Professional Documents

Culture Documents

BEE Q400 AHG Aircraft Handling Guide MAY13

Uploaded by

zacklawsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BEE Q400 AHG Aircraft Handling Guide MAY13

Uploaded by

zacklawsCopyright:

Available Formats

Aircraft Handling Guide

Version 11

Bombardier Dash 8-Q400

Agent name: ____________

This guide supersedes all previous versions, guides or memos

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 1

CONTENTS

Item Page

Aim 3

Aircraft Specifics 3

Passenger Cabin Layout 4

Seating & Emergency Exits Exit Seats 5

Seating of PRMs 5

LMC Passengers 5

Cabin Baggage 5-6

Load Planning 6

Flight Envelope 6

Loading Guide 7

Hold Baggage 7

Ballast 8

Holds & Netting Overview 8

Rear Holds 6&7 8-9

Rear Hold Prop Strut 9

Rear Hold Netting 9

Forward Hold 5 10

GPU Ground Power Unit 11

Chocking of Aircraft 11

Nose Gear 12

Fuelling Point 12

Equipment & Safe Zones 13

Door Closing 13 - 14

Steps 14

Anti-Collision Warning Beacon 15

PRM Acceptance 16

(Passenger with Reduced Mobility) Seating 16

Loading of Electric Mobility Aids 16

Safety Reporting & Culture 17

Contact us 18

Your Notes Pages jot your notes, thoughts and reminders 19 - 20

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 2

Bombardier Q400 - QUICK GUIDE

Aim

The aim of this brief is to familiarise all handling agents with Flybes Q400 aircraft in order to carry

out passenger handling, dispatch or ramp duties.

AIRCRAFT SPECIFICS

The Q400 is a high winged, T tailed monoplane with two wing mounted turboprop engines.

Engines: 2 x Pratt & Whitney PW150A turboprops producing 5071 shaft

horsepower each, driving a Dowty 6 bladed composite propeller

Fuel Burn: 600kg per engine per hour

Range: 1296nm with passenger load of 70

Cruise: 350kts TAS (402 mph) Service ceiling 25,000

Climb performance: Take-off 20,000 10 minutes

DOM: 17.5 tonnes (approx)

MZFM: 25,855 kg

MTOM: 28,998 kg

MLDM: 28,009 kg

Max fuel capacity: 5318 kg

Seating: Capacity is 78 passengers

Standard Crew configuration 2/2

These aircraft do NOT have a row 13

Toilets: A toilet is located at the front of the cabin

Door Operation

Wind Limits: Do not operate external doors if wind speeds or wind gust speeds are

greater than 65 kts

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 3

PASSENGER CABIN LAYOUT

NOTE: Seat rows are numbered 1 -21, however, this aircraft type has no row 13 so there are actually

20 seat rows available.

Preferred

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 4

SEATING & EMERGENCY EXITS

Passengers should be distributed across the 4 bays, with a preference toward the rear.

1A/1B AND 2C/2D are emergency exit row seats. 2C or 2D MUST be allocated for every flight.

Emergency exit row seats must have at least one passenger seated in each pair of seats.

1A & 1B below 2C & 2D below

As these are Emergency Exit rows the seats cannot be used by PRMs, passengers with infants or a

large passenger needing an extension seatbelt.

Seating of PRMs

When allocating seats, passengers with limited mobility should be seated towards the front of the

cabin, near to the only toilet, but not in the seats listed above. Where PRM passengers allocate their

own seats, every reasonable effort should be made to accommodate the PRM in the seats they have

selected.

LMC Passengers

Bay C has no trim effect so should be used for all LMC passengers wherever possible. LMCs placed

into bay C have no limits other than the maximum for the bay (i.e. if bay C is empty, 20 passengers

without hold bags can be accepted). All other LMCs (passengers not in bay C, fuel, ballast, bags,

freight etc) have a maximum limit of +/-300kg before a new loadsheet must be produced.

CABIN BAGGAGE

Passengers carry-on baggage must fit into approved bag sizers. When gate staff do not check

passenger bags they will be creating an evacuation / trip hazard during boarding for passengers and

crew alike. Large bags must not be taken by the cabin crew as the passengers board, as they build up

in the doorways.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 5

Due to crew procedures and required passenger checks, the bags

cannot be passed out to the loaders whilst passengers are boarding.

