Professional Documents

Culture Documents

Motor Control Sensor Feedback Circuits: Author: Jim Lepkowski Microchip Technology Inc

Uploaded by

CAe SpecialistOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Motor Control Sensor Feedback Circuits: Author: Jim Lepkowski Microchip Technology Inc

Uploaded by

CAe SpecialistCopyright:

Available Formats

M AN894

Motor Control Sensor Feedback Circuits

A list of the sensors that can be used to feedback

Author: Jim Lepkowski

information to a microcontroller are listed below:

Microchip Technology Inc.

• Current sensors

- Shunt resistor

INTRODUCTION

- Current-sensing transformer

Sensors are a critical component in a motor control - Hall effect current sensor

system. They are used to sense the current, position, • Speed/position sensors

speed and direction of the rotating motor. Recent

- Quadrature encoder

advancements in sensor technology have improved

the accuracy and reliability of sensors, while reducing - Hall efect tachometer

the cost. Many sensors are now available that integrate • Back EMF/Sensorless control method

the sensor and signal-conditioning circuitry into a single

package.

In most motor control systems, several sensors are

used to provide feedback information on the motor.

These sensors are used in the control loop and to

improve the reliability by detecting fault conditions that

may damage the motor. As an example, Figure 1 pro-

vides a block diagram of a DC motor control system to

show the sensor feedback provided for a typical motor

control.

Power Management

Torque

PICmicro®

Speed Input Microcontroller Driver Motor

Direction

Current

Sensor

Feedback

Sensors

* Speed

* Shaft Position

* Rotation Direction

FIGURE 1: Typical DC Motor Block Diagram.

2003 Microchip Technology Inc. DS00894A-page 1

AN894

CURRENT SENSORS applications. A summary of the advantages and

disadvantages of each of the current sensors is

The three most popular current sensors in motor provided in Table 1.

control applications are:

Figure 2 shows an example of an AC motor powered by

• Shunt resistors a three-phase inverter bridge circuit. This example

• Hall effect sensors shows that the composite current of all three Insulated

• Current transformers Gate Bipolar Transistor (IGBT) circuit legs can be

measured with a single shunt resistor, or that the

Shunt resistors are popular current sensors because

current in each individual leg can be determined with

they provide an accurate measurement at a low cost.

three shunt resistors. Figure 2 shows a system that

Hall effect current sensors are widely used because

uses shunt resistors. However, Hall effect and current-

they provide a non-intrusive measurement and are

sensing transformers can also be used to provide the

available in a small IC package that combines the

current measurement.

sensor and signal-conditioning circuit. Current-sensing

transformers are also a popular sensor technology,

especially in high-current or AC line-monitoring

TABLE 1: COMPARISON OF CURRENT SENSING METHODS

Current Sensing Method Shunt Resistor Hall Effect Current Sensing Transformer

Accuracy Good Good Medium

Accuracy vs.Temperature Good Poor Good

Cost Low High Medium

Isolation No Yes Yes

High Current-Measuring Poor Good Good

Capability

DC Offset Problem Yes No No

Saturation/Hysteresis No Yes Yes

Problem

Power Consumption High Low Low

Intrusive Measurement Yes No No

AC/DC Measurements Both Both Only AC

Current Measurement with Current Measurement with

a Single Shunt Resistor AC Three Shunt Resistors AC

Motor Motor

VDC VDC

IA IB IC

IA IB IC VOUT_C

I = IA+ IB + IC VOUT_A VOUT_B

VOUT

RSENSE R SENSE_A

RSENSE_B RSENSE_C

FIGURE 2: AC Motor Current Measurement.

DS00894A-page 2 2003 Microchip Technology Inc.

AN894

Shunt Resistors • Special-purpose, low inductance resistors are

required if the current has a high-frequency

Shunt resistors are a popular current-sensing sensor content.

because of their low cost and good accuracy. The

• The power rating of RSENSE must be evaluated

voltage drop across a known low value resistor is

because the I2 x R power dissipation can produce

monitored in order to determine the current flowing

self heating and a change in the nominal

through the load. If the resistor is small in magnitude,

resistance of the shunt.

the voltage drop will be small and the measurement will

not have a major effect on the motor circuit. The power Special-purpose, shunt current measurement resistors

dissipation of the resistance makes current shunts are available from a number of vendors. If standard

impractical for measurements of more than resistors are used, it is recommended that metal-film

approximately 20 amperes. resistors be used rather than wire-wound resistors that

have a relatively large inductance.

The selection criteria of a shunt current resistor

requires the evaluation of several trade-offs, including: A shunt resistor can also be created from the trace

resistance on a PCB, as shown in Figure 3. PCB shunt

• Increasing R SENSE increases the VSENSE voltage,

resistors offer a low cost alternative to discrete resis-

which makes the voltage offset (VOS) and input

tors. However, their accuracy over a wide temperature

bias current offset (IOS) amplifier errors less

range is poor when compared to a discrete resistor.

significant.

The temperature coefficient of a copper PCB trace

• A large RSENSE value causes a voltage loss and a shunt resistor is equal to approximately +0.39%/°C.

reduction in the power efficiency due to the I2 x R Further details on PCB trace resistors are given in ref-

loss of the resistor. erence (2).

• A large RSENSE value will cause a voltage offset to

the load in a low-side measurement that may

impact the EMI characteristics and noise

sensitivity of the system.

Trace resistance is based on: Example: What is the resistance of the PCB shunt resistor

* Length (L) using the parameters listed below?

* Thickness (t) Given: 1 oz Cu PCB

* Width (w) w = 50 mils (0.050 in)

* Resistivity (ρ) L = 1 inch

I = 5 ampere

* 1 oz. Copper (Cu) is defined to be a layer L / w = number of squares (

)

with 1 oz. of Cu per square foot. = 1 in / 0.050 in

= 20 squares

t ≈ 1.37 mil./oz. Copper R ≈ (L / w) x R

ρ ≈ 0.68 µΩ-inch ≈ (20 squares) x 0.50 mΩ/

≈ 10 mΩ

R

≈ (0.50 mΩ /

) x [(1 oz. Cu) / (# oz. Cu)]

P = I2 x R

= (5A)2 x (0.010Ω)

= 0.25 Watt

RPCB

⇔

L

t

PCB Trace Resistor

w

FIGURE 3: PCB Shunt Resistor.

2003 Microchip Technology Inc. DS00894A-page 3

AN894

High-Side vs. Low-Side Current Shunt High-side resistive shunt measurements will not have a

Measurements significant impact on the system if the sensing resistor

is small and the resulting voltage drop across the shunt

SYSTEM INTEGRATION ISSUES is small compared to the supply voltage. In contrast,

low-side monitoring disrupts the ground path of the

Shunt resistors can provide either a high-side or low- load, which can cause noise and EMI problems in the

side measurement of the current through the load, as system.

shown in Figure 4. A high-side monitor has the resistor

connected in series with the power source, while the Low-side current measurements are often chosen

low-side monitor locates the resistor between the load because low voltage op amps can be used to sense the

and the ground current return path. Both approaches voltage across the shunt resistor. Note that low-side

pose a trade-off to the designer. The attributes of the monitoring is not possible in some applications

two methods, along with the typical monitor circuits, will because the ground connection is made via the

be shown in the following sections. Reference (3) mechanical mounting of the motor on the chassis or

provides more details on high-side and low-side metal frame. For systems powered via a single wire

shunts. connection, it may not be practical to insert a shunt

resistor between the device and the chassis that

High-side current measurements are the preferred functions as the ground wire.

method from a system-integration standpoint because

they are less intrusive than low-side measurements.

The trade-off with the high-side measurement is that

the circuitry is more complex than the low-side method.

