Professional Documents

Culture Documents

Why Hips Fail by Graham Isaac - End Game Memo

Uploaded by

Lisa BartleyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Why Hips Fail by Graham Isaac - End Game Memo

Uploaded by

Lisa BartleyCopyright:

Available Formats

END GAME

The Failure of Total Hip Replacement

Graham Isaac PhD, Development Manager Hips

What causes failure ?

Generally hips fail for Infection or Recurrent Dislocation, (both of which result in failure

after a relatively short period of time), or finally aseptic loosening the predominant cause of

long term failure. It results from a breakdown of fixation, the main cause of which is

considered to be the body's reaction to wear debris.

"The results show that UIIIVIWPE wear products alone can cause massive

osteolysis by triggering foreign body granuloma formation"

Willert et al : (1990)

".... a high wear rate precludes a long service life"

Isaac et al : (1992)

"Osteolysis caused by polyethylene wear particles is the ultimate cause of failure"

Eftekhar : (1993)

Conclusion:- Wear is a major problem.

How does wear appear ?

Because the majority of joints have a polyethylene acetabular component, wear usually

involves the generation of polyethylene debris. This wear occurs by the femoral head

'tunnelling' its way into the acetabular cup. The diameter of the 'tunnel' is the same as the

femoral head. This means that penetration of the femoral head correlates to wear and that

the volume of wear debris generated can be calculated from penetration (assuming that creep

is a relatively small amount).

What are the alternatives ?

There are two bearing surface combinations in use which do not have a polyethylene

component:- Ceramic-on-ceramic and metal-on-metal, both of which have identical surfaces

articulating against each other - which would be normally considered to be bad engineering

practice.

PROTECTED DOCUMENT. DOCUMENT SUBJECT TO PROTECTIVE ORDER . DEPUY050669539

Ceramic-on-Ceramic

Whilst this combination can perform well in the laboratory it is clear from the literature that

in a clinical situation things can go wrong, and produce large volumes of wear debris.

"It is clear from these failures that incorrect angulation of the acetabular cup

leads to problems of exaggerated wear over relatively large surface areas."

Nevelos et al (1993)

Furthermore, the results of survivorship studies are certainly no better and in some cases

significantly worse than joints with a polyethylene component.

"Survivorship analysis depicted a 97.5 % rate at 5 years , a 89.4 % at 10 years and

86.2% at 11 years."

Sedel et al (1994)

Metal-on-Metal

It is clear from the literature that the survivorship of Cobalt Chrome, Metal-on-Metal

prostheses in the past has been far from satisfactory.

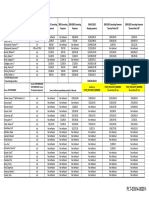

McKee-Farrar Prosthesis 27.5% at 20 years

August et al 1986

Stanmore Prosthesis 53% at 11 years

Dobbs 1980

This poor survivorship has been attributed to poor component design and poor tolerancing of

the femoral head and acetabular cups. Despite this a small but significant number of

components function for many years and upon retrieval the bearing surfaces are undamaged

and have worn relatively little. It was also clear that all successful components were so

called 'polar bearing', i.e. contact is made at the pole, not at the equator of the bearing

surface. Manufacturing methods have improved to the extent that all components can be

made thus, and together with an 'improved' Cobalt-Chrome material, a modern stem design,

and a cushioned cup had lead its proponents to suggest that metal-on-metal is the bearing

surface of the future. However, simulator testing of such components suggest that their

performance is as unpredictable as ever, working well for a period of time before suffering

a sudden catastrophic breakdown of the bearing surface accompanied by a release of a large

volume of wear debris. Why should this be?

"..... if the clearance between the ball and the cup has been selected and

manufactured optimally a phase of steady wear with stable friction and wear

ratios at a low level after 0.5 - 1 million cycles follows".

Streicher et al (1992)

PROTECTED DOCUMENT. DOCUMENT SUBJECT TO PROTECTIVE ORDER. DEPUY050669540

Thus the metal-on-metal bearing surface relies upon the manufacture and maintenance of an

appropriate clearance between head and cup to give a high quality bearing surface after a

period of 'Bedding-in'. However, in a clinical situation the maintenance of the bearing

surface quality is far from certain.