All large bags MUST be tagged at the gate, given to the loaders and

placed into the hold.

These should be tagged with a Flybe Limited Release tag as shown

below.

LOAD PLANNING

Essentially, it is the Load Controllers responsibility to ensure a safe trim/load plan is obtained.

Because of the variety of routes this aircraft will operate, these guidelines may be deviated from

should the load controller see fit. Optimal trim for most efficient flight is between MAC 27 and 29%

(at all weights).

FLIGHT ENVELOPE

Note that the Q400 has THREE forward trim limits when the aircraft is below its MZFM. Above this

weight the full envelope is available.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 6

LOADING GUIDE

The guide below gives you an indication of how passengers / baggage should be distributed. This

however, is not exhaustive and particular care should be taken depending on the flight/route and

baggage weight.

Caution is needed when the bag figure or average bag weight is low as the aircraft will become very

nose heavy. In these circumstances ballast may be required or passengers may have to be moved.

** DO NOT MOVE ANY PASSENGERS WHO HAVE PRE ASSIGNED THEIR SEATS **

HOLD BAGGAGE

Even with passengers spread throughout the cabin the Q400 can become nose heavy, so Hold 7

should always be filled first. Handlers must take note that Hold 7 has a floor loading limit of 454 kg.

Flybe uses standard weights of 13kg per bag for international flights and 12kg per bag for domestic

flights but actuals may be used if annotated on the loadsheet. When standard bag weights are used

for calculating the loadsheet, plan for 34 bags in H7 with the remainder (up to capacity) in H6.

H5 should be used as an overflow.

It should also be noted that Holds 6 and 7 also have a combined maximum load of 1225 kg.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 7

BALLAST

If ballast is used it must be clearly marked on the LIR and loadsheet and the crew must be made

aware of its location. The crew is required to add the ballast into the aircrafts technical log to ensure

it is annotated as on board and does not get forgotten by any subsequent crews.

Do not remove any previously loaded ballast from a hold without consulting the crew; it may be

required for the flight.

During training flights, extra crew are located on the jump seat and the a/c has no weight in the tail, it

is recommended that (where available) ballast is used for these flights, and a standard weight of

200kg is positioned in Hold 7 to enable an in trim loadsheet.

HOLDS & NETTING

There are 3 Holds all of which are above cabin floor level i.e. there is no underfloor loading. While not

directly heated, all of the holds are located inside the pressure hull of the cabin and will therefore

remain at a similar temperature as set for the passenger compartment.

Animals should be loaded in either of the rear holds and not the forward hold.

Rear Holds (6 & 7)

Behind the rear passenger door, is the main baggage hold, accessed through a large cargo door. As

the door is opened you will see Hold 6 in front of you and Hold 7 to the right, where the floor level

steps up.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 8

The door is supported by a door overextension prop. Ensure that this is fully extended and locked

before placing in to the insert, to the left of the door frame.

.

Red Clasp: Slightly pull the lower part of the

strut down and then press the top of the red

clasp to extend or collapse the pole.

.

Twist: twist the central point to release the

prop and allow for the pole to extend and

detract.

Pull Clasp: Pull the circular lever out to

release the prop and allow for the pole to

extend of detract.

If the door is particularly heavy, which may suggest a fault, please ensure that this is reported to the

crew so that the appropriate entries can be added to the aircraft tech log.

Rear Hold Netting

The Q400 rear holds have cargo restraint netting separating hold 6 (in the doorway) and hold 7 (to

the right of the door). These nets must be secured whenever there is any load placed in either hold.

They can only be left unsecured when no load is present.

The door nets MUST be secured for EVERY FLIGHT, regardless of load.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 9

Forward Hold (5)

Hold 5 is located at the front of the aircraft on the right hand side and is accessible from an outside

door and also from inside the cabin. The external door is between the co-pilots window and the

passenger emergency exit (the hold door does not have a window). The inside cabin door remains

locked during flight.

Hold 5 is of limited size but has a

large effect on the trim, due to being

located so far forward.

Crews usually use H5 for their crew

bags, and loaders, unloading bags

from Hold 5, have accidentally

removed the crew bags as well as any

payload bags.

Any bags found in the hold, check

with the crew.

For this reason it is normally recommended that Hold 5 is only used for trim purposes or as an

overflow after the other holds are full.

