Professional Documents

Culture Documents

ACI Flexural Strength Design PDF

Uploaded by

Adam AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI Flexural Strength Design PDF

Uploaded by

Adam AhmadCopyright:

Available Formats

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no. 105-S53

Flexural Strength Design of Concrete Beams Reinforced

with High-Strength Steel Bars

by Robert F. Mast, Mina Dawood, Sami H. Rizkalla, and Paul Zia

This paper presents a methodology for the flexural strength design high-strength steel: Grade 100 and 120 (690 and 830 MPa).

of concrete beams reinforced with high-strength reinforcing steel It cautions designers, however, that current design requirements

that conforms to the requirements of ASTM A1035-07. The design limit the allowable design strength of reinforcements to 80 ksi

method is based on simple analysis techniques that satisfy (550 MPa). This limitation prevents engineers from fully

fundamental principles of equilibrium and compatibility. Strain

using the enhanced strength characteristics of these materials

limits for tension-controlled sections and compression-controlled

sections are proposed that are consistent with the approach of the and therefore represents a practical obstacle to the transfer of

current and past ACI 318 Codes. The proposed method is the technology to the engineering community.

compared with experimental results previously reported by others. To lift the 80 ksi (550 MPa) yield strength limitation of the

The application of the proposed method is demonstrated by a current ACI 318 Code, a design methodology is proposed

numerical design example. based on accepted engineering principles and analysis

techniques. The proposed design methodology demonstrates

Keywords: flexure; flexural design; high-strength reinforcement; high- that the flexural strength of members reinforced with high-

strength steel; reinforcing bars; strength design. strength steel will be comparable with the flexural strength of

members designed according to the current design provisions.

INTRODUCTION

Recently, high-strength steel reinforcement conforming to RESEARCH SIGNIFICANCE

ASTM A1035-071 has been developed. The stress-strain This paper presents a design methodology, in similar

characteristics of the reinforcement are quite different from format to the current ACI 318 provisions, for the flexural

conventional Grade 60 (400 MPa) steel reinforcement. The strength design of concrete beams reinforced with ASTM

new steel is considerably stronger than conventional A1035-071 Grade 100 (690 MPa) steel bars. The discussion

reinforcing steel and lacks a well-defined yield point. There is limited to reinforcing bars having stress-strain characteristics

are several practical advantages to using this new high- that are similar to the high-strength steel commercially

strength material, including reduction of congestion in known as MMFX; however, the proposed design concept is

heavily reinforced members, improved concrete placement, valid for any high-strength steel that does not exhibit a distinct

savings in the cost of labor, reduction of construction time yield plateau. The proposed tension-controlled strain limits

and, in some cases, enhanced resistance to corrosion. ensure that the strain, curvature, and deflection deformability

Research on the use of high-strength steel as reinforcement ratios of beams designed according to the proposed method-

for reinforced concrete members has been ongoing for some ology are comparable to the ratios for beams designed

time. The flexural behavior of concrete beams reinforced according to current and previous ACI 318 provisions. The

with high-strength reinforcing bars has been investigated proposed method will enable the designers to take full

experimentally by a number of researchers.2-4 The available advantage of high-strength steel bars as reinforcement for

research indicates that, when properly designed, beams concrete structures.

reinforced with high-strength reinforcing bars will achieve

similar strength characteristics to beams reinforced with CHARACTERISTICS OF HIGH-STRENGTH

conventional steel reinforcements. REINFORCING STEELS

Other research has indicated that high-strength reinforcing A number of high-strength reinforcing steels are currently

bars can be effectively used as a replacement for conventional available for the design and construction of reinforced

steel reinforcing bars for typical reinforced concrete bridge concrete flexural members. The typical stress-strain relationships

decks.5 The research indicates that, due to the use of high- of several different high-strength reinforcing steels are

strength steel reinforcing bars, the required steel area can be presented in Fig. 1(a), along with the stress-strain relationship of

reduced by up to 33% while maintaining comparable conventional Grade 60 (400 MPa) steel for comparison. As seen

behavior to bridge decks reinforced with conventional Grade 60 in the figure, the stress-strain curve of typical high-strength

(400 MPa) steel. Detailing requirements, including the steel is characterized by an initial linear portion followed by

strength of bent bars and bond characteristics, have also a nonlinear section. The absence of a distinct yield plateau is

been investigated5 and additional research is ongoing at characteristic of most high-strength steel. Despite the lack of

several universities. a well-defined yield point, most high-strength reinforcing

In addition to the ongoing research in this field, the recent

publication of ASTM A1035-071 that outlines structural ACI Structural Journal, V. 105, No. 4, September-October 2008.

MS No. M-2006-491.R2 received November 14, 2007, and reviewed under Institute

specifications for low-carbon and chromium steel bars publication policies. Copyright 2008, American Concrete Institute. All rights reserved,

further facilitates the use of high-strength steel as reinforcing including the making of copies unless permission is obtained from the copyright proprietors.

Pertinent discussion including authors closure, if any, will be published in the July-

for concrete structures. The standard specifies two grades of August 2009 ACI Structural Journal if the discussion is received by March 1, 2009.

570 ACI Structural Journal/September-October 2008

ACI Honorary Member Robert F. Mast is a Past President and Past Chairman of

BERGER/ABAM Engineers Inc., Seattle, WA, where he continues to serve as a

Senior Principal. He is a Past President of ACI and a member of ACI Committees

314, Simplified Design of Concrete Buildings; 318, Structural Concrete Building

Code; 376, Concrete Structures for Refrigerated Liquified Gas Containment; TAC

Technology Transfer Committee; and the Concrete Research Council. He authored the

Unified Design Provisions, which were incorporated in the 2002 and later editions of

the ACI 318 Code.

ACI member Mina Dawood is a PhD Candidate at North Carolina State University,

Raleigh, NC. He received his BSc from the University of Manitoba, Winnipeg, MB,

Canada, in 2003 and his MS from North Carolina State University in 2005.

