Professional Documents

Culture Documents

Pet Degradation

Uploaded by

LAURA VALENTINA PEREZ RODRIGUEZOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pet Degradation

Uploaded by

LAURA VALENTINA PEREZ RODRIGUEZCopyright:

Available Formats

fonyl diisocyanate, chlorine, and sulfur dioxide in Sulfonyl diisocyanate is also formed on prolonged

excellent yields: boiling of NCSA with silver cyanate [721.

Sulfonyl diisocyanate appears to be rather less reactive

than NCSA, but reacts with the above-mentioned

classes of compounds, including olefins, to give prod-

ucts similar to those obtained with NCSA. Many of

At about 400 "C in the presence of catalysts containing these reactions can be controlled to give predominant

FeC13, sulfonyl diisocyanate is formed directly from reaction of both isocyanate groups or of only one iso-

SO3 and cyanogen chloride L711: cyanate group [301.

Received: August 10, 1967 [ A 621 IE]

German version: Angew. Chem. 80, 179 1968

Translated by Express Translation Service, London.

[71] K. Mutterstock and R . Gruf, German Pat. 1171 887, Farb- [721 R. Appel and W. Senkpiel, Angew. Chem. 70, 271 (1958);

werke Hoechst AG (1961). Chem. Ber. 91, 1200 (1958).

The Degradation of Poly(ethy1ene terephthalate) [**I

BY L. H. BUXBAUM I*]

The penetration of new markets by polyester fibers has emphasized the need for increased

stability of the polyester to ward a variety of degradative reactions. Extensive studies

of the nature of the thermal, hydrolytic, oxidative, and radiation-induced degradation

reactions have been reported. The interpretation of kinetic investigations and the identifi-

cation of the reaction products have been facilitated by using suitable esters as model

compounds in place of the polymeric species.

1. Introduction 1.1. Preparation of Poly(ethy1ene terephthalate)

Poly(ethy1ene terephthalate) is prepared in two stages from

Poly(ethy1ene terephthalate) has the reputation of dimethyl terephthalate and ethylene glycol. In the first stage

being a polymer of great resistance to environments a precondensate is formed which chiefly consists of the di-

which might be expected to limit its useful life as a glycol ester together with a certain amount of oligomers (up

fiber, film, or other end product. However, even the to the tetramers).

small amount of decomposition occurring under This trans-esterification, which is catalyzed by small amounts

of metal salts (Zn, Mn, Cd, Pb, Ca, Mg, etc.), is carried out

normal manufacturing and processing conditions is at 200 "C, the methanol formed being continually removed

important to the manufacture of a uniform product. by distillation. The complete removal of the methanol is

Polyester fibers and films, although of excellent dur- most important since it can drastically interfere with the

ability, can be affected by hydrolysis, aminolysis, and formation of sufficiently long chains; as a monofunctional

alcohol it forms stable end groups and thus prematurely

various kinds of radiation.

stops chain growth.

To avoid a gradual deterioration of the physical In the second stage, polycondensation of the precondensate

properties of the product, such degradation reactions is carried out at ca. 280C in high vacuum (< 1 torr) and

must be inhibited or retarded. In turn, successful with addition of a heavy metal salt (usually Sb), the glycol

stabilization must be based on an understanding of formed being continually removed.

the precise mechanism by which each type of degrada- Concentration of catalyst and temperature control are very

significant factors in determining the stability of the resulting

tion occurs. Much research in this direction has been polyesters. Additionally, of course, stabilizers (usually P-

conducted by the polyester producers and by textile compounds) can also be added.

research institutes.

[*I Dr. L. H. Buxbaum 1.2. Properties of Poly(ethy1ene terephthalate)

Goodyear Tire and Rubber Co., Polyester Research and

Development Division, Akron, Ohio (USA)

Present address: Poly(ethy1ene terephthalate) exhibits a number of interesting

Alpine Chemische AG., Schaftenau

A-6330 Kufstein (Austria) physical, and chemical, properties, only the most important

[**I Publication No. 4 from the Polyester Research and of which shall be briefly mentioned here. On account of the

Development Division, hydrophobic nature of this polymer (absorption of water at

The Goodyear Tire and Rubber Co., 20 O C and at a relative humidity of 25 % is less than 0.5 %) its

Akron, Ohio (USA) mechanical properties are almost uninfluenced by water (i.e.

182 Angew. Chem. internat. Edit. 1 VoI. 7 (1968) 1 No. 3

it has a high wet strength, and there is no flat spotting of Maccoll[41 proposed that the reaction is a pseudo bi-

the polyester tire cord). Poly(ethy1ene terephthalate) is very molecular electrophilic substitution, (E2), involving

resistant t o attack by most organic solutions and reagents,

nucleophilic attack of the carbonyl oxygen atom on

especially acids, and also t o biological degradation. It is

much more stable toward the effect of light and atmospheric the ?-hydrogen atom.

conditions than most of the other polymers. This field has been widely but unsystematically studied.

Poly(ethy1ene terephthaiate) fibers are distinguished by A good survey of the earlier literature up to about 1928

their excellent resilience and by their dimensional sta- has been presented by Uurdr51. Ritchie@l has summa-

bility. Up t o a temperature of ca. 150C the properties

of the fiber deteriorate very little. Other properties which are rized nine of the breakdown routes which occur most

responsible for the popularity of poly(ethy1ene terephthalate) frequently.

fiber in the textile industry are its good permanent-set

property and high melting point (260 C ) .

