Professional Documents

Culture Documents

DIN 7500 - Trilobular Thread Rolling Screws

Uploaded by

DerekCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DIN 7500 - Trilobular Thread Rolling Screws

Uploaded by

DerekCopyright:

Available Formats

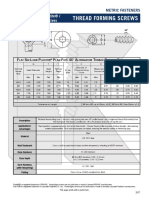

METRIC FASTENERS

DIN 7500 Trilobular

THREAD FORMING SCREWS Thread Rolling Screws

B C P

METRIC - Trilobular Thread Rolling Screws

DIN 7500-

1

C B P Minimum Minimum Maximum

Nominal Hole

Size & Diameter of Major Thread Point Test Plate Breaking Breaking Screw-in

Diameter

Thread Circumscribing Circle Diameter Diameter Thickness Torque Force Torque

Pitch

Max Min Max Min Max Max Min Nm N Nm

M2-0.40 2.06 1.98 1.98 1.90 1.67 2.0 1.825 1.8 0.4 1650 0.3

M2.5-0.45 2.55 2.47 2.48 2.38 2.11 2.5 2.325 2.3 1 2700 0.6

M3-0.5 3.05 2.97 2.95 2.87 2.57 3.0 2.775 2.75 1.8 4000 1

M3.5-0.6 3.58 3.48 3.46 3.36 3.00 3.5 3.230 3.2 2.8 5400 1.6

M4-0.7 4.07 3.99 3.93 3.85 3.39 4.0 3.680 3.65 4.1 7000 2.4

M5-0.8 5.08 5.00 4.92 4.84 4.30 5.0 4.630 4.6 8.7 11,400 4.7

M6-1.0 6.10 5.97 5.90 5.77 5.13 6.0 5.530 5.5 15 16,000 8

3-6mm: 0.375 over 6-10mm: 0.45 over 10-18mm: 0.55

Tolerance on Length

over 18-30mm: 0.65 over 30 - 50mm: 0.80 over 50-80: 0.95

A trilobular thread forming screw with a machine screws thread pitch. As each lobe of the screw moves through the

Description pilot hole in the nut material, it forms and work hardens the nut thread metal, producing an uninterrupted grain flow.

For use in drilled, punched or cored holes in ductile metals and punch

extruded metals. They provide superior prevailing torque than can be

achieved with most locking screws. Eliminates chips that result from using

Applications/ Can be used to roll threads in

thread cutting screws. Requires low drive torque and provides excellent

Advantages resistance to vibrational loosening. Since these thread rolling screws are

aluminum or non-ferrous materials.

case hardened, it is not recommended they be used in die-cast or extruded

aluminum or zinc.

Carbon Steel Stainless

Material

AISI 1022 Steel A2 Stainless Steel

Surface Hardness 450 HV 0.3 Min. -

M2 & M2.5: 0.05-0.15 mm

M3 & M3.5: 0.07-0.18 mm

Case Depth M4 & M5: 0.10-0.25 mm

-

M6 & M8: 0.15-0.28 mm

M2 - M3.5: 290 - 370 HV 5

Core Hardness M4 & larger: 290 - 370 HV 10

-

Torque required to cause failure shall be equal to or greater than breaking

Torsional Strength torque values shown in above table.

-

Tensile force required to cause failure shall be equal to or greater than

Tensile Strength breaking force values shown in above table.

-

Stainless thread-rolling screws are

Thread rolling screws shall have a zinc finish with a wax coating. For more

Plating details see Appendix-A.

typically passivated with a wax

coating.