Sami H. Rizkalla, FACI, is a Distinguished Professor of Civil and Construction

Engineering in the Department of Civil, Construction and Environmental Engineering,

North Carolina State University. He is the Director of the Constructed Facilities

Laboratory and NSF I/UCRC in Repair of Structures and Bridges at North Carolina

State University. He is a member of ACI Committees 118, Use of Computers;

440, Fiber Reinforced Polymer Reinforcement; Joint ACI-ASCE Committees 423,

Prestressed Concrete, and 550, Precast Concrete Structures; and E803, Faculty

Network Coordinating Committee.

ACI Honorary Member Paul Zia is a Distinguished University Professor Emeritus at

North Carolina State University. He is an ACI Past President and is Chair of

ITG-6, High-Strength Steel Bars. He is a member of ACI Committees 363, High-

Strength Concrete; 440, Fiber Reinforced Polymer Reinforcement; Joint ACI-

ASCE Committees 423, Prestressed Concrete, and 445, Shear and Torsion; and the

Concrete Research Council.

steels are capable of achieving ultimate strain values up to

0.05 or higher.

Several equations have been proposed to represent the

actual stress-strain behavior of high-strength reinforcing

steels in tension.6,7 As shown in Fig. 1(b), the stress-strain

relationship of one specific type of reinforcing steel

conforming to ASTM A1035-07,1 known as MMFX steel,

can be approximately represented by the following equation

Fig. 1(a) Material characteristics of high-strength

29, 000 s ( ksi ) s 0.00241

reinforcing steel; and (b) existing and proposed limitations

fs = 0.345 (1) and material models.

170 ------------------------------ ( ksi ) 0.00241 < s < 0.060

s + 0.00104

fully, a simplified elastic-plastic relationship has been

proposed for design purposes.9 The simplified model

200, 000 s ( MPa ) s 0.00241 consists of an initial linear-elastic portion with an elastic

fs = 2.379 modulus of 29,000 ksi (200,000 MPa) followed by a

1172 ------------------------------ ( MPa ) 0.00241 < s < 0.060 perfectly plastic yield plateau with a yield strength of 100 ksi

s + 0.00104

(690 MPa), as shown in Fig. 1(b). The discussion presented in

this paper and the proposed increase in the allowable yield

where fs is the stress in the steel and s is the corresponding strength limit are recommended for high-strength steel

strain. This equation was developed following the same reinforcing bars in tension only. When high-performance

format of the equation adopted by PCI to represent the stress- reinforcing bars are used as compression reinforcement, the

strain curve of the prestressing strand that exhibits a similar current ACI limitation of 80 ksi (550 MPa) should be maintained

trend of the stress-strain curve to that of MMFX steel.8 The because the stress in the steel is controlled by the maximum

PCI stress-strain equation for prestressing steel beyond the compressive strain of 0.003 used for concrete in design.

proportional limit is of the form

BASIS OF CURRENT DESIGN PRACTICE

B Based on current design practice, the design of a flexural

f s = A -------------- (2)

s + C member should take into account the overall behavior of the

member throughout the service range and up to the nominal

The same form of the equation was used and the capacity of the member. Beginning with the ACI 318-6310

constants A, B, and C were adjusted to closely match the Code, flexural members were required to have reinforcement

measured stress-strain curve of MMFX steel. The tensile ratios not greater than 75% of the balanced reinforcement

stress-strain curve represented by Eq. (1) will be used for ratio b. By 1993, this criterion had been in use for 30 years,

analysis in this paper. and the behavior of flexural members was judged to be

The current ACI 318 Code limits the maximum allowable satisfactory. The current criterion based on tensile strain in

yield strength of steel reinforcement to 80 ksi (550 MPa). To the reinforcement was selected to provide similar behavior to

use the high-strength properties of the reinforcing steel more that experienced under the 0.75b criterion.

ACI Structural Journal/September-October 2008 571

It should be noted that this principle does not apply to the

special case of energy dissipation in seismic resisting frames.

Most typical flexural members are loaded monotonically and

are expected to reach nominal strength no more than once.

The proposed flexural strength design methodology is not

intended for structures required to resist high seismic loads.

Past and present ACI 318 Code requirements

Ultimate strength design (now called strength design) was

introduced in the ACI 318 Code in 1963.10 For flexural

members, the maximum reinforcement ratio was limited to

0.75 of the balanced reinforcement ratio b. The purpose of

this requirement was to ensure that the member would be

under-reinforced such that the reinforcement would yield

before the concrete reached its limiting strain of 0.003 prior

to failure. This requirement remained essentially in effect

from 1963 to 1999.

In the 1995 ACI 318 Code,12 an alternative requirement

was introduced in Appendix B. Rather than limiting the

maximum reinforcement ratio , a minimum strain level in

the reinforcement at nominal strength was required for the

Fig. 2Deflection of a prestressed concrete fender pile. use of the high factor of 0.9 for flexure. A tension-controlled

section was defined as a cross section in which the net tensile

strain in the extreme tension steel at nominal strength was greater

Desirable behavior for flexural members than or equal to 0.005. For tension-controlled sections, a factor

In the design of reinforced concrete flexural members, to of 0.9 was used. If the steel strain at nominal strength was less

apply the higher resistance factor of 0.9, a member should than 0.005, a reduced factor was used to account for the less

exhibit desirable behavior. At service load, small deflections desirable behavior of these sections. Compression-controlled

and minimal cracking are desired. At higher loads, however, sections are defined as having steel strains at nominal strength at

the member should exhibit large deflections and/or excessive or below the yield strain of the reinforcement. For

cracking to provide warning before reaching nominal compression-controlled sections, the factor for compression

strength. Both deflection and cracking are primarily a function of was used. For sections with steel strains between the

steel strain near the tension face of the member.

aforementioned two limits, the factor was determined by

In general, desirable behavior of a member is related to

linear interpolation between the factor for compression and

ductility. Whereas there are many definitions of ductility,

the factor for tension. In the 2002 ACI 318 Code,13 these

they all typically relate to yielding or inelastic deformation.