RSENSE ILOAD

ILOAD

VSENSE Load

VS + +

- Load VS - Measurement VSENSE

Measurement

Circuit

Circuit

RSENSE

High-Side Current Measurement Low-Side Current Measurement

ILOAD = VSENSE / RSENSE ILOAD = VSENSE / RSENSE

FIGURE 4: High-Side and Low-Side Resistive Current Shunts.

DS00894A-page 4 2003 Microchip Technology Inc.

AN894

HIGH-SIDE CURRENT SHUNT Disadvantages:

MEASUREMENTS • The VSENSE voltage is approximately equal to the

High-side current measurements can be implemented supply voltage, which may be beyond the

with a differential amplifier circuit that produces an maximum input voltage range of the operational

output voltage that is proportional to VSENSE or the amplifier.

current flowing through the load. Figure 5 provides an • A differential amplifier’s CMRR will be degraded

example of a high-side shunt circuit. The differential by mismatches in the amplifier resistors.

amplifier circuit can be implemented with an op amp • The input impedance of the differential circuit is

and discrete resistors or with an integrated IC device. relatively low and is asymmetrical. The input

Integrated differential amplifier ICs are available from a impedance at the amplifier’s non-inverting input is

number of semiconductor vendors and offer a equal to R IN + R*, while the impedance at the

convenient solution because the amplifier and well- inverting terminal is equal to R IN.

matched resistors are combined in a single device. • May require rail-to-rail-input op amps because of

The attributes of high-side monitoring are listed below: the high voltage level of the input signal.

Advantages: The high-side shunt circuit requires a high-voltage

• Less intrusive than low-side monitors and will not amplifier that can withstand a high common mode

affect the EMI characteristics of the system. voltage. In addition, the key amplifier specifications are

a high CMRR and a low VOS because of the relatively

• Can detect overcurrent faults that can occur by

small magnitude of VSENSE. High voltage op amps and

short circuits or inadvertent ground paths that can

integrated differential amplifier ICs are available for

increase the load current to a dangerous level.

systems that have a maximum voltage of

• A differential amplifier circuit will filter undesirable approximately 60V. For voltage requirements beyond

noise via the common-mode-rejection-ratio 60V, a current mirror circuit can be used to sense the

(CMRR) of the amplifier. current. A current mirror can be implemented with

• A resistive network can be used to reduce the readily available, high-voltage transistors. References

voltage at the amplifier’s input terminals. For (1) and (5) provide examples of high-voltage, high-side

example, if RIN = R*, the input voltage will be current monitor circuits.

reduced in half and the amplifier will be biased at

Table 2 provides a list of the recommended Microchip

VS/2. Note that the amplifier gain will be equal to

op amps that can be used in a high-side circuit.

one and that a second amplifier may be needed to

increase the sensor’s output voltage.

VSENSE

RSENSE

RIN RIN R* ILOAD

VS +

- PICmicro® Load

ADC Micro-

VOUT

controller

R* VOUT = VSENSE x (R*/RIN )

= (ILOAD x RSENSE) x (R*/R IN)

FIGURE 5: High-Side Resistive Current Measurement Circuit.

TABLE 2: RECOMMENDED MICROCHIP OP AMPS FOR HIGH-SIDE CURRENT SHUNTS

Product Operating Voltage CMRR (Typ.) VOS (Max.) Features

TC7652 6.5 to 16V 140 dB 10 µV • Low Noise

• Chopper Stabilized

TC913A 6.5 to 16V 116 dB 15 µV • Auto-zeroed Op Amp

TC913B 6.5 to 16V 110 dB 30 µV • Auto-zeroed Op Amp

2003 Microchip Technology Inc. DS00894A-page 5

AN894

LOW-SIDE CURRENT MEASUREMENT Disadvantages

Low-side current measurements offer the advantage • The low-side resistor disrupts the ground path

that the circuitry can be implemented with a low voltage and the added resistance to the grounding system

op amp because the measurement is referenced to produces an offset voltage which can cause EMI

ground. The low-side measurement circuit can use a noise problems.

non-inverting amplifier, as shown in Figure 6. • Low-side current monitors are unable to detect a

The low-side current monitor can also be implemented fault where the load is accidently connected to

with a differential amplifier. The advantages of ground via an alternative ground path.

differential amplification are limited because RSENSE is Table 3 provides a list of the recommended Microchip

connected to ground and the common mode voltage is op amps that can be used in a low-side circuit. The key

very small. Note that integrated IC low-side monitors op amp specifications for selecting a low-side amplifier

that combine the op amp and resistors are not readily are rail-to-rail input and a low offset voltage (VOS).

available because of the simplicity of the circuit that can

be implemented with a few discrete resistors and low

voltage op amp.

The attributes of low-side monitoring are:

Advantages

• VSENSE is referenced to ground. Therefore, a low

voltage amplifier can be used.

• A non-inverting amplifier can be used and the

input impedance of the circuit will be equal to the

large input impedance of the amplifier.

Load

+ VSENSE VOUT

VS

- ILOAD PICmicro®

ADC

Microcontroller

RSENSE

R2 VOUT = (VSENSE) x (1 + R 2/R1)

R1

= (ILOAD x RSENSE ) x (1 + R2/R 1)

FIGURE 6: Low-Side Resistive Current Measurement Circuit.

TABLE 3: RECOMMENDED MICROCHIP OP AMPS FOR LOW-SIDE CURRENT SHUNTS

Product Operating Voltage CMRR (Typ.) VOS (Max.) Features

TC913A 6.5 to 16V 116 dB 15 µV • Auto-zeroed Op Amp

TC913B 6.5 to 16V 110 dB 30 µV • Auto-zeroed Op Amp

MCP606 2.5 to 5.5V 91 dB 250 µV • Rail-to-Rail Output

• Low Operating Current

MCP616 2.3 to 5.5V 100 dB 150 µV • Rail-to-Rail Output

• Low Operating Current

DS00894A-page 6 2003 Microchip Technology Inc.

AN894

SHUNT OFFSET ADJUSTMENT CIRCUIT NOISE REDUCTION TECHNIQUES

The circuit shown in Figure 7 can be used to provide an The combination of a differential amplifier with a high

offset to the amplification of the VSENSE signal. CMRR and discrete RC filters can be used to minimize

Resistor R 1 is used to prevent the offset voltage the effect of EMI noise. The effect of EMI on a

provided by resistors R4 and R5 from changing the measurement typically results in poor DC performance

value of VSENSE. The offset can be used to center the and a large DC offset at the output of the op amp.

amplifier’s output to the midpoint of the voltage supply Figure 8 provides an example of a circuit that can be

(VDD/2). The VSENSE signal is typically only 10 to used in a motor application to reduce noise.

100 mV above ground and the offset often is needed if The addition of the common mode filters formed by the

the amplifier is connected to an ADC. RC combinations of R1C1 and R2C2 are used to reduce

the noise that is imposed on the two input lines of the

VS amplifier. Discrete RC networks lower the voltage level

of the noise signal by functioning as a low pass filter.

VDD However, an EMI filter, such as a TVS zener diode, is

R4 R5 required to ensure that the input noise is clamped to a

Load

safe voltage level that will not damage the amplifier.

VDD

VSENSE R1 The common mode resistors and capacitors should be

ILOAD

VOUT matched as close as possible. The resistors should

have a tolerance of 1% or better, while the capacitors

RSENSE

should have a tolerance of 5% or better. Capacitor C3

is used to add a RC differential filter that compensates

R2 R3 for any mismatch of R1C1 and R2C2. Any difference in

the RC combinations will result in a degradation of the

RSENSE << R1 amplifier’s CMRR. The differential filter formed by R1C3

Amplifier Gain = (1 + (R3 / R2)) and R2C3 will attenuate the differential signal at the

VOUT = [(VSENSE (1 + (R3/R2)) + ((R5 / (R 4+R5)VDD)] amplifier caused by the tolerances of the common

mode filters.