Incidence of damage to Cobalt- Chrome femoral heads . 54 heads retrieved at

revision surgery. Fine scratches 1-10m deep were found:-

11 out of 23 cemented (48%)

25 out of 31 uncemented /hydrid (80%)

Jasty et al (1994)

So even when the surfaces are manufactured optimally there is a mechanism' whereby the

surface can become damaged, the bearing surface breakdown, and large volumes of wear

debris produced.

It is also clear that whilst volumetric wear rate provides a useful comparison of different

materials combinations the effect of that wear debris is very different.

"CoCr produced a more florid foreign body and chronic inflammatory reaction

and was associated with decreased ingrowth of bone compared to particles of

polyethylene"

Goodman (1994)

and just to emphasise the point

"... the only combination of materials which is likely to give rise to toxic levels

of metal under clinical conditions is Cobalt-Chrome articulating against itself".

Rae (1981)

Therefore whilst CoCr components may be manufactured optimally there is no guarantee that

this quality can be maintained and if the surfaces do breakdown the debris produced has been

shown to be more harmful then polyethylene.

What is the solution?

What is the problem?

The more appropriate question is what is the problem? Consider the long term results with

metal-on-polyethylene joints.

85% non-revision at 20 years Schulte et al (1993)

84% survivorship at 20 years Kavanagh et al (1994)

89.3% survivorship at 20 years Neuman et al (1994)

86% non-revisions at 20 years Johnsson et al (1994)

89% non-revisions at 10 years Onsten et al (1994)

91% non-revisions at 11 years Malchau et al (1.993)

PROTECTED DOCUMENT. DOCUMENT SUBJECT TO PROTECTIVE ORDER. DEPUY050669541

Whilst the problem of wear is present, the results are still excellent when compared with the

results from metal-on-metal given above. When dealing with patients, a modification to

something that is very successful would appear to be a safer and more appropriate solution.

Problem :- Femoral Heads

A major problem is in vivo damage to metal femoral heads. (Isaac et al, 1992; Jasty et at,

1994). Relatively small amounts of damage can produce dramatic effects:-

".... a single transverse scratch can increase the wear rate of the polyethylene to

a remarkable extent."

Dowson et al (1987)

However, ceramic femoral heads have been shown to behave in significantly different ways:

"A ceramic femoral head is not only less prone to damage by particles of bone

cement in three body wear processes , but any damage produced is less likely to

cause increased wear rates of UHMWPE acetabular cups."

Cooper et al (1991)

This has been shown to have significant effects on clinical wear rates:

Wear rate , metal head :- 0.10mm per year

Wear rate , ceramic head:- 0.03mm per year

Schuller and Marti (1990)

It has also been shown that the new generation of Zirconia ceramics perform significantly

better as a bearing surface than the current generation of Alumina ceramics offering a further

45 % reduction in polyethylene wear (Kumar et al, 1991)

It has further been shown that femoral head-size affects volumetric wear rates.

"Volumetric wear rates , ....., were found to increase in a linear manner with

component diameter."

Kabo et al (1993)

The increased fracture toughness of Zirconia means that a ceramic 22.225mm head is now

available.

PROTECTED DOCUMENT. DOCUMENT SUBJECT TO PROTECTIVE ORDER. DEPUY050669542

Solution :- Zirconia 22.25mm Head

Simulator tests

Zirconia v. PE (22.225mm) 3mm3 per year (PE wear debris)

Derbyshire et al (1994)

CoCr v. CoCr (28mm) 5.1mm3 per year (CoCr wear debris)

Sulzer Technical Publication (1993)

Zirconia clinical experience:- analysis of samples after 2 - 3 years in vivo - no change in

mechanical properties or surface finish (Cales and Stefani 1994).

Problem :- Variable Quality Polyethylene

"Statistically significant correlations were observed between the extents of defects,

cracking , delamination , total wear and duration in vivo .

Wrona et al (1994)

Solution :- Enhanced Polyethylene - Hylame

Still polyethylene but with enhance mechanical properties.

Wear resistance 30% improvement

Compressive strength 75% improvement

Oxidation resistance 100% improvement

Dupont Data on File

Hylamer clinical experience:- 5 year in vivo no reported problems.

