Professional Documents

Culture Documents

Electric Discharge Detection (EDD) in Motor Bearings - BP 40

Uploaded by

Jay Rameshbhai ParikhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electric Discharge Detection (EDD) in Motor Bearings - BP 40

Uploaded by

Jay Rameshbhai ParikhCopyright:

Available Formats

Title of the Best Practice

KAP

(Knowledge Acquisition Point)

Best Practices

Electric Discharge Detector

Aditya Cement Works, Shambhupura

1 | KAP | Best Practices | Title of the Best Practice

Title of the Best Practice

Attribute Description

Title Electric Discharge Detection (EDD) in motor bearings.

Abstract* Monitoring Electric Discharge count in motor bearings by EDD pen, to

identify the Electrical erosion in bearing of VFD operated motors.

Applicability* Across Businesses

Business Impact / Reduction in breakdowns due to premature bearing failure in VFD

Benefits * operated motors.

Problem In electric motors that are controlled by Variable Frequency Drives

definition* (VFD), induces electrical currents that may increase until they find

discharge paths to earth via the motor frame. The electric currents pass

through the bearing and when the voltage reaches a level to overcome

the lubricant film layer in the bearing, electrical discharge occurs. Over

time this can cause electrical erosion. Electrical erosion can cause

bearings to fail very prematurely causing motor failure and unplanned

downtime.

Approach * Premature bearing failure happened in clinker cooler fan 2 FN

354.

Damaged bearings are studied carefully and brainstorming done

to identify the root cause.

Mechanical causes like misalignment and lack of lubrications

were not there in the equipment.

Fluting in the bearing race ways noticed and this initiated to

check the EDD count in motor bearings.

EDD counts were more in that particular motor where as it was

very less in other similar motors.

Remedial measures taken to reduce EDD count.

EDD count found reduced and premature bearing failure not

occurred afterwards.

Process* Like all condition monitoring equipment used for predictive

maintenance, we are using the EDD Pen used in a consistent way.

Every measurement is made at the same distance and direction

from the bearing in periodic interval.

The present EDD counts are compared with the base line made

with previous data.

To get the best results the EDD measurement is used to

compare motors in the same running conditions over time, this means

that the results are compared while motor is running at same speed

and loads.

Higher EDD counts and deviation from base readings are

discussed with maintenance team and suitable remedial actions taken

to prevent break downs.

If a motor shows a reading significantly different then it is more

likely to suffer from electrical erosion than the other bearings.

For example if you measure 25 motors using the EDD Pen and

motors # 1 to # 24 show a reading between 1100 and 2400 but motor

# 25 shows a reading of 10000 this means that motor # 25 is more

likely to suffer the effects of electrical discharge currents. In this case

the bearing of motor # 25 should be checked at the first opportunity.

2 | KAP | Best Practices | Title of the Best Practice

Title of the Best Practice

EDD Pen

Case Study of cooler fan 2FN 354

1. Premature bearing failure happened in cooler fan 2 FN 354

motor.

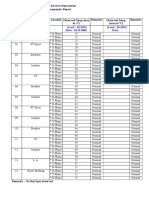

2. EDD count was measured in Feb 11 for 10sec(DE : 3538 & NDE :

4937)

3. The bearings found damaged and fluting noticed in bearing inner

race.

4. Remedial measures taken in motor and EDD counts found

reduced in March 11(DE : 54 & NDE : 0).

5. By that the motor bearing premature failure avoided.

EDD measurement Fluting in bearing

Since the fan is one of the critical equipment in Pyro section this

avoided the breakdown of kiln by identifying the fault in advance.

Approximate production loss of one breakdown ( Unit 2 Kiln)

= 6 hrs stoppage of kiln to replace the motor

= 2250 MT of clinker (Considering average kiln out put of 9000 TPD)

= 2250 MT of clinker * Rs 1000(Approx)

= Rs. 22.5 Lacs

3 | KAP | Best Practices | Title of the Best Practice

Title of the Best Practice

4 | KAP | Best Practices | Title of the Best Practice

Title of the Best Practice

Other applicability Same can be used to motor operated through VFD

Uniqueness 1. Hand held instrument and take less time to check.

2. Safe to use since no rotating components are comes across.

3. No special training required

4. Capable of detecting electrical discharges on a time base of 10

seconds, 30 seconds or indefinite

KPI Reduction in breakdowns due to premature motor bearing failure.