H5 must always be checked for bags before the LIR can be signed on every turnaround with the

assistance of the cabin crew.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 10

GPU GROUND POWER UNIT

A GPU hookup is located at the front of the fuselage and accepts 28V DC.

The aircraft is very sensitive and will not accept power fluctuations from the GPU or FEGP.

CAUTION:

Whenever a GPU is connected to an aircraft the draw bar must be removed from the tug.

CHOCKING OF AIRCRAFT

Use either one double-width chock or two single width chocks. Do not place only one single-width

chock between double nose wheels. If using double width chocks always ensure that the chock will

not become trapped under the towbar when the aircraft settles as passengers board the aircraft.

Chocks should be positioned so that they just touch the wheel of the aircraft. Gaps must not be left

as this can create a rocking effect which will cause the aircraft to nudge chocks out of position thus

allowing the aircraft to move. Similarly both nosewheels or mainwheels on the same oleo most be

chocked.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 11

NOSE GEAR

A nose gear lock is fitted to the aircraft (black and

yellow chevron panel); located above the GPU and

headset hookup. This is used when towing the

aircraft, see GSB07-10 or Section 8.4.9 of Flybes

Ground Handling Manual, Part 1, (Ramp) for details

of this procedure.

The nose gear doors will close when hydraulic

pressure is generated. This will occur when the

number 2 engine is started. Staff should take care in

this area and not approach if aircraft engines during

start up.

The area will only be safe to approach once engines

are running and the door has closed. The tow bar can

then be disconnected if necessary.

FUELLING POINT

The aircraft pressurised refuelling point is located at

the rear of the right hand engine cowling.

There are also unpressurised, over-wing refuelling

points on the top surfaces of the wings.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 12

EQUIPMENT & SAFE ZONES

are the fuel vent safety

zones, these must remain clear of

equipment and people while

refuelling is taking place.

To allow for evacuation, all door

areas and passenger walkways should

remain clear during turn arounds.

DOOR CLOSING

Warnings can be triggered if the doors are not properly closed. After closing the doors or when

completing the walk around, check the door handles are fully closed and secure.

Rear cabin doors and forward hold (Hold 5) door handle, check the centre hub of the handle is flush

with the fuselage.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 13

Rear hold (Hold 6/7) door handle, check the push to release button is flush with the handle.

STEPS

The aircraft is fitted with one set of steps built into the forward passenger door and one set of

manually operated airstairs at the rear passenger door opening. The operation of the front passenger

door steps should be completed by 1 member of staff only.

Do not operate unless training has been received

Ensure PRMs are only boarded and disembarked through a passenger door and NOT the service door.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 14

ANTI-COLLISION WARNING BEACONS

A red anti-collision light is positioned on the top of the fuselage, forward of the wings.

WARNING the beacon cannot be seen if standing behind the aircraft

The following diagram indicates the range of visibility, of the beacon.

Beacon is VISIBLE Beacon is VISIBLE

Beacon is NOT VISIBLE Beacon is NOT VISIBLE

Beacon is NOT VISIBLE

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 15

PRM SPECIFICS

Acceptance

49% of the aircraft capacity, ensuring 1 abled bodied passenger to every PRM travelling (not including

crew). Further policies in relation to PRMs can be found at www.flybe.com under the FAQs section.

Seating

When allocating seats, passengers with limited mobility should be seated towards the front of the

cabin, near to the only toilet, but not in emergency exits. Where PRM passengers allocate their own

seats, every reasonable effort should be made to accommodate the PRM in the seats they have

selected. Please see page 4 of this handling guide for cabin layout and preferred seating.

Carriage & loading of Electric Mobility Aids

Guaranteed loading of EMAs: 2

Maximum wheelchair dimensions: 37inches wide x 35inches high

(W70cm x H90cm)

Electric mobility devices may require the use of spreaders. The Flybe spreader

calculator will show if they are necessary and can be found in the Flybe Ground

Handling Manuals at http://ghm.flybeas.com/manuals/

Wherever possible, PRM devices should be loaded into Hold 6 and tied down to the net mounting

rings. All devices will be loaded into the hold doorways and will be netted off from all baggage

Mobility aids will need to be stored if they exceed these limitations.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 16

SAFETY REPORTING & CULTURE

Flybe promote and welcome a Just Culture, and encourage open reporting and self-reporting by

airline staff and our contracted partners and agencies.