FIGURE 7: Shunt Offset Adjustment

Circuit. VS

Providing an offset to the shunt resistor circuit can also

R1 R4

improve the linearity of the amplification, especially if

standard op amps are used. The linearity, accuracy ILOAD C1

and power consumption of a standard single power RSENSE C3

VOUT

supply op amp is typically degraded when the output

R2

signal is at, or near, the power supply rails. Thus, the

offset circuit can be used to avoid this problem. The C2

preferred op amps to use in a shunt circuit have a small R3

Load

offset voltage (VOS) and a rail-to-rail, input-output

specification.

RSENSE << R 1 and R2

R1 = R2

C1 = C2

C3 >> C1 and C3 >> C2

Common Mode Filter

f-3dB = 1 / (2π R1 C1)

= 1 / (2π R2 C2)

Differential Mode Filter

f-3dB =1/ [2π (R1+R2) (((C1 x C2)/(C1+C2)) + C3)]

FIGURE 8: RC Noise Reduction Circuit.

2003 Microchip Technology Inc. DS00894A-page 7

AN894

Figure 9 provides an example of a shunt amplifier Hall Effect Current Sensors

circuit that combines the filtering of the shunt current

signal with an offset adjustment. The RC components Hall effect sensors are a current-measuring sensor that

R1C1, R2C 2 and C 3 are used to provide EMI and ESD can be easily integrated into an embedded application.

protection to the amplifier. The RC feedback networks Several vendors offer devices that combine the

of R 7C5 and R6C4 are selected to provide a low pass magnetic sensor and conditioning circuit in a small IC

filter response to the differential amplifier. package. These IC sensors typically produce an

analog output voltage that can be input directly into the

A trade-off with discrete filter networks is that the microcontroller’s ADC. The main disadvantages of Hall

frequency response of the filter is dependent on the effect current sensors are that they are expensive and

source and load impedance. The filter equations shown their accuracy varies with temperature.

are only an approximation. A more detailed analysis or

SPICE simulation may be required to accurately model The Hall effect is based on the principle that a voltage

the filter response of the circuit. (VH) is created when current (IC) flows in a direction

perpendicular to a magnetic field (B), as shown in

Figure 10. Hall effect current sensors are available in

VDD either an open-loop or closed-loop implementation.

R7

The closed-loop Hall effect sensors offer the advantage

VS

EMI Filter R5 that their output linearity is better than an open-loop

R1 R3 C5 sensor over a wider current measurement range.

VDD Further details on Hall effect sensors are available in

ILOAD

C1 references (4), (7) and (12).

RSENSE C3

R2 R4 VOUT

VH-

Load C2 R6 C4

B

RSENSE << R 1 and R2 IC IC

R1 = R2 = RIN* R3 = R4 = R IN

RIN >> RIN* R7 = R5 ll R6 = RF

C1 = C2

C3 >> C1 and C3 >> C2

C4 = C5 = CF VH+

DC Amplifier Gain = -RF / (RIN* + R IN)

FIGURE 10: Hall Effect Principle.

Amplifier Feedback Low Pass Filter

The Hall effect current sensor can be placed on the

f-3dB @ 1 / (2π RF CF)

VOUT = [((ILOAD x RSENSE) x (RF/(R IN + RIN*))

PCB directly over the current trace that will be

+ ((R6/(R5+R6)VDD )]

monitored. The sensor functions by measuring the

magnetic flux that is created by the current flowing

through the trace. Figure 11 provides an example of a

FIGURE 9: Combining the Offset and PCB mounted Hall effect sensor that measures the

Noise Reduction Circuit. current through a wire placed on the top of the IC. Hall

effect current sensors are also available in a package

Integrated EMI filters can be used to simplify the circuit

that is mounted on the PCB, with the current-carrying

shown in Figure 9 and reduce the number of discrete

wire passing through a hole in the sensor.

components. Integrated Passive Device (IPD) EMI

filters that consist of resistors and transient

suppression (TVS) zener diodes are available from a

number of IC venders. IPD filters integrate the discrete I

components in a small IC package, while providing

transient voltage protection.

TVS devices offer the advantage that the input signal is I

clamped to a safe value that is equal to the breakdown

voltage of a zener diode. The zener diode functions as

a capacitor when the voltage is below the breakdown

voltage. Thus, the IPD filter is equivalent to a RC filter Printed Circuit Board

when the input voltage is small. Further details on IPD

EMI filters and ESD protection devices are provided in

FIGURE 11: Hall Effect Current Sensor.

reference (8).

DS00894A-page 8 2003 Microchip Technology Inc.

AN894

Current-Sensing Transformers Figure 12 provides schematics of a single turn and a

multi-turn primary current-sensing transformers. The

Current-sensing transformers offer an alternative to single-turn primary transformer offers the advantage

shunt resistors and Hall effect sensors to measure cur- that the measurement is non-intrusive and the current-

rent. These sensors use the principle of a transformer, carrying wire can be passed directly through a hole in

where the ratio of the primary current to the secondary the transformer. The multi-turn transformer offers the

current is a function of the turns ratio. The main advan- advantages of improved magnetic coupling, since

tage of current transformers is that they provide gal- many turns of the primary wire can be provided.

vanic isolation and can be used in high-current

applications. The main disadvantage of current trans-

formers is that an AC input signal is required to prevent

the transformer from saturating.

B

Ip

A

3 1 4 2

2 1

Ip Is 3

Ip Is 1

1

A +

+

Np Ns VOUT Rt Np Ns VOUT Rt

-

- 2

B

2 4

Single-Turn Primary Is = Ip / N where N = turns ratio Multi-Turn Primary

VOUT = Is x Rt

FIGURE 12: Current-Sensing Transformers.

2003 Microchip Technology Inc. DS00894A-page 9

AN894

BACK EMF CONTROL METHOD The back EMF is created when the motor’s armature

turns, which creates a electrical kickback or EMF that

The back electro-magnetic-force (EMF) or sensorless is sensed as a voltage through a resistor. The

motor control method obtains the speed and position of amplitude of the EMF signal increases with the speed

the motor directly from the voltage at the motor of the armature rotation. A limitation of the back EMF

windings. This method is typically used in brushless DC method is that the amplitude of the signal is very small

motors to provide commutation. The back EMF control at low shaft RPMs.

method eliminates the requirement for relatively expen-

The zero-crossing circuit can be constructed from

sive sensors, such as Hall effect devices. The back

either discrete comparator ICs or comparators that are

EMF voltage produces a sine or trapezoidal waveform

located inside the PICmicro® microcontroller. Figure 13

that is sensed at the motor’s winding and typically is

provides a block diagram of a sensorless control for a

converted into a digital square wave by a zero-crossing

Brushless Direct Current (BLDC) motor that uses

comparator circuit. The comparator signal is inputted to

discrete comparator circuits.

the microcontroller, which calculates the commutation

sequence and motor position from the phase

relationship of the square wave representation of the

back EMF signals.

VDC

PWM5

A

PWM4

PIC18FXX31 PWM3 3-Phase

Inverter Bridge

PWM2

PWM1

PWM0

C B

VDC

BEMFA

VREF_A

VDC

BEMFB

VREF_B

VDC

BEMFC

VREF_C

BACK EMF

ZERO-CROSSING

COMPARATOR CIRCUITS

FIGURE 13: Block Diagram of a Sensorless BLDC Motor Control.

DS00894A-page 10 2003 Microchip Technology Inc.