When lower strength reinforcing materials are used, the only requirements were moved to the main body of the code,

way to obtain high strains near the tension face at nominal replacing the former limit on for flexural members.

strength is to ensure yielding of the tension steel. With high- The background information on the development of these

strength materials, this is no longer necessary. Figure 2 limits has been provided by Mast.14 Whereas the tension-

shows the test of a prestressed concrete fender pile designed controlled strain limit of 0.005 was developed from studies

to absorb energy of impacting ships. The pile was purposely of the behavior of members reinforced with Grade 60 (400 MPa)

designed so that the prestressing strand would not yield at the steel, it was also permitted to be used with Grade 75 (520 MPa)

deformation shown. So, by most definitions, it has no steel reinforcement.

ductility; but it certainly can undergo large deflection and

cracking prior to failure. ANALYTICAL INVESTIGATION

The ductility ratios, the ratios of strain, curvature, or The objective of the following analytical investigation was

deflection at ultimate to the corresponding values at yield, to assess the adequacy of the proposed 100 ksi (690 MPa)

are not the only measure of desirable behavior. Instead, the material model and to establish acceptable strain limits for

ratio of nominal strength behavior to service load behavior,

tension-controlled sections and compression-controlled

otherwise referred to hereafter as the deformability ratio,

sections reinforced with high-strength steel. The behavior of

may also be a suitable indicator. The larger this ratio, the

beams was studied at nominal strength and at the service

larger the spread between the behavior at service load and

the behavior at nominal strength. A similar approach was level. The section behavior was determined by using a

previously recommended for the design of concrete beams cracked section analysis that satisfied equilibrium and

reinforced with fiber reinforced polymer (FRP) materials.11 compatibility. At nominal strength, the ACI Code rectangular

Because FRP materials do not yield, the ductility ratio is not stress block was used. Elastic stress distribution was considered

an appropriate indicator of desirable behavior. Rather, to under service load condition. Between these two limits, a

assess the adequacy of a member, the ratio of energy dissipation trapezoidal stress block for concrete was used consisting of

at ultimate conditions to energy dissipation at serviceability an initial linear portion with an elastic modulus equal to

limits are considered. In this paper, similar deformability 57,000 f c psi (4730 f c MPa) up to a stress of 0.85fc

ratios are considered and expressed in terms of the strain followed by a plastic plateau. The details of the analysis are

ratio, the curvature ratio, and the deflection ratio. shown schematically in Fig. 3.

572 ACI Structural Journal/September-October 2008

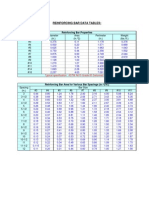

Table 1Comparison of beam capacity for

different reinforcing steel material models

Reinforcing steel Moment capacity, Increase Reserved capacity,

material model kip-ft (kN-m) of capacity, % kip-ft (kN-m)

Grade 60

327 (443)

(400 MPa) steel

Actual behavior 639 (867) 95 0 (0)

Simplified 100 ksi

524 (711) 60 115 (156)

(690 MPa) model

80 ksi (550 MPa)

427 (579) 31 212 (288) Fig. 3Sectional analysis procedure.

limitation

Nominal strength analysis

The nominal moment capacity of a rectangular, singly

reinforced concrete section was considered for a number of

different reinforcement ratios using a cracked section analysis.

A concrete compressive strength of 6500 psi (45 MPa) was

considered with an ultimate strain of 0.003 at the extreme

compression face of the concrete. The stress level in the

reinforcement was calculated using three different material

models to represent the behavior of the high-strength steel

reinforcement. The actual behavior of the reinforcing steel,

as defined in Eq. (1), the current ACI limitation of 80 ksi

(550 MPa), and the proposed 100 ksi (690 MPa) simplified

model were each considered in the analysis.

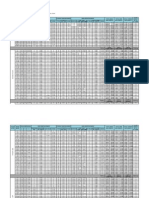

Figure 4 shows the relationship between the nominal

moment capacity of the section and the reinforcement ratio

for each of the three steel material models under consideration.

The nominal moment capacity of sections reinforced with

conventional Grade 60 (400 MPa) reinforcement is also

shown for comparison purposes. Also plotted in the figure

are test results of several beams that were reinforced with Fig. 4Nominal moment capacity as a function of reinforcing

high-strength steel reinforcing bars and were tested at the ratio.

Florida DOT2 and at the University of North Florida.3

The experimental results are in good agreement with the the three different high-strength material models and also for

analysis that considered the actual behavior of the high- conventional Grade 60 (400 MPa) reinforcement.

strength reinforcing steel. Table 1 indicates that, for the example beam, using high-

The balanced reinforcement ratios b were calculated as strength reinforcing steel would result in an increase of the

3.95%, 2.60%, and 1.85% for the sections using the Grade 60 moment capacity of 95% when compared with the beam

(400 MPa), 80 ksi (550 MPa), and 100 ksi (690 MPa) material using the conventional Grade 60 (400 MPa) reinforcement.

models, respectively. Figure 4 indicates that, for a given For the same section, if the ACI limitation of 80 ksi (550 MPa)

reinforcement ratio greater than 3.95%, the calculated is imposed, the increase of the moment capacity would be

nominal moment capacity of the section was equal for all of only 31% over the moment capacity of the section reinforced

the different material models because failure of the heavily with Grade 60 (400 MPa) steel. When compared with the

reinforced sections was governed by crushing of the concrete actual behavior, however, there is a reserved capacity of

prior to yielding of the reinforcing steel. For a reinforcement 212 kip-ft (288 kN-m), which corresponds to 33% of the

ratio less than 3.95%, the models with the higher yield nominal capacity of the member. If the simplified 100 ksi

strengths typically predicted higher nominal moment capacities. (690 MPa) model is used, the increase of the moment

For sections reinforced with a reinforcement ratio less than capacity would be 60% over the capacity of the section

1.75%, which represents the majority of typical reinforced reinforced with conventional steel. The actual reserved

concrete beams, use of the 100 ksi (690 MPa) model typically capacity is 18% of the nominal capacity when compared

underpredicted the nominal moment capacity of the section with the actual behavior. This demonstrates that the design

as compared with the actual behavior. Conversely, for using the proposed simplified model results in more efficient

reinforcement ratios from 1.75 to 2.7%, use of the 100 ksi use of the high-strength characteristics of the steel than the

(690 MPa) limitation slightly overpredicted the capacity current 80 ksi (550 MPa) limitation while still providing a

of the section. The analysis indicates, however, that this significant reserved capacity as compared with the actual

difference is on the order of only 2.5%, which is insignificant capacity of the reinforced section.

for design purposes.