Reference Being used in UltraTech Cements Ltd, Aditya Cement Works

About Author* J. Jayaseelan

Sr. Manager Technical Services,

Having 21 years of experience in the fields of Manufacturing, Project

and Condition Monitoring.

Contact details* jayaseelan.j@adityabirla.com

UltraTech Cements Ltd

Unit - Aditya Cement Works,

Chittorgarh, Rajasthan

Mobile : 09887482037

Key words Electric discharge detector, Fluting in bearings

Note - * - Mandatory fields

5 | KAP | Best Practices | Title of the Best Practice

You might also like

- Fuji G9 IMO VX ManualDocument91 pagesFuji G9 IMO VX ManualMalek KamelNo ratings yet

- Design of A Three Phase Squirrel Cage Induction Motor For Electric Propulsion SystemDocument6 pagesDesign of A Three Phase Squirrel Cage Induction Motor For Electric Propulsion SystemBahi EzioNo ratings yet

- Published by The Center For Metals Fabrication 1,: Vol. NoDocument2 pagesPublished by The Center For Metals Fabrication 1,: Vol. Norlc_bal2723No ratings yet

- Project Standards and Specifications Electrical Induction Motors Rev01webDocument4 pagesProject Standards and Specifications Electrical Induction Motors Rev01webSatyam PrajapatiNo ratings yet

- El Cid Handout PP v1Document66 pagesEl Cid Handout PP v1Carlos MolinaNo ratings yet

- 52TMSS02R0Document13 pages52TMSS02R0engrandyNo ratings yet

- .Automatic Brake Failure Indicator and Over Heating Alarm PDFDocument11 pages.Automatic Brake Failure Indicator and Over Heating Alarm PDFmahendran100% (1)

- STD Specs of FLP MotorDocument9 pagesSTD Specs of FLP Motordheeraj1993No ratings yet

- VC-040 - ParkerDocument10 pagesVC-040 - ParkerwagnerNo ratings yet

- Motor Standards Applicable - Part1Document1 pageMotor Standards Applicable - Part1Ranjan MuthannaNo ratings yet

- How To Test and Assess Stator Core Condition Using A Loop TestDocument21 pagesHow To Test and Assess Stator Core Condition Using A Loop TestKhaled Aboul-ELa100% (1)

- Proposal For 12 KWP Roof Top On-Grid Solar System For Hotel atDocument9 pagesProposal For 12 KWP Roof Top On-Grid Solar System For Hotel atAsterism TechPro RajasthanNo ratings yet

- Materials System SpecificationDocument10 pagesMaterials System SpecificationMudabbir Hussain100% (1)

- Materials System SpecificationDocument24 pagesMaterials System SpecificationGOSP3 QC MechanicalNo ratings yet

- Guidelines For LV Motor MaintenanceDocument5 pagesGuidelines For LV Motor MaintenanceDILIPNo ratings yet

- FS For Medium Voltage Motor PDFDocument8 pagesFS For Medium Voltage Motor PDFMd SajjadNo ratings yet

- Investigative Fault Analysis of 11KV Slip-Ring Induction MotorsDocument12 pagesInvestigative Fault Analysis of 11KV Slip-Ring Induction MotorsInternational Journal of Innovative Science and Research Technology100% (1)

- HLMK 10 Mono DeltaDocument12 pagesHLMK 10 Mono DeltaAsterism TechPro RajasthanNo ratings yet

- Repair BookDocument86 pagesRepair BookFlywheel060% (1)

- Why To Match The Impedance of The VFD CableDocument1 pageWhy To Match The Impedance of The VFD CableAbdulyunus AmirNo ratings yet

- Industry Visit Report RahulDocument25 pagesIndustry Visit Report RahulVaibhavNo ratings yet

- Shri Balaji EssarDocument9 pagesShri Balaji EssarAsterism TechPro RajasthanNo ratings yet

- Far LZ400895Document10 pagesFar LZ400895Soubhagya BeheraNo ratings yet

- Condition Monitoring of Transformers Gyanendra Sharma Npti DelhiDocument135 pagesCondition Monitoring of Transformers Gyanendra Sharma Npti DelhiNPTI100% (1)

- 15 KW Net Metering System 3997 Ace Solar Energy Honorable Admiral Naeem SarwarDocument5 pages15 KW Net Metering System 3997 Ace Solar Energy Honorable Admiral Naeem SarwarTaimur KhattakNo ratings yet

- 2 Article Failure Rate Analysis of IC Engine ComponentsDocument10 pages2 Article Failure Rate Analysis of IC Engine ComponentsMIKINo ratings yet

