Professional Documents

Culture Documents

Wir 000095

Uploaded by

Kish Shan S SubediOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wir 000095

Uploaded by

Kish Shan S SubediCopyright:

Available Formats

STATE OF CALIFORNIA--BUSINESS,TRANSPORTACTION AND HOUSING AGENCY Arnold Schwarzenegger, Governor

DEPARTMENT OF TRANSPORTATION

DIVISION OF ENGINEERING SERVICES

Office of Structural Materials

Quality Assurance and Source Inspection

Contract #: 04-0120F4

Bay Area Branch

690 Walnut Ave.St. 150 Cty: SF/ALA Rte: 80 PM: 13.2/13.9

Vallejo, CA 94592-1133

File #: 69.28

(707) 649-5453

(707) 649-5493

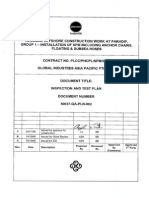

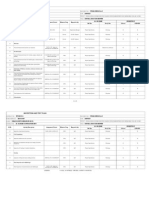

WELDING INSPECTION REPORT

Resident Engineer:Pursell, Gary Report No: WIR-000095

Address: 333 Burma Road Date Inspected: 15-Mar-2007

City: Oakland, CA 94607

Project Name: SAS Superstructure OSM Arrival Time: 800

Prime Contractor: American Bridge/Fluor Enterprises, a JV OSM Departure Time: 1730

Contractor: Zhenhua Port Machinery Company, Ltd (ZPMC), Changxing Island Location: Shanghai, China

CWI Name: Liu Liu CWI Present: Yes No

Inspected CWI report: Yes No N/A Rod Oven in Use: Yes No N/A

Electrode to specification: Yes No N/A Weld Procedures Followed: Yes No N/A

Qualified Welders: Yes No N/A Verified Joint Fit-up: Yes No N/A

Approved Drawings: Yes No N/A Approved WPS: Yes No N/A

Delayed / Cancelled: Yes No N/A

Bridge No: 34-0006 Component: Bid: 52, 55 Tower & Girder

Summary of Items Observed:

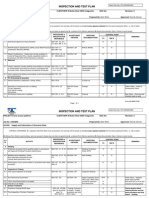

Item Description WBS Dwg No. Status

1

Caltrans Quality Assurance (QA) Inspector was present to witness procedure qualification (PQR) retesting for

HP200713-1 as requested by ZPMC. The test plate was welded in the 2F (horizontal) position, using the flux core arc

welding (FCAW) semi-automatic welding process. The test consisted of a minimum multi pass weld. The welding

consumable (electrode) is identified as specification E71T1-1, classification AWS A5.20 and 1.4 mm diameter. The

welding was performed in accordance with AWS D1.5, Section 5.10.3 fillet weld soundness requirements. The

welding appeared to comply with the contract documents. See Caltrans Welding Witness Report (TL-6032), dated

March 15, 2007 for additional information. Caltrans QA Inspector assigned lot number B49-007-07 for minimum

multi pass weld.

TL-6031,Welding Inspection Report Page 1 of 3

WELDING INSPECTION REPORT

( Continued Page 2 of 3 )

2

Caltrans QA inspector observed machining of the mechanical test specimens for welding procedure HP200710 at

Shan Xun Gong Mao Machine Company and was accompanied by ZPMC QA Inspector, Mr. Liu Jian Hua. Caltrans

QA inspector observed that the mechanical test sampling was being performed to AWS D1.5, Figure 5.1. The welding

procedure was performed to AWS D1.5, paragraph 5.13. This calls out the machining of the mechanical test samples

to Figure 5.3. Caltrans Quality Assurance Inspector (QA) spoke with ABF welding engineer Craig Knops regarding

the machining of PQR HP-200710. Caltrans QA inspector had observed that they appeared to be machining the plate

as though it was performed to AWS D1.5, Figure 5.1 which includes All Weld Metal Tension (AWMT) and

Charpy-V notch samples. The welding was actually performed to AWS D1.5, Figure 5.3 for weld soundness and does

not require either the AWMT or Charpy samples. Mr. Knops spoke with ZPMC Testing Center Director Mr. Liu Liu

about this and was informed that this was due to miscommunication with the Machine Shop, and that ZPMC did not

intend to test either the AWMT or Charpy samples.

