Professional Documents

Culture Documents

Il04209007e HVR

Uploaded by

HilderrpOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Il04209007e HVR

Uploaded by

HilderrpCopyright:

Available Formats

Effective May 2011

Installation Leaflet IL04209007E-HVR Supersedes March 2011

C441 Motor Insight Overload Relay (120V

Control Powered) Product Installation Leaet

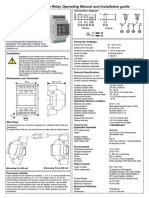

DANGER 3.31 (84.1)

HAZARDOUS VOLTAGE CAN CAUSE ELECTRIC SHOCK AND 0.20

BURNS. TO AVOID SHOCK HAZARD, DISCONNECT ALL POWER (5.1)

BEFORE ANY WORK IS PERFORMED ON THIS DEVICE. FAILURE 4 Places

TO DO SO WILL RESULT IN PERSONAL INJURY, DEATH OR

SUBSTANTIAL PROPERTY DAMAGE

3.90 3.50

(99.1) (88.9)

AVERTISSEMENT

UNE TENSION LECTRIQUE DANGEREUSE PEUT CAUSER DES

CHOCS LECTRIQUES ET DES BRLURES. POUR VITER DES

CHOCS LECTRIQUES, DBRANCHER LALIMENTATION AVANT

DY EFFECTUER DU TRAVAIL. LINOBSERVATION DE CES

INSTRUCTIONS ENTRANERA DES BLESSURES CORPORELLES 3.90 (99.1)

GRAVES, LA MORT OU DES DGTS MATRIELS SUBSTANTI-

ELS. Figure 1. Mount with 10-32 Hardware Torque to 25

in-lb.

Voltage Ratings

Motor Insight overload relay is powered by 120V control 1 / L1 3 / L2 5 / L3

ATTENTION

power between X1 - X2. This voltage range for the vari-

CONTROL CIRCUITS ARE B300 RATED USE A

ous models is given in the following table. A1 A2

CPT AND SEPRATATE CONTROL WHEN LINE

VOLTAGE IS ABOVE 240VAC.

2/13 CPT

M

Table 1. Voltage Range 3/14 120V

2/T1 4/T2 6/T3

Nominal Rating Catalog Voltage

Number

CONTROL POWER C441P3309NOUI-HVR 110 - 120 Vac;

INPUT C441059ONOUI-HVR (50/60 Hz)

L X1 N X2 95 96 97 98 X1 X2 R1 R2 REMOTE PILOT DEVICES

110 - 120V +10% - 15%

2 WIRE CONTROL

Line Voltage C441P3309NOUI-HVR 0 - 1200Vac NOT FOR USE

1 WHEN MORE THAN ONE

PUSH BUTTON STATION IS

C441059ONOUI-HVR WITH AUTO RESET

OL RELAYS.

USED OMIT CONNECTOR

A AND CONNECT PER

T1 T2 T3 3 WIRE CONTROL SKETCH BELOW.

START START A START

3 3

Wiring 3 PHASE

STOP

2

1

STOP STOP

2

1

AC MOTOR

Pass motor leads through Motor Insight overload relay

NOTE:

CT pass through. If multiple passes of the motor leads X1, X2 - 120V Control Power Input.

R1, R2 - 120V RESET INPUT

are required, make sure that the current flow is from

top to bottom through Motor Insight overload relay. If

external CTs are used, pass the 5 amp secondary of the

external CTs through Motor Insight overload relay inter- Figure 2. Typical Starter Application Sample Wiring

nal CTs. See Table 3A for wrap and CT multiplier. Diagram

Motor Insight overload relay is factory set for manual

reset operation. See Table 5 for automatic reset opera-

tion.

WARNING AVERTISSEMENT

AUTOMATIC RESET IS NOT INTENDED FOR TWO-WIRE CON-

TROL DEVICES.

CE DISPOSITIF DE REENCLENCHEMENT AUTOMATIQUE NE

CONVIENT PAS AUX COMMANDES DEUX

CONDUCTEURS.

Installation Leaflet IL04209007E-HVR C441 Motor Insight Overload Relay (120V

Effective May 2011 Control Powered) Product Installation Leaflet

Terminal Connections Programming Set Points

Motor Insight overload relay provides the following terminal connec- Motor Insight overload relay is easy to configure. Viewing and

tions. NC 95/96 contact is open when the device is unenergized. editing protection set points can be performed in the Protection

and Operation Mode. The following steps outline the procedure

USE 75C CU WIRE ONLY 18-12 AWG Torque 0.6 Nm/5.3 lb-in. for modifying any of the set points.