How to report

It is easy to report a safety event, simply go to either www.flybe.com/rampmanual or follow the

direct link https://www.flybe.com/incidentReport/login.do

What to report

Anything which you feel has a safety risk, safety impact on the operation or has the potential to

impact the safe operation over time.

Examples of what to report may include:

Aircraft damage and unintended contact

Vehicles or equipment obstructing the aircraft whilst moving

Significant spillage during fuelling operations

Connecting or removing ground equipment when it unsafe to do so

Unsatisfactory de-icing

Unsatisfactory loading of holds including netting, clips, lashing, misloaded baggage or cargo,

ballast

People endangered by aircraft or relating to aircraft including approaching aircraft whilst

warning beacons are on, lack of passenger guidance around engine area

Signed incorrect documentation including Loadsheet, LIR

Injury

Flybe would also welcome and encourage near miss reporting. This is where an event may occur but

is rectified by staff before the flight departs. The report will detail what happened and who/what

actions prevented it from going ahead ultimately preventing a safety event taking place.

These reports may also include events where simply luck prevented a safety event or potential safety

event.

How do Flybe recognise this?

Since 2008 Flybe has recognised staff who prevent a safety event taking place, through the form of

our Safety Award. Nominations can be made either by staff and management, or recognised through

the self-reporting of near miss events as explained above.

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 17

CONTACT US

Hopefully this guide has answered the majority of questions in relation to how to handle the Flybe

Bombardier Q400 aircraft.

If you have any further questions, or suggestions for this handling guide, please contact us using the

following addresses.

Email: GroundSafety@flybe.com

Post: Flybe Ground Safety Team

Airport Delivery Department

New Walker Hangar

Exeter International Airport

Exeter

Devon

EX5 2BG

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 18

Your Notes

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 19

Your Notes

Flybe Q400 Handling Guide VERSION 11 March 2014 Page 20

You might also like

- Q400 Line Training Guidelines Manual-1 LTGDocument116 pagesQ400 Line Training Guidelines Manual-1 LTGCapt. Salil Sharma100% (1)

- Q400 Technical Manual V8.4 Oct 14Document262 pagesQ400 Technical Manual V8.4 Oct 14Rufat Ilyasov100% (6)

- Q 400 FlowsDocument3 pagesQ 400 Flowsspickle27250% (4)

- Landing The Q 400Document27 pagesLanding The Q 400dismalmusicNo ratings yet

- Dash 8 A 4 Checklist 100203Document2 pagesDash 8 A 4 Checklist 100203Claire Dowsett100% (3)

- Q400 Normal ExpandedDocument35 pagesQ400 Normal ExpandedCristian Calvillo50% (2)

- Q400 Normal Expanded PDFDocument35 pagesQ400 Normal Expanded PDFWesley St GeorgeNo ratings yet

- DCH8 Q400 Handout PDFDocument79 pagesDCH8 Q400 Handout PDFShreepad Shivkar100% (2)

- Q400 ManualDocument46 pagesQ400 Manualckbt7691% (11)

- Q400 Manual Section 2 Training ProceduresDocument136 pagesQ400 Manual Section 2 Training ProceduresCaptainchandan Chakravarthy100% (9)

- Q400 Study Guide 4C.Document129 pagesQ400 Study Guide 4C.JAVIER TIBOCHA100% (3)

- DHC-8 Sop PDFDocument251 pagesDHC-8 Sop PDFdismalmusic100% (10)

- Horizon Air Q400 FlashcardsDocument9 pagesHorizon Air Q400 FlashcardsAnish ShakyaNo ratings yet

- Bee Q400 Normchk Jun14 PDFDocument2 pagesBee Q400 Normchk Jun14 PDFReljaNo ratings yet

- Q400 CommunicationsDocument54 pagesQ400 CommunicationsMoshiurRahmanNo ratings yet

- Qref Q400Document6 pagesQref Q400ReljaNo ratings yet

- CRJ QRH 11 01 2008Document314 pagesCRJ QRH 11 01 2008bnolasco100% (2)

- Aom R18 DHC-8 Q400Document1,884 pagesAom R18 DHC-8 Q400Rafid Al Islam100% (15)