To investigate the adequacy of the various proposed material Moment-curvature analysis

models, the nominal moment capacity of an example beam To establish suitable design limits for tension-controlled

was considered. The example beam had a width b of 12 in. and compression-controlled sections, a moment-curvature

(305 mm), an effective depth d of 24 in. (610 mm), and a analysis was conducted to investigate the limits of desirable

reinforcement ratio of 1%. The calculated nominal behavior based on current design practice. A total of eight

moment capacity of the section, Mn, is given in Table 1 for concrete beams were considered in the analysis. Three of the

ACI Structural Journal/September-October 2008 573

Fig. 5Behavior of beam designed according to ACI 318-9915 Fig. 6Behavior of beam designed according to ACI 318-0213

and previous: (a) moment curvature; and (b) moment deflection. and later: (a) moment curvature; and (b) moment deflection.

beams were designed according to ACI 318 Code requirements additional deflection after yielding because the flat-top shape of

using conventional reinforcing steel. For each of the beams, the moment-curvature diagram causes yielding to occur only

the strain, curvature, and deflection deformability ratios over a short length of the beam near midspan. The deflection at

were considered to evaluate the limits of desirable behavior. nominal strength is 1.95 times that at service load ( ratio).

The remaining five beams were reinforced with high-strength

reinforcement and the deformability ratios were also considered. Behavior based on ACI 318-0213 and later Codes

The example beams all consisted of a 12 x 30 in. (305 x Flexural members at the current reinforcement limits for

760 mm) cross section with a simple span of 40 ft (12,200 mm). tension-controlled sections given in ACI 318-0213 and later

The depth to the reinforcement from the top of the section

Codes were examined to form a basis for what is currently

was 28 in. (710 mm) in all cases. A concrete strength of 5000 psi

acceptable behavior. Sections reinforced with Grade 60

(34 MPa) was assumed, but for the beams reinforced with

(400 MPa) and Grade 75 (520 MPa) steel were considered.

high-strength steel, concrete strengths from 4000 to

The service load was assumed to be 2/3 of nominal strength

10,000 psi (28 to 69 MPa) were considered.

based on an average load factor equal to 1.35 and a resistance

factor equal to 0.9. For the example beam reinforced with

Behavior based on ACI 318-9915 and previous Codes

Using ACI 318-9915 and previous Codes, the beam was Grade 60 (400 MPa) steel, the limiting area of tension

designed at the 0.75b limit with a reinforcing steel area of reinforcing steel was calculated as 7.14 in.2 (4610 mm 2).

8.45 in.2 (5450 mm 2). Based on a load factor of 1.5 and a The corresponding service moment and tension stress in the

resistance factor of 0.9, the service load was taken to be 0.6 times steel were 560 kip-ft (759 kN-m) and 39 ksi (239 MPa),

the calculated nominal strength of the member. The calculated respectively. When considering Grade 75 (520 MPa) steel,

service moment and corresponding steel tension stress were the corresponding area of reinforcement, service moment,

577 kip-ft (783 kN-m) and 34 ksi (234 MPa), respectively. and stress in the steel were 5.71 in.2 (3680 mm 2), 559 kip-ft

Figure 5(a) shows a moment-curvature diagram for a (758 kN-m), and 48 ksi (330 MPa), respectively.

beam at the reinforcement limit of 0.75b, as permitted by Figure 6(a) shows a moment-curvature diagram for beams

the ACI 318 Codes prior to 2002. The behavior was almost at the net tensile strain limit of 0.005 for tension-controlled

bilinear, with the break point occurring very close to a steel stress sections. The behavior is almost bilinear, with the break

equal to fy. The curvature at nominal strength was 3.03 times that point occurring very close to a steel stress equal to fy. For

at service load ( ratio). The net tensile strain of the steel at Grade 75 (520 MPa) steel, the curvature at nominal strength

nominal strength was 2.87 times that at service load ( ratio). was 2.92 times that at service load ( ratio). The net tensile

Figure 5(b) shows the moment-deflection relationship for a strain of the steel at nominal strength was 2.98 times that at

uniformly loaded beam. There is only a small amount of service load ( ratio). Figure 6(b) shows the moment-deflection

574 ACI Structural Journal/September-October 2008

relationship for a uniformly loaded beam. The deflection at high-strength reinforcing steel. The bilinear elastic-plastic

nominal strength was 1.74 times that at service load ( ratio). model simplifies hand calculations and permits the use of

conventional software for reinforced concrete design.

Behavior with high-strength reinforcing steel For a given section at the tension-controlled strain limit of

To evaluate behavior, it is necessary to use a good 0.0066, the actual steel stress in the reinforcement is

approximation of the true stress-strain characteristics of approximately 125 ksi (862 MPa) at the nominal moment

high-strength steel, as given in Eq. (1). Strain compatibility strength of the beam, whereas the assumed steel stress in the

studies indicate that using a tension-controlled strain limit of simplified method is 100 ksi (690 MPa). To compensate for

0.0066 for beams reinforced with high-strength steel the difference, the calculated neutral axis depth (and the

produce behavior characteristics comparable with beams tension-controlled strain limit) must be adjusted when using

reinforced with Grade 60 (400 MPa) and Grade 75 (520 MPa) the simplified method. Using a tension-controlled strain

steel under the ACI 318 Code. Table 2 compares the strain

ratios, the curvature ratios, and the deflection ratios for

the 12 x 30 in. (305 x 760 mm) beams reinforced with

Grades 60 (400 MPa), 75 (520 MPa), and high-strength

steel reinforcement. In this analysis, Eq. (1) was used to

represent the stress-strain characteristics of the high-strength

reinforcement steel. The ratios are comparable when the

tension-controlled strain limit is taken as 0.0066 for the

beams reinforced with high-strength steel for the various

concrete strengths considered in the analysis. The corresponding

area of reinforcement for each of the example beams are also

provided in the table for reference purposes.