This page prints with a watermark

446

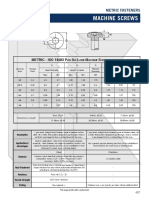

METRIC FASTENERS

Thread Rolling Screws

Head Dimensions to DIN 965 & 7985 THREAD FORMING SCREWS

A

A M

G H

METRIC - Type Z (1A) Flat Heads for Tapping Screws DIN 965

A H M G

Recess

Nominal Size Head Diameter Head Height Recess Penetration Drive Size

Diameter

Max Min Max Ref Max Min

M2.5 4.7 4.4 1.5 2.5 1.73 1.48 1

M3 5.6 5.3 1.65 2.8 2.01 1.76 1

M4 7.5 7.14 2.2 4 2.51 2.06 2

M5 9.2 8.84 2.5 4.4 3.05 2.60 2

M6 11 10.57 3 6.1 3.3 2.8 3

M A

A H

G

METRIC - Type Z (1A) Pan Heads for Tapping Screws DIN 7985

A H M G

Nominal Recess

Head Diameter Head Height Recess Penetration Drive Size

Size Diameter

Max Min Max Min Ref Max Min

M2 4.00 3.70 1.72 1.48 2.4 1.35 1.10 1

M2.5 5.00 4.70 2.12 1.88 2.6 1.52 1.27 1

M3 6.00 5.70 2.52 2.28 3.0 1.93 1.68 1

M4 8.00 7.64 3.25 2.95 4.3 2.36 1.90 2

M5 10.00 9.64 3.95 3.65 5.0 3.10 2.64 2

M6 12.0 11.57 4.75 4.45 6.8 3.53 3.03 3

This page prints with a watermark

447

METRIC FASTENERS

DIN 7500 Thread Rolling Screw

THREAD FORMING SCREWS Hole Size Data

dh

d

dh

DIN

Guideline Values for Hole Diameters Using DIN 7500 Thread Rolling Screws 7500

Thread Size M2.5 M3 M3.5 M4 M5 M6

Material Hole Diameter (dh)

thickness or

length of

engagement Max Min Max Min Max Min Max Min Max Min Max Min

0.8 2.31 2.25

0.9 2.31 2.25

1 2.31 2.25 2.76 2.7 3.18 3.13

1.2 2.31 2.25 2.76 2.7 3.21 3.16

1.5 2.31 2.25 2.76 2.7 3.21 3.16 3.66 3.6 4.56 4.5

1.6 2.31 2.25 2.76 2.7 3.24 3.19 3.66 3.6 4.56 4.5

1.7 2.31 2.25 2.76 2.7 3.24 3.19 3.66 3.6 4.56 4.5

1.8 2.31 2.25 2.81 2.75 3.24 3.19 3.66 3.6 4.56 4.5

2 2.31 2.25 2.81 2.75 3.24 3.19 3.66 3.6 4.56 4.5 5.46 5.4

2.2 2.31 2.25 2.81 2.75 3.24 3.19 3.66 3.6 4.56 4.5 5.46 5.4

2.5 2.31 2.25 2.81 2.75 3.29 3.24 3.71 3.65 4.56 4.5 5.46 5.4

3 2.36 2.3 2.81 2.75 3.29 3.24 3.71 3.65 4.56 4.5 5.51 5.45

3.2 2.375 2.3 2.825 2.75 3.29 3.24 3.725 3.65 4.625 4.55 5.525 5.45

3.5 2.375 2.3 2.825 2.75 3.29 3.24 3.725 3.65 4.625 4.55 5.525 5.45

4 2.375 2.3 2.825 2.75 3.32 3.27 3.725 3.65 4.625 4.55 5.525 5.45

5 2.375 2.3 2.825 2.75 3.32 3.27 3.775 3.7 4.675 4.6 5.525 5.45

5.5 2.825 2.75 3.32 3.27 3.775 3.7 4.675 4.6 5.575 5.5

6 2.825 2.75 3.32 3.27 3.775 3.7 4.675 4.6 5.575 5.5

6.3 3.79 3.7 4.74 4.65 5.59 5.5

6.5 3.79 3.7 4.74 4.65 5.59 5.5

7 3.79 3.7 4.74 4.65 5.59 5.5

7.5 3.79 3.7 4.74 4.65 5.59 5.5

8 thru 10 4.74 4.65 5.74 5.65

NOTE:

The values listed above are assigned to various materials and lengths of engagement and should be used as guidelines.