- Q400 TOLD Speed v2.1Document4 pagesQ400 TOLD Speed v2.1Pires FPNo ratings yet

- Bombardier Dash 8 Q400 Navigation PDFDocument187 pagesBombardier Dash 8 Q400 Navigation PDFSwapnil kapadia100% (1)

- CRJ QRH Vol.1 Rev07Document276 pagesCRJ QRH Vol.1 Rev07Pablo Guigou100% (1)

- Ops CircularDocument41 pagesOps CircularSwastika MishraNo ratings yet

- Bombardier Dash 8 Q400: Standard Operating ProceduresDocument35 pagesBombardier Dash 8 Q400: Standard Operating ProceduresDanielNo ratings yet

- Bombardier Dash-8-300 QRHDocument142 pagesBombardier Dash-8-300 QRHjohn heath50% (4)

- DASH-8 SOP CompleteDocument181 pagesDASH-8 SOP CompleteNil100% (11)

- Horizon Air Q400 Pre-Training Memory Items Flashcards - QuizletDocument12 pagesHorizon Air Q400 Pre-Training Memory Items Flashcards - QuizletAnish Shakya100% (2)

- Dash 8-Q Series Flight Deck Issue 2 2014Document31 pagesDash 8-Q Series Flight Deck Issue 2 2014hsotilg100% (3)

- Erj 195 Pilot QRH Rev3Document33 pagesErj 195 Pilot QRH Rev3aivanov3No ratings yet

- Sop B190 Mac .2Document94 pagesSop B190 Mac .2edward leparakuoNo ratings yet

- Dowty Q400 PDFDocument4 pagesDowty Q400 PDFVijay Gunalan80% (5)

- Dash 8 100 Non Normal Rev 10Document94 pagesDash 8 100 Non Normal Rev 10DJ100% (2)

- Dash8 Q400ManualDocument16 pagesDash8 Q400ManualCaptainchandan Chakravarthy100% (2)

- FCTM Norm Emer ProcDocument168 pagesFCTM Norm Emer Procjim justinNo ratings yet

- Osds Omr SheetDocument412 pagesOsds Omr SheetAnil kumarNo ratings yet

- Q400 PropellerDocument10 pagesQ400 PropellerMoshiurRahman100% (1)

- QRH CRJ 200Document392 pagesQRH CRJ 200Andres Carpena100% (1)

- Erj Qrh-3708-204-Rev04-FullDocument258 pagesErj Qrh-3708-204-Rev04-Fullaivanov3No ratings yet

- Embraer Training ManualDocument270 pagesEmbraer Training ManualKent100% (1)

- Flight ControlsDocument51 pagesFlight ControlsJonathan FajardoNo ratings yet

- Q400-Landing Gear 1Document43 pagesQ400-Landing Gear 1MoshiurRahman100% (2)

- Dash 8 TOLDDocument20 pagesDash 8 TOLDspickle272100% (1)

- Q400 Presentation - APUDocument9 pagesQ400 Presentation - APUTom100% (1)

- Challenger 604 Operations Reference ManualDocument588 pagesChallenger 604 Operations Reference ManualCielo Molina100% (2)

- Q400 Power PlantDocument70 pagesQ400 Power PlantMoshiurRahman100% (2)

- CRJ700 ChecklistDocument5 pagesCRJ700 Checklistaviaced972100% (4)

- Cessna Sovereign S&DDocument27 pagesCessna Sovereign S&DPeter Victor100% (1)

- Sop Bae 146 Avro RJ 2 PartDocument296 pagesSop Bae 146 Avro RJ 2 Partali4957270100% (7)

- General: CL 605 Flight Crew Operating Manual PSP 605 6Document6 pagesGeneral: CL 605 Flight Crew Operating Manual PSP 605 6Fidel Arellano0% (1)

- cl605 QRHDocument136 pagescl605 QRHFidel Arellano100% (1)

- 111307149-Dash-8-PHB-a28-1146-041 2 PDFDocument241 pages111307149-Dash-8-PHB-a28-1146-041 2 PDFjul100% (2)

- Dash 8 & Q Series Aircraft Guide: Specs, Analysis & CostsDocument17 pagesDash 8 & Q Series Aircraft Guide: Specs, Analysis & CostsMyles100% (1)