AN894

SELECTING A COMPARATOR Though op amps can be used as a comparator, the

designer must consider the trade-offs of using an

A comparator is designed to provide a logic-level

amplifier in a non-linear mode. Op amps are designed

output signal that indicates whether the voltage at the

to linearly amplify a small signal and use negative

non-inverting input is larger or smaller than the voltage

feedback to function in the linear region. By contrast,

at the inverting input. Figures 14 and 15 show the cir-

comparators are designed to function in the non-linear

cuit topology and design equations for a non-inverting

region and use positive feedback to force the output to

and inverting comparator, respectively. The non-invert-

have a fast transition to the saturation region where the

ing circuit’s output is in phase with the sinewave input,

output is at either the high or low power supply rail.

while the inverting circuit that has an output 180° out of

phase from the input signal. Reference (6) provides Though op amps can function as a comparator by

further details on the comparator voltage transition and using positive feedback, the switching speed of the cir-

hysteresis equations. cuit is typically poor. The propagation delay of an op

amp comparator is large in comparison with a typical

For example, the output voltage of a single voltage

comparator. In addition, the current consumption of an

supply, non-inverting comparator will be analyzed. The

op amp comparator usually is much larger than a

output will be the same for a push-pull or an open-drain

standard comparator.

output device that is connected to voltage VDD through

a pull-up resistor. If the voltage at the non-inverting (+) Table 4 provides a list of recommended Microchip

terminal is larger than the voltage at the inverting (-) comparators. A key specification for motor control

terminal, the output will be equal to approximately VDD. applications is the propagation delay of the comparator.

In contrast, if the voltage at the (+) terminal is less than

the voltage at the (-) terminal, the output will be equal

to approximately V SS or ground.

TABLE 4: RECOMMENDED MICROCHIP COMPARATORS

Operating Propagation Delay

Product IQ (Typ.) Features

Voltage (typ.)

TC1025 1.8 to 5.5V 8 µA 4 µs • Rail-to-rail input and output

TC1027 1.8 to 5.5V 18 µA 4 µs • On-board V REF

TC1028 1.8 to 5.5V 10 µA 4 µs • Shutdown pin (TC1028)

TC1031 1.8 to 5.5V 6 µA 4 µs • Prog. Hysteresis

• Shutdown pin

• On-board V REF

TC1037 1.8 to 5.5V 4 µA 4 µs

TC1038 1.8 to 5.5V 4 µA 4 µs • Shutdown pin (TC1038)

TC1039 1.8 to 5.5V 6 µA 4 µs

• On-board V REF (TC1039)

TC1040 1.8 to 5.5V 10 µA 4 µs • On-board V REF

TC1041 1.8 to 5.5V 10 µA 4 µs • Prog. Hysteresis (TC1041)

MCP6541/2/3/4 1.6 to 5.5V 0.6 µA 4 µs • Low IQ

per comparator • Push-pull output

MCP6546/7/8/9 1.6 to 5.5V 0.6 µA 4 µs • Low IQ

per comparator • Open-drain output

2003 Microchip Technology Inc. DS00894A-page 11

AN894

From

VPULL-UP

Motor Windings

VOUT

VM R3

RPULL-UP VOH

R1A VDD

VIN

VOUT

VDD

R2 VOL

R1B VREF

R4 VIN

VTL VTH

Hysteresis Plot

Assume: VOH = VDD, VOL = 0, R3 >> R1 and R3 >> R PULL-UP

R 1B

V IN = --------------------------

- × V M R 1 = R 1A || R 1B

R + R Design Procedure:

1A 1B

R4 1. Select VREF, the “zero-crossing” voltage

V RE F = V DD × -------------------- -

R + R 2. Select VHYS to be equal to 10 to 100 mV

2 4

( R 1 + R 3 )V REF – ( R 1 × V DD ) 3. Select R3 >> R1

V TL ≅ ----------------------------------------------------------------------

-

R3

( R 1 + R 3 )V REF

V TH ≅ ------------------------------------

-

R3

V HYS = V TH – V TL

R

V HYS ≅ -----1- × V DD Note: RPULL-UP is required for open drain outputs,

R but is not required for push-pull output comparators.

3

FIGURE 14: Single Supply Non-Inverting Comparator Circuit.

VDD VPULL-UP VOUT

R3

From VOH

RPULL-UP

Motor Windings R2 VDD

R1

VM

R1A VREF VOUT

VIN VOL

VIN

VTL VTH

R1B

Hysteresis Plot

Design Procedure:

Assume: VOH = VDD, VOL = 0, R3 >> R1 ll R2 and R3 >>RPULL-UP

1. Select VREF, the “zero-crossing” voltage

R 1B

V IN = --------------------------

- × V M R 1 = R 1A || R 1B 2. Select VHYS to be equal to 10 to 100 mV

R + R

1A 1B 3. Select R3 >> R1 ll R2

R1

V REF ≅ V DD × ------------------

R + R

1 2

R1

V TL ≅ ------------------ × VD D

R + R

1 2

R1 ( R 1 || R 2 ) × V DD

V TH ≅ ------------------ × V DD + ---------------------------------------

-

R + R R

1 2 3

V H YS = V TH – V TL

Note: RPULL-UP is required for open drain outputs,

( R 1 || R 2 ) × V DD

V H YS ≅ ---------------------------------------

- but is not required for push-pull output

R3 comparators.

FIGURE 15: Single-Supply Inverting Comparator Circuit.

DS00894A-page 12 2003 Microchip Technology Inc.

AN894

COMPARATOR REFERENCE VOLTAGE HYSTERESIS

In single supply comparators, a reference voltage must Hysteresis can be used to provide noise reduction and

be created. The circuits create VREF by using a resistor prevent oscillation when the comparator switches

voltage divider. The offset voltage of VREF enables the output states. A comparator provides hysteresis by

circuit to function as a zero-crossing detector without feeding back a small fraction of the output signal to the

requiring a dual voltage power supply. The back EMF positive input terminal. This additional voltage provides

voltage produces a sine or trapazoidal waveform that for a polarity sensitive offset voltage, which either

swings above and below power ground. The back EMF increases or decreases the threshold value of the

voltage can be sensed as a sine or trapazoidal wave- switching voltage. Hysteresis produces two different

form offset by a DC voltage if the comparator circuit is switching points that result in a transition voltage that is

either referenced to center point of the motor windings, dependent on whether the input voltage is rising or

or if a resistor network is used. The resistor network falling in amplitude.

can either pull-up the floating signal to VDD or pull- Frequency-dependent hysteresis can be provided by

down the signal to ground. Further details on the back placing a capacitor in the positive feedback network, as

EMF comparator circuit used in a brushless DC motor shown in Figure 16. The capacitor adds an additional

controller are provided in reference (11). pole that changes the amount of hysteresis as a

function of frequency. At frequencies below fp, the

hysteresis will be a constant voltage determined by

resistors R1 and R3. However, at frequencies above the

pole fp, the hysteresis will be increased as a function of

the frequency, as shown in the equations provided in

Figure 16.

C3

R3

High Frequency Pole @ fp = 1 / (2π R3 C3)

VDD

R1 Z3 = R3 ll C 3

VIN = R3 / (sR3C3 +1) where s = jω = j2πf

VOUT

VDD

R2 VHYS ≅ [(R1 / Z 3) x VDD]

VREF ≅ [(R1 x (sR3C3 +1)) / R3)] x VDD

R4

FIGURE 16: Frequency Dependent Hysteresis for a Comparator.

2003 Microchip Technology Inc. DS00894A-page 13

AN894

QUADRATURE ENCODER reverse direction. The Index signal provides the

position of the motor and, typically, a single pulse is

A quadrature encoder can be used to provide the generated for every 360 degrees of shaft rotation.

speed, direction and shaft position of a rotating motor.