This page prints with a watermark

448

You might also like

- Metric Fastener Dimensions and SpecificationsDocument1 pageMetric Fastener Dimensions and SpecificationsDerekNo ratings yet

- Iso 14581 CSK ScrewDocument1 pageIso 14581 CSK ScrewMitesh MakvanaNo ratings yet

- Iso 7093 PDFDocument9 pagesIso 7093 PDFMalcolmNo ratings yet

- Technical recommendations for threaded fittings and tapped holesDocument3 pagesTechnical recommendations for threaded fittings and tapped holesJai Bhandari0% (1)

- Din 13Document1 pageDin 13dedosimoesNo ratings yet

- Iso 7379Document2 pagesIso 7379Ahmed ElsafouryNo ratings yet

- Din Iso 965-1 PDFDocument25 pagesDin Iso 965-1 PDFbonnaventure100% (3)

- Iso 4042 PDFDocument25 pagesIso 4042 PDFAditya Pratap100% (6)

- Hexagon Socket Button Head Screw With Flange - IsO 7380-2Document9 pagesHexagon Socket Button Head Screw With Flange - IsO 7380-2Corneliu VilcuNo ratings yet

- Din en 1663-EnDocument9 pagesDin en 1663-EnThiago GoncalvesNo ratings yet

- Din 929 - 01-00Document5 pagesDin 929 - 01-00qualidade1fameqNo ratings yet

- Din 50942-96Document13 pagesDin 50942-96RONALD100% (2)

- N67F CM-ZN-2 - 5001.110.016 - NormDocument22 pagesN67F CM-ZN-2 - 5001.110.016 - Normgokul100% (1)

- ISO 2341-1986 en 22341-1992 Clevis Pins With HeadDocument6 pagesISO 2341-1986 en 22341-1992 Clevis Pins With HeadMaurícioAndrade100% (2)

- DEXT 085 DIN 928 Porca Solda QuadradaDocument10 pagesDEXT 085 DIN 928 Porca Solda Quadradatestesada100% (2)

- Iso 4029Document9 pagesIso 4029ellisforheroesNo ratings yet

- Din 8062-3 2009 PDFDocument10 pagesDin 8062-3 2009 PDFkoalaboi33% (3)

- Engineered Coating SDocument2 pagesEngineered Coating SHo Bach100% (1)

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- Din 7500 enDocument10 pagesDin 7500 enCălin Bălăiţă100% (1)

- Fasteners DIN en ISO StandardsDocument32 pagesFasteners DIN en ISO StandardsNo NameNo ratings yet

- Din en Iso 7089 2000-11Document8 pagesDin en Iso 7089 2000-11REKHANo ratings yet

- Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument2 pagesWorldwide Fastener Standard: Printed Copies Are UncontrolledRasatja Yongskulrote100% (1)

- Asme B18.2.2-2015Document39 pagesAsme B18.2.2-2015DmitriyNo ratings yet

- Din 13-51Document1 pageDin 13-51anks_raNo ratings yet

- Din 13-1Document4 pagesDin 13-1Sankha Dasgupta100% (3)

- WX 100Document17 pagesWX 100anon_967426204100% (1)

- DIN 128 en PDFDocument3 pagesDIN 128 en PDFDaniel PuiaNo ratings yet

- 247 DIN EN 13858 Engl PDFDocument15 pages247 DIN EN 13858 Engl PDFAlejo Leal100% (4)

- Din 928 en PDFDocument1 pageDin 928 en PDFroyroverNo ratings yet

- ISO 228 - Pipe Threads Where Pressure-Tight Joints Are Not Made On The ThreadsDocument4 pagesISO 228 - Pipe Threads Where Pressure-Tight Joints Are Not Made On The ThreadsjesusNo ratings yet

- WX100 Fastener Finish Speecification PDFDocument16 pagesWX100 Fastener Finish Speecification PDFJulion2009No ratings yet

- Din 434Document1 pageDin 434RaduZapciroiuNo ratings yet

- Iso 3302 1 2014Document9 pagesIso 3302 1 2014Sandhya SinghNo ratings yet

- Ford Fastener Standard for WashersDocument17 pagesFord Fastener Standard for WashersRico MalibiranNo ratings yet

- Din 8140-1Document5 pagesDin 8140-1main46prairieNo ratings yet

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDocument4 pagesForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNo ratings yet