Figure 7(a) shows the moment-curvature relationship for a

beam reinforced with high-strength steel at the tension-

controlled strain limit of 0.0066 and a concrete strength fc of

5000 psi (34 MPa). Equation (1) was used to represent the

stress-strain relationship of the reinforcing steel in this

example. Figure 7(b) shows the moment-deflection rela-

tionship for a uniformly loaded beam reinforced with high-

strength steel. The corresponding curves for beams with

conventional reinforcement from Fig. 5 and 6 are also shown

in Fig. 7 for comparison purposes. It should be noted that the

absolute deflections are greater using the higher strength

steel, and this needs to be accounted for by appropriately

designing the depth of the member. Due to the higher tension

strain in the high-strength reinforcement under service

loading conditions, the beams may exhibit higher crack widths

than those reinforced with conventional steel. Previous testing,4

however, indicates that the measured crack width under service

loading conditions is only slightly larger than the acceptable

crack widths for beams reinforced with conventional steel.

Considering that some high-strength steel also exhibits reduced

corrosion rates under severe environmental conditions,5 the

slightly increased crack widths may be justified provided it is

not objectionable from the aesthetics point of view.

CRITERIA FOR SIMPLIFIED DESIGN METHOD Fig. 7Behavior of beam designed with high-strength

The simplified design method uses the simplified 100 ksi reinforcing steel: (a) moment curvature; and (b) moment

(690 MPa) material model to describe the behavior of the deflection.

Table 2Results of moment-curvature analysis

Area of steel, Steel stress at service,

ACI 318 Code Criterion Steel type in.2 (mm2) ksi (MPa) fc, ksi (MPa) ratio ratio ratio

1963 10

to 1999 15 = 0.75 b Grade 60 (400 MPa) 8.45 (5450) 34 (234) 5 (34) 2.87 3.03 1.95

200213 and 200512 t = 0.005 Grade 60 (400 MPa) 7.14 (4610) 39 (269) 5 (34) 3.71 3.44 1.81

2002 13

and 2005 12 t = 0.005 Grade 75 (520 MPa) 5.71 (3680) 48 (331) 5 (34) 2.98 2.92 1.74

Proposed t = 0.0066 High-strength 2.43 (1570) 67 (462) 4 (28) 2.85 2.96 2.47

Proposed t = 0.0066 High-strength 2.86 (1850) 67 (462) 5 (34) 2.92 3.01 2.51

Proposed t = 0.0066 High-strength 3.21 (2070) 67 (462) 6 (41) 3.10 3.09 2.57

Proposed t = 0.0066 High-strength 3.71 (2390) 67 (462) 8 (55) 3.44 3.34 2.75

Proposed t = 0.0066 High-strength 4.64 (2920) 67 (462) 10 (69) 3.33 3.19 2.66

ACI Structural Journal/September-October 2008 575

limit of 0.009 in the simplified method produces essentially The proposed variation of the resistance factor is presented

the same result as using the 0.0066 strain limit in the more exact in Fig. 8. To help prevent compression-controlled failure, high-

method, as demonstrated in Table 3. That is, for a given strength or conventional compression reinforcement can be

section designed at the tension-controlled strain limit of 0.0066 provided. If high-strength compression steel is used, however,

using the actual behavior of the high-strength reinforcing the ACI yield strength limit of 80 ksi (550 MPa) should

steel, analysis of the section using the simplified 100 ksi be maintained for the compression bars.

(690 MPa) model yields a corresponding strain of 0.009.

Therefore, it is proposed that the simplified design method DESIGN EXAMPLE

should use the idealized 100 ksi (690 MPa) material model with To illustrate the simplified design method, the behavior of

a corresponding tension-controlled strain limit of 0.009. an example beam was evaluated using the proposed simplified

Flexural members should normally be designed as design method. The example beam had a width b of 12 in.

tension-controlled members, but the compression-controlled (305 mm) and a section depth h of 18 in. (460 mm). The

strain limit should also be defined for flexural members section was reinforced with three No. 6 high-strength steel

subjected to compression. A compression-controlled strain reinforcing bars located 15 in. (400 mm) from the top of the

limit of 0.004 is proposed. To verify that beams designed at section. Two additional No. 4 Grade 60 (400 MPa) steel

the proposed compression-controlled strain limit exhibit reinforcing bars were provided in the compression zone

elastic behavior under service loading conditions, several 2-1/4 in. (60 mm) from the top surface of the beam. The

example beams were considered. The dimensions of the beam had a span of 15 ft (4570 mm) and was loaded in four-

example beams were the same as those described previously. point bending with a constant moment region of 3 ft (915 mm).

Several concrete compressive strengths, ranging from 4 to The concrete compressive strength was 7250 psi (50 MPa).

10 ksi (28 to 69 MPa) were considered and a load factor of The example beam was also fabricated and tested in a

1.35 was used. The corresponding service load level, based previous study.4

on a reduction factor of 0.65 was 48% of the calculated The nominal strength of the example beam was calculated

nominal strength using the simplified design method. For all using the simplified method. Assuming that the steel had

of the beams considered, the calculated strain in the tension yielded at nominal strength, the tension force T in the steel

reinforcement at the service load level was between 60 and 70% reinforcement would be 132.5 kips (590 kN). Using the ACI

of the proportional limit strain of the high-strength steel. rectangular stress block, the calculated neutral axis depth c

The proposed strain limit was twice that for Grade 60 was 2.6 in. (66 mm). The corresponding strain at the level of

(400 MPa) steel, and it lead to a simple equation for in the the tension reinforcement t was 0.015, which was above the

transition region between tension and compression proposed tension-controlled strain limit of 0.009. The

controlled sections calculated nominal moment capacity of the section Mn was

162 kip-ft (220 kN-m), which corresponded to an applied

load of 54 kips (240 kN). The nominal strength of the

= 0.45 + 50 t 0.004 < t < 0.009 (3) example beam, calculated using the proposed simplified

design procedure, was 30% lower than the measured nominal

capacity of the tested beam. After applying a reduction factor

of 0.9, the calculated ultimate strength of the beam was 49 kips

(220 kN).