B300 PILOT DUTY ONLY

* No Motor Loads, 9A Max

120VAC 120VAC

120VAC Step 1: Press Mode button until Protection or Operation

120VAC Control Power 50/60 Hz NC NO CTRL PWR RESET Mode Led is lit.

L X1 N X2 95 96 97 98 X1 X2 R1 R2 Mode

Step 2: Press Up or Down button until the desired O/P LED

is lit. Display shows the current parameter value.

110

Step 3: Press the Edit/Save button. The display now shows

Figure 3. Terminal Connection Diagram the parameter value but is now flashing.

Edit/Save 110

Table 2. Terminal Connection Specifications Step 4: Use the Up/Down button to adjust the parameter

to the desired value.

Name Designation Input Description 120

L1, L2 93.5 - 132Vac Voltage input Step 5: Press the Edit/Save button. The Display now shows

- X1*, X2*, = 120V the new parameter value that has been saved by the device.

Control Power L, N - Tie X1 to X1 Edit/Save 120

- Tie X2 to X2

- Inputs should have short circuit Configuring the Thermal Overload Protection Feature

protection

- Terminal provided for wiring Motor Insight overload relay features electronic motor overload pro-

control power transformer tection. This feature protects the motor and power wiring against

(9A maximum capacity). overheating caused by excessive current for extended periods

of time.

Fault Relay 95/96 UL 508 - 95/96 Contact opens when the unit

B300 is faulted or unpowered. The trip current is programmed by entering the motor full load

amperes (FLA) using the Motor FLA parameter. The trip class

Programable 97/98 UL 508 -97/98 Contact closes when the unit (5 to 30) is set using the Trip Class parameter.

Auxiliary Relay* B300 is faulted or unpowered.

The FLA range of the overload relay can be modified with the use

Reset R1 120 Vac Fault Reset Input. of multiple turns through the CTs or with the use of external CTs.

Input R2 +10%/-15% Use the following tables to appropriately configure the device for the

application. If the application requires the FLA range to be extended,

* See section 6.7 of Users Manual MN04209001E for instructions to config- program the CT multiplier first.

ure the programmable auxiliary relay, which changes the behavior of the relay

from the default and allows for greater flexibility and alarming.

Table 3A. FLA Range

Number of

CAUTION! Current Catalog Motor Conductors CT

THE OPENING OF BRANCH-CIRCUIT PROTECTIVE DEVICE MAY BE AN INDI- Range Number FLA Through CT Multiplier

CATION THAT A FAULT HAS BEEN INTERRUPTED. TO REDUCE THE RISK OF .33 9 C441P3309NOUI-HVR .33 - 1.5 6 6

FIRE OR ELECTRIC SHOCK, CURRENT-CARRYING PARTS AND OTHER COM- .4 - 1.8 5 5

PONENTS OF THE CONTROLLER SHOULD BE EXAMINED AND REPLACED .5 - 2.25 4 4

IF DAMAGED. IF BURNOUT OF THE ELEMENT OF AN OVERLOAD RELAY .67 - 3.0 3 3

OCCURS, THE COMPLETE OVERLOAD RELAY SHOULD BE REPLACED. 15 2 2

29 1 1

60 135 1 150 - (150:5)

120 270 1 300 - (300:5)

ATTENTION 240 540 1 600 - (600:5)

LE DCLENCHEMENT DU DISPOSITIF DE PROTECTION DES DRIVATIONS 5 90 C441059ONOUI-HVRI 5 22.5 4 4

PEUT SIGNIFIER QUUN COURANT DE DFAUT A T INTERROMPU. POUR 6.67 30 3 3

RDUIRE LE RISQUE DINCENDIE OU DE CHOC LECTRIQUE, LES PICES 10 45 2 2

PORTEUSES DE COURANT ET LES AUTRES COMPOSANTS DE LA COM- 20 90 1 1

MANDE DOIVENT TRE VRIFIS ET REMPLACS SILS SONT ENDOM-

MAGS. SI LLMENT PORTEUR DE COURANT DU RELAIS DE SURCHARGE Important Note: After an overload trip, Motor Insight relay cannot be reset

GRILLE, LE RELAIS DE SURCHARGE ENTIER DOIT TRE REMPLAC. until the thermal model decays to a thermal capacity that is thermally safe for

a motor restart. Cycling the power does not reset the thermal model.