Conclusion

The use of Zirconia Ceramic heads and Hylamer enhanced polyethylene offers significant

reductions in the amount of wear debris without significantly affecting the modus operandi

of an already highly successful system of joint replacement. The alternatives have either

mixed results (Ceramic-on-Ceramic) or are building upon past failures (Metal-on-Metal) with

partial solutions in the hope of future success.

- which option would you favour?

Final Thought

"All prostheses fail sometime . It is a race between the life of the patient and the

life of the prosthesis."

Mallory 1988

PROTECTED DOCUMENT. DOCUMENT SUBJECT TO PROTECTIVE ORDER. DEPUY050669543

References

August, Adlam, Pynsent: The McKee Farrar Hip Arthroplasty a Long Term Study.

JBJS, 68B:520, 1986

Cales, Stefani: Mechanical Properties and Surface Analysis of Retrieved Zirconia Hip Joint

Heads after an Implantation time of two to three years.

J. Mater Sci., Mater Med, 5:376, 1994

Cooper, Dowson, Fisher, Jobbins: Ceramics Bearing Surfaces in Total Artificial Joints:

Resistance to Third Body Wear Damage from Bone Cement Particles.

J.Med Engng Tech, 15:63, 1991

Derbyshire, Fisher, Dowson, Hardaker, Brummitt: Comparative Study of the Wear of

UHMWPE with Zirconia Ceramic and Stainless Steel Femoral Heads in Artificial Hip Joints.

Med Eng Phys, 16:229, 1994

Dobbs: Survivorship of Total Hip Replacement

JBJS, 62B: 168, 1980

Dowson, Taheri, Wallbridge: The Role of Counterface Imperfections in the Wear of

Polyethylene.

Wear, 119:277, 1987

Eftekhar: Joint Hip Arthroplasty, 1993

Goodman: The Effects of Micromotion and Particulate Material on Tissue Differentiation

Acta Orthop Scan, S 258:65 1994

Isaac, Wroblewski, Atkinson, Dowson: A Tribological Study of Retrieved Hip Prostheses

Clin. Orthop, 276:115, 1992

Jasty, Bragdon, Lee , Hanson, Harris: Surface Damage to Cobalt-Chrome Femoral Head

Prostheses

JBJS, 76B : 73, 1994

Johnson, Franzen, Nilsson: Combined Survivorship and Multivariate Analysis of Revisions

in 799 Hip Prostheses

J. Arthro, 9:3, 1994

Kabo, Gebhard, Loren, Amstutz: In vivo Wear of Polyethylene Acetabular Components

JBJS, 75B: 254, 1993

Kavanagh, Wallrichs, Dewitz, Berry, Currier, Ilstrup, Coventry: Charnley Low Friction

Arthroplasty of the Hip. Twenty year Results with Cement

J. Arthro, 9:229, 1994

PROTECTED DOCUMENT. DOCUMENT SUBJECT TO PROTECTIVE ORDER. DEPUY050669544

Kumar, Oka, Ikeuchi , Shimizu, Yamamuro , Okumura, Kotoura : Low Wear Rate of

UHMWPE Against Zirconia Ceramic (Y-PSV) in Comparison to Alumina Ceramic and SUS

316L Alloy

J.Bio Mater Res, 25: 813, 1991

Malchau, Herberts, Ahnfelt: Prognosis of Total Hip Replacement in Sweden

Acta Orthop Scan, 64: 497, 1993

Mallory: Mallory Head Hip System

Current Concepts of Joint Replacement , Ed. Greenwald 1988

Neumann, Freund, Sorenson : Long Term Results of Charnley Total Hip Replacement

JBJS, 76B: 245, 1994

Nevelos , Evans, Harrison , Rainforth : Examination of Alumina Ceramic Components from

Total Hip Arthroplasties

Proc I Mech E, 207 : 155, 1993

Onsten, Besjakov , Carlsson: Improved Radiographic Survival of the Charnley Prosthesis in

Rheumatoid Arthritis and Osteoarthritis

J. Arthro, 9 : 3, 1994

Rae: The Toxicity of Metals used in Orthopaedic Prostheses

JBJS, 63B : 435, 1981

Schuller, Marti : Ten Year Socket Wear in 66 Hip Arthroplastics : Ceramic versus Metal

Heads

Acta Orthop Scan, 61:240, 1990

Schulte, Callaghan , Scott, Johnston : The Outcome of Charnley Total Hip Arthroplasty with

Cement after a Minimum 20 year Follow-up

JBJS, 75A: 961, 1993

Sedel, Nizard , Kerboull, Witroet : Alumina-Alumina Hip Replacement in Patients Younger

than 50 years old.