2.2. Thermal Degradation of Model Compounds

The excellent electrical properties of poly(ethy1ene tere-

phthalate), such as high specific resistance, high dielectric

strength, together with its thermal stability and small moisture Difficulties in studying the polyester itself suggested

absorption, make it a very good insulating material.

the use of simplified model systems representing

specific segments of the intact PET chain, segments

with terminal hydroxyethyl groups and representing

2. Thermal Degradation the known incorporation of occasional ether linkages.

Ethylene dibenzoate (2), 2-hydroxyethyl benzoate (3)

and diethylene glycol dibenzoate ( 4 ) have been chosen

The nature of thermal degradation of polyesters is not most often for such studies. The degradation of (2)

entirely clear. The primary fission of the ester linkage

in the polymer is probably not a homolytic, reaction, C~HS-CO-O-CH~-CH~-O-CO-C~HS

since thermal degradation cannot be inhibited by free (21

radical trapping agents. The close agreement between

C6HS-CO-O-CH2-CHzOH

the behavior of poly(ethy1ene terephthalate) (PET)

and model ester compounds (see Section 2.2) suggests (31

that the mechanism for polymer degradation is prob- C~H~-CO-O-CH~-CHZ-O-CH~-CH~-O-CO-C~HS

ably similar to that for simple ester pyrolysis.

(4)

between 250 Cand 350 C has been well studied [*, 7,9J,

2.1. Thermal Degradation of Carboxylic Esters and is thought to proceed via a cyclic transition state.

in General

Benzoic acid (6) and vinyl benzoate (7) are formed.

The mechanism by which esters containing at least

one p-hydrogen atom decompose pyrolytically to give

olefins and acids is generally considered to involve a

cyclic transition state ( I ) 1 1 1 .

Ritchie 161 also reported benzophenone as a reaction product,

although there is n o confirmation of this product by other

workers. It is possible that this difference in product forma-

tion may have resulted from the use of different temperatures

In (I), the C-H bond and the alkoxy C-0 bond are in the pyrolysis.

partiy broken, while the olefinic C=C bond and the

3-Oxapentylene dibenzoate (4) decomposes by a

0-H bond are partially formed. Previous work [21 has

similar route to give benzoic acid and 2-vinyloxyethyl

shown that the C-0 bond breakage is heterolytic and

benzoate (8).

that the alpha-carbon atom develops some carbonium-

C~H~-CO-OCHZ-CHZ-OCH=CHZ

ion character in the transition state. It appears that

for a given ester at a fixed temperature, the rate of (8)

decomposition is determined more by the stability of

[4] A. Maccoll, J. chem. SOC.(London) 1958, 3398.

the breaking alkoxy C-0 bond than by the breaking

151 C. D . Hurd The Pyrolysis of Carbon Compounds. Chemical

C-H bond or the forming C=C bond 131. Catalog Co., New York 1929.

[6] P. D . Ritchie, Soc. chem. Ind. (London) Monograph No. 13,

111 C. H . DePuy and R . W. Kong, Chem. Reviews 60,431 (1960), 107 (1961).

and references therein. [7] E. P. Goodings, SOC.chem. Ind. (London) Monograph No.

[21 R. Taylor, G. G . Smith, and W. H . Wetzel, J. Amer. chem. 13, 211 (1961).

SOC. 84, 4817 (1962). 181 H. V. R. Iengar and P . D . Ritchie, J. chem. SOC. (London)

[31 G . G. Smith, F. D . Bagley, and R . Taylor, J. Amer. chem. 1987, 2556; 1956, 3563.

S O C . 83, 3647 (1961). 191 G. Challa, Makromolekulare Chem. 38, 138 (1960).

Angew. Chem. internat. Edit. f Vol. 7 (1968) / No. 3 183

Despite the importance of 2-hydroxyethyl esters in the The vinyl compounds formed during these reactions

formation of PET, few studies with model compounds react further to give a complex mixture of end products.

such as 2-hydroxyethyl benzoate (3) have been per- The pyrolysis of vinyl benzoate (7) has been studied

formed. Iengar and Ritchie [8J studied the pyrolysis of extensively and it has been shown, that, as expected,

(3) at temperatures 'between 375 "C and 500 "C and this vinyl compound reacts very rapidly at 280C.

proposed a complex degradation mechanism. Our After 30min at this temperature (7) yielded a black

results, which were obtained at 280"C, suggest a mass in which benzoic acid (6), benzoic anhydride

different mechanism involving a seven-membered ring (12) and a diene (14) could be detected.

(9) as transition state and the formation of an active The following facts can be given as proof that the intermedi-

species ( l o ) [141. This mechanism explains the low ates (11) and (13) are formed in the reaction: Ethylidene di-

benzoate (11) could be isolated from the reaction mixture

activation energy found for this reaction (28 kcal/mole) containing compounds (6) and (7) by gas chromatography

and the formation of ether linkages. (The dehydration and was identified by IR- and NMR-spectroscopy. Starting

reaction is not significant at 280 "C, as could be shown from compound (11) a n equilibrium is once again set up at

with ethylene glycol [91.) 28OoC between (7) and (6) as well as with (12) and acet-

aldehyde. Polyvinyl benzoate (13) (prepared from vinyl

benzoate and a radical chain initiator) similarly gives com-

pounds (6) and (14) at 280 "C; the presence of (14) was con-

firmed by IR- and UV-spectroscopy.

Recently Zimmermann and Leibnitz (101 investigated the

(3) (91 influence of catalysts on a number of theindividual reactions.

The primary chain splitting reaction of ethylene dibenzoate

(2) to benzoic acid (6) and vinyl benzoate (7), as well as the

reaction of (7) with alcohols and the polymerization of (7),

are accelerated e.g. by zinc acetate. It was found that the

catalysts zinc acetate and lead acetate have no influence o n the

HOCH2-CH20H + ICH2CH201 + thermal degradation of polyvinyl benzoate(l3) to (6) and (14)

HOCH2-CH2-O-CH2-CH20H or o n the formation of acetaldehyde and (12) from (7) and (6).