Initial Configuration Table 3B. Service Factor FLA Setting

On initial power-up, Motor Insight overload relay displays a rOF

message. This indicates that the fault relay is OFF. Configure the Service Factor Motor FLA Setting

device for the application prior to resetting the device. >1.15 Enter the motor nameplate FLA

To turn the fault relay OFF, press the Trip button. =1.10 Enter the FLA as (1.1* nameplate FLA/1.15)

2 EATON CORPORATION www.eaton.com

Installation Leaflet IL04209007E-HVR C441 Motor Insight Overload Relay (120V

Effective May 2011 Control Powered) Product Installation Leaflet

Fault Codes

After a trip, Motor Insight overload relay will indicate the Trip reason with a Fault Code on the display and by illuminating the appropriate

Protection/Operation (P/O) LEDs.

Table 6. Fault Codes

Fault Code User Interface Notes

Mode LED P/O LED Display

Number of Restarts Exceeded 1 Operation Fault Reset Tries & Load rEt Could result from excessive motor or load faults.

Reset Tries

Remote Off 2 None None rOF Relay turned off (network or UI).

Contactor Failure 3 Protection Current Unbalance % F.03 Voltage and current phase loss.

Low Power (kW) 15 Protection Low Power (kW) F.04 Only for applications between 120V - 660V are these settings appli-

cable. Reference USER Manual MN04209001E for configuration.

Motor Overload 5 Operation Trip Class F.05

Ground Fault 6 Protection Ground Fault (A) F.06

Current Unbalance 7 Protection Current Unbalance % F.07

Current Phase Loss 8 Protection Current Unbalance % F.08 Current phase loss without voltage phase loss.

Reserved 9

High Power (kW) 10 Protection High Power (kW) F.10 Only for applications between 120V - 660V are these settings appli-

cable. Reference USER Manual MN04209001E for configuration.

Overvoltage 11 Protection Overvoltage (V) F.11 Only for applications between 120V - 660V are these settings appli-

cable. Reference USER Manual MN04209001E for configuration.

Undervoltage 12 Protection Undervoltage (V) F.12 Only for applications between 120V - 660V are these settings appli-

cable. Reference USER Manual MN04209001E for configuration.

Voltage Unbalance 13 Protection Voltage Unbalance % F.13 Only for applications between 120V - 660V are these settings appli-

cable. Reference USER Manual MN04209001E for configuration.

Jam 14 Protection Jam Trip % F.14

Under Current 4 Protection Under Current % F.15

Phase Rotation 16 Protection Phase Rotation F.16

Other Consult User Manual.

Display Messages

The following display messages may appear on Motor Insight overload relay user interface to indicate status.

Table 7. Display Messages

Message Description

rOF The relay has been turned off.

rSt The Restart Delay is timing down. Caution an auto-reset attempt is pending.

rEt The number of auto-resets attempts has been exceeded. A manual reset is required.

ub Only for applications between 120V - 660V are these settings applicable. Reference USER Manual MN04209001E for configuration.

HI Only for applications between 120V - 660V are these settings applicable. Reference USER Manual MN04209001E for configuration.

LO Only for applications between 120V - 660V are these settings applicable. Reference USER Manual MN04209001E for configuration.

1PH Only for applications between 120V - 660V are these settings applicable. Reference USER Manual MN04209001E for configuration.

gnd A ground fault condition has been detected. This message will flash with the displayed parameter in the alarm-no-trip mode.

OFF The protection parameter is disabled.

999 The display parameter exceeds the display range.

Eaton Corporation

Electrical Sector

1000 Cherrington Parkway

Moon Township, PA 15108

United States

877-ETN-CARE (877-386-2273)

Eaton.com

PowerChain Management is a registered

2009 Eaton Corporation trademark of Eaton Corporation.

All Rights Reserved

Publication No. IL04209007E-HVR Rev003 All other trademarks are property of their

May 2011 respective owners.