Clin. Orthop . 298:175, 1994

Streicher, Weber , Schoen, Semlitsch : Wear Resistant Couplings for Longer Testing

Articulating Total Joint Replacement

Biomaterial-Tissue Interfaces, Advances in Biomaterials 10, Ed . Doherty: 179. 1992

Willert, Bertram , Buchhorn: Osteolysis in Alloarthroplasy of the Hip

Clin. Orthop ., 258:95, 1990

Wrona, Mayor, Collier , Jensen: The Correlation between Fusion Defects and Damage in

Tibial Polyethylene Bearings

Clin. Orthop ., 299:92, 1993

PROTECTED DOCUMENT . DOCUMENT SUBJECT TO PROTECTIVE ORDER . DEPUY050669545

You might also like

- 2003 - Ozcan M - Fracture Reasons in Ceramic Fused To Metal RestorationsDocument6 pages2003 - Ozcan M - Fracture Reasons in Ceramic Fused To Metal RestorationsdwinaNo ratings yet

- Fracture Reaons in PFMDocument5 pagesFracture Reaons in PFMShounak GhoshNo ratings yet

- TMP 4214Document5 pagesTMP 4214FrontiersNo ratings yet

- Ceramic EditorialDocument4 pagesCeramic EditorialDenis AlexandruNo ratings yet

- Criteria For Skin Rupture and Core Shear Cracking Induced by Impact On Sandwich PanelsDocument7 pagesCriteria For Skin Rupture and Core Shear Cracking Induced by Impact On Sandwich PanelsMihaela NastaseNo ratings yet

- Spike Energy (Deteccion Temprana para Muy Altas Frecuencias) PDFDocument22 pagesSpike Energy (Deteccion Temprana para Muy Altas Frecuencias) PDFMarcos Manzano100% (1)

- Simulator 1Document8 pagesSimulator 1Sreedhar PugalendhiNo ratings yet

- Experimental Analysis of CFRP Laminates Subjected To CompressionDocument11 pagesExperimental Analysis of CFRP Laminates Subjected To Compressionghalib ibrahimNo ratings yet

- Fatigue Behavior of FRP Composites and CDocument24 pagesFatigue Behavior of FRP Composites and CAnilNo ratings yet

- Root End Filling MaterialsDocument9 pagesRoot End Filling MaterialsRuchi ShahNo ratings yet

- Zirconia Phase Transformation in Zirconia-Toughened Alumina Ceramic Femoral Heads An Implant Retrieval AnalysisDocument5 pagesZirconia Phase Transformation in Zirconia-Toughened Alumina Ceramic Femoral Heads An Implant Retrieval AnalysisJD2750No ratings yet

- Wang 2013Document5 pagesWang 2013Nawal ZafarNo ratings yet

- Vibra K Cmva 2006 Spike Energy Paper 430kb PDFDocument22 pagesVibra K Cmva 2006 Spike Energy Paper 430kb PDFmarvin17No ratings yet

- 82044701Document5 pages82044701James LinNo ratings yet

- Fatigue Analysis of Hybrid Composites of Kenaf/Kevlar Fibre Reinforced Epoxy CompositesDocument6 pagesFatigue Analysis of Hybrid Composites of Kenaf/Kevlar Fibre Reinforced Epoxy CompositesRajasekar RamachandranNo ratings yet

- DK1915 CH20Document9 pagesDK1915 CH20gao379No ratings yet

- Damage Evolution in A Tensile Specimen of A Ductile Stainless SteelDocument14 pagesDamage Evolution in A Tensile Specimen of A Ductile Stainless SteelGabrielAlejandroMontalvoQuinterosNo ratings yet

- 1 s2.0 S0892687523005526 MainDocument10 pages1 s2.0 S0892687523005526 Mainjmsj28No ratings yet

- PG 1Document1 pagePG 1Liladhar Ganesh DhobleNo ratings yet

- Perfomance of Dental CeramicDocument16 pagesPerfomance of Dental CeramicGunawan Ang ⓿⏝⓿No ratings yet