The quadrature encoder’s speed and direction

A simplified block diagram of an optical quadrature

information can be determined either with discrete

encoder is shown in Figure 17. The typical quadrature

logic, a quadrature encoder logic IC or a PICmicro®

encoder is packaged inside the motor assembly and

microcontroller. Vendors, such as LSI Computer

provides three logic-level signals that can be directly

Systems, offer an IC that converts the three encoder

connected to the microcontroller.

signals to a signal that represents the velocity, position

Motor speed is determined by the frequency of the and distance that the motor has moved. Alternatively,

Channel A and B signals. Note that the counts-per-rev- the encoder information can be obtained from the

olution (CPR) depends on the location of the encoder hardware registers and software logic inside a

and whether motor-gearing is used. The phase PICmicro microcontroller. For example, the

relationship between Channel A and B can be used to PIC18FXX31 dsPIC® MCUs have a Quadrature

determine if the motor is turning in either a forward or Encoder Interface logic integrated into the processor.

VDD Motor (+)

VDD

Channel A

Quadrature

Encoder 0V

VDD

Channel A Motor Channel B

Channel B 0V

Index

Forward Direction Reverse

Change

Motor (-) Index

VDD

Codewheel

Photodiode

Channel A

Signal

LED Lens Processing Channel B

Circuitry

Index

Ground

Simplified Block Diagram of a Quadrature Encoder

FIGURE 17: Quadrature Encoder.

DS00894A-page 14 2003 Microchip Technology Inc.

AN894

HALL EFFECT TACHOMETERS An example of a Hall effect rotary interrupt switch is

provided in Figure 18. A notch is placed in the rotating

Hall effect sensors can be used to sense the speed and shaft that provides a magnetic field to the sensor when

position of a rotating motor. Further information on Hall the notch is positioned directly in-line with the magnet

effect tachometer sensors are provided in references and the Hall effect sensor, turning the switch “ON”.

(4) and (12). These sensors are based on using the When the solid portion of the disk is between the Hall

Hall element to sense the change influx in the air gap effect sensor and the magnet, the magnetic field is

between a magnet and a notch in a rotating shaft or a interrupted and the switch is in the “OFF” position.

passing ferrous gear tooth. The main advantage of Hall

Hall effect tachometers can also be used as a

effect tachometers is that they are a non-contact

geartooth sensor. A Hall effect geartooth sensor,

sensor that is not limited by mechanical wear. Hall

shown in Figure 19, senses the variation in the flux in

effect tachometers that integrate the sensor and

the air gap between the passing ferrous geartooth and

sensor-conditioning circuit in a small IC package are

the magnet. Geartooth sensors typically provide a

available from a number of vendors. The circuitry inside

digital output that can be directly connected to the I/O

the sensor typically consists of a comparator or Schmitt

port of the microcontroller. In addition to detecting the

trigger to provide a digital output signal that can be

speed of the rotation, some Hall effect tachometers

directly connected to the microcontroller.

also detect the direction of the turning gears.

Magnet

Refer to Reference 12 for additional information

FIGURE 18: Hall Effect Rotary Interrupt Switch Tachometer.

Hall Effect

Sensor

Refer to Reference 12 for additional information

FIGURE 19: Hall Effect Geartooth Tachometer.

2003 Microchip Technology Inc. DS00894A-page 15

AN894

CONCLUSION BIBLIOGRAPHY

Feedback sensors serve a critical role in a motor 1. Bell, Bob and Hill, Jim, “Circuit Senses High-

control system. These sensors provide information on Side Current”, EDN, March 1, 2001.

the current, position, speed and direction of a rotating 2. Blake, Kumen, “Analog PCB Layout

motor. In addition, the sensors improve the reliability of Techniques”, 2002 Microchip Master

the motor by detecting fault conditions that may Conference, Microchip Technology Inc., 2002.

damage the motor. 3. Farley, Mike, “High-Side ICs Simplify Current

The four major feedback sensors discussed in this Measurements”, Power Electronics Technology,

document are: current sensors, back EMF or September 2003.

sensorless control, quadrature encoders and Hall effect 4. Gilbert, Joe and Dewey, Ray, “Application Note

tachometers. Each of these sensors offer advantages 27702A, Linear Hall-Effect Sensors, Allegro

and disadvantages that the designer must evaluate in Microcsystems, Worcester, MA, 2002.

order to provide a stable, reliable and cost-effective 5. Klein, William, “Circuit Measures Small Currents

control system. Referenced to High Voltage Rails”, Electronic

Further details on motor control circuits and sensors Design, January 7, 2002.

are provided in several books, including “Motor Control 6. Moghimi, Reza, “Curing Comparator Instability

Electronics” (10). In addition, please review Microchip’s with Hysteresis”, Analog Dialogue 34-7, Analog

web site (www.microchip.com) for reference designs Devices, Norwood, MA, 2000.

and applications notes on motor control systems. 7. Law, Lou, “Measuring Current with IMC Hall

References (9) and (11) are just two of the many Effect Technology”, Sensors, November 2003.

documents available that demonstrate how Microchip’s

8. Lepkowski, Jim, “AND8027 - Zener Diode

PICmicro microntrollers and analog products can be

Based Integrated Passive Device Filters, An

used in a motor control system.

Alternative to Traditional I/O EMI Filter Devices”,

ON Semiconductor, Phoenix, AZ, 2001.

9. Parekh, Rakesh, “AN889 - VF Control of 3-

Phase Induction Motors using PIC16F7X7

Microcontrollers”, Microchip Technology Inc.,

2003.

10. Valentine, Richard, editor, “Motor Control Elec-

tronics Handbook”, McGraw-Hill, Boston, 1998.

11. Yedamale, Padmaraja, “AN885 - Brushless DC

(BLDC) Motor Fundamentals”, Microchip

Technology Inc., Chandler, AZ, 2003.

12. “Hall Applications Guide”, Melexis

Microelectronics, Concord, N.H., 1997.

DS00894A-page 16 2003 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device Trademarks

applications and the like is intended through suggestion only

The Microchip name and logo, the Microchip logo, Accuron,

and may be superseded by updates. It is your responsibility to

dsPIC, KEELOQ, MPLAB, PIC, PICmicro, PICSTART,

ensure that your application meets with your specifications. PRO MATE and PowerSmart are registered trademarks of

No representation or warranty is given and no liability is

Microchip Technology Incorporated in the U.S.A. and other

assumed by Microchip Technology Incorporated with respect

countries.

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such AmpLab, FilterLab, microID, MXDEV, MXLAB, PICMASTER,

use or otherwise. Use of Microchip’s products as critical SEEVAL, SmartShunt and The Embedded Control Solutions

components in life support systems is not authorized except Company are registered trademarks of Microchip Technology

with express written approval by Microchip. No licenses are Incorporated in the U.S.A.

conveyed, implicitly or otherwise, under any intellectual Application Maestro, dsPICDEM, dsPICDEM.net,

property rights. dsPICworks, ECAN, ECONOMONITOR, FanSense,

FlexROM, fuzzyLAB, In-Circuit Serial Programming, ICSP,

ICEPIC, microPort, Migratable Memory, MPASM, MPLIB,

MPLINK, MPSIM, PICkit, PICDEM, PICDEM.net, PICtail,

PowerCal, PowerInfo, PowerMate, PowerTool, rfLAB, rfPIC,

Select Mode, SmartSensor, SmartTel and Total Endurance

are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in October

2003 . The Company’s quality system processes and procedures are

for its PICmicro ® 8-bit MCUs, KEELOQ® code hopping devices, Serial

EEPROMs, microperipherals, non-volatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

2003 Microchip Technology Inc. DS00894A-page 17

M

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC Korea

168-1, Youngbo Bldg. 3 Floor

Corporate Office Australia

Samsung-Dong, Kangnam-Ku

2355 West Chandler Blvd. Suite 22, 41 Rawson Street

Seoul, Korea 135-882

Chandler, AZ 85224-6199 Epping 2121, NSW

Tel: 82-2-554-7200 Fax: 82-2-558-5932 or

Tel: 480-792-7200 Australia

82-2-558-5934

Fax: 480-792-7277 Tel: 61-2-9868-6733

Technical Support: 480-792-7627 Fax: 61-2-9868-6755 Singapore

Web Address: http://www.microchip.com 200 Middle Road

China - Beijing

#07-02 Prime Centre

Atlanta Unit 706B

Singapore, 188980

3780 Mansell Road, Suite 130 Wan Tai Bei Hai Bldg.

Tel: 65-6334-8870 Fax: 65-6334-8850

Alpharetta, GA 30022 No. 6 Chaoyangmen Bei Str.