- Preflight Manual EMB-145: Uncontrolled Copy When Downloaded or Printed From An Electronic DocumentDocument62 pagesPreflight Manual EMB-145: Uncontrolled Copy When Downloaded or Printed From An Electronic DocumentKentNo ratings yet

- CRJ Poh 12 01 2008 PDFDocument780 pagesCRJ Poh 12 01 2008 PDFGeoffrey MontgomeryNo ratings yet

- Pressing On: Unstable Approach Continuation BiasFrom EverandPressing On: Unstable Approach Continuation BiasRating: 5 out of 5 stars5/5 (1)

- CircularDocument2 pagesCircularasif farhan sheikhNo ratings yet

- MG 1P Series Disclaimer and Safety Guidelins v1.0 ENDocument23 pagesMG 1P Series Disclaimer and Safety Guidelins v1.0 ENwanderley caldeira pereiraNo ratings yet

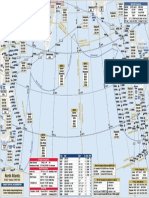

- North Atlantic ChartDocument1 pageNorth Atlantic ChartzacklawsNo ratings yet

- Active Armour OrbatsDocument13 pagesActive Armour OrbatszacklawsNo ratings yet

- PBP Time Schedule 2019Document4 pagesPBP Time Schedule 2019zacklawsNo ratings yet

- USArmy NKvsUSTacticsDocument33 pagesUSArmy NKvsUSTacticszacklawsNo ratings yet

- Yssy PDFDocument42 pagesYssy PDFzacklawsNo ratings yet

- KindDocument28 pagesKindzacklawsNo ratings yet

- KABQDocument27 pagesKABQzacklawsNo ratings yet

- Old 240 CP's INFO ControlsDocument2 pagesOld 240 CP's INFO ControlszacklawsNo ratings yet

- PBP Time Schedule 2019Document4 pagesPBP Time Schedule 2019zacklawsNo ratings yet

- LEBLDocument155 pagesLEBLzacklaws100% (1)

- ELLXDocument8 pagesELLXzacklawsNo ratings yet

- KEWRDocument46 pagesKEWRzacklawsNo ratings yet

- FLLSDocument9 pagesFLLSzacklawsNo ratings yet

- KindDocument28 pagesKindzacklawsNo ratings yet

- LR25 CockpitReferenceHandbookDocument592 pagesLR25 CockpitReferenceHandbookChiragCharania100% (3)

- IL-2 Sturmovik Mission Editor and Multiplayer Server ManualDocument350 pagesIL-2 Sturmovik Mission Editor and Multiplayer Server Manualzacklaws100% (1)

- DEN Airport Info - Fuel, Runways, ServicesDocument86 pagesDEN Airport Info - Fuel, Runways, ServiceszacklawsNo ratings yet

- SBGRDocument64 pagesSBGRzacklawsNo ratings yet

- Vantaa Airport InformationDocument61 pagesVantaa Airport InformationzacklawsNo ratings yet

- KPDXDocument44 pagesKPDXzacklawsNo ratings yet

- SKBODocument53 pagesSKBOzacklaws100% (1)

- KlaxDocument75 pagesKlaxzacklawsNo ratings yet

- Airport Information: Details For ONTARIO INTLDocument30 pagesAirport Information: Details For ONTARIO INTLzacklawsNo ratings yet

- KJACDocument29 pagesKJACzacklawsNo ratings yet

- KENNEDY INTL Airport InformationDocument56 pagesKENNEDY INTL Airport Informationzacklaws100% (1)

- Vancouver Intl Airport Info: Runways, Fuel, Customs & MoreDocument56 pagesVancouver Intl Airport Info: Runways, Fuel, Customs & MorezacklawsNo ratings yet

- Airport Information: Details For Armstrong New Orleans IntlDocument24 pagesAirport Information: Details For Armstrong New Orleans Intlzacklaws100% (1)

- KMSPDocument52 pagesKMSPzacklawsNo ratings yet

- YPPHDocument33 pagesYPPHzacklawsNo ratings yet

- Cleveland-Hopkins Intl Airport InformationDocument48 pagesCleveland-Hopkins Intl Airport InformationzacklawsNo ratings yet

- Delhi Metro PPT FinalDocument20 pagesDelhi Metro PPT FinalkalpanayadavNo ratings yet