- Sutherland & GS 2004 APAET ImpactDocument10 pagesSutherland & GS 2004 APAET ImpactleighNo ratings yet

- Ferro Cement 11Document11 pagesFerro Cement 11Cage PrabhuNo ratings yet

- Recycling in OrthodonticsDocument71 pagesRecycling in OrthodonticsReene Mary100% (1)

- Chawla (2005)Document8 pagesChawla (2005)Ana Carolina TrindadeNo ratings yet

- WEAR TypesDocument2 pagesWEAR TypesRăzvan IordacheNo ratings yet

- Influence of Disc Topography On Generation of Brake SquealDocument8 pagesInfluence of Disc Topography On Generation of Brake Squealsharanmit2039No ratings yet

- Materials Science and Engineering CDocument13 pagesMaterials Science and Engineering CAnonymous 5AmJ13mLkNo ratings yet

- TMP 2 A10Document10 pagesTMP 2 A10FrontiersNo ratings yet

- Fracture Strength and Fatigue Resistance of All-Ceramic Molar Crowns Manufactured With CAD/CAM TechnologyDocument8 pagesFracture Strength and Fatigue Resistance of All-Ceramic Molar Crowns Manufactured With CAD/CAM TechnologyDr Sai Govind GavaraNo ratings yet

- CB-McCormack96 000Document6 pagesCB-McCormack96 000steigmannNo ratings yet

- Metallurgical Failure Analysis of Various ImplantDocument7 pagesMetallurgical Failure Analysis of Various Implantdiegomez84100% (1)

- Modell Exfol Corrnin Aluminium Alloysfinalrev 11 GCDocument19 pagesModell Exfol Corrnin Aluminium Alloysfinalrev 11 GCFahad AbdullahtNo ratings yet

- Polymer Degradation and Stability: M.S. Loo, J.B. Le Cam, A. Andriyana, E. Robin, J.F. CoulonDocument11 pagesPolymer Degradation and Stability: M.S. Loo, J.B. Le Cam, A. Andriyana, E. Robin, J.F. CoulonSebastian DiazNo ratings yet

- Bearings of The Future For Total Hip Arthroplasty: Michael T. Manley, Frsa, PHD, and Kate Sutton, Ma, ElsDocument5 pagesBearings of The Future For Total Hip Arthroplasty: Michael T. Manley, Frsa, PHD, and Kate Sutton, Ma, ElsGERARDO TORRES RUIZNo ratings yet

- Fit Accuracy of Metal Partial Removable Dental Prosthesis Frameworks Fabricated by Traditional or Light Curing Modeling Material TechniqueDocument6 pagesFit Accuracy of Metal Partial Removable Dental Prosthesis Frameworks Fabricated by Traditional or Light Curing Modeling Material TechniquedentureNo ratings yet

- A Review of Surface Roughness in Antifouling Coatings Illustrating The Importance of Cutoff LengthDocument11 pagesA Review of Surface Roughness in Antifouling Coatings Illustrating The Importance of Cutoff LengthRyan InghamNo ratings yet

- FRP Rods For Brittle Fracture ResistantDocument9 pagesFRP Rods For Brittle Fracture Resistantdmsoares1989No ratings yet

- 2006DurabilityofGFRC Experimentalmethodsandresults CompositespartADocument10 pages2006DurabilityofGFRC Experimentalmethodsandresults CompositespartAHary OaNo ratings yet

- Eucalyptus Pulp Fibres As Alternative ReDocument8 pagesEucalyptus Pulp Fibres As Alternative ReDiego JavierNo ratings yet

- By Measuring The Gap Dimension Between The Crowns Margin and Finishing Line of The Prepared ToothDocument7 pagesBy Measuring The Gap Dimension Between The Crowns Margin and Finishing Line of The Prepared ToothNaveen S YadavNo ratings yet

- Production of Accurately Fitting Full-Arch Implant Frameworks Part I Clinical Procedures.Document8 pagesProduction of Accurately Fitting Full-Arch Implant Frameworks Part I Clinical Procedures.Javier MaldonadoNo ratings yet

- Ballistic Impact of Fibre Composite Armours by Fragment Simulating ProjectilesDocument7 pagesBallistic Impact of Fibre Composite Armours by Fragment Simulating ProjectilesdjNo ratings yet