Beijing, 100027, China Taiwan

Tel: 770-640-0034

Tel: 86-10-85282100 Kaohsiung Branch

Fax: 770-640-0307

Fax: 86-10-85282104 30F - 1 No. 8

Boston Min Chuan 2nd Road

China - Chengdu

2 Lan Drive, Suite 120 Kaohsiung 806, Taiwan

Westford, MA 01886 Rm. 2401-2402, 24th Floor, Tel: 886-7-536-4818

Tel: 978-692-3848 Ming Xing Financial Tower Fax: 886-7-536-4803

Fax: 978-692-3821 No. 88 TIDU Street

Chengdu 610016, China Taiwan

Chicago Tel: 86-28-86766200 Taiwan Branch

333 Pierce Road, Suite 180 Fax: 86-28-86766599 11F-3, No. 207

Itasca, IL 60143 Tung Hua North Road

China - Fuzhou Taipei, 105, Taiwan

Tel: 630-285-0071

Unit 28F, World Trade Plaza Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Fax: 630-285-0075

No. 71 Wusi Road

Dallas Fuzhou 350001, China EUROPE

4570 Westgrove Drive, Suite 160 Tel: 86-591-7503506

Austria

Addison, TX 75001 Fax: 86-591-7503521

Tel: 972-818-7423 Durisolstrasse 2

China - Hong Kong SAR A-4600 Wels

Fax: 972-818-2924 Unit 901-6, Tower 2, Metroplaza Austria

Detroit 223 Hing Fong Road Tel: 43-7242-2244-399

Tri-Atria Office Building Kwai Fong, N.T., Hong Kong Fax: 43-7242-2244-393

32255 Northwestern Highway, Suite 190 Tel: 852-2401-1200 Denmark

Farmington Hills, MI 48334 Fax: 852-2401-3431 Regus Business Centre

Tel: 248-538-2250 China - Shanghai Lautrup hoj 1-3

Fax: 248-538-2260 Room 701, Bldg. B Ballerup DK-2750 Denmark

Kokomo Far East International Plaza Tel: 45-4420-9895 Fax: 45-4420-9910

2767 S. Albright Road No. 317 Xian Xia Road France

Kokomo, IN 46902 Shanghai, 200051 Parc d’Activite du Moulin de Massy

Tel: 765-864-8360 Tel: 86-21-6275-5700 43 Rue du Saule Trapu

Fax: 765-864-8387 Fax: 86-21-6275-5060 Batiment A - ler Etage

China - Shenzhen 91300 Massy, France

Los Angeles

Rm. 1812, 18/F, Building A, United Plaza Tel: 33-1-69-53-63-20

18201 Von Karman, Suite 1090 No. 5022 Binhe Road, Futian District Fax: 33-1-69-30-90-79

Irvine, CA 92612 Shenzhen 518033, China

Tel: 949-263-1888 Germany

Tel: 86-755-82901380 Steinheilstrasse 10

Fax: 949-263-1338 Fax: 86-755-8295-1393 D-85737 Ismaning, Germany

Phoenix China - Shunde Tel: 49-89-627-144-0

2355 West Chandler Blvd. Room 401, Hongjian Building Fax: 49-89-627-144-44

Chandler, AZ 85224-6199 No. 2 Fengxiangnan Road, Ronggui Town Italy

Tel: 480-792-7966 Shunde City, Guangdong 528303, China Via Quasimodo, 12

Fax: 480-792-4338 Tel: 86-765-8395507 Fax: 86-765-8395571 20025 Legnano (MI)

San Jose China - Qingdao Milan, Italy

1300 Terra Bella Avenue Rm. B505A, Fullhope Plaza, Tel: 39-0331-742611

Mountain View, CA 94043 No. 12 Hong Kong Central Rd. Fax: 39-0331-466781

Tel: 650-215-1444 Qingdao 266071, China Netherlands

Tel: 86-532-5027355 Fax: 86-532-5027205 P. A. De Biesbosch 14

Toronto

6285 Northam Drive, Suite 108 India NL-5152 SC Drunen, Netherlands

Divyasree Chambers Tel: 31-416-690399

Mississauga, Ontario L4V 1X5, Canada

1 Floor, Wing A (A3/A4) Fax: 31-416-690340

Tel: 905-673-0699

Fax: 905-673-6509 No. 11, O’Shaugnessey Road United Kingdom

Bangalore, 560 025, India 505 Eskdale Road

Tel: 91-80-2290061 Fax: 91-80-2290062 Winnersh Triangle

Japan Wokingham

Benex S-1 6F Berkshire, England RG41 5TU

3-18-20, Shinyokohama Tel: 44-118-921-5869

Kohoku-Ku, Yokohama-shi Fax: 44-118-921-5820

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122 11/24/03

DS00894A-page 18 2003 Microchip Technology Inc.

You might also like

- Electronic Circuit Diagram: Recent ArticlesDocument3 pagesElectronic Circuit Diagram: Recent ArticlesSHOOTEENo ratings yet

- Universal Current SensorDocument12 pagesUniversal Current SensorBhargav MushiniNo ratings yet

- A New Concept of Power Quality Monitoring: AbstractDocument6 pagesA New Concept of Power Quality Monitoring: AbstractlokvisNo ratings yet

- Chapter 6 16052020 045213pm 19062023 052331pmDocument49 pagesChapter 6 16052020 045213pm 19062023 052331pmAbdullah ZamirNo ratings yet

- Integrated Electronic Metering Insulator For Medium Voltage Overhead LinesDocument4 pagesIntegrated Electronic Metering Insulator For Medium Voltage Overhead LinesdodutaNo ratings yet

- Kamarudin B.khalidDocument7 pagesKamarudin B.khalidHusni Rois AliNo ratings yet

- Automated Unified System For LPG UsingDocument84 pagesAutomated Unified System For LPG UsingVirat KaliNo ratings yet

- Chapter 3 Signal Conditioning CircuitDocument30 pagesChapter 3 Signal Conditioning CircuittcsNo ratings yet

- AN295036 Current Sensor ICs in Current Divider ConfigurationsDocument11 pagesAN295036 Current Sensor ICs in Current Divider ConfigurationsmicroperuNo ratings yet

- Capacitance Adapter For Multimeter: (Document Subtitle)Document11 pagesCapacitance Adapter For Multimeter: (Document Subtitle)Kashif Hassan100% (1)

- Voltage Drop After NEC RequirementsDocument3 pagesVoltage Drop After NEC Requirementsnadeem UddinNo ratings yet

- A Fully Isolated Delta-Sigma ADC For Shunt Based Current SensingDocument9 pagesA Fully Isolated Delta-Sigma ADC For Shunt Based Current Sensingpramani90No ratings yet

- OptoModules SolidStateRelaysDocument44 pagesOptoModules SolidStateRelaysalltheloveintheworldNo ratings yet

- Presentation - On-Chip Current Sensing Technique For Cmos Monolithic Switch-ModeDocument30 pagesPresentation - On-Chip Current Sensing Technique For Cmos Monolithic Switch-Modesohailasghar_tNo ratings yet