C~HS-CO-O-CH~-CH~OH [CHpCHzOJ + + 2-Vinyloxyethyl benzoate (8), the first degradation

C~HS-CO-O-CH~-CH~-O-CH~-CH~OH product of 3-oxapentylene dibenzoate ( 4 ) , decomposes

further to benzoic acid (6),acetaldehyde, and acetylene

A transesterification reaction takes place also, and at at temperatures above 350 "C 181. At 280 "C, however,

280 "C the equilibrium 2 (3) + (2) + ethylene glycol another reaction is of importance: in the presence of

is established in ca. 10 min. benzoic acid the diester (2) is formed, the "acylal"

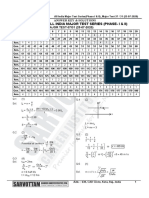

Figure 1 shows the thermal degradation of (21, (3), (IZ), which is known to form in the reactions of other

and (4). vinylethers 1111, probably occurring as intermediate.

At 280 "C at least 50 % of the carboxyl groups formed

500 t I in the degradation of ( 4 ) react with the vinyl ether (8)

i to give (2) and acetaldehyde [141.

LOO L

I I

i

IOU C'i _________----------

*

i

I -

0 1 2 3 L

m t lhl- [lo] H . Zimmermann and E. Leibnitz, Faserforsch. u. Textil-

Fig. 1 . Thermal degradation of ethylene dibenzoate (2) -, 3-oxa- techn. 16, 282 (1965).

pentyl enedibenzoate (41 -,and 2-hydroxyethyl benzoate (3) .- .- [Ill M . F. Shostakovskii, 2. ObSE. Chim .18, 1989 (1948); Chem.

at 280 "C under nitrogen. Abstr. 43, 3785 h (1949).

184 Angew. Chem. internat. Edit. VoI. 7 (1968) / No. 3

In general, caution is necessary in correlating the the functional groups react with one another, and the

results obtained from studies with model compounds polymer becomes colored.

with the reactions of the polymer itself. However, it

2.3.1.1. G a s e o u s P r o d u c t s

has been found that in this case model compound

reactions d o not differ much from the reactions taking A gaseous mixture with the following composition

place during the thermal degradation of PET, especi- (concentration in mole- %) is formed at temperatures

ally at temperatures between 200 "C and 300 "C. between 280 "C and 306 "C [73: C O = 8.0; C 0 2 = 8.5;

H20 = 0.8; CH3CH0 = 79.5; CzH4 = 2.0; 2-methyl-

2.3. Thermal Degradation of dioxolane =- 0.4; CH4 = 0.4; C6H6 = 0.4. Although

Poly(ethy1ene terephthalate) this composition varies appreciably with temperature

acetaldehyde is always the major product.

Various research teams have studied the thermal

degradation of polyester during the last few years[6.7, 2.3.1.2. N o n - g a s e o u s P r o d u c t s , O l i g o m e r s

10-131. From their results and from extensive studies

with model compounds we know that PET breaks During melt spinning of PET a white "dust" is formed

down by a molecular mechanism with random chain and covers various parts of the spinning apparatus [ 1 5 a I .

scission at the ester links. Although a radical mech- A similar sublimate can be produced in the laboratory

anism has been proposedf121, no evidence for such a by bubbling nitrogen through molten polyester. This

mechanism could be established. sublimate consists primarily of terephthalic acid and

Pohl1131 proposed that the principal point of weakness acidic oligomers 17,141.

in the polyester chain is the P-methylene group. The Cyclic oligomers (mainly the trimer) are also formed

main reactions in the thermal degradation of PET are during the thermal degradation of PET. A kind of

summarized in the following scheme: equilibrium between the cyclic oligomers and the

polymer seems to exist. After extracting these oligo-

mers from PET and heating the extracted polymer for

f o r m a t i o n of

crosslinks 11 J-

-C6H4-COOH + Polyene Polyenaldehyde

Scheme I .

about one hour at 280"C, the same amount of cyclic

If 2-hydroxyethyl end groups are present in the poly- oligomer is again formedr16J. It is not known how

mer the following reactions take place also: these oligomers are formed in the polymer, although

Scheme 2. a transesterification involving end groups can be

assumed.

Thus, as long as free hydroxyl end groups exist in a Goodings "1 isolated a number of compounds, mainly

PET melt, every broken polymer link will be reformed. derivatives of substituted benzoic acids and biphenyl-

When most of the hydroxyl end groups have been di- and monocarboxylic acids, from extensively pyro-

consumed, the molecular weight will begin to fall. lyzed PET. However, these materials were found in

very low concentration (0.005-0.09 wt. %).

2.3.1. P r o d u c t s of T h e r m a l D e g r a d a t i o n -

[14] Unpublished observations by the Polyester Research &

Development Division, Goodyear Tire & Rubber Co., Akron,

When PET is maintained in a molten state under Ohio (USA).

nitrogen at about 28OoC, it decomposes slowly to [15] H . Zimmermann, Faserforsch. u. Textiltechn. 17,228 (1964).

gaseous and to solid, low molecular weight products; [15a] A. Mifine, S . Ishida, A . Kobayashi, and S . Sakajiri, Kogyo

Kagaku Zassi 65, 992 (1962).