- Titanium AlloysDocument19 pagesTitanium AlloysMila DevitaNo ratings yet

- Nguyen 2019Document5 pagesNguyen 2019Tejas krishnakanthNo ratings yet

- Ceramics For Medical Applications: A Picture For The Next 20 YearsDocument11 pagesCeramics For Medical Applications: A Picture For The Next 20 YearsNguyen Cong HanhNo ratings yet

- Tiempo de Vida Geomembrana 85 GradosDocument13 pagesTiempo de Vida Geomembrana 85 GradosCarlofrancisco Sebastián Quispe LeguiaNo ratings yet

- Self Healing Composite Sandwich StructuresDocument10 pagesSelf Healing Composite Sandwich Structurespuiying80No ratings yet

- Neves 2012Document7 pagesNeves 2012Manuel Humberto Rojas ArcaNo ratings yet

- AISI 1040 steel tribological studyDocument32 pagesAISI 1040 steel tribological studySAGUN MURMUNo ratings yet

- Kuo 2015Document6 pagesKuo 2015Nguyen Thanh CuongNo ratings yet

- Adhesive resin for bonding orthodontic bracketsDocument8 pagesAdhesive resin for bonding orthodontic bracketsFabian BarretoNo ratings yet

- Aadnoy 2007Document7 pagesAadnoy 2007Víctor CarvallidoNo ratings yet

- (V) Biotribology: Z.M. Jin, M. Stone, E. Ingham, J. FisherDocument9 pages(V) Biotribology: Z.M. Jin, M. Stone, E. Ingham, J. Fishermesfin DemiseNo ratings yet

- Antonin BermondDocument19 pagesAntonin BermondKlockerNo ratings yet

- A Study of The Mechanical Properties of As-Received and Intraorally Exposed Single-Crystal and Polycrystalline Orthodontic Ceramic BracketsDocument6 pagesA Study of The Mechanical Properties of As-Received and Intraorally Exposed Single-Crystal and Polycrystalline Orthodontic Ceramic Bracketskris.halim1997No ratings yet

- Gridtech 2009 PDFDocument8 pagesGridtech 2009 PDFAnonymous rAFSAGDAEJNo ratings yet

- Article 2 - Bearing Surfaces in Hip ReplacementDocument6 pagesArticle 2 - Bearing Surfaces in Hip ReplacementAbishkar ShresthaNo ratings yet

- Journal Homepage: - : IntroductionDocument12 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- In Vivo Behavior of Acrylic Bone Cement in Total HDocument7 pagesIn Vivo Behavior of Acrylic Bone Cement in Total HAmaury Sousa SáNo ratings yet

- LASD Beating Convictions Upheld by 9th CircuitDocument35 pagesLASD Beating Convictions Upheld by 9th CircuitLisa BartleyNo ratings yet

- Tally BillDocument5 pagesTally BillLisa BartleyNo ratings yet

- DePuy Payments To Pinnacle & Ultamet Hip Design SurgeonsDocument2 pagesDePuy Payments To Pinnacle & Ultamet Hip Design SurgeonsLisa BartleyNo ratings yet

- 12-18-15 - Niedernhofer Vs DePuy J&J - Wrongful Death PDFDocument33 pages12-18-15 - Niedernhofer Vs DePuy J&J - Wrongful Death PDFLisa BartleyNo ratings yet

- 2011 Johnson & Johnson Deferred Prosecution AgreementDocument38 pages2011 Johnson & Johnson Deferred Prosecution AgreementLisa BartleyNo ratings yet

- 2010 Email From Dr. Andy Engh To DePuy's Paul BermanDocument2 pages2010 Email From Dr. Andy Engh To DePuy's Paul BermanLisa BartleyNo ratings yet

- 2010 Email From Dr. John Irving To DePuy's Paul BermanDocument3 pages2010 Email From Dr. John Irving To DePuy's Paul BermanLisa BartleyNo ratings yet

- Rackauckas FPPC ComplaintDocument1 pageRackauckas FPPC ComplaintLisa Bartley100% (1)

- Mold Inspection ReportDocument22 pagesMold Inspection ReportLisa BartleyNo ratings yet