3

Caltrans QA inspector observed welder and welder operator qualification testing being performed at ZPMC testing

center. American Bridge/Fluor (ABF) representative, Mr. David Williams submitted a welder qualification list stating

the names of the welders and welding processes. The list called out seven (7) submerged arc welding (SAW) welder

operators, thirty (30) shield metal arc welding (SMAW) welders and thirteen (13) flux core arc welding (FCAW)

welders for testing. Caltrans QA inspector observed Moody International Inspection conduction welder qualification

tests. Caltrans QA inspector observed SAW welder operators performing 1G test in the flat position, SMAW welders

performing 3G welder qualification test in the vertical position and FCAW welders performing 3G welder

qualification testing in the vertical position. The testing appeared to be performed in conformance AWS D1.5

TL-6031,Welding Inspection Report Page 2 of 3

WELDING INSPECTION REPORT

( Continued Page 3 of 3 )

requirements.

Summary of Conversations:

As identified within the contents of this report.

Comments

This report is for the purpose of determining conformance with the contract documents and is not for the purpose

of making repair or fit for purpose recommendations. Should you require recommendations concerning repairs or

remedial efforts please contact Mazen Wahbeh, (818) 292-0659, who represents the Office of Structural Materials

for your project.

Inspected By: Hasler,Mike Quality Assurance Inspector

Reviewed By: McClary,David QA Reviewer

TL-6031,Welding Inspection Report Page 3 of 3

You might also like

- Caltrans Welding Inspection Report for SAS SuperstructureDocument3 pagesCaltrans Welding Inspection Report for SAS SuperstructureSinaga93No ratings yet

- CA Bridge Welding Inspection ReportDocument2 pagesCA Bridge Welding Inspection ReportbacabacabacaNo ratings yet

- Pr-w-1102.21-4012-004 Rev A Welder Qualification Testing For Steel Structure (WQT) - SWDocument18 pagesPr-w-1102.21-4012-004 Rev A Welder Qualification Testing For Steel Structure (WQT) - SWMehmet Soysal100% (1)

- Non-Conformity Report ExampleDocument16 pagesNon-Conformity Report ExamplekumarNo ratings yet

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- Weld Repair Procedure SummaryDocument10 pagesWeld Repair Procedure SummaryRAMAKRISHNANo ratings yet

- Oakland Bay Bridge Pile Connection Plate Welding Investigation Report PDFDocument62 pagesOakland Bay Bridge Pile Connection Plate Welding Investigation Report PDFIndra MishraNo ratings yet

- 1TB03300 300C04 STC Wir Me 0001Document11 pages1TB03300 300C04 STC Wir Me 0001heerkhanheerkhan435No ratings yet

- ITP - Steel ErectionDocument10 pagesITP - Steel ErectionGhayas RanjhaNo ratings yet

- SFLC STD Spec 0740 - Welding and Allied ProcessesDocument37 pagesSFLC STD Spec 0740 - Welding and Allied ProcessesRobert Delafosse100% (1)

- Itp For Fabn. & Erection of Structural WorksDocument4 pagesItp For Fabn. & Erection of Structural Workscrm 2No ratings yet

- NiWest KNS ITP - AS 1554 1 Crane Access PlatformDocument3 pagesNiWest KNS ITP - AS 1554 1 Crane Access PlatformGilbert PereiraNo ratings yet

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Document10 pagesQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- 05-1R1404_DR_CDS_07-24-23_JobsiteDocument6 pages05-1R1404_DR_CDS_07-24-23_Jobsiteshernell concessioNo ratings yet

- Record of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Document1 pageRecord of Welder or Welding Operator Qualification Test: Welders's Name: Stamp No.: WQT No.Weld Bro SandeepNo ratings yet

- Qualification of Welding Procedures and WeldersDocument10 pagesQualification of Welding Procedures and WelderstxjiangNo ratings yet

- 05-1R1404-DR-NEL-08-02-23-JobsiteDocument5 pages05-1R1404-DR-NEL-08-02-23-Jobsiteshernell concessioNo ratings yet

- WPS 001Document7 pagesWPS 001babjihanumanthuNo ratings yet

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- Fabrication of Steel Structure and Steel Equipment (Itp)Document4 pagesFabrication of Steel Structure and Steel Equipment (Itp)Javed MANo ratings yet

- Welding InspectionDocument9 pagesWelding InspectionJackNo ratings yet

- 11-QC40-F-667_A Commissioning Test Procedure for 380kv GISDocument155 pages11-QC40-F-667_A Commissioning Test Procedure for 380kv GISIbrahim AliNo ratings yet

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- A-Qac-Pro-730-38928 Rev ADocument10 pagesA-Qac-Pro-730-38928 Rev ARamzi ZoghlamiNo ratings yet