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Automatic Power Factor Controller Relay: Operating InstructionsDocument7 pagesAutomatic Power Factor Controller Relay: Operating InstructionsKatty MenaNo ratings yet

- Operating Instruction 7ug0 Apfc LedDocument5 pagesOperating Instruction 7ug0 Apfc LedRajajiNo ratings yet

- Current Protection Relay Manual and Installation GuideDocument2 pagesCurrent Protection Relay Manual and Installation GuideRakay RashidNo ratings yet

- T2300Document2 pagesT2300kylegazeNo ratings yet

- ABB EF-146 Electronic Relay Data SheetDocument8 pagesABB EF-146 Electronic Relay Data Sheetvishnu ramkaranNo ratings yet

- T2200 Data Sheet UK PDFDocument2 pagesT2200 Data Sheet UK PDFmarioNo ratings yet

- Crown RP4500 PDFDocument26 pagesCrown RP4500 PDFmarceloo1993No ratings yet

- LG 29fs2amb - MC 05haDocument40 pagesLG 29fs2amb - MC 05hazakeer1966No ratings yet

- T2500Document2 pagesT2500kylegazeNo ratings yet

- ADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualDocument6 pagesADVR-16: Universal Hybrid Analog-Digital Voltage Regulator Operation ManualMahendraLiyanage0% (1)

- Ficha Tecnica Generador Tensite Ts4000iyDocument2 pagesFicha Tecnica Generador Tensite Ts4000iyRaúl Cañete AmorósNo ratings yet

- LG Rz-21fb35mx Rz-21fg35rx Chasis Mc-049bDocument30 pagesLG Rz-21fb35mx Rz-21fg35rx Chasis Mc-049bAurelio MachadoNo ratings yet

- Overcurrent Grading TutorialDocument28 pagesOvercurrent Grading Tutorialmubarakkirko100% (1)

- Aevr Z1haDocument1 pageAevr Z1haasanga.solarNo ratings yet

- LG 29FS2AL/ALX Color TV Service ManualDocument32 pagesLG 29FS2AL/ALX Color TV Service ManualTeo DTNo ratings yet

- Be1 59n Bull9Document8 pagesBe1 59n Bull9Suresh Kumar VengaliNo ratings yet

- 29FB5RNX MC05HBDocument39 pages29FB5RNX MC05HBbajak erorrNo ratings yet

- Automatic Voltage Regulating Relay EE 301-M: Instruction ManualDocument22 pagesAutomatic Voltage Regulating Relay EE 301-M: Instruction ManualnarendragahlotNo ratings yet

- T2400Document2 pagesT2400kylegazeNo ratings yet

- Three-Phase Alternator Technical SpecificationsDocument7 pagesThree-Phase Alternator Technical Specificationsmohammad javad golNo ratings yet

- Intech BookDocument20 pagesIntech BookADDIS JOHNNo ratings yet

- 138SiemensE02+R24F501 7VK611BreakerPDocument5 pages138SiemensE02+R24F501 7VK611BreakerPJonasNo ratings yet

- NullDocument10 pagesNullapi-25932525No ratings yet

- Buku Panduan TV LG LG - 29fs4rl - Chassis - Cw62aDocument32 pagesBuku Panduan TV LG LG - 29fs4rl - Chassis - Cw62azoomgun39No ratings yet

- G100-G102-Chassis-Manual #4Document75 pagesG100-G102-Chassis-Manual #4Daihatsu Charade BanjarnegaraNo ratings yet

- LG 29fb5rl Chasis Cw62aDocument32 pagesLG 29fb5rl Chasis Cw62asoms65No ratings yet

- Color TV: Service ManualDocument30 pagesColor TV: Service Manualพัฒนชัย บุญทาNo ratings yet

- Alternator E1X13S C/4: Technical Data SheetDocument7 pagesAlternator E1X13S C/4: Technical Data SheethirararaNo ratings yet

- MC 049B ChassisDocument29 pagesMC 049B Chassissandy98173dfrNo ratings yet

- 250W Industrial 1U ATX 12V/P4 PC Power Supply: SpecificationDocument3 pages250W Industrial 1U ATX 12V/P4 PC Power Supply: SpecificationAlexis MorenoNo ratings yet

- Type CV Voltage RelayDocument28 pagesType CV Voltage Relayหนุ่ม วัยทองNo ratings yet

- Color TV: Service ManualDocument31 pagesColor TV: Service ManualСергей СергеевичNo ratings yet

- DRP 240 SpecDocument2 pagesDRP 240 SpecEfren AcostaNo ratings yet

- Avr (M) FaDocument1 pageAvr (M) FaReymundo SantiagoNo ratings yet

- Danger: O&M Manual For 40-1200A (480/600 Vac) ATC-800 3-Position, Open/Closed Transition Contactor Based Transfer SwitchDocument1 pageDanger: O&M Manual For 40-1200A (480/600 Vac) ATC-800 3-Position, Open/Closed Transition Contactor Based Transfer SwitchmrtabiehjNo ratings yet