- DIN ISO Equivalent FastenersDocument12 pagesDIN ISO Equivalent FastenersGunnie PandherNo ratings yet

- Din & IsoDocument94 pagesDin & IsoZeinHarisHasibuan100% (5)

- ISO-10664Document10 pagesISO-10664leandrobsousaNo ratings yet

- Din 439Document1 pageDin 439Oleh SmolovyiNo ratings yet

- DIN125ADocument1 pageDIN125AManoj PatilNo ratings yet

- Din-En Iso 3506-1 1998 PDFDocument24 pagesDin-En Iso 3506-1 1998 PDFPaco100% (2)

- DIN 82-1973-Eng-Knurls PDFDocument4 pagesDIN 82-1973-Eng-Knurls PDFmrccrmmrc100% (2)

- BMI Division ... : Iso Metric Screw ThreadsDocument10 pagesBMI Division ... : Iso Metric Screw ThreadsAbdul Qadir TambeNo ratings yet

- Cross Recessed Cheese Head Screws: UDC 621 882 215.3.091 2 July 1986Document5 pagesCross Recessed Cheese Head Screws: UDC 621 882 215.3.091 2 July 1986Charmaine DrafkeNo ratings yet

- DIN13Document1 pageDIN13Mesut ÜnalNo ratings yet

- Iso 7040Document1 pageIso 7040serzo75No ratings yet

- Knurling Profiles DIN 82Document3 pagesKnurling Profiles DIN 82mirzasinanovic100% (1)

- Screw, IsO 14583, PAN, Metric, TorxDocument1 pageScrew, IsO 14583, PAN, Metric, TorxDerekNo ratings yet

- Metric Fastener Specifications for ISO 14583 Pan Six-Lobe Machine ScrewsDocument1 pageMetric Fastener Specifications for ISO 14583 Pan Six-Lobe Machine ScrewsDerekNo ratings yet

- Section 10 Useful Information: General Information - Stainless Steel FastenersDocument1 pageSection 10 Useful Information: General Information - Stainless Steel FastenersMiguel QueirosNo ratings yet

- MetmachthreadDocument3 pagesMetmachthreadPatrick - Assist. Técnica - CetemNo ratings yet

- Screw, ISO 7380, Six Lobe, Metic, TorxDocument1 pageScrew, ISO 7380, Six Lobe, Metic, TorxDerekNo ratings yet

- Metric DIN 934 Hexagon Nuts: Visit Our For Product AvailabilityDocument4 pagesMetric DIN 934 Hexagon Nuts: Visit Our For Product AvailabilityThiago CurvoNo ratings yet

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- DIN 929 Hexagon Weld Nut Technical Specifications and DimensionsDocument4 pagesDIN 929 Hexagon Weld Nut Technical Specifications and DimensionsDobrica PetrovicNo ratings yet

- Metric Socket Set ScrewsDocument2 pagesMetric Socket Set ScrewsvvvvvvNo ratings yet

- Thread Geometry - Metric CoarseDocument4 pagesThread Geometry - Metric CoarseMociran FlorinNo ratings yet

- Metric Fasteners: Metric - Iso 7045 P P E T SemsDocument1 pageMetric Fasteners: Metric - Iso 7045 P P E T SemsAdriana PérezNo ratings yet

- Screw Flat Head, TorxDocument1 pageScrew Flat Head, TorxDerekNo ratings yet

- Technical Standards Board Standard: Rev. MAY1999Document39 pagesTechnical Standards Board Standard: Rev. MAY1999wilian_coelho3309No ratings yet

- Screw, IsO 14583, PAN, Metric, TorxDocument1 pageScrew, IsO 14583, PAN, Metric, TorxDerekNo ratings yet

- Metric Fastener Specifications for ISO 14583 Pan Six-Lobe Machine ScrewsDocument1 pageMetric Fastener Specifications for ISO 14583 Pan Six-Lobe Machine ScrewsDerekNo ratings yet

- Machine Screws: DIN 965 & ISO 7045 TorxDocument1 pageMachine Screws: DIN 965 & ISO 7045 TorxDerekNo ratings yet