- Maybank Debit Card Kiosk LocationDocument2 pagesMaybank Debit Card Kiosk LocationZana SulaimanNo ratings yet

- 1SBC100214C0201 - Main Catalog 2019 PDFDocument912 pages1SBC100214C0201 - Main Catalog 2019 PDFDangQuangTrungNo ratings yet

- Hara PDFDocument16 pagesHara PDFAYUSH RANANo ratings yet

- Electronic Ticket Receipt 10FEB For SIMPLICIA CANEZADocument4 pagesElectronic Ticket Receipt 10FEB For SIMPLICIA CANEZARacquel SolivenNo ratings yet

- NPTEL Bridge Engineering Video CourseDocument3 pagesNPTEL Bridge Engineering Video CoursedevaNo ratings yet

- John Deere Tractor Service Manual 4040 Tractor 4240 TractorDocument12 pagesJohn Deere Tractor Service Manual 4040 Tractor 4240 Tractormymisel0% (1)

- Supplemental Restraint System OverviewDocument12 pagesSupplemental Restraint System OverviewMACHINo ratings yet

- TaiYuan South Railway StationDocument1 pageTaiYuan South Railway StationASHWIN BNo ratings yet

- E Paper IT8951 Driver HAT B Schematic PDFDocument1 pageE Paper IT8951 Driver HAT B Schematic PDFfirsttenor100% (1)

- Wirtgen - 2200 SMDocument22 pagesWirtgen - 2200 SMDanu Putra100% (2)

- Highway & Structure Drawing - TAJPURDocument16 pagesHighway & Structure Drawing - TAJPURsmithNo ratings yet

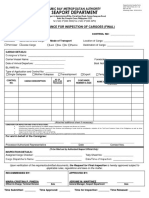

- Clearance For Inspection Form (Final) Rev 2Document1 pageClearance For Inspection Form (Final) Rev 2Carlo GiancarloNo ratings yet

- Fault Codes: Engine ElectronicsDocument14 pagesFault Codes: Engine ElectronicsSTO UAndriivNo ratings yet

- Captain GopinathDocument2 pagesCaptain GopinathAnonymous aCTfqG9RNo ratings yet

- Network 1 Unit 5Document3 pagesNetwork 1 Unit 5FranciscaBalasSuarezNo ratings yet

- Shimano Compatibility PDFDocument32 pagesShimano Compatibility PDFBob Lablaw100% (1)

- CES Wrong Answer Summary-1Document2 pagesCES Wrong Answer Summary-1Владислав Комаров100% (1)

- Ebook PDF Urbanization An Introduction To Urban Geography 3rd EditionDocument61 pagesEbook PDF Urbanization An Introduction To Urban Geography 3rd Editionmario.becker25298% (41)

- Marine CV Captain Template Modern Seafarer Application FormDocument1 pageMarine CV Captain Template Modern Seafarer Application FormMarine CVNo ratings yet

- Abraham Path-Petra Atlas v1.0Document21 pagesAbraham Path-Petra Atlas v1.0Abraham Path InitiativeNo ratings yet

- Packaging, Marking, and Loading Methods For Steel Products For Domestic ShipmentDocument41 pagesPackaging, Marking, and Loading Methods For Steel Products For Domestic Shipmentamer100% (1)

- Automatic differential locking systemDocument24 pagesAutomatic differential locking systemJeevan Landge PatilNo ratings yet

- Airlines and Aircraft Update ReadmeDocument30 pagesAirlines and Aircraft Update Readmeclip215No ratings yet

- Cotton WarehousesDocument34 pagesCotton WarehousesJoseph PanglossNo ratings yet

- Insulation ResistanceDocument41 pagesInsulation Resistancekhozema_goodluck75% (4)

- Maintenance Wall Chart KPM 001 0612 Rev2Document1 pageMaintenance Wall Chart KPM 001 0612 Rev2fahrul amirNo ratings yet

- Maruti Suzuki Training Report Full ReportDocument62 pagesMaruti Suzuki Training Report Full ReportAnkit Dua76% (21)

- Flag State Change Log September 2019 PDFDocument45 pagesFlag State Change Log September 2019 PDF111No ratings yet

- Chapter 3 Reverse Charge & ECO NOV 19 1565841627927Document5 pagesChapter 3 Reverse Charge & ECO NOV 19 1565841627927Manoj BothraNo ratings yet