I121 I. Marshall and A . Todd, Trans. Faraday SOC.49, 67 (1953). [16] I. Goodman and B. F. Nesbitt, Polymer (London) I , 384

1131 H. A. Pohl, J . Amer. chem. SOC. 73, 5660 (1951). (1960); J. Polymer Sci. 19, 423 (1960).

Angew. Chem. internat. Edit. J Vol. 7 (1968) No. 3 185

2.3.1.3. Reactions of Functional G r o u p s energies found by different authors using one or more

of the methods mentioned above. It is interesting that

PET has an average molecular weight of 25000 all the rate constants have the same order of magnitude.

(intrinsic viscosity [q] = 0.68 dl g-1). The concentration

The effect of molecular weight (or intrinsic viscosity)

of carboxyl groups depends on the catalyst and is of

on the thermal degradation of PET per unit time, and

the order 10-50 equiv/l06 g of polymer. The concen-

at various temperatures, is shown in Figure 2.

tration of hydroxyl end groups is about 60 equiv/l06 g.

During thermal degradation, the concentration of

Table 1. Reaction rate constant and activation energy of the thermal

hydroxyl groups tends to fall and the carboxyl group degradation of PET.

content of the polymer increases. Anhydride groups

can be formed; they begin to accumulate when most k and Ea calculated from 1 k(h-1.103) at 282C 1 Ea (kcal/mol)

of the hydroxyl end groups have been consumed[71. I711 [a1 1.3 2.3 1.4 62.3

The anhydride groups are formed by the reaction of M.V. [bl 1.7 (290 "C) 32.0 48

Total gas - 38

vinyl end groups with carboxyl groups and by dehy-

-COOH 3.5 41.7

dration of two carboxyl groups. Goodings [71 reported -OH 2.4

that PET which had been degraded at 306C for 65 -CHO 0.2

Total end groups 1.2 58.7

hours under nitrogen gave an IR-spectrum indicating References r71 1121 r141 171 1121 r171 r141

that anhydride and carboxyl groups were present in

[a] Intrinsic viscosity.

the ratio 1:2.6.

[bl Melt Viscosity.

2.3.1.4. Di scol oration

Discoloration is a serious problem in the production

of PET since the consumer of white polyester goods

demands a brilliant white color. As PET degrades, its

color changes first to yellow, then to brown, and

finally to black. Since the chromophoric substances

involved are very difficult to isolate, contradictory

results have been reported about their nature and com-

position. At least part of thechromophore seems to be [?I Idl.g"1-

chemically bonded to the polymer. The chromophore Fig. 2. The thermal degradation of PET per minute as a function of [71l

at different temperatures.

is believed to be a highly unsaturated aliphatic mole-

cule with a molecular weight of about 300-1000 17,141.

Two routes leading to color formation in PET are

3. Oxidation

discussed in the literature. Goodings 171 assumes the

formation of polyenaldehydes from acetaldehyde.

Zimmermann [ l o , 151, on the other hand, has shown The degradation of PET in various oxygen-nitrogen

that unsaturated, color forming molecules are formed mixtures between 280C and 325C has been in-

from polyvinyl esters. Our own studies show that both vestigated by Marshall and Todd[l21. The rate of

reactions contribute to color formation; the precise degradation (measured by the decrease in the melt

polymerization conditions will determine which viscosity) increased linearly with increasing oxygen

reaction sequence predominates. content. Passing oxygen through molten polyester

causes rapid degradation, noticeable by color forma-

2.3.2. K i n e t i c s tion, an increase in carboxyl content and a decrease in

molecular weight 1141.

Investigations on the kinetics of simple esters r3-51

3.1. Course of Oxidation

show that their decomposition reactions are homo-

geneous, follow first order kinetics in both the vapor

and the liquid phase, and are unaffected by radical No generally accepted concept for the course of the

scavengers. The activation energy found for ester oxidation of PET has been reported. In previous

pyrolysis was about 40 kcal/mole; on a theoretical studies, the mechanism developed by Bolland et. a/[191

basis pure chain scission of the ester link would re- for the oxidation of hydrocarbons has generally been

quire an activation energy of almost 60 kcal/mole. The referred to and adopted in the interpretation of the

lower value observed indicates a mechanism probably oxidation of polymers [181.

involving a cyclic transition state ( I ) . The high molecular weight of PET and the influence

The rate of thermal degradation of PET can be meas- of the physical structure make it difficult to study the

ured in terms of: a) the products formed, b) the rate of oxidation of the polymer directly. Consequently,

change of molecular weight of the polymer (as meas-

[17] S. Straus and L. A . Wall, J. Res. nat. Bur. Standards, A . 60,

ured by the melt viscosity or the intrinsic viscosity), 39 (1958).

or c) the rate of change in concentration of end groups. [18] W. L. Hawkins, SPE Trans. July 1964, 187.

Table 1 shows reaction rate constants and activation [19] J. L. Bolland, Quart. Rev. chem. SOC.(London) 3, 1 (1949).

186 Angew. Chenz. internat. Edit. Vol. 7 (1968) I No. 3

studies with model compounds have provided most of which oxygen and moisture play an important role in

the mechanistic information available. 3-Oxapentylene the degradation.

dibenzoate ( 4 ) oxidizes readily at 130 oC[2*1 to give Stephenson et al. [211 and Marcotte et al. 1 2 showed

~

2-benzoyloxyethyl benzoyloxyacetate, 2-benzoyIoxy- that the polymer turns to an amber color, becomes

ethyl formate, benzoyloxyacetic acid, benzoic acid, brittle, evolves gas (mainly CO and COz), and be-

formic acid and water. Ethylene dibenzoate (2), and 2- comes partly insoluble in trifluoroacetic acid, after it

hydroxyethyl benzoate, ( 3 ) , can not be oxidized at has been exposed to monochromatic light of wave-

130 OC; above 200 C decomposition occurs, but this lengths 2537 and 3130 A. From their results the reac-

is probably a combination of oxidative and thermal tion sequencegshown in Scheme 4 seem probable:

degradation. The mechnism of the oxidation of these

two model compounds is therefore inaccessible to

direct study. When comparing the degradation of

these compounds under oxygen and under nitrogen at

210 C, the higher carboxyl-group content and the

darker color of the samples heated under oxygen sug-

gest a breakdown to acidic and color forming species

similar to those obtained from ( 4 ) .