Based on an average load factor of 1.35, the service load

level for the example beam was 35 kips (157 kN). The reported

crack width for the tested beam at this load level was 0.02 in.

(0.5 mm),4 which was minimal and demonstrated the

desirable behavior of the beam under service loading conditions.

The calculated ultimate strength and service load levels for

the example beam are presented in Fig. 9 relative to the

measured load-deflection behavior of the beam. The figure

also presents the predicted load-deflection relationship using

the actual behavior of the high-strength steel, Eq. (1), and the

simplified model. The figure shows that the predicted

behavior using the actual material properties closely matches

Fig. 8Proposed variation of resistance factor for the the measured behavior. The calculated ratios of strain ,

simplified design procedure. curvature , and deflection , for the example beam, using

Table 3Comparison of design methods

Actual behavior Simplified method

Tension-controlled strain limit 0.0066 0.009

Neutral axis depth c 0.3125d 0.25d

Stress block depth a = 1c 0.31251d 0.251d

Compressive force C 0.85fc ab 0.85fc ab

0.85fc (0.31251d)b/125 (in.2) 0.85fc (0.251d)b/100 (in.2)

Steel area As = C/fs

0.85fc (0.31251d)b/862 (mm2) 0.85fc (0.251d)b/689 (mm2)

Reinforcement ratio = As/bd 0.002125fc 1 0.002125fc 1

576 ACI Structural Journal/September-October 2008

Transition zone sections: = 0.45 + 50t 0.004 < t < 0.009

Flexural members designed using the simplified design

method and the aforementioned criteria will have comparable

flexural strength characteristics with members designed

according to current ACI 318 requirements using conventional

Grade 60 (400 MPa) and Grade 75 (520 MPa) reinforcing steel.

ACKNOWLEDGMENTS

The preparation of the paper is based on the results of a number of

research projects sponsored by MMFX Technologies whose support is

gratefully acknowledged.

REFERENCES

1. ASTM A1035, Standard Specification for Deformed and Plain, Low-

Carbon, Chromium, Steel Bars for Concrete Reinforcement, ASTM

International, West Conshohocken, PA, 2007, 5 pp.

2. Ansley, M. H., Investigation into the Structural Performance of

MMFX Reinforcing, 2002, http://www.mmfxsteel.com/technical_resources/

Default.asp.

Fig. 9Measured and predicted load-deflection behavior 3. Malhas, F. A., Preliminary Experimental Investigation of the Flexural

of the example beam. Behavior of Reinforced Concrete Beams Using MMFX Steel, University

of North Florida, Jacksonville, FL, 2002, http://www.mmfxsteel.com/

technical_resources/Default.asp.

Table 4Calculated deformability ratios 4. Yotakhong, P., Flexural Performance of MMFX Reinforcing Rebars

for example beam in Concrete Structures, masters thesis, North Carolina State University,

Ratio Value Raleigh, NC, 2003.

5. Seliem, H. M. A., Behavior of Concrete Bridges Reinforced with

Strain, s /n 6.18 High-Performance Steel Reinforcing Bars, doctoral dissertation, North

Curvature, s /n 5.37 Carolina State University, Raleigh, NC, 2007, http://www.lib.ncsu.edu/

theses/available/etd-05042007-174633/unrestricted/etd.pdf.

Deflection, s /n 2.94

6. Vijay, V. S.; GangaRao, H. V. S.; and Prachasaree, W., Bending

Behavior of Concrete Beams Reinforced with MMFX Steel Bars, WVU

College of Engineering, Morgantown, WV, 2002, http://www.mmfxsteel.com/

the actual behavior of the reinforcing steel, are presented in technical_resources/Default.asp.

Table 4. All of these ratios exceed the limits for acceptable 7. Collins, M. P., and Mitchell, D., Prestressed Concrete Structures,

behavior according to currently accepted design practice. Response Publications, Toronto, ON, Canada, 1997, 766 pp.

8. Martin, L. D., and Perry, C. J., eds., PCI Design Handbook, sixth

This design example demonstrates that the proposed simplified edition, Precast/Prestressed Concrete Institute, Chicago, IL, 2004, 728 pp.

design procedure is conservative and consistent with 9. Mast, R. F., Memorandum: Simplified Strength Design of Flexural

currently accepted design practice. Members Using MMFX Steel, Jan. 2007, 8 pp.

10. ACI Committee 318, Building Code Requirements for Reinforced

CONCLUSIONS Concrete (ACI 318-63), American Concrete Institute, Farmington Hills,

This paper proposes a simplified method for flexural MI, 1963, 144 pp.

design of concrete beams reinforced with high-strength steel 11. Vijay, P. V., and GangaRao, H. V. S., Bending Behavior and

Deformability of Glass Fiber-Reinforced Polymer Reinforced Concrete

reinforcements. The design of the beams may be based on an Members, ACI Structural Journal, V. 98, No. 6, Nov.-Dec. 2001, pp. 834-842.

idealized elastic-plastic material model, with an elastic 12. ACI Committee 318, Building Code Requirements for Structural

modulus of 29,000 ksi (200,000 MPa) and yield strength of Concrete (ACI 318-95) and Commentary (318R-95), American Concrete

100 ksi (690 MPa) to represent the stress-strain behavior of Institute, Farmington Hills, MI, 1995, 391 pp.

the reinforcing steel. Based on this model and current limitations 13. ACI Committee 318, Building Code Requirements for Structural

for acceptable behavior, flexural members should be Concrete (ACI 318-02) and Commentary (318R-02), American Concrete

Institute, Farmington Hills, MI, 2002, 443 pp.

designed using the following criteria 14. Mast, R. F., Unified Design Provisions for Reinforced and

Prestressed Concrete Flexural and Compression Members, ACI Structural

Tension-controlled sections: = 0.9 t 0.009 Journal, V. 89, No. 2, Mar.-Apr. 1992, pp. 185-199.