- W47.1 CWBDocument2 pagesW47.1 CWBSangam JonNo ratings yet

- Ur W28rev2Document25 pagesUr W28rev2Karla JTNo ratings yet

- 5welding BasicsDocument70 pages5welding BasicssreeNo ratings yet

- Quality Control Plan: QCF NRDocument6 pagesQuality Control Plan: QCF NRAlirza AliyevNo ratings yet

- Installation of GRP Ladder InspectedDocument2 pagesInstallation of GRP Ladder InspectedmorshedNo ratings yet

- Quality Control Plan: QCF NRDocument6 pagesQuality Control Plan: QCF NRAlirza Aliyev0% (1)

- Overhead Crane ProcedureDocument10 pagesOverhead Crane ProcedureHarris ShehzadNo ratings yet

- Warranty Inspection Procedures SheetDocument2 pagesWarranty Inspection Procedures SheetKhaja SayeedNo ratings yet

- (B) Welding Replacement1Document6 pages(B) Welding Replacement1amirkhakzad498No ratings yet

- 50037-QA-PLN-002 Rev.0Document13 pages50037-QA-PLN-002 Rev.0seehari100% (3)

- VT DOT Field Welding ManualDocument14 pagesVT DOT Field Welding Manualjaheer1No ratings yet

- SE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core CableDocument11 pagesSE-HIO-4AEL-MST-0014 Testing and Commissioning of Wires and Single Core Cablevishwas salunkheNo ratings yet

- CHECKLIST - FORK LIFT UpdatedDocument4 pagesCHECKLIST - FORK LIFT UpdatedAkhilNo ratings yet

- Welder Qualification (ALL CODES)Document3 pagesWelder Qualification (ALL CODES)narutothunderjet216No ratings yet

- Data Sheet of Local Control StationsDocument4 pagesData Sheet of Local Control StationsDharmenderSinghChoudharyNo ratings yet

- Welder's Performancequalification (WPQ) FormDocument1 pageWelder's Performancequalification (WPQ) FormAbhinandan BastiNo ratings yet

- PP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0Document14 pagesPP-005 METHOD STATEMENT FOR AG PIPE INSTALLATION - NIGHT SHIFT - Rev 0ibrahimNo ratings yet

- Saep 744Document7 pagesSaep 744Anonymous 4IpmN7OnNo ratings yet

- 05-Welder Certification PDFDocument11 pages05-Welder Certification PDFAnonymous bfxeE1zvY100% (1)

- WPS-PQR For Split TeeDocument9 pagesWPS-PQR For Split TeemaheshmalaichamyNo ratings yet

- Asme-Ix PDFDocument9 pagesAsme-Ix PDFMuhammad ThohirNo ratings yet

- Checklist de Control de Calidad de SoldaduraDocument21 pagesChecklist de Control de Calidad de SoldaduraAnatolie6No ratings yet

- ITP 007 - Inspection & Test Plan for FTB Encased HDPE Duct BankDocument2 pagesITP 007 - Inspection & Test Plan for FTB Encased HDPE Duct Bankbcdavid100% (3)

- Pages From PU BRI 23 018 Auto Transformer IR001 (093) DraftDocument2 pagesPages From PU BRI 23 018 Auto Transformer IR001 (093) DraftumairNo ratings yet

- STD Spec For Piping WeldingDocument14 pagesSTD Spec For Piping WeldingknsaravanaNo ratings yet

- Saep 321Document28 pagesSaep 321brecht1980No ratings yet

- Updated WMS - Welding of Duplex Stainless SteelDocument5 pagesUpdated WMS - Welding of Duplex Stainless Steelcameron toolseeNo ratings yet

- Asme Sec - IxDocument132 pagesAsme Sec - IxBoran YelkenciogluNo ratings yet

- ITP For LpseperatorDocument2 pagesITP For LpseperatorRichard PeriyanayagamNo ratings yet

- Rasheed K H - CVDocument5 pagesRasheed K H - CVKshama RaiNo ratings yet

- Wilhelm WPS - WH-WPS-012 - WH-WPS-055Document70 pagesWilhelm WPS - WH-WPS-012 - WH-WPS-055Elgen Igloria100% (3)

- Ci Nice Mri 001Document1 pageCi Nice Mri 001Alvene TagocNo ratings yet

- LADBS Research Report: Bar-lock Coupler SystemsDocument3 pagesLADBS Research Report: Bar-lock Coupler SystemsAntonio CastilloNo ratings yet

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- Subsea Pipeline Design, Analysis, and InstallationFrom EverandSubsea Pipeline Design, Analysis, and InstallationRating: 3 out of 5 stars3/5 (1)