- 12-18-15 - Niedernhofer Vs DePuy J&J - Wrongful Death PDFDocument33 pages12-18-15 - Niedernhofer Vs DePuy J&J - Wrongful Death PDFLisa BartleyNo ratings yet

- 2007 DePuy DPA DismissedDocument1 page2007 DePuy DPA DismissedLisa BartleyNo ratings yet

- 2007 Deferred Prosecution Agreement - USA vs. DePuyDocument26 pages2007 Deferred Prosecution Agreement - USA vs. DePuyLisa BartleyNo ratings yet

- 2016 Department of Health & Human Services Report On Cobalt IonsDocument8 pages2016 Department of Health & Human Services Report On Cobalt IonsLisa BartleyNo ratings yet

- 4-8-11 - Johnson & Johnson Press Release Announces Settlement With U.S. Department of Justice and SECDocument2 pages4-8-11 - Johnson & Johnson Press Release Announces Settlement With U.S. Department of Justice and SECLisa BartleyNo ratings yet

- DePuy Investigation Into Ultima Metal-On-Metal HipsDocument58 pagesDePuy Investigation Into Ultima Metal-On-Metal HipsLisa BartleyNo ratings yet

- DePuy Payments To Pinnacle & Ultamet Hip Design SurgeonsDocument2 pagesDePuy Payments To Pinnacle & Ultamet Hip Design SurgeonsLisa BartleyNo ratings yet

- 7-24-17 - Baca Appeal To 9th On BailDocument93 pages7-24-17 - Baca Appeal To 9th On BailLisa BartleyNo ratings yet

- USA Vs DePuy - 2007 Criminal ComplaintDocument2 pagesUSA Vs DePuy - 2007 Criminal ComplaintLisa BartleyNo ratings yet

- DePuy Appeals Verdict in California CasesDocument98 pagesDePuy Appeals Verdict in California CasesLisa BartleyNo ratings yet

- 7-18-16 - Leroy Baca Sentencing HearingDocument48 pages7-18-16 - Leroy Baca Sentencing HearingLisa BartleyNo ratings yet

- LASD Appeals Denied 8-4-16 - Published OpinionDocument32 pagesLASD Appeals Denied 8-4-16 - Published OpinionLisa BartleyNo ratings yet

- LASD Appeal Denied - Unpublished Opinion 8-4-16Document31 pagesLASD Appeal Denied - Unpublished Opinion 8-4-16Lisa BartleyNo ratings yet

- DA Charge Evaluation Worksheet - Baca & TurnerDocument23 pagesDA Charge Evaluation Worksheet - Baca & TurnerLisa Bartley100% (1)

- 5 17 16 Leavins Supplemental Brief AppealDocument16 pages5 17 16 Leavins Supplemental Brief AppealLisa BartleyNo ratings yet

- 5-13-16 - Reply Brief Appeal - Long & CraigDocument37 pages5-13-16 - Reply Brief Appeal - Long & CraigLisa BartleyNo ratings yet

- 5-20-16 - Joint Reply Six LASD Defendants - AppealDocument97 pages5-20-16 - Joint Reply Six LASD Defendants - AppealLisa BartleyNo ratings yet

- 5-13-16 - Judicial Notice of Baca Plea DealDocument25 pages5-13-16 - Judicial Notice of Baca Plea DealLisa BartleyNo ratings yet

- 5-20-16 - James Sexton Reply BriefDocument41 pages5-20-16 - James Sexton Reply BriefLisa BartleyNo ratings yet

- Hip PrecautionsDocument2 pagesHip PrecautionsGriffin DouglasNo ratings yet

- Why Hips Fail by Graham Isaac - End Game MemoDocument7 pagesWhy Hips Fail by Graham Isaac - End Game MemoLisa BartleyNo ratings yet

- Tips and Tricks in HIP AND KNEE ARTHROPLASTYDocument173 pagesTips and Tricks in HIP AND KNEE ARTHROPLASTYNoel Alonso Calleros Hernandez100% (5)

- Chapter 1: Introduction To Materials Science & EngineeringDocument24 pagesChapter 1: Introduction To Materials Science & EngineeringArct John Alfante ZamoraNo ratings yet

- Modern Techniques in Total Hip Arthroplasty From Primary To ComplexDocument199 pagesModern Techniques in Total Hip Arthroplasty From Primary To Complexdeepak100% (5)