- AC Motor Repair SpecificationDocument13 pagesAC Motor Repair SpecificationErgys Lika100% (1)

- Model Repair Specifications For Low Voltage Induction MotorsDocument27 pagesModel Repair Specifications For Low Voltage Induction MotorsHenryGaltNo ratings yet

- I RJ Mets 557022Document8 pagesI RJ Mets 557022Bharat RathodNo ratings yet

- El-CID Testing PDFDocument16 pagesEl-CID Testing PDFA.YOGAGURUNo ratings yet

- FinalDocument20 pagesFinalvedant kapseNo ratings yet

- 44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorDocument8 pages44AD0600-00-E.02-001A-A4 - Rev 0 - Standard Specification For LV Induction MotorAvinash ShuklaNo ratings yet

- V04-De18 Instruction Manual (Operation)Document109 pagesV04-De18 Instruction Manual (Operation)RM Haroon50% (2)

- Aviation Inspection Report (Sukkur)Document10 pagesAviation Inspection Report (Sukkur)Noman AliNo ratings yet

- 9916 - TECHNOLOGY REFERENCE GUIDE TO ELECTRIC MOTORS 3Rs REPAIR REWIND REPLACE 3002009182Document4 pages9916 - TECHNOLOGY REFERENCE GUIDE TO ELECTRIC MOTORS 3Rs REPAIR REWIND REPLACE 3002009182Anonymous kuSnz0kl1No ratings yet

- Big Blue 500X PRO 2021Document8 pagesBig Blue 500X PRO 2021Seida Rojas CabelloNo ratings yet

- EIL Document On Motor, PanelDocument62 pagesEIL Document On Motor, PanelArindam Samanta100% (1)

- JETIR2107059Document8 pagesJETIR2107059Gebrerufael GebrelibanosNo ratings yet

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocument1 pageIPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesYork LiaoNo ratings yet

- 63MVA 220KV-66KV Power Transformer - Syd Specific 1 - TenderDocument103 pages63MVA 220KV-66KV Power Transformer - Syd Specific 1 - TendermidhunvarNo ratings yet

- Qasif Shahid 10KW ProposalDocument23 pagesQasif Shahid 10KW ProposalAttiqueNo ratings yet

- Nerators PDFDocument34 pagesNerators PDFShi YoshiNo ratings yet

- ED115 Big Blue 600 Series EnglishDocument8 pagesED115 Big Blue 600 Series EnglishAris Diego PrabowoNo ratings yet

- 9AKK107743 - IEC LV Synchronous Reluctance Motors - 09-2023 - LowresDocument48 pages9AKK107743 - IEC LV Synchronous Reluctance Motors - 09-2023 - LowresFabro CoronelNo ratings yet

- Ravisankar 2021 IOP Conf. Ser. Mater. Sci. Eng. 1055 012132Document16 pagesRavisankar 2021 IOP Conf. Ser. Mater. Sci. Eng. 1055 012132tejas9280No ratings yet

- Limpeza de Gerador Com Co2 in Loco - InglesDocument5 pagesLimpeza de Gerador Com Co2 in Loco - InglesPilegoNo ratings yet

- 107 sb3 12 5009 GN en 01 255455 v1Document4 pages107 sb3 12 5009 GN en 01 255455 v1Anibal QuezadaNo ratings yet

- Adoption of Higher Efficiency Motors (Hems) : Abhishek DhuparDocument29 pagesAdoption of Higher Efficiency Motors (Hems) : Abhishek DhuparSrishti SinghalNo ratings yet

- DC Machine Laboratory ManualDocument15 pagesDC Machine Laboratory ManualNikka BasanNo ratings yet

- 15-SDMS-02 Overhead Line Polymer. Insulators PDFDocument26 pages15-SDMS-02 Overhead Line Polymer. Insulators PDFMehdi Salah100% (1)

- Powder Mixed Electric Discharge Machining of HastelloyDocument4 pagesPowder Mixed Electric Discharge Machining of HastelloyIJRASETPublicationsNo ratings yet

- Simhadri Super Thermal Power ProjectDocument7 pagesSimhadri Super Thermal Power Projectvenkatesh bitraNo ratings yet

- Edms 04-101-1 AaacDocument16 pagesEdms 04-101-1 Aaackaramsec2023No ratings yet

- SSDEDocument4 pagesSSDEDoanh NguyenNo ratings yet

- Solar Panel With Sun Position Tracking and Automatic Cleaning SystemDocument8 pagesSolar Panel With Sun Position Tracking and Automatic Cleaning SystemIJRASETPublicationsNo ratings yet