- CableDocument296 pagesCablevinaybabaNo ratings yet

- Screw, Thread Forming Plastics, Metric, Torx PDFDocument1 pageScrew, Thread Forming Plastics, Metric, Torx PDFDerekNo ratings yet

- Screw, Thread Forming Plastics, Metric, Torx PDFDocument1 pageScrew, Thread Forming Plastics, Metric, Torx PDFDerekNo ratings yet

- Metric Pin Dimensional StandardsDocument1 pageMetric Pin Dimensional StandardsDerekNo ratings yet

- DIN 7500 - Trilobular Thread Rolling ScrewsDocument3 pagesDIN 7500 - Trilobular Thread Rolling ScrewsDerek100% (1)

- 6935 2011Document13 pages6935 2011Tufan Ünal100% (4)

- Screw, ISO 10664-2014, Truss Head, Flat Head, 6-Lobe, TorxDocument1 pageScrew, ISO 10664-2014, Truss Head, Flat Head, 6-Lobe, TorxDerekNo ratings yet

- Screw, ISO 7380, Six Lobe, Metic, TorxDocument1 pageScrew, ISO 7380, Six Lobe, Metic, TorxDerekNo ratings yet

- ANSI-AGMA 2004-B89-1995 Gear Materials and Heat Treatment ManualDocument79 pagesANSI-AGMA 2004-B89-1995 Gear Materials and Heat Treatment ManualSantosh Shankarappa100% (4)

- Ariens, Snow Blower, 921018 - Deluxe 30 Platinum PDFDocument44 pagesAriens, Snow Blower, 921018 - Deluxe 30 Platinum PDFDerekNo ratings yet

- Design Guide - O-Ring, Quad-Ring, ERIKSDocument13 pagesDesign Guide - O-Ring, Quad-Ring, ERIKSDerekNo ratings yet

- AGMA6011-I03 - Specification For High Speed Helical Gear UnitsDocument58 pagesAGMA6011-I03 - Specification For High Speed Helical Gear UnitsConradodaMatta67% (3)

- Document Guide - 21-Tips To Clear Requirements DocumentationDocument13 pagesDocument Guide - 21-Tips To Clear Requirements DocumentationDerekNo ratings yet

- Design Guide - O-Ring, Quad-Ring, TrelleborgDocument32 pagesDesign Guide - O-Ring, Quad-Ring, TrelleborgDerekNo ratings yet

- ASME Y14.6-2001 (R2007), Screw Thread RepresentationDocument27 pagesASME Y14.6-2001 (R2007), Screw Thread RepresentationDerekNo ratings yet

- Design Guide - Stepper Motor Linear Actuators 101Document16 pagesDesign Guide - Stepper Motor Linear Actuators 101DerekNo ratings yet

- Design Guide, Spring, Pin, Coiled, SPIROLDocument24 pagesDesign Guide, Spring, Pin, Coiled, SPIROLDerekNo ratings yet

- CRP600-00 Benchtop PRO Assembly Instructions v2014Q2 1Document13 pagesCRP600-00 Benchtop PRO Assembly Instructions v2014Q2 1DerekNo ratings yet

- Parker Fluid Power Seal Design Guide 5370Document300 pagesParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- A Lesson in Profile Tolerancing For Complex Parts, MDDIDocument4 pagesA Lesson in Profile Tolerancing For Complex Parts, MDDIDerekNo ratings yet

- AGMA - ANSI 1006-A97 Tooth Proportions For Pastic Gears PDFDocument56 pagesAGMA - ANSI 1006-A97 Tooth Proportions For Pastic Gears PDFDerekNo ratings yet

- Screw, Thread Forming Plastics, Metric, TorxDocument1 pageScrew, Thread Forming Plastics, Metric, TorxDerekNo ratings yet

- Flux-Cored Arc WeldingDocument4 pagesFlux-Cored Arc WeldingCarlos BustamanteNo ratings yet

- Chemical and mechanical properties of 19MnVS6 steelDocument3 pagesChemical and mechanical properties of 19MnVS6 steelTeodor EzaruNo ratings yet