- TD-CV2 Vacuum TypeDocument30 pagesTD-CV2 Vacuum TypeabidNo ratings yet

- 7VK610Document6 pages7VK610Afsar AliNo ratings yet

- Ups Kstar-1-3kva 120V 0.9PFDocument5 pagesUps Kstar-1-3kva 120V 0.9PFoscar mauricio caballero camachoNo ratings yet

- Smooth Move Instructions SheetDocument2 pagesSmooth Move Instructions SheetAbdul KurniadiNo ratings yet

- tmcs1100 q1Document48 pagestmcs1100 q1Toma PatarauNo ratings yet

- Extremely Inverse IDMT Form 0.63/10 Relays Type 2TJM30: Easun ReyrolleDocument2 pagesExtremely Inverse IDMT Form 0.63/10 Relays Type 2TJM30: Easun Reyrollebaviskar_vrNo ratings yet

- Ea5k3 Manual enDocument3 pagesEa5k3 Manual enOscarito VázquezNo ratings yet

- B 812 C 75 A 5Document8 pagesB 812 C 75 A 5HoangNo ratings yet

- 300ma Cmos Ldo: Features General DescriptionDocument13 pages300ma Cmos Ldo: Features General DescriptionAndres CamachoiNo ratings yet

- S3Document3 pagesS3allhmfwk81No ratings yet

- C441 Motor Insight Overload RelayDocument4 pagesC441 Motor Insight Overload RelayFlo MircaNo ratings yet

- MMR17-PDE-A230-108: Technical Data DescriptionDocument3 pagesMMR17-PDE-A230-108: Technical Data DescriptionMarian M SNo ratings yet

- Operating Instructions for Earth Fault Monitoring RelaysDocument4 pagesOperating Instructions for Earth Fault Monitoring Relaysdian JaelaniNo ratings yet

- LT8637Document33 pagesLT8637AnonNo ratings yet

- DO020 - Universal Interface FPS 2070 & 0271Document2 pagesDO020 - Universal Interface FPS 2070 & 0271Chien liang LiuNo ratings yet

- Cpc1008N: Single-Pole, Normally Open 4-Pin Sop Optomos RelayDocument6 pagesCpc1008N: Single-Pole, Normally Open 4-Pin Sop Optomos Relaym3y54mNo ratings yet

- Tc1014/Tc1015/Tc1185: 50ma, 100ma and 150ma Cmos Ldos With Shutdown and Reference BypassDocument21 pagesTc1014/Tc1015/Tc1185: 50ma, 100ma and 150ma Cmos Ldos With Shutdown and Reference BypassThomas ThomasNo ratings yet

- Generator Automatic Voltage Regulator Operation ManualDocument3 pagesGenerator Automatic Voltage Regulator Operation Manualflorensius suparyantoNo ratings yet

- Color TV: Service ManualDocument39 pagesColor TV: Service ManualJosé Ricardo de SouzNo ratings yet

- Et100 Series Owner/Installer Instruction Manual: Electronic 24 Hour Time SwitchesDocument2 pagesEt100 Series Owner/Installer Instruction Manual: Electronic 24 Hour Time SwitchesShannon AdamsNo ratings yet

- Automatic Voltage Regulating Relay (Avr-03) : FeaturesDocument1 pageAutomatic Voltage Regulating Relay (Avr-03) : Featuresss subramanyamNo ratings yet

- 1 500Document95 pages1 500juan manuelNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Testing Commissioning Process Light Rail ProjectDocument5 pagesTesting Commissioning Process Light Rail Projectsuraiyya begumNo ratings yet

- Mesatutorial - Isa101 HmiworkshopDocument104 pagesMesatutorial - Isa101 HmiworkshopHilmer Irving Marcha HuancaNo ratings yet

- CT535 How To Improve Plant Operations Through Better HMI GraphicsDocument42 pagesCT535 How To Improve Plant Operations Through Better HMI GraphicsTadeo Agustín Guerrero VargasNo ratings yet

- Manual Stratix Switch 1783 In001 en PDocument28 pagesManual Stratix Switch 1783 In001 en PfdovazquezNo ratings yet

- Diodes GP4504MTR G1Document15 pagesDiodes GP4504MTR G1Jose Luis ValduezaNo ratings yet

