Professional Documents

Culture Documents

Beede Instrument - Stara Ploča Cummins 6BT Serija 546213

Uploaded by

godlike110Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Beede Instrument - Stara Ploča Cummins 6BT Serija 546213

Uploaded by

godlike110Copyright:

Available Formats

Beede Electrical Instrument Company, Inc.

AGRICULTURAL WARRANTY

88 Village Street, Penacook, NH 03303 AUTOMOTIVE

Phone: (603) 753-6362 FAX: (603) 753-6201 Beede Electrical Instrument Co., Inc. warrants all

INDUSTRIAL instruments and accessories free from all defects in

www.beede.com MARINE workmanship and materials on gauges that are less than

Since 1917 An ISO-9001 Certified Company TRUCK three (3) years old or have been in service fewer than two

BUS (2) years and, at no charge, will replace or repair at

Beede's option all instruments that fail.

3" Model 3-14 Advanced Tachometer Installation Instructions Contact Beede for complete details.

TO STARTER VOLTAGE

WARNING SOLENOID REGULATOR

OPTIONAL LCD SPST

Improper installation may damage the instrument and/or

RESET SWITCH MOMENTARY ON

cause injury to the installer. If you have installation questions,

please contact the factory.

Disconnect battery cables before installing the instrument. IGNITION SW ALTERNATOR

Check for obstructions behind dash panel such as wires REAR VIEW OF

and hoses before cutting the mounting hole for the instrument. INSTRUMENT

BATTERY

TO LIGHT

MOUNTING SWITCH OR

Recommended dash hole size: 3.380.015 in (85.850.38mm) DIA. BATTERY SOURCE

PUSH-IN

Secure the instrument into dashboard with mounting "U" clamp, lock washers and hex nuts.

OPTIONAL 24V LAMP

If dashboard thickness exceeds clamp grip range, clamp legs may be shortened.

ADAPTOR

Position instrument in dash board prior to tightening clamp nuts to recommended torque.

Maximum recommended tightening torque for all hardware: 6 lb-in (0.68 N-m).

Caution, over tightening mounting hardware may damage the instrument.

+

HOUR

MAINTENANCE METER

Periodically check and torque all hardware per mounting specifications. (OPTIONAL)

Clean electrical connections if corrosion develops around hardware. -

Clean glass with a soft, damp, clean cloth.

THANK YOU! GND

Thank you for purchasing a Beede instrument.

Our instruments are made for you in the U.S.A.

Visit our WEB site at www.beede.com or

contact customer service for information

on this or other Beede instruments.

LOCK WASHER COIL, MPU, ECM,

DISTRIBUTOR,

HEX NUT ALTERNATOR,

PULSE GENERATOR RANGING SWITCH

OR ELECTRONIC ( SEE RANGING SWITCH

IGNITION LABEL FOR APPROPRIATE

For electrical connections, use

SWITCH SETTING

hex nuts and lockwashers supplied

546213 REV D MOUNTING IF APPLICABLE)

4.18.11 with the mounting kit.

"U" CLAMP

Beede Electrical Instrument Company, Inc. AGRICULTURAL WARRANTY

88 Village Street, Penacook, NH 03303 AUTOMOTIVE

Phone: (603) 753-6362 FAX: (603) 753-6201 Beede Electrical Instrument Co., Inc. warrants all

INDUSTRIAL instruments and accessories free from all defects in

www.beede.com MARINE workmanship and materials on gauges that are less than

Since 1917 An ISO-9001 Certified Company TRUCK three (3) years old or have been in service fewer than two

BUS (2) years and, at no charge, will replace or repair at

Beede's option all instruments that fail.

3" Model 3-14 Advanced Tachometer Installation Instructions Contact Beede for complete details.

TO STARTER VOLTAGE

WARNING SOLENOID REGULATOR

OPTIONAL LCD SPST

Improper installation may damage the instrument and/or

RESET SWITCH MOMENTARY ON

cause injury to the installer. If you have installation questions,

please contact the factory.

Disconnect battery cables before installing the instrument. IGNITION SW ALTERNATOR

Check for obstructions behind dash panel such as wires REAR VIEW OF

and hoses before cutting the mounting hole for the instrument. INSTRUMENT

BATTERY

TO LIGHT

MOUNTING SWITCH OR

Recommended dash hole size: 3.380.015 in (85.850.38mm) DIA. BATTERY SOURCE

PUSH-IN

Secure the instrument into dashboard with mounting "U" clamp, lock washers and hex nuts.

OPTIONAL 24V LAMP

If dashboard thickness exceeds clamp grip range, clamp legs may be shortened.

ADAPTOR

Position instrument in dash board prior to tightening clamp nuts to recommended torque.

Maximum recommended tightening torque for all hardware: 6 lb-in (0.68 N-m).

Caution, over tightening mounting hardware may damage the instrument.

+

HOUR

MAINTENANCE METER

Periodically check and torque all hardware per mounting specifications. (OPTIONAL)

Clean electrical connections if corrosion develops around hardware. -

Clean glass with a soft, damp, clean cloth.

THANK YOU! GND

Thank you for purchasing a Beede instrument.

Our instruments are made for you in the U.S.A.

Visit our WEB site at www.beede.com or

contact customer service for information

on this or other Beede instruments.