The results from these model compound studies are in

good agreement with results obtained with PET.

Diethylene glycol links lower the stability of polyester

toward oxidation. The reaction sequences shown in Hydrogen abstraction from neighboring molecules

Scheme 3 have been proposed as an interpretation of leads to the formation of radicals such as (21) and (22).

the oxidation of PET:

1

These radicals can recombine to form crosslinks, the

nature of which is, at present, unknown. The forma-

tion of polyphenyl systems, in which reactions involv-

ing the radical (22) (see section 4.2.) seem to be of

little importance, has also been suggested [221.

4. Degradation by Radiation

4.1. Photolysis

Generally speaking poly(ethy1ene terephthalate) is

very stable toward ultraviolet light; however, some

long term degradation occurs especially when it is

exposed to light of wavelength 3000-3300 ,k[21aI.

There seems to be a threshold photon energy of about

3 eV below which no damage is done[211. For practical purposes, weathering experiments give a

good picture of the performance of PET in specific outdoor

The present understanding of the photodegradation applications. Under these conditions the ether content of the

of polyesters is very rudimentary since most reports polymer is of extreme importance. Coleman [221 exposed

on this subject are of weathering experiments, in copolymers of PET containing polyoxyethylene gIycoI to

ultraviolet light. After 300 hours of exposure, a yarn con-

1201 L. H. Buxbaum, ACS Polymer Preprints, 8, 552 (1967). taining 17% by weight of polyoxyethylene glycol (MW =

[21] C. V . Stephenson, B. D . Moses, and W. S . Wilcox, J. Poly- 2800) showed a 40% decrease in intrinsic viscosity while

mer Sci. 55,451, 465,477 (1961). pure PET was not affected. Therefore this copolymer was not

[21a] F. B. Marcotte, D . Campell, J. A . Cleaveland, and D . T .

Turner, J. Polymer Sci. A-1, 5,481 (1967). 12-21 D. Coleman, J. Polymer Sci. 14, 15 (1954).

Angew. Chem. internat. Edit. / VoZ. 7 (1968) 1 No. 3 187

accepted on the market even though the dyeability of fibers groups are formed - and no gel formation has been

of this material was much superior to that of fibers prepared observed. At higher dose rates (over 5000 Mrad) a

from the homopolymer.

network is formed in the polymer [291 and fewer car-

boxyl groups are formed.

4.2. Degradation by High Energy Ionizing Radiation Some investigations have been carried out using high speed

electrons [26,281 instead of gamma-rays 1271. The results of

these experiments were expected to be different since elec-

The mechanical properties of PET fibers are relatively trons are known to cause a temperature increase in the poly-

unchanged by moderate doses of high energy radia- mer (electron microscopy) and are reported to destroy

crystallinity in PET by changing the steric conformation of

tion. When subjected to doses of more than 50 Mrad the chainc281. No gel formation has been observed at tem-

the tensile strength and ultimate elongation of the peratures up to 175 "C for doses of up to 2000 Mrad [29aI; at

PET begin to decrease considerably and deteriorate temperatures above 200 'C rapid gelation occurs even with

rapidly when the dose reaches the 100-500 Mrad low doses.

range. Radiation doses exceeding 1000 Mrad 1231 lead ESR studies of free radicals formed by gamma-irradi-

to the lowering of the glass transition temperature, ation of PET1291 support the suggestion of the reac-

which probably results from the lowering of the mole- tion sequences shown in Scheme 5 as being the prim-

cular weight by chain cleavage and from plasticization ary steps in the degradation:

Crosslinking: (24) + (23) + -CsH4-CO-O-CH-CH2-O-OC-C6H4-

I

CHz-CHz-O-OC-Cs&-

by the low molecular weight fragments formed. It is

interesting to note that by simply exchanging the

benzene rings in PET for naphthalene rings a polymer

is formed which is much more stable toward ionizing

radiation. Although cross-linked, an unoriented film

(24) - c o l o r formation Scheme 5 .

of poly(ethy1ene 2,6-naphthalene dicarboxylate) was

still tough and flexible after 1000 Mrad of gamma The differences between photolysis of PET and degra-

radiation 1401. dation by high energy radiation can be summarized

as follows:

Rather contradictory results have been reported

concerning the reactions occurring during high energy Photolysis:

irradiation. Both crosslinking 124,261 and chain cleav- Primary reaction products:

age [*51 have been claimed to be predominant; the

former claim was based upon partial insolubilization - C6H4. + CO f 'OCH2-CH2-O-OC-C6H4 -;

of the polymer, while the latter was based upon com- Only few carboxyl groups, and no hydrogen, are

formed.

plete solubility, a steady decrease in molecular weight

with increasing dose, and physical evidence of chain Crosslinking occurs.

cleavage.

Degradation by high energy radiation:

More recent evidence suggests that both chain cleav-

Primary reaction products:

age and crosslinking occur and that the reaction

conditions determine which process is predominant. - C6H4-CO-O-CH-CH2-O-Oc-c6H4

0

- + H'

Dose rate, kind of radiation, temperature, crystallinity, Hydrogen and carboxyl groups are formed.

and impurities, such as waterQ61 or oxygen, are ex- No gelation occurs (up to 2000-5000 Mrad).

amples. At low dose rates of gamma-rays, carboxyl

I271 S. D. Burow, D . T. Turner, G. F. Pezdirtz, and G. D. Sands,

[23] D . E. KIine and J . A. Sauer, Polymer (London) 2,401 (1961). J. Polymer Sci. A-1, 4, 613 (1966).