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- Ahpl PG LK2 Img 100 PDFDocument1 pageAhpl PG LK2 Img 100 PDFKish Shan S SubediNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- Steel GradesDocument8 pagesSteel GradesSanket Arun MoreNo ratings yet

- PDF To WordDocument6 pagesPDF To WordKish Shan S SubediNo ratings yet

- Pipe ChecklistDocument1 pagePipe ChecklistKish Shan S SubediNo ratings yet

- Test Report (Primer Coating)Document1 pageTest Report (Primer Coating)Kish Shan S SubediNo ratings yet

- Section I General Technical Specifications 30 July 2019Document37 pagesSection I General Technical Specifications 30 July 2019Kish Shan S SubediNo ratings yet

- Section II Special Technical Specifications 30 July 2019Document41 pagesSection II Special Technical Specifications 30 July 2019Kish Shan S SubediNo ratings yet

- Trash Cleaning MachineDocument1 pageTrash Cleaning MachineKish Shan S SubediNo ratings yet

- Hoist CapacityDocument2 pagesHoist CapacityKish Shan S SubediNo ratings yet

- PDF To WordDocument6 pagesPDF To WordKish Shan S SubediNo ratings yet

- Hoist CapacityDocument2 pagesHoist CapacityKish Shan S SubediNo ratings yet

- HRP1, HRP2, HPPP 50Document10 pagesHRP1, HRP2, HPPP 50Kish Shan S SubediNo ratings yet

- 4-2-20 Questionnaire Mov TRCDocument2 pages4-2-20 Questionnaire Mov TRCKish Shan S SubediNo ratings yet

- 4-2-20 Questionnaire Mov TRCDocument2 pages4-2-20 Questionnaire Mov TRCKish Shan S SubediNo ratings yet

- Annex 1:: Consultant's Relevant Services Completion CertificatesDocument5 pagesAnnex 1:: Consultant's Relevant Services Completion CertificatesKish Shan S SubediNo ratings yet

- Ahpl PG LK2 Img 100 PDFDocument1 pageAhpl PG LK2 Img 100 PDFKish Shan S SubediNo ratings yet

- ACFrOgD9tF29iKKA0vhCiDUn3GoDbkKmKHzbk - zAXCrAf2KdpxXZI AC 2B38tGKnpoB47At9ivanFvUk7m4QJow LM XA27OK8jxpSxrACtzzlzc2xmhH3mWGp608Document5 pagesACFrOgD9tF29iKKA0vhCiDUn3GoDbkKmKHzbk - zAXCrAf2KdpxXZI AC 2B38tGKnpoB47At9ivanFvUk7m4QJow LM XA27OK8jxpSxrACtzzlzc2xmhH3mWGp608Kish Shan S SubediNo ratings yet

- Letter To Ithari MunicipalityDocument6 pagesLetter To Ithari MunicipalityKish Shan S SubediNo ratings yet

- Ghalemdi Khola Hydropower Project: Site Visit Report FOR LOT-2Hydraulic Steel StructureDocument6 pagesGhalemdi Khola Hydropower Project: Site Visit Report FOR LOT-2Hydraulic Steel StructureKish Shan S SubediNo ratings yet

- Type Major Diameter Pitch Depth of Thread Bolt Nut Bolt Nut 46mm 46mm: 46.5mm 38mm 8mm 4mm:4.25mm Nominal Diameter Minor Diameter Normal SeriesDocument1 pageType Major Diameter Pitch Depth of Thread Bolt Nut Bolt Nut 46mm 46mm: 46.5mm 38mm 8mm 4mm:4.25mm Nominal Diameter Minor Diameter Normal SeriesKish Shan S SubediNo ratings yet

- Self Decleration SmartDocument1 pageSelf Decleration SmartKish Shan S SubediNo ratings yet

- Subject: Request For ChequeDocument1 pageSubject: Request For ChequeKish Shan S SubediNo ratings yet

- Ritha Khola Micro Hydro Project Located in BaglungDocument48 pagesRitha Khola Micro Hydro Project Located in BaglungKish Shan S SubediNo ratings yet

- Letter To Ithari MunicipalityDocument1 pageLetter To Ithari MunicipalityKish Shan S SubediNo ratings yet

- Standared WeightDocument16 pagesStandared WeightKish Shan S SubediNo ratings yet

- Letter To AEPCDocument1 pageLetter To AEPCKish Shan S SubediNo ratings yet

- Tax ClearanceDocument3 pagesTax ClearanceKish Shan S SubediNo ratings yet

- Letter To Ithari MunicipalityDocument1 pageLetter To Ithari MunicipalityKish Shan S SubediNo ratings yet

