control DeviceMário Pereira100% (5)

- CD 526 Spacing of Road Gullies-WebDocument65 pagesCD 526 Spacing of Road Gullies-WebpraalankarNo ratings yet

- AsphaltDocument9 pagesAsphaltIAN BRUCE LIGARAYNo ratings yet

- Bridge Design CodeDocument49 pagesBridge Design CodeAnnisa PurnamaNo ratings yet

- A 2 Mumbai Coastal Road MainDocument29 pagesA 2 Mumbai Coastal Road MainAsawari JoshiNo ratings yet

- Regulatory SignsDocument10 pagesRegulatory SignsAngel QuingaluisaNo ratings yet

- Navara Brochure All Pages 2019 MAY17 PDFDocument8 pagesNavara Brochure All Pages 2019 MAY17 PDFKattie ValerioNo ratings yet

- Myanmar ReportDocument21 pagesMyanmar ReportthanNo ratings yet

- Travego Edition 1Document12 pagesTravego Edition 1Philippine Bus Enthusiasts SocietyNo ratings yet

- Direct Buried Cable Installation PDFDocument8 pagesDirect Buried Cable Installation PDFnecmettinsengunNo ratings yet

- Catalogo TEREX RT600 SeriesDocument2 pagesCatalogo TEREX RT600 SeriesRafaelMallquiAntialonNo ratings yet

- Chamblee PlazaDocument44 pagesChamblee PlazaZachary HansenNo ratings yet

- UntitledDocument339 pagesUntitledBart SimpsonNo ratings yet

- FASTag Application FormDocument4 pagesFASTag Application FormAtul Kumar DixitNo ratings yet

- Springs Shock Absorbers BizHouse - UkDocument3 pagesSprings Shock Absorbers BizHouse - UkAlex BekeNo ratings yet