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Handbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryFrom EverandHandbook of Electrical Engineering: For Practitioners in the Oil, Gas and Petrochemical IndustryNo ratings yet

- Breaker Sf6 Vs VaccumDocument2 pagesBreaker Sf6 Vs VaccumJAY PARIKHNo ratings yet

- DC Trace PDFDocument48 pagesDC Trace PDFJay Rameshbhai ParikhNo ratings yet

- Comparison Between Vacuum & SF6 Circuit Breaker For Medium Voltage ApplicationDocument12 pagesComparison Between Vacuum & SF6 Circuit Breaker For Medium Voltage ApplicationcheedingNo ratings yet

- Instruction Manual 60Document1 pageInstruction Manual 60Jay Rameshbhai ParikhNo ratings yet

- RTU Specs PDFDocument1 pageRTU Specs PDFJay Rameshbhai ParikhNo ratings yet

- 11 02 7UM62 enDocument39 pages11 02 7UM62 enJay Rameshbhai ParikhNo ratings yet

- Light, Sound&forceDocument3 pagesLight, Sound&forceJay Rameshbhai ParikhNo ratings yet

- Insulation Testers: Users ManualDocument38 pagesInsulation Testers: Users ManualJay Rameshbhai ParikhNo ratings yet

- BA Bediengeraet xP270 eDocument274 pagesBA Bediengeraet xP270 eJiang Jin WuNo ratings yet

- Electric Discharge Detection (EDD) in Motor Bearings - BP 40Document5 pagesElectric Discharge Detection (EDD) in Motor Bearings - BP 40Jay Rameshbhai ParikhNo ratings yet

- Summation MeterDocument1 pageSummation MeterJay Rameshbhai ParikhNo ratings yet

- ISO 10816-1 Normativa VibracionesDocument10 pagesISO 10816-1 Normativa Vibracionesumendibil100% (1)

- Cable 10 02 2011Document1 pageCable 10 02 2011Jay Rameshbhai ParikhNo ratings yet

- HighPROTEC TechnicalDocument7 pagesHighPROTEC TechnicalJay Rameshbhai ParikhNo ratings yet

- Keeping SafeDocument3 pagesKeeping SafeJay Rameshbhai ParikhNo ratings yet

- XXXXDocument5 pagesXXXXJay Rameshbhai ParikhNo ratings yet

- Motor Protection RelayDocument21 pagesMotor Protection RelayJay Rameshbhai ParikhNo ratings yet

- XXXXDocument5 pagesXXXXJay Rameshbhai ParikhNo ratings yet

- PV System Design For Power Plant - 28 09 11Document27 pagesPV System Design For Power Plant - 28 09 11Jay Rameshbhai ParikhNo ratings yet

- PV System Design For Power Plant - 28 09 11Document27 pagesPV System Design For Power Plant - 28 09 11Jay Rameshbhai ParikhNo ratings yet

- DATE:25/02/07 Grid Islanding ReportDocument1 pageDATE:25/02/07 Grid Islanding ReportJay Rameshbhai ParikhNo ratings yet

- Fluke 37x Calibation Manual PDFDocument24 pagesFluke 37x Calibation Manual PDFAllamNo ratings yet

- Thermography Tieline 10122005Document1 pageThermography Tieline 10122005Jay Rameshbhai ParikhNo ratings yet

- SUB: Install Import / Export Features in EM 3460 MetersDocument2 pagesSUB: Install Import / Export Features in EM 3460 MetersJay Rameshbhai ParikhNo ratings yet

- Meter SpecificationsDocument22 pagesMeter SpecificationsJay Rameshbhai ParikhNo ratings yet

- Fluke 117: Electrician's MultimeterDocument2 pagesFluke 117: Electrician's Multimeterh4rmoni.quNo ratings yet

- Protection Signal and Alarm Signal Checking ST 2Document10 pagesProtection Signal and Alarm Signal Checking ST 2Jay Rameshbhai ParikhNo ratings yet

- SND Z Q DQ PDFDocument42 pagesSND Z Q DQ PDFJay Rameshbhai ParikhNo ratings yet

- 3 DDocument2 pages3 DJay Rameshbhai ParikhNo ratings yet

- Adrian - Borbe - CHAPTER 1 5 1Document149 pagesAdrian - Borbe - CHAPTER 1 5 1ecilaborbe2003No ratings yet

- Mine Ventilation Using CFDDocument5 pagesMine Ventilation Using CFDmitevNo ratings yet