- D04 BuscouplerDocument65 pagesD04 BuscouplerபாரதிNo ratings yet

- Three Conductor Underground Direct Burial: Ampacity TablesDocument2 pagesThree Conductor Underground Direct Burial: Ampacity TablesalbertoNo ratings yet

- Course Code: 19ASC303A Course Title: Aerodynamics - 2 (Fundamentals of Compressible Flow) Assignment # 5Document5 pagesCourse Code: 19ASC303A Course Title: Aerodynamics - 2 (Fundamentals of Compressible Flow) Assignment # 5RD412No ratings yet

- Analysis & Design of Multistorey BuildingDocument124 pagesAnalysis & Design of Multistorey Buildingriyasproject86% (36)

- Glow Plug System (From The Web)Document6 pagesGlow Plug System (From The Web)Abdul R. MustaphaNo ratings yet

- RINA 2009 Bulk Carriers - Allowable Hold Mass Curves - Bureau Veritas - FINALDocument16 pagesRINA 2009 Bulk Carriers - Allowable Hold Mass Curves - Bureau Veritas - FINALKonstantis_chNo ratings yet

- 02 Statics of Rigid Bodies 03 Rigid Bodies PDFDocument10 pages02 Statics of Rigid Bodies 03 Rigid Bodies PDFjollyrosegonzalesNo ratings yet

- Student Exploration: Energy Conversions Part 2Document2 pagesStudent Exploration: Energy Conversions Part 2yareliNo ratings yet

- LED Driver Circuit GuideDocument5 pagesLED Driver Circuit GuideTanzimNo ratings yet

- MechanicsDocument558 pagesMechanicsfejiloNo ratings yet

- Gyroscope and GyrocompassDocument26 pagesGyroscope and Gyrocompassdragonborn dragonbornNo ratings yet

- Electric Basic Measure ExperimentDocument10 pagesElectric Basic Measure ExperimentselniNo ratings yet

- BrakeClutch Ch2 AnalysisDocument65 pagesBrakeClutch Ch2 AnalysisIhsan Naufal RidhwanNo ratings yet

- Product Data Sheet 3RP1560-1SP30Document6 pagesProduct Data Sheet 3RP1560-1SP30leolimbNo ratings yet

- 3 Hydrostatic Force Tutorial SolutionDocument25 pages3 Hydrostatic Force Tutorial SolutionGerold Molina91% (11)

- Ge2151 Basic Electrical and Electronics Engineering L T P CDocument1 pageGe2151 Basic Electrical and Electronics Engineering L T P CKannan Kathiravan100% (1)

- Prob Thermo chp1Document6 pagesProb Thermo chp1Muhammad FaizanNo ratings yet

- Topic 3: Shear Force of A BeamDocument19 pagesTopic 3: Shear Force of A BeamhafizNo ratings yet

- Earth Fault Protection Principles and Techniques in Solidly Grounded SystemsDocument27 pagesEarth Fault Protection Principles and Techniques in Solidly Grounded SystemsSuresh Chandra PadhyNo ratings yet

- Defect and Material MechanicsDocument287 pagesDefect and Material MechanicsqwertyNo ratings yet

- Solution: Statics Example 1Document3 pagesSolution: Statics Example 1Sohaib Raja RajaNo ratings yet

- Electric Charges & Fields DPP 7Document3 pagesElectric Charges & Fields DPP 7kijetNo ratings yet

- Emc Systems Installations 2000 Part 1 EarthingDocument11 pagesEmc Systems Installations 2000 Part 1 EarthingFernando VidalNo ratings yet

- Sci PPT q3 WK 2 Day 1-5Document82 pagesSci PPT q3 WK 2 Day 1-5Mej Landayan - CayananNo ratings yet

- Thermal Protector P06 DatasheetDocument2 pagesThermal Protector P06 DatasheetRafael RodriguesNo ratings yet

- 03-Physic F5 2018-ElectricityDocument32 pages03-Physic F5 2018-ElectricitySreedrannNo ratings yet

- College of Arts and Sciences Department of Mathematics and PhysicsDocument6 pagesCollege of Arts and Sciences Department of Mathematics and PhysicsLorna BacligNo ratings yet

- 05 PEmag Assorted Features - v2017Document15 pages05 PEmag Assorted Features - v2017ShradhaSharma100% (1)

- Everything You Need Toknowabout Airpel Anti-Stiction AircylindersDocument24 pagesEverything You Need Toknowabout Airpel Anti-Stiction AircylindersAlek KrótkiNo ratings yet