[24] 0. Terszler and H . A . Rutherford, Textile Res. J. 26, 96 [28] N. A . Slovokhotova, G. K . Sadovskaya, and V. A . Kargin,

(1956). J. Polymer Sci. 58, 1293 (1962).

[25] K . Little, Nature (London) 170, 1075 (1952); A. Todd, ibid. [29] K . Araki, D . Campell, and D . T . Turner, ACS Polymer

174, 613 (1954). Preprints 6, 1007 (1965).

f261 K . H . HeNwege, V .Johnson, and W. Seuofert, Angew. Chem. I29a] S. D . Burow, D . T . Turner, G . F. Pezdirtr, and G. D . Sands,

76, 59 (1964); Kolloid-Z., Z. Polymere 188, 11 (1963). ACS Polymer Preprints 5, 396 (1964).

188 Angew. Chem. internat. Edit. Vol. 7 (1968) No. 3

5. HydroIytic Degradation The reaction rate depends on both the proton con-

centration and the amount of water. This is in agree-

ment with the observation that the hydrolysis rate for

In contrast to other polyesters, PET is very resistant PET depends on the relative humidity. The adsorp-

to attack by water, acids, and bases; this is due, tion isotherm[331 shows that the rate of hydrolysis is

presumably, to its aromatic character and to the directly proportional to the concentration of water in

tight packing of its chains. Nevertheless, it does the polymer.

hydrolyze at temperatures above 100 "C. Of the forms

of degradation discussed thus far, hydrolysis is by far The influence of proton concentration on the hydro-

the most troublesome reaction. The hydrolysis of lysis rate is evident in the hydrolysis of PET in hydro-

PET at 100"-120"C and 100% relative humidity chloric acid [33-36,42-441. The rate is only slightly

proceeds 10000 times faster than that of thermal influenced by acid concentrations below 3 N but

degradation and 5000 times faster than that of oxida- increases rapidly at concentrations above this value.

tion in air in the same temperature range 1311. Ravens 1341 explains this by considering the acid con-

centration not in the aqueous phase, but in the poly-

It is known that dry PET adsorbs moisture rapidly

mer itself. Because of the low dielectric constant of

and that the extent of adsorption is dependent upon

PET (< 4), one can assume that the acid in the poly-

the time of exposure, the particle size, crystallinity, and

mer is only slightly dissociated. This is in agreement

relative humidity.

with the work of Sheard"'], who observed that am-

monia will diffuse through films of PET whereas am-

5.1. Neutral-, and Acid-Catalyzed Hydrolysis monium ions will not. The importance of the dielectric

constant is further emphasized by the fact that the

rate of acid hydrolysis is slower in drawn fibers than

5.1.1. A d s o r p t i o n a n d D i f f u s i o n o f W a t e r

it is in undrawn fibers.

The hydrolysis of ester bonds must proceed via (i) the in drawn fibers the crystallinity is of a higher order

adsorption of water on the surface of the polymer and than it is in undrawn fibers. During crystallization,

(ii) diffusion to the interior of the polymer from the the molecules assume a trans-configuration; hence,

point of attack. Knowledge of the rates of adsorption the polymer has a smaller dipole moment and there-

and diffusion are of practical and theoretical impor- fore a smaller dielectric constant. This in turn leads

tance. The adsorption of water by dry PET cubes of to a decrease in the degree of dissociation of the hy-

length 3/16" (or 0.4762 cm) amounts to 0.025 % after drochloric acid, so that the proton concentration

112 h, and, by dry PET powder (40 mesh), to ca. 0.125 %. within the polymer is lower than that in the surround-

ing medium.

The influence of the diffusion of moisture on the rate

of hydrolysis has been considered by several groups of Organic acids, e.g. adipic acidC451, also catalyze the

workers, but the results are contradictory. Golike and hydrolysis of PET 1363. Terminal carboxyl groups of a

Lasoski[30] and McMuhon et al. [311 assume that the polyester, which enter into all reactions characteristic

diffusion of moisture into the polymer is the rate- of carboxylic acids, also have a catalytic effect. From

controlling step. However, the rate of diffusion of investigations on polymers with initial carboxyl-group

water into PET at temperatures above 100C is at concentrations of from 8 to 97 equiv./lWgram of

least 1000-fold higher than the rate of hydroIysis [32,331. polymer, Ravens and Ward1331 concluded that the

The observed differences are probably due to dif- hydrolysis rate can be expressed by

ferences in morphology and molecular geometry of

the polymers studied. d[-COOH] / dt = k[-COOH] 'h

5.1.2. C o u r s e o f H y d r o l y s i s where the square root term arises from the weakly

acidic nature of the carboxyl group of the polymer.

The hydrolysis of esters in neutral or acid media This is a catalytic effect and is not due to adsorption

generally proceeds according to the reactions shown of water in the polymer at carboxyl end groups only,

in Scheme 6: since the adsorption isotherm is independent of the

carboxyl end group concentration 1331.

s

R-C-0-R' + PH

H@ +e R - C - 0 - R '

~-

[301 R. C. Golike and S . W . Lasoski, J. physic. Chem. 64, 895

O (I960).

1311 W. McMahon, H. A . Birdsall, G. R. Johnson, and C . T.

?H

R-C-0-R' + HzO

?H

R-C-0-R' Z

PH B

R-C-O,O

CamiIIi, J. chem. Engng. Data 4, 57 (1959).