15. ACI Committee 318, Building Code Requirements for Structural

Concrete (ACI 318-99) and Commentary (318R-99), American Concrete

Compression-controlled sections: = 0.65 t 0.004 Institute, Farmington Hills, MI, 1999, 369 pp.

ACI Structural Journal/September-October 2008 577

You might also like

- Project Supervision and AdministratioinDocument26 pagesProject Supervision and AdministratioinSIMEON AJULONo ratings yet

- Portal Frames ConstructionDocument47 pagesPortal Frames ConstructionYashi GuptaNo ratings yet

- NBCP PD1096of1977Document77 pagesNBCP PD1096of1977jjahaddinNo ratings yet

- Reinforcing Bar Data Tables: Sizes, Areas, WeightsDocument1 pageReinforcing Bar Data Tables: Sizes, Areas, WeightsgrbucaNo ratings yet

- Design of RC BeamsDocument42 pagesDesign of RC BeamsHarold Jackson MtyanaNo ratings yet

- c7-20 Paving For Estate Roads, Driveways and FootwaysDocument25 pagesc7-20 Paving For Estate Roads, Driveways and FootwaysJacky TiongNo ratings yet

- Location: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. AzagraDocument11 pagesLocation: M. H. Del Pilar Street, Polillo, Quezon Project Owner: Mrs. Necerina T. Azagramy dlNo ratings yet

- Building Construction CAP 123B PDFDocument28 pagesBuilding Construction CAP 123B PDFJustin NgNo ratings yet

- Seismological Consideration in DesignsDocument14 pagesSeismological Consideration in DesignsIbie Scandie Shain QuimanNo ratings yet

- Ancoring RebarsDocument44 pagesAncoring Rebarsrvsingh17gmailcomNo ratings yet

- General Specifications: 1. EarthworksDocument7 pagesGeneral Specifications: 1. Earthworksenvironmental100% (1)

- She-Lea-Concrete Construction DetailsDocument2 pagesShe-Lea-Concrete Construction Detailsapi-515610659No ratings yet

- Plant schedule and planting specificationDocument1 pagePlant schedule and planting specificationlaNo ratings yet

- Themaar 1 Building-Investigation ReportDocument53 pagesThemaar 1 Building-Investigation ReportRamsha YasirNo ratings yet

- Construction Contract Philippines: I. Free ServicesDocument4 pagesConstruction Contract Philippines: I. Free ServicesRafael DeocuarizaNo ratings yet

- Estimating Guide: Types of EstimatesDocument238 pagesEstimating Guide: Types of EstimatesKC Benavidez100% (1)

- General Construction Notes: Bureau of DesignDocument15 pagesGeneral Construction Notes: Bureau of DesignRicoyan YanNo ratings yet

- 4.8 Procedures For Nonstructural Components: CommentaryDocument20 pages4.8 Procedures For Nonstructural Components: CommentarymanohargudNo ratings yet

- Curing System For Mat-FoundationDocument8 pagesCuring System For Mat-FoundationDayo100% (1)

- Sta. Maria Mixed Use Building Beam Reinforcement DetailsDocument5 pagesSta. Maria Mixed Use Building Beam Reinforcement DetailsGia GuallarNo ratings yet

- Precast ConcreteDocument5 pagesPrecast ConcreteSurya TejNo ratings yet

- Specification-Module 1Document6 pagesSpecification-Module 1BaijuNo ratings yet

- 2006 - Ding - Automating Code Checking For Building Designs - DesignCheck PDFDocument18 pages2006 - Ding - Automating Code Checking For Building Designs - DesignCheck PDFVicente MedianoNo ratings yet

- UFC 3-490-06 - 2018.06 - ElevatorsDocument48 pagesUFC 3-490-06 - 2018.06 - ElevatorsMofasa ENo ratings yet

- Chapter One Specifications and Quantity Survey 1.1 SpecificationsDocument15 pagesChapter One Specifications and Quantity Survey 1.1 Specificationsyeshi janexoNo ratings yet

- BusvsDuct Brown 13 PDFDocument2 pagesBusvsDuct Brown 13 PDFmathianandmNo ratings yet

- Analysis For Schedule-2009 PDFDocument2,393 pagesAnalysis For Schedule-2009 PDFVikrant Narayan VasudevaNo ratings yet

- Pl-Herbert Yu-P-2 PDFDocument1 pagePl-Herbert Yu-P-2 PDFSoy DesignoNo ratings yet

- Types of BridgesDocument31 pagesTypes of BridgesbifefumiNo ratings yet

- AJ Handbook of Structural AnalysisDocument47 pagesAJ Handbook of Structural AnalysisHafiz FahmiNo ratings yet

- Home Drawings Backup PDFDocument10 pagesHome Drawings Backup PDFromy321No ratings yet

- 1997jan StruclDocument7 pages1997jan StruclEdzon LacayNo ratings yet

- Baa2213 - Reinforced Concrete Design I 21516 PDFDocument7 pagesBaa2213 - Reinforced Concrete Design I 21516 PDFAizat HermanNo ratings yet

- Arup - Ground MovementDocument4 pagesArup - Ground MovementJinsun JeongNo ratings yet

- Structural Standard Details: Construction NotesDocument4 pagesStructural Standard Details: Construction Notesjohn rey toledo100% (1)

- Construction Issues: Anchoring MEP Items Into Suspended SlabsDocument2 pagesConstruction Issues: Anchoring MEP Items Into Suspended SlabsMario SandovalNo ratings yet

- Cracking Concrete SurfacesDocument2 pagesCracking Concrete SurfacesCivilEngClubNo ratings yet

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocument1 pageBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNo ratings yet

- ACI Mix Design Example #2 Class ACI Mix Design ExampleDocument3 pagesACI Mix Design Example #2 Class ACI Mix Design ExamplePhea SakNo ratings yet

- Construction Document Sheet Numbers and Sheet OrderDocument4 pagesConstruction Document Sheet Numbers and Sheet OrderAnnisa SyahraniNo ratings yet

- Beam Design 1Document23 pagesBeam Design 1kanishkaNo ratings yet

- Which Is The Best Excavator?: 7 AnswersDocument4 pagesWhich Is The Best Excavator?: 7 AnswersMuhammad IqbalNo ratings yet