- GTS Surgical TechniqueDocument22 pagesGTS Surgical TechniqueMaurinho MnhNo ratings yet

- Classification Systems in OrthopaedicsDocument8 pagesClassification Systems in OrthopaedicsluckyariadneeNo ratings yet

- Melbourne Doctor Upset by Defective DePuy ASR Hip ImplantDocument2 pagesMelbourne Doctor Upset by Defective DePuy ASR Hip ImplantKaiser Gornick LLPNo ratings yet

- BIOMECHANICS - Hip ImplantsDocument12 pagesBIOMECHANICS - Hip Implantslucas washingtonNo ratings yet

- Widowed 72-year-old woman discharged to rehabilitationDocument5 pagesWidowed 72-year-old woman discharged to rehabilitationsyedNo ratings yet

- Implants in OrthopaedicsDocument20 pagesImplants in OrthopaedicsDr. F. Abdul KhaderNo ratings yet

- No Change in Serum Metal Ions Levels After Primary Total Hip R - 2022 - ArthroplDocument4 pagesNo Change in Serum Metal Ions Levels After Primary Total Hip R - 2022 - ArthroplSanty OktavianiNo ratings yet

- StinchfieldDocument2 pagesStinchfieldirongrafNo ratings yet

- Osteonecrosis of The Femoral Head: Evaluation and TreatmentDocument10 pagesOsteonecrosis of The Femoral Head: Evaluation and TreatmentHector Ulises Quintanilla SotoNo ratings yet

- AMP Vs Cemented Thompson 2010Document7 pagesAMP Vs Cemented Thompson 2010docpanchuNo ratings yet

- Orthopedic Nursing. Lecture Notes at Philipine Orthopedic CenterDocument7 pagesOrthopedic Nursing. Lecture Notes at Philipine Orthopedic Centerhannjazz100% (5)

- Girdle Stone Procedure in Bilateral Rheumatoid Hip: A Case ReportDocument2 pagesGirdle Stone Procedure in Bilateral Rheumatoid Hip: A Case Reportumer ilyasNo ratings yet

- Use of Cement in Hip Arthroplasty-Blankstein2020Document9 pagesUse of Cement in Hip Arthroplasty-Blankstein2020Mohan DesaiNo ratings yet

- Protrusio Acetabuli Diagnosis and TreatmentDocument10 pagesProtrusio Acetabuli Diagnosis and TreatmentFerney Leon BalceroNo ratings yet

- White Paper: On Joint ReplacementDocument144 pagesWhite Paper: On Joint ReplacementCosme MejiaNo ratings yet

- F1714 1479757-1Document7 pagesF1714 1479757-1Thaweekarn ChangthongNo ratings yet

- J&J Recalls Hip Implants Due to High Failure RatesDocument2 pagesJ&J Recalls Hip Implants Due to High Failure RatesShiela Mae Catalan Aludo100% (2)

- Bicontact: Aesculap OrthopaedicsDocument52 pagesBicontact: Aesculap OrthopaedicsMohamed Swar Eldahab0% (1)

- Exeter Technical GuideDocument34 pagesExeter Technical GuideMorshed Mahbub AbirNo ratings yet

- G.R. No. 161104Document9 pagesG.R. No. 161104Axia KnightwalkerNo ratings yet

- Bone Cement Implantation Syndrome in Cemented Hemiarthroplasty For Femoral Neck FractureDocument7 pagesBone Cement Implantation Syndrome in Cemented Hemiarthroplasty For Femoral Neck FractureBubumed3212No ratings yet

- Shoulder Arthroplasty WIC - Dr. LSDocument56 pagesShoulder Arthroplasty WIC - Dr. LSDifitasari Cipta Perdana100% (1)

- Chapter 1 IntroductionDocument33 pagesChapter 1 IntroductionNumair HussainNo ratings yet

- Robots With Hip Prostheses: Intelligent Solution From One SourceDocument2 pagesRobots With Hip Prostheses: Intelligent Solution From One SourceomkarnadkarniNo ratings yet

- Sejarah Orthopaedi Dunia dari Zaman Prasejarah hingga Abad ke-18Document17 pagesSejarah Orthopaedi Dunia dari Zaman Prasejarah hingga Abad ke-18KdpNo ratings yet