- Load Cell Cabling: GeneralDocument8 pagesLoad Cell Cabling: Generalalessandro80No ratings yet

- Current MeasurementDocument7 pagesCurrent Measurementmuhd_paehNo ratings yet

- IRXm Product GuideDocument8 pagesIRXm Product Guidedeepak2628No ratings yet

- Transistor and Voltage DividerDocument10 pagesTransistor and Voltage DividerAya SaleemNo ratings yet

- Universal - Current - Sensors - Report KARTHIKDocument23 pagesUniversal - Current - Sensors - Report KARTHIKKarthik SDNo ratings yet

- Linear IC ApplicationsDocument8 pagesLinear IC ApplicationsSwarna SugandhNo ratings yet

- Cable Fault DetectorDocument25 pagesCable Fault DetectorHarshalNo ratings yet

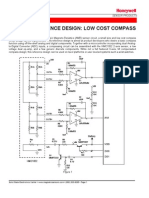

- Reference Design Low Cost CompassDocument4 pagesReference Design Low Cost CompassHany MaximousNo ratings yet

- Inductors: Application NotesDocument4 pagesInductors: Application Notesm.muthu lakshmiNo ratings yet

- New generation of ultra-compact universal current sensorsDocument4 pagesNew generation of ultra-compact universal current sensorsmsivakumarvarmaNo ratings yet

- Load Cell Cabling Setup and Trimming GuideDocument8 pagesLoad Cell Cabling Setup and Trimming GuideTong Van NgocNo ratings yet

- Universal Currnet SensorDocument15 pagesUniversal Currnet SensorJohnny Rider100% (1)

- Digital Multimeter - Basic GuideDocument4 pagesDigital Multimeter - Basic GuidetowfiqeeeNo ratings yet

- AN3396 MaximDocument11 pagesAN3396 MaximFlavioHernanNo ratings yet

- LIC Question BankDocument7 pagesLIC Question BankParvathy S ParvathyNo ratings yet

- Lic QB With AnswerDocument29 pagesLic QB With AnswerNoddy SenNo ratings yet

- Low Swing Signaling Using A Dynamic Diode-Connected DriverDocument4 pagesLow Swing Signaling Using A Dynamic Diode-Connected DriverAkash RaykarNo ratings yet

- Loadcell CablingDocument8 pagesLoadcell CablingDemian Matias BadinNo ratings yet

- Project For ElectronicDocument26 pagesProject For ElectronicGanesh GaradNo ratings yet

- Busbar Protection SystemsDocument12 pagesBusbar Protection SystemsAhmed Said GhonimyNo ratings yet

- Measure Resistance of Circuit Breakers with UltracapacitorsDocument5 pagesMeasure Resistance of Circuit Breakers with UltracapacitorsAislanGaldino100% (1)

- Me 4326 Analog and Digital Electronics: Assignment No 01Document24 pagesMe 4326 Analog and Digital Electronics: Assignment No 01Gayashan KulathungaNo ratings yet

- 5042 AppDocument18 pages5042 AppAgustio Sahela BukhariNo ratings yet

- Cropico Guide To Low Resistance MeasurementDocument37 pagesCropico Guide To Low Resistance MeasurementacebouzouadNo ratings yet

- ECE 252 Lecture 4Document36 pagesECE 252 Lecture 4Anderson LeblancNo ratings yet

- Second Stage Filter DesignDocument6 pagesSecond Stage Filter DesignNnamdiNo ratings yet

- Design Precise Ohmmeter Circuit Measure Resistances 0.01-10kΩ 0.1% AccuracyDocument5 pagesDesign Precise Ohmmeter Circuit Measure Resistances 0.01-10kΩ 0.1% AccuracyNabil IshamNo ratings yet

- Chapter 3Document10 pagesChapter 3Vikas UpadhyayNo ratings yet

- Using a Multimeter to Measure CircuitsDocument32 pagesUsing a Multimeter to Measure CircuitsDamodaran SrinivasanNo ratings yet

- E L RelayDocument31 pagesE L RelayBal SubramaniNo ratings yet

- Instrumentation AmplifierDocument3 pagesInstrumentation AmplifierFreddy LlusionNo ratings yet

- Components FullDocument15 pagesComponents FullFlux PrimeNo ratings yet

- Report On Power SupplyDocument14 pagesReport On Power SupplyBhavesh MaheshwariNo ratings yet

- 2 Marks Ldica NotesDocument8 pages2 Marks Ldica NotesRAJOLI GIRISAI MADHAV100% (2)

- Thermal Overload ProtectorDocument69 pagesThermal Overload ProtectorSai Printers100% (1)

- Current Sensor Ic 4017Document55 pagesCurrent Sensor Ic 4017Alan RejiNo ratings yet

- Ao Lab Report 5Document7 pagesAo Lab Report 5Umar Ali BaigNo ratings yet

- Review of a simple adjustable power supply using linear and switching componentsDocument4 pagesReview of a simple adjustable power supply using linear and switching componentsramesh ranjitNo ratings yet

- Basics of Electrical EngineeringDocument100 pagesBasics of Electrical Engineeringdeep voraNo ratings yet

- T Mlambo 202001587 Anologue Electronis LabDocument14 pagesT Mlambo 202001587 Anologue Electronis Labthabangmlambo796No ratings yet

- AN1646Document7 pagesAN1646Duc HuynhNo ratings yet

- Digitally Controlled Oscillator ReportDocument18 pagesDigitally Controlled Oscillator ReportVinidhra ShivakumarNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- 04da SDocument2 pages04da SasyfingNo ratings yet

- RS-485 wiring and register overviewDocument2 pagesRS-485 wiring and register overviewbebe_roalbaNo ratings yet

- DVP04AD-S: Instruction SheetDocument2 pagesDVP04AD-S: Instruction SheetCLAUDIO0% (1)

- Chapter 2 FBS-PLC Memory AllocationDocument18 pagesChapter 2 FBS-PLC Memory AllocationAmmar Al-KindyNo ratings yet

- Delta Ia-Plc DVP TP C en 20160922Document48 pagesDelta Ia-Plc DVP TP C en 20160922max_ingNo ratings yet

- Delta DOP Series Human Machine InterfaceDocument28 pagesDelta DOP Series Human Machine InterfaceminlwintheinNo ratings yet

- Delta Ia-Plc DVP TP C en 20160922Document48 pagesDelta Ia-Plc DVP TP C en 20160922max_ingNo ratings yet

- DELTA - IA PLC - DVP PLC S H2 H3 Series - MDM - EN - 20131112 PDFDocument344 pagesDELTA - IA PLC - DVP PLC S H2 H3 Series - MDM - EN - 20131112 PDFEnrique Francisco WekwertNo ratings yet

- Fatek Fb/Fbs/B1/B1Z Series: Hmi SettingDocument12 pagesFatek Fb/Fbs/B1/B1Z Series: Hmi SettingAmmar Al-KindyNo ratings yet

- Fatek Fb/Fbs/B1/B1Z Series: Hmi SettingDocument12 pagesFatek Fb/Fbs/B1/B1Z Series: Hmi SettingAmmar Al-KindyNo ratings yet

- B1/B1z/HB1 Model List: Module Name SpecificationDocument2 pagesB1/B1z/HB1 Model List: Module Name SpecificationAmmar Al-KindyNo ratings yet

- Manual Winproladder (PLC's FATEK)Document195 pagesManual Winproladder (PLC's FATEK)José Luis Aros RiveraNo ratings yet

- Economical and High-Quality PLC from a Reliable Brand Since 1992Document8 pagesEconomical and High-Quality PLC from a Reliable Brand Since 1992Fernando BalsecaNo ratings yet