- Welding GuideDocument48 pagesWelding Guideedu_canete100% (2)

- FORMER BUDGET TERMINAL FUEL HYDRANT INSPECTIONDocument2 pagesFORMER BUDGET TERMINAL FUEL HYDRANT INSPECTIONmohd as shahiddin jafri100% (1)

- Gas Liquid Separator V 2001 DatasheetDocument1 pageGas Liquid Separator V 2001 DatasheetMathias OnosemuodeNo ratings yet

- Basics of the Kraft Pulping and Recovery ProcessDocument50 pagesBasics of the Kraft Pulping and Recovery ProcessTri PutriNo ratings yet

- Common Injection Moulding Defects, Causes, andDocument5 pagesCommon Injection Moulding Defects, Causes, andsharuziNo ratings yet

- Eni Functional Spec for Protective Coatings & Hot Dip GalvanisingDocument108 pagesEni Functional Spec for Protective Coatings & Hot Dip GalvanisingMaffone NumerounoNo ratings yet

- Fisa Tehnica Weldox 700Document2 pagesFisa Tehnica Weldox 700Daniel CringusNo ratings yet

- Press Working Operations GuideDocument2 pagesPress Working Operations GuideJermane Delos SantosNo ratings yet

- QQ P 416 - FDocument18 pagesQQ P 416 - Fkabardey46No ratings yet

- 5th Sem. / Mechanical Engg. (F.T.) Subject: Workshop Technology - III (F.T.)Document2 pages5th Sem. / Mechanical Engg. (F.T.) Subject: Workshop Technology - III (F.T.)Neat & Clean ReviewNo ratings yet

- Tank Lining Chart 1-26-10Document2 pagesTank Lining Chart 1-26-10Guatemalan1979No ratings yet

- p955 963Document9 pagesp955 963albertokochNo ratings yet

- Industrial PharmacyDocument9 pagesIndustrial PharmacyMr nobodyNo ratings yet

- Interplate 317: Zinc Silicate Shop PrimerDocument4 pagesInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerNo ratings yet

- Epoweld 48173 58173 TDSDocument2 pagesEpoweld 48173 58173 TDSTom HookNo ratings yet

- Example BHA Tally Directional Drilling 12.25 SectionDocument2 pagesExample BHA Tally Directional Drilling 12.25 Sectionfauzanhaq1602100% (1)

- Platinum Metals Review, 32Document2 pagesPlatinum Metals Review, 32Rafael Ricardo Celin ManceraNo ratings yet

- Shiva Packaging Industry.. - Copy123Document10 pagesShiva Packaging Industry.. - Copy123Pradeep KumarNo ratings yet

- Design Standards: SAE J534Document2 pagesDesign Standards: SAE J534alucard3750% (1)

- 4b. Uniline Unirail Datasheet - USDocument36 pages4b. Uniline Unirail Datasheet - USJHON ESTEBAN TILANO REOMERONo ratings yet

- 02 ConsumablesDocument38 pages02 ConsumablesWeldingSupply.com.au100% (1)

- Diamond and CBN WheelsDocument22 pagesDiamond and CBN WheelsM. AguiarNo ratings yet

- B. Training MatrixDocument5 pagesB. Training MatrixwidiNo ratings yet

- ASME 2023 BPVC Key ChangesDocument32 pagesASME 2023 BPVC Key ChangesBonnie Fajrie Amril90% (10)

- BASF industrial+Metal+CoatingsDocument12 pagesBASF industrial+Metal+CoatingsMaria Eugenia CiveiraNo ratings yet

- Fy1800a-H FX Cruiser Ho Repair Kit 1 PDFDocument2 pagesFy1800a-H FX Cruiser Ho Repair Kit 1 PDFKADA KADDANo ratings yet

- Site Handbook - Repair To ConcreteDocument24 pagesSite Handbook - Repair To Concretemalcolm_gingell100% (1)

- ASME Bronze Flange Sizes and Specs for 150 and 300 lb ClassesDocument6 pagesASME Bronze Flange Sizes and Specs for 150 and 300 lb ClassesKarim ShamsNo ratings yet