- 2020 Fee Guideline: Guideline For Setting Fees For Consulting Engineering ServicesDocument17 pages2020 Fee Guideline: Guideline For Setting Fees For Consulting Engineering Servicesmohammed abrahimeNo ratings yet

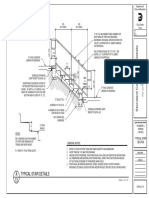

- Typical Stair DetailsDocument1 pageTypical Stair DetailsM IQbalNo ratings yet

- Construction of Moiben Sub-County Office BlockDocument152 pagesConstruction of Moiben Sub-County Office Blockapi-258641606No ratings yet

- Seismic Technical Guide Seismic Expansion Joints en SC2496Document15 pagesSeismic Technical Guide Seismic Expansion Joints en SC2496carrimonn11No ratings yet

- ICC ESR-1385 For Kwik Bolt 3 Expansion Anchors For Masonry Approval Document ASSET DOC LOC 23Document5 pagesICC ESR-1385 For Kwik Bolt 3 Expansion Anchors For Masonry Approval Document ASSET DOC LOC 23Anonymous eoQuq9tNo ratings yet

- Enhanced Use of The Work Breakdown Structure by Application of Unique Activity Coding As A Universal Reference Throughout A Project's Lifecycle.Document94 pagesEnhanced Use of The Work Breakdown Structure by Application of Unique Activity Coding As A Universal Reference Throughout A Project's Lifecycle.Theo MoolmanNo ratings yet

- Volume 3 - Div 9 - 21 PDFDocument676 pagesVolume 3 - Div 9 - 21 PDFnap_carinoNo ratings yet

- Specs PDFDocument9 pagesSpecs PDFLhewiz BrionesNo ratings yet

- Hybrid MMC PDFDocument11 pagesHybrid MMC PDFVignesh AyyathuraiNo ratings yet

- 1905 National - Building - Code PDFDocument275 pages1905 National - Building - Code PDFHimad Beg, P.E.No ratings yet

- Architect'S Perspective: Republic of The PhilippinesDocument1 pageArchitect'S Perspective: Republic of The PhilippinesAlexxis LipuraNo ratings yet

- HIGH STRENGTH REBAR DESIGNDocument5 pagesHIGH STRENGTH REBAR DESIGNChristian JaberNo ratings yet

- Design Considerations and Guidelines in The Use of Grade 600 Steel Reinforcements For Reinforced Concrete ConstructionDocument11 pagesDesign Considerations and Guidelines in The Use of Grade 600 Steel Reinforcements For Reinforced Concrete ConstructionFreddie KooNo ratings yet

- Performance of RC Beams With Embedded Steel TrusseDocument9 pagesPerformance of RC Beams With Embedded Steel TrussevignamNo ratings yet

- High-Strength Reinforcement in Exterior Beam-Column Joints Under Cyclic LoadingDocument14 pagesHigh-Strength Reinforcement in Exterior Beam-Column Joints Under Cyclic LoadingRafie Itharani UlkhaqNo ratings yet

- B500CDocument28 pagesB500CFlorin CiocanelNo ratings yet

- Grillage Layout by Morris and WestDocument2 pagesGrillage Layout by Morris and WestAdam AhmadNo ratings yet

- Aqeedah Al-Wasitiyyah - Ibn TaymiyyahDocument47 pagesAqeedah Al-Wasitiyyah - Ibn TaymiyyahOzod AchilovNo ratings yet

- Flexural Behavior of Two-Span Continuous Prestressed Concrete Girders With Highly Eccentric External TendonsDocument10 pagesFlexural Behavior of Two-Span Continuous Prestressed Concrete Girders With Highly Eccentric External TendonsAdam AhmadNo ratings yet

- Review of Design Procedures For Shear and Torsion in Reinforced and Prestressed ConcreteDocument197 pagesReview of Design Procedures For Shear and Torsion in Reinforced and Prestressed ConcreteAdam AhmadNo ratings yet

- How To Make A Good Company ProfileDocument4 pagesHow To Make A Good Company ProfileKarina ZalfaNo ratings yet

- Nonlinear Analysis of Prestressed Concrete Structures Considering Slip Behavior of TendonsDocument22 pagesNonlinear Analysis of Prestressed Concrete Structures Considering Slip Behavior of TendonsAdam AhmadNo ratings yet

- SAFE 12 Paper For Long Term DeflectionDocument3 pagesSAFE 12 Paper For Long Term DeflectionOttawa Canada100% (4)

- How To Make A Good Company ProfileDocument4 pagesHow To Make A Good Company ProfileKarina ZalfaNo ratings yet

- SAFE 12 Paper For Long Term DeflectionDocument3 pagesSAFE 12 Paper For Long Term DeflectionOttawa Canada100% (4)

- BASIS OF STRUCTURAL DESIGN (EN1990:2002Document15 pagesBASIS OF STRUCTURAL DESIGN (EN1990:2002kiss_59856786100% (1)

- Fiqh Us Sunnah Complete by Sayyid SabiqDocument451 pagesFiqh Us Sunnah Complete by Sayyid SabiqUmm Eris Arleta AmatullahNo ratings yet

- Surah Abasa - Dream Tafseer Notes - Nouman Ali KhanDocument35 pagesSurah Abasa - Dream Tafseer Notes - Nouman Ali Khanspeed2kxNo ratings yet

- Gravity Wall Verification Manual enDocument26 pagesGravity Wall Verification Manual enradem3No ratings yet

- Gravity Wall Verification Manual enDocument26 pagesGravity Wall Verification Manual enradem3No ratings yet

- Soil Structure InteractionDocument16 pagesSoil Structure InteractionEmad Ahmed Khan67% (3)

- GEO GEOGUIDE 7 - Guide To Soil Nail Design and Construction (2008)Document100 pagesGEO GEOGUIDE 7 - Guide To Soil Nail Design and Construction (2008)aescarameiaNo ratings yet

- Tafsir Ibn AbbasDocument789 pagesTafsir Ibn Abbascomfreek5000100% (7)