- FBs Special Relay Register List ENDocument19 pagesFBs Special Relay Register List ENAmmar Al-KindyNo ratings yet

- Manual Winproladder (PLC's FATEK)Document195 pagesManual Winproladder (PLC's FATEK)José Luis Aros RiveraNo ratings yet

- An Offline Trained Artificial Neural Network To Predict A Photovoltaic Panel Maximum Power PointDocument3 pagesAn Offline Trained Artificial Neural Network To Predict A Photovoltaic Panel Maximum Power PointAmmar Al-KindyNo ratings yet

- Supervisory Control and Data Acquisition (SCADA) Section3-2019 PDFDocument13 pagesSupervisory Control and Data Acquisition (SCADA) Section3-2019 PDFAmmar Al-KindyNo ratings yet

- State-Variable AnalysisDocument22 pagesState-Variable AnalysisrameshNo ratings yet

- may911 مهم جدا مودلنك سكادا ستيت اوف جارجDocument8 pagesmay911 مهم جدا مودلنك سكادا ستيت اوف جارجAmmar Al-KindyNo ratings yet

- mayada5977 مهمDocument7 pagesmayada5977 مهمAmmar Al-KindyNo ratings yet

- Supervisory Control and Data Acquisition (SCADA) Section2-2019 PDFDocument24 pagesSupervisory Control and Data Acquisition (SCADA) Section2-2019 PDFAmmar Al-KindyNo ratings yet

- Hussain Kassim Ahmad (Thesis) .pdf اطروحه dfig PDFDocument157 pagesHussain Kassim Ahmad (Thesis) .pdf اطروحه dfig PDFAmmar Al-KindyNo ratings yet

- balijepalli2017.pdf سولر جديدDocument12 pagesbalijepalli2017.pdf سولر جديدAmmar Al-KindyNo ratings yet

- Tipos de BateríasDocument5 pagesTipos de BateríasIvann Linkink TorresNo ratings yet

- may992 حسابات مهمة PDFDocument6 pagesmay992 حسابات مهمة PDFAmmar Al-KindyNo ratings yet

- Introduction To Control Theory PDFDocument8 pagesIntroduction To Control Theory PDFAmmar Al-KindyNo ratings yet

- א א א א J J J J א א א א אא אא אא אא !"א#"א$%& !"א#"א$%& !"א#"א$%& !"א#"א$%& Ffff ٣٥١١ ٣٥١١ ٣٥١١ ٣٥١١ Eeee ,,,, Kkkk ./ 0123& ./ 0123& ./ 0123& ./ 0123&Document21 pagesא א א א J J J J א א א א אא אא אא אא !"א#"א$%& !"א#"א$%& !"א#"א$%& !"א#"א$%& Ffff ٣٥١١ ٣٥١١ ٣٥١١ ٣٥١١ Eeee ,,,, Kkkk ./ 0123& ./ 0123& ./ 0123& ./ 0123&Ammar Al-KindyNo ratings yet

- Honeywell Dcs ArchitectureDocument14 pagesHoneywell Dcs ArchitectureVanama MalaiNo ratings yet

- Introduction To Control Theory PDFDocument8 pagesIntroduction To Control Theory PDFAmmar Al-KindyNo ratings yet

- Supervisory Control and Data Acquisition (SCADA) Section2-2019 PDFDocument24 pagesSupervisory Control and Data Acquisition (SCADA) Section2-2019 PDFAmmar Al-KindyNo ratings yet

- Weighbridge Preventive Maintenance ChecklistDocument12 pagesWeighbridge Preventive Maintenance ChecklistKrishna Jasha80% (5)

- A Product Line of Diodes Incorporated: Document Number: DSXXXXX Rev. 1 - 0Document11 pagesA Product Line of Diodes Incorporated: Document Number: DSXXXXX Rev. 1 - 0rdbm rdbmNo ratings yet

- A4 ExDocument27 pagesA4 ExPham LongNo ratings yet

- SSP 232 5sp Auto 09a-09bDocument72 pagesSSP 232 5sp Auto 09a-09bภูเก็ต เป็นเกาะNo ratings yet

- Ertiga (58-59)Document2 pagesErtiga (58-59)Boccor AlussNo ratings yet

- NMW Smart Busbar 2.0 User ManualDocument121 pagesNMW Smart Busbar 2.0 User ManualTariku TesfayeNo ratings yet

- Crankshaft Hardening: A Guide To The Benefits of Induction HeatingDocument4 pagesCrankshaft Hardening: A Guide To The Benefits of Induction HeatingskluxNo ratings yet

- Ricoh AF 2035 2045 Service ManualDocument852 pagesRicoh AF 2035 2045 Service Manualacecopyinc100% (5)

- KC7IEU's Guide To The Yaseu VX5rDocument22 pagesKC7IEU's Guide To The Yaseu VX5razhighlanderNo ratings yet

- Eleganza 5 Service ManualDocument89 pagesEleganza 5 Service ManualdvedvNo ratings yet

- Goodwill Acceptable and Unaccepted Items!Document2 pagesGoodwill Acceptable and Unaccepted Items!David NguyenNo ratings yet

- SW2020 Users Manual V10Document81 pagesSW2020 Users Manual V10Antonio Antonio100% (2)

- Rav4 EbrochureDocument28 pagesRav4 EbrochureAmin AminNo ratings yet

- 8.4 Spherical Roller BearingsDocument68 pages8.4 Spherical Roller Bearingsrrobles011No ratings yet

- Baja Group Progress ReportDocument19 pagesBaja Group Progress ReportBrijesh YadavNo ratings yet

- G531GW r16 - CompressedDocument103 pagesG531GW r16 - Compressedakhmadmukhsin1986No ratings yet

- 2-Wire Detector Compatibility Chart: 579-832 Rev. GDocument20 pages2-Wire Detector Compatibility Chart: 579-832 Rev. Gjunrey dasigNo ratings yet

- Catálogo Sensor XS Telemecanique PDFDocument141 pagesCatálogo Sensor XS Telemecanique PDFJeferson Tadeu100% (1)

- Manual Elverk 004965 - 200702 - Se-No-Pl-EnDocument42 pagesManual Elverk 004965 - 200702 - Se-No-Pl-EnSkrapNo ratings yet

- 1508747-t6000 SeriesDocument4 pages1508747-t6000 SeriesRonNo ratings yet

- Switches PresentationDocument20 pagesSwitches PresentationAnushree Gupta100% (3)

- Electric Mooring Winches 320kN, 65kW Technical SpecificationDocument31 pagesElectric Mooring Winches 320kN, 65kW Technical SpecificationLovre PerkovićNo ratings yet

- Magnochem: Installation/Operating ManualDocument110 pagesMagnochem: Installation/Operating Manualjaelani sidikNo ratings yet

- Vp Electronics Winter Training - Inverters Basics, Types, Applications & PWM TechnologyDocument25 pagesVp Electronics Winter Training - Inverters Basics, Types, Applications & PWM TechnologyLenowahira DillemanowaryNo ratings yet

- Metal Series2Document23 pagesMetal Series2sagarNo ratings yet

- Sihg33N60E: Vishay SiliconixDocument8 pagesSihg33N60E: Vishay SiliconixRK ComputacionNo ratings yet

- TFE 731 Chap 74Document6 pagesTFE 731 Chap 74Egor85No ratings yet

- Service Manual: Freestanding Cooling Double Door ARC 3630Document5 pagesService Manual: Freestanding Cooling Double Door ARC 3630buzbonNo ratings yet

- WABCODocument2 pagesWABCOMihai PopaNo ratings yet

- MullerEnergy JBD BMS InstructionsDocument13 pagesMullerEnergy JBD BMS InstructionsgrillonNo ratings yet