O I I321 T. Davies, P. L. Goldsmith, D . A . S . Ravens, and I . M . Ward,

HOH AH R ' J. physic. Chem. 66, 175 (1962).

O

1331 D . A . S . Ravens and I. M . Ward, Trans. Faraday SOC. 57,

150 (I 961).

?H

R-C-O,O

FI R'-OH + PH

R-CO

::

R-C-OH + HO

1341 D . A . S. Ravens, Polymer (London) I , 375 (1960).

I 1351 D. R. Sheard, unpublished results.

AH R ' OH

1361 W. Brennecke and H. Richier, Melliand Textilbei. 40, 531

Scheme 6 . (1959).

Angew. Chem. internut. Edit. / Vol. 7 (1968) J No. 3 189

5.2. Base Catalyzed Hydrolysis crystallinity was unattacked after 1 6 hours in aqueous

methylamine, whereas samples having other morpho-

Very little has been published about the base catalyzed logical properties were considerably degraded. The

hydrolysis of PET. This is especially important in view attack by methylamine takes place in three stages:

of the potential interactions between polyester fibers The initial attack is in the amorphous regions; in the

and various organic and inorganic bases used in dyeing, second stage, scission produces more low molecular

aftertreatment, and washing. weight material and gives rise to an increase in the

Sodium or potassium hydroxide solutions normally degree of crystallinity of the polymer; the third stage,

attack only the surface of a PET fiber; however, distinguished by a gradual decrease in the rate of reac-

changes in the fine structure of the inner part of the tion, is attributed to a decrease in the rate of attack on

fiber after such treatment have been observed recent- both crystalline and amorphous regions.

ly[371. The dielectric properties of the polymer and The rate of aminolysis in the presence of primary and second-

the formation of carboxylate ions on the fiber surface ary amines is of the same order of magnitude as the rate of

alcoholysis [371. Tertiary amines react with polyester only at

presumably present a barrier to the penetration of the higher temperatures; but these reactions are not, as yet, fully

polymer by hydroxyl ions. The formation of a skin understood. For example, the products of the thermal de-

around the fiber and the fact that the rate constant for gradation of PET seem to react with the tertiary amine; the

base catalyzed hydrolysis of esters of dibasic acids is products of this reaction and the amine itself are subject t o

further thermal and oxidative degradation. The known

smaller than the rate constant for acid hydrolysis is

catalytic effect of hydroxyl compounds on the aminolysis of

taken as further evidence for the greater stability of esters [411 further complicates the picture.

polyester fibers in alkaline solutions than in acid solu-

tions. The author gratefulry acknowledges permission by the

Goodyear Tire and Rubber Company to publish this

The degradation of PET in the presence of amines is

work.

accompanied by the formation of amide bonds. The Received: June 8, 1967 [A 622 IEI

German version: Angew. Chem. SO, 225 (1968)

final formation of the terephthalic acid diamide takes

place via oligoester amides and oligoamides [37,3*1. [40] Chem. Engng. News 43, No. 20, p. 38 (1965).

The morphology of the polymer is again of great [41] M . Gordon, J. C . Miller, and A . B. Day, J. Amer. chem. SOC.

importance. Thus Farrow, Ravens, and Wardt391 have 71, 1245 (1947).

shown that a fiber sample with high orientation and [42] B. P. Ridge, J. Textile Inst. 44, 48 (1953).

[43] E. Dyhrenfurth, Dissertation ETH Zurich 1954; Textil-

[37] H. Pfeifer, Forsch.-Ber. Landes Nordrhein-Westfalen Nr. Rdsch. (St. Gallen) II, 573 (1956).

1212 (1964). [44] E. Furrer, Dissertation ETH Zurich 1955; Textile-Rdsch.

[38] H . Zahn and H . Pfeifer, Polymer (London) 4 , 429 (1963). (St. Gallen) 13, 129 (1958).

1391 G. Farrow, D. A . S . Ravens, and I. M . Ward, Polymer 3, 17 [45] V . V. Korsak, N. I. Bekasowa, and Y . A . Zamjatina, Dok-

(~1962). lady Akad. Nauk SSSR 1958, 614.

Formation and Properties of Solvated Electrons

BY U. SCHINDEWOLF I *I

In the formulation of many chemical reactions, electrons are regarded as readily trans-

ferable particles, though their participation in these reactions cannot be directly ob-

served. However, the discovery that electrons can be produced in various ways in suitable

solutions and that they are stabilized by solvation and can thus be studied directly has

recently led to a rapid growth of interest in these, the simplest and mcst reactive particles

of chemistry. The solvated electron has physical properties that permit its detection by

various methods even at very low concentrations, so that it is also possible to follow its

many reactions, most of which are extremely fast.

1. General ever, dissolved electrons are by no means a very

recent discovery, but were observed more than a

hundred years ago on dissolution of alkali metals in

It has been shown in recent years that dissolved elec-

trons [1,21 occur as reaction intermediates in the ['I Doz. Dr. u . Schindewolf

Institut fur Kernverfahrenstechnik

course of many energy-consuming chemical processes. der Universitat und des Kernforschungszentrums

They are formed on radiolysis, photolysis, and electrol- 75 Karlsruhe Postfach 947 (Germany)

ysis of aqueous and other polar systems. They also [l] American Chemical Society Publication: Solvated Electron,

Advances Chem. Ser. 50, 1965.

occur in the base-promoted ionization of hydrogen in [21 E. J . Hart in M . Haissinsky: Actions Chimiques et Bio,ogi-

sohtion, and probably in some redox processes. How- ques des Radiations 10,1 (1966).