- Data-Driven and Physics-Informed Deep Learning Operators For Solution of Heat Conduction EquationDocument8 pagesData-Driven and Physics-Informed Deep Learning Operators For Solution of Heat Conduction EquationStephen PanNo ratings yet

- Wlguide PDFDocument130 pagesWlguide PDFElaine MagcawasNo ratings yet

- CSProxyCache DLLDocument36 pagesCSProxyCache DLLRadient MushfikNo ratings yet

- Chapter 2 Conceptualized InteractionDocument32 pagesChapter 2 Conceptualized InteractionnancyNo ratings yet

- Designing A 3D Jewelry ModelDocument4 pagesDesigning A 3D Jewelry ModelAbdulrahman JradiNo ratings yet

- Use CaseDocument5 pagesUse CaseRoy MasterNo ratings yet

- Managed Fortiswitch 604Document110 pagesManaged Fortiswitch 604Netsys BilisimNo ratings yet

- Documents of Interest Re Synthetic Telepathy May 26, 2015Document235 pagesDocuments of Interest Re Synthetic Telepathy May 26, 2015Stan J. CaterboneNo ratings yet

- Audacity 2.1Document39 pagesAudacity 2.1Sharbate AzamNo ratings yet

- CDGAN - Cyclic Discriminative GAN For Image2image TranslationDocument11 pagesCDGAN - Cyclic Discriminative GAN For Image2image TranslationPulkit DwivediNo ratings yet

- AMDE Brochure-Mine Safety Accountability Integrated SystemDocument1 pageAMDE Brochure-Mine Safety Accountability Integrated SystemHakimNo ratings yet

- A Study of The Impact of Social Media On Consumer Buying Behaviour Submitted ToDocument25 pagesA Study of The Impact of Social Media On Consumer Buying Behaviour Submitted ToAnanya GhoshNo ratings yet

- Management Studies (CP-202) : Unit IDocument2 pagesManagement Studies (CP-202) : Unit IArman KhanNo ratings yet

- 5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Document8 pages5/2 and 5/3 Valves Solenoid and Pilot Actuated Sub-Base Mounted ISO 5599-1 #1, #2, #3, #4Hdhm TdhNo ratings yet

- System Imaging and SW Update Admin v10.6Document102 pagesSystem Imaging and SW Update Admin v10.6tseiple7No ratings yet

- User Guide 1531 Clas - 3ag - 21608 - Ahaa - Rkzza - Ed01Document338 pagesUser Guide 1531 Clas - 3ag - 21608 - Ahaa - Rkzza - Ed01iaomsuet100% (2)

- NGSPICE Manual-Devices and Circuits LabDocument15 pagesNGSPICE Manual-Devices and Circuits LabShreya R HNo ratings yet

- ByD DemoScript Project MGMTDocument21 pagesByD DemoScript Project MGMTLakhbir SinghNo ratings yet

- Synopsis College Fest AdministrationDocument18 pagesSynopsis College Fest AdministrationRaj Bangalore67% (3)

- Unit 8: Future Outlook: Central Business Configuration For SAP S/4HANA CloudDocument9 pagesUnit 8: Future Outlook: Central Business Configuration For SAP S/4HANA CloudKarina San MartinNo ratings yet

- Britt Support Cat 9710Document47 pagesBritt Support Cat 9710Jim SkoranskiNo ratings yet

- B.TECH SyllabusDocument184 pagesB.TECH Syllabusjonas knoxNo ratings yet

- +12V, 30ma Flash Memory Programming Supply: Evaluation Kit Manual Follows Data SheetDocument6 pages+12V, 30ma Flash Memory Programming Supply: Evaluation Kit Manual Follows Data SheetJuan Carlos TellezNo ratings yet

- How To Register The HospitalDocument55 pagesHow To Register The HospitalAkhilesh Dwivedi0% (1)

- Microsoft Access - Use ADO To Execute SQL StatementsDocument18 pagesMicrosoft Access - Use ADO To Execute SQL StatementsjorgemachigueNo ratings yet

- Classification Tree - Utkarsh Kulshrestha: Earn in G Is in Learnin G - Utkarsh KulshresthaDocument33 pagesClassification Tree - Utkarsh Kulshrestha: Earn in G Is in Learnin G - Utkarsh KulshresthaN MaheshNo ratings yet

- Fc75 DB Structure Dif10 enDocument15 pagesFc75 DB Structure Dif10 enChristian CamposNo ratings yet