- 5.1 Operating Conditions - Turning, Milling & DrillingDocument31 pages5.1 Operating Conditions - Turning, Milling & DrillingjpmanikandanNo ratings yet

- Partitura El Vuelo Del Abejorro para Saxo AltoDocument4 pagesPartitura El Vuelo Del Abejorro para Saxo AltoEd ElvesaxNo ratings yet

- Chapter 04 - MOSFET CharacteristicsDocument4 pagesChapter 04 - MOSFET CharacteristicsRasim KozarevićNo ratings yet

- Optimized Die Steel Reference GuideDocument16 pagesOptimized Die Steel Reference GuideKeattikhun ChaichanaNo ratings yet

- Eeprom: Stmicro M24C02 (HTTP://WWW - St.Co M/Resource/En/Datasheet/M24C02-F. PDF) I C Serial Type EepromDocument9 pagesEeprom: Stmicro M24C02 (HTTP://WWW - St.Co M/Resource/En/Datasheet/M24C02-F. PDF) I C Serial Type EepromAndrés Alejandro PereiraNo ratings yet

- Protective Coating For Steel StructuresDocument21 pagesProtective Coating For Steel StructurescrazyrimzyNo ratings yet

- Stick Diagram BasicsDocument26 pagesStick Diagram Basicssanju012100% (1)

- 12 Material Heat and Power Balances For Pulp MillsDocument7 pages12 Material Heat and Power Balances For Pulp Millsjhony1523No ratings yet

- Monsters Inc. Saxophone Quartet PDFDocument5 pagesMonsters Inc. Saxophone Quartet PDFBocabNo ratings yet

- Host Driver Logs CurrentDocument2,212 pagesHost Driver Logs Currentfavian starsNo ratings yet

- Erw Welding PDFDocument2 pagesErw Welding PDFChristineNo ratings yet

- A 484 - A 484m - 03Document16 pagesA 484 - A 484m - 03etwcNo ratings yet

- Sheet Metal Forming - PpsDocument26 pagesSheet Metal Forming - PpsNhan LeNo ratings yet

- Banknote Production Process: From Raw Materials to Printed CurrencyDocument14 pagesBanknote Production Process: From Raw Materials to Printed CurrencyMark Anthony Lluvido PlatinoNo ratings yet

- Thesis PHD Cagdas SSDDocument196 pagesThesis PHD Cagdas SSDUsha ChevulaNo ratings yet

- Techs Up Insert Wear Hand OutDocument2 pagesTechs Up Insert Wear Hand OutShahed FacebookNo ratings yet

- Sheet Metal Guide MateDocument72 pagesSheet Metal Guide MateRAI MUNDONo ratings yet

- Machining of MetalsDocument23 pagesMachining of MetalsFiq IskandarNo ratings yet

- Expanded MetalDocument2 pagesExpanded Metalebastien2No ratings yet

- Gasifier Modification Methods for Tar ReductionDocument16 pagesGasifier Modification Methods for Tar ReductionisttNo ratings yet

- Module 1: Mos Transistor Theory: Dr. G. Lakshmi Priya, AP (SG), SENSE, VIT, ChennaiDocument14 pagesModule 1: Mos Transistor Theory: Dr. G. Lakshmi Priya, AP (SG), SENSE, VIT, ChennaiASHUTOSHNo ratings yet

- 5Document70 pages5rikeshbeharryNo ratings yet

- Monthly Sales Data of Air Compressors at Kirkland IndustriesDocument12 pagesMonthly Sales Data of Air Compressors at Kirkland Industriesian mercadoNo ratings yet

- Model Exam NTM QPDocument2 pagesModel Exam NTM QPRuby SmithNo ratings yet

- Agglomeration of Iron OresDocument41 pagesAgglomeration of Iron OresAnonymous NxpnI6jC100% (1)

- Requisition Form Requisition FormDocument13 pagesRequisition Form Requisition FormMike AdvinculaNo ratings yet

- Milling MachineDocument32 pagesMilling MachineIrfan Shaikh100% (2)

- Machining: Machining Is Any of Various Processes in Which A Piece of RawDocument7 pagesMachining: Machining Is Any of Various Processes in Which A Piece of RawAshwin KumarNo ratings yet

- Advanced Manufacturing Process: Course Code:13ME1149 L TPC 4 0 0 3Document3 pagesAdvanced Manufacturing Process: Course Code:13ME1149 L TPC 4 0 0 3anuragNo ratings yet

- Blue BossaDocument5 pagesBlue BossaDream TeamNo ratings yet