190 Angew. Chem. internat. Edit.1 Vol. 7 (1968) 1 No. 3

You might also like

- Ratios 2017 - 2018Document4 pagesRatios 2017 - 2018LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Jeronimo Martins Colombia S.A.S. (Colombia)Document4 pagesJeronimo Martins Colombia S.A.S. (Colombia)LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Jeronimo Martins Colombia S.A.S. (Colombia)Document6 pagesJeronimo Martins Colombia S.A.S. (Colombia)LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Jeronimo Martins Colombia S.A.S. (Colombia)Document4 pagesJeronimo Martins Colombia S.A.S. (Colombia)LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Jeronimo Martins Colombia S.A.S. (Colombia)Document4 pagesJeronimo Martins Colombia S.A.S. (Colombia)LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Ratios 2017 - 2018Document4 pagesRatios 2017 - 2018LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Jeronimo Martins Colombia S.A.S. (Colombia)Document4 pagesJeronimo Martins Colombia S.A.S. (Colombia)LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Ratios 2017 - 2018Document4 pagesRatios 2017 - 2018LAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- DataDocument1 pageDataLAURA VALENTINA PEREZ RODRIGUEZNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- A Review of Lithium Extraction From Natural Resources:, Baozhong Ma, Yingwei Lü, Chengyan Wang, and Yongqiang ChenDocument16 pagesA Review of Lithium Extraction From Natural Resources:, Baozhong Ma, Yingwei Lü, Chengyan Wang, and Yongqiang Chen201400738No ratings yet

- High Performance Thin Layer ChromatographyDocument69 pagesHigh Performance Thin Layer ChromatographyAliefanugerahsani Attabe100% (1)

- Pre-Medical All India Major Test Series (Phase-I & Ii)Document4 pagesPre-Medical All India Major Test Series (Phase-I & Ii)Tejas DhandaNo ratings yet

- Extend Shelf Life of Bread with Propionic AcidDocument5 pagesExtend Shelf Life of Bread with Propionic AcidnajwaNo ratings yet

- PolymersDocument42 pagesPolymersMuhammad Waqas AkbarNo ratings yet

- General Characteristic of Crude OilDocument20 pagesGeneral Characteristic of Crude Oildassi99No ratings yet

- Gmaw WQTDocument23 pagesGmaw WQTDera LesmanaNo ratings yet

- Lubriplate Synxtreme Fg/220 Series: ISO-9001 Registered Quality System. ISO-21469 CompliantDocument2 pagesLubriplate Synxtreme Fg/220 Series: ISO-9001 Registered Quality System. ISO-21469 Compliantnalky1975No ratings yet

- Lipids ExperimentDocument3 pagesLipids ExperimentCyra LumibaoNo ratings yet

- Chatoyer KRO1500 ManualDocument20 pagesChatoyer KRO1500 Manualrazaq athabNo ratings yet

- Engel & Sheilan - The Seven Deadly Sins' of Filtration and Separation SystemsDocument9 pagesEngel & Sheilan - The Seven Deadly Sins' of Filtration and Separation SystemsiquimicaNo ratings yet

- Viskrings Seals SDSDocument6 pagesViskrings Seals SDSTarik ConceptNo ratings yet

- Periodic TableDocument23 pagesPeriodic Tabled anjilappaNo ratings yet

- Zinc Chloride Sol and Solid DataDocument4 pagesZinc Chloride Sol and Solid DataAnonymous jDvJoTNo ratings yet

- UV and Fe2+ Activated PersulfateDocument8 pagesUV and Fe2+ Activated Persulfate孔為鳴No ratings yet

- KromatografiDocument51 pagesKromatografiNadia Ulfa BurhanuddinNo ratings yet

- Ijftr 29 (2) 239-259Document21 pagesIjftr 29 (2) 239-259aymanNo ratings yet

- Sliding TB 105mmDocument42 pagesSliding TB 105mmSaud AffanNo ratings yet

- Belt Conveyor Design - Apex FennerDocument94 pagesBelt Conveyor Design - Apex Fennerdhangka100% (12)

- 3 - D Printer Carbon Fiber Reinforced WithDocument17 pages3 - D Printer Carbon Fiber Reinforced With19 CH 056 Vaishali VivekNo ratings yet

- GBSA Oil Seals CatalogDocument4 pagesGBSA Oil Seals CatalogAnonymous ItzBhUGoiNo ratings yet

- Millar 2017Document54 pagesMillar 2017Krishna DangiNo ratings yet

- FreseDocument140 pagesFresea9r8f4g5d4s8r0% (1)

- Aerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsDocument10 pagesAerospace Material Specification: (R) Gas Nitriding of Low-Alloy Steel PartsVIJAY YADAVNo ratings yet

- High Pressure Acid Leaching of A Refractory Lateritic Nickel OreDocument10 pagesHigh Pressure Acid Leaching of A Refractory Lateritic Nickel OreFabian MansillaNo ratings yet

- Chapter 23Document43 pagesChapter 23Jose Prima Boang ManaluNo ratings yet

- Molar Mass, Moles, Percent Composition ActivityDocument2 pagesMolar Mass, Moles, Percent Composition ActivityANGELYN SANTOSNo ratings yet

- 2015 Chandra - Basic Concepts of BiotechnologyDocument518 pages2015 Chandra - Basic Concepts of BiotechnologyPavani ReddyNo ratings yet

- Shell Gadus S2 High Speed Coupling Grease Technical Data SheetDocument3 pagesShell Gadus S2 High Speed Coupling Grease Technical Data Sheetjuan felipe diazgranados santosNo ratings yet

- 9701 s12 Ms 22 PDFDocument6 pages9701 s12 Ms 22 PDFtinoda almaNo ratings yet