LOCK WASHER COIL, MPU, ECM,

DISTRIBUTOR,

HEX NUT ALTERNATOR,

PULSE GENERATOR RANGING SWITCH

OR ELECTRONIC ( SEE RANGING SWITCH

IGNITION LABEL FOR APPROPRIATE

For electrical connections, use

SWITCH SETTING

hex nuts and lockwashers supplied

546213 REV D MOUNTING IF APPLICABLE)

4.18.11 with the mounting kit.

"U" CLAMP

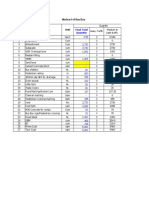

DIESEL ENGINE MAGNETIC PICK-UP DIP SWITCH SETTING CHART OUTBOARD ENGINE ALTERNATOR INPUT

DIP SWITCH SETTING CHART

NUMBER OF TEETH NUMBER OF TEETH NUMBER OF TEETH

CLOSE SWITCH CLOSE SWITCH CLOSE SWITCH

ON FLYWHEEL ON FLYWHEEL ON FLYWHEEL NUMBER OF

- OPEN SWITCH

80 120 1,3,7,9 160 1,2,4,5,6,7,8,9 ALTERNATOR POLES

81 7,8 121 1,3,7,8,9,10 161 1,2,3,5,6,10 4 1,2

82 6,7,8 122 1,3,6,7 162 1,2,3,5,6,9,10 6 2,3

83 5,7,9 123 1,3,6,7,8,10 163 1,2,3,5,6,8,9,10 8 2

84 5,6,7,10 124 1,3,5,9 164 1,2,3,5,6,7,8,10 10 4,5

85 3,7 125 1,3,5,7,9 165 1,2,3,5,6,7,8,9,10 12 4

86 3,6,10 126 1,3,4 166 1,2,3,4,6,9 20 6

87 3,6,7,8,9 127 1,3,4,7 167 1,2,3,4,6,8,10

88 3,5,7,8 128 1,3,4,7,8 168 1,2,3,4,6,8,9,10 NON-OUTBOARD GAS ENGINE IGNITION

89 3,5,6,7 129 1,3,4,6,10 169 1,2,3,4,6,7,8,10 INPUT DIP SWITCH SETTING CHART

90 3,4,6,8 130 1,3,4,6,7 170 1,2,3,4,5,10

91 3,4,5 131 1,3,4,6,7,8 171 1,2,3,4,5,9,10 NUMBER OF

OPEN SWITCH

92 3,4,5,7,8 132 1,3,4,5,10 172 1,2,3,4,5,8,9 ENGINE CYLINDERS

93 2,7 133 1,3,4,5,7 173 1,2,3,4,5,7,9,10 4 1,2

94 2,6 134 1,3,4,5,7,8 174 1,2,3,4,5,7,8,9 6 2,3

95 2,6,7,8 135 1,3,4,5,6,10 175 1,2,3,4,5,6,10 8 2

96 2,5,8 136 1,3,4,5,6,7 176 1,2,3,4,5,6,9,10

97 2,4 137 1,3,4,5,6,7,8 177 1,2,3,4,5,6,8,9 PULSE GENERATOR INPUT

98 2,4,8,9,10 138 1,2,6,10 178 1,2,3,4,5,6,8,9,10

DIP SWITCH SETTING CHART

99 2,3,9 139 1,2,6,8 179 1,2,3,4,5,6,7,8,10

100 2,3,7,8,10 140 1,2,6,7,8 180 1,2,3,4,5,6,7,8,9,10 RATIO OF PTO SPEED

2,3,6,8 1,2,6,7,8,9,10 OPEN SWITCH

101 141 TO ENGINE RPM

102 2,3,6,7,8,9 142 1,2,5,9 .5 TO 1.0 1,2,3,4,5

103 2,3,5,7,10 143 1,2,5,7,10 1.0 TO 1.0 2,3

104 2,3,4 144 1,2,5,7,8,10 1.5 TO 1.0 3,4

105 2,3,4,7,9 145 1,2,5,6,10 2.0 TO 1.0 ALL CLOSED

106 2,3,4,6,10 146 1,2,5,6,8,10

107 2,3,4,6,7,9 147 1,2,5,6,7,9,10

108 2,3,4,5,10 148 1,2,5,6,7,8,9

109 2,3,4,5,7,9 149 1,2,4,6,9 SWITCH POSITIONS

110 2,3,4,5,6,10 150 1,2,4,6,8,9 1 THRU 8 ARE

111 2,3,4,5,6,7,9 151 1,2,4,6,7,9,10 SHOWN IN THE

112 1,6,10 152 1,2,4,6,7,8,9,10 OPEN POSITION

113 1,6,7,10 153 1,2,4,5,9

114 1,5 154 1,2,4,5,8,9

115 1,5,7,10 155 1,2,4,5,7,9,10

116 1,5,7,8,9 156 1,2,4,5,7,8,9,10

117 1,4,7 157 1,2,4,5,6,9 SWITCH POSITIONS

118 1,4,7,8,10 158 1,2,4,5,6,8,10 9 AND 10 ARE

119 1,3,9 159 1,2,4,5,6,7,9,10 SHOWN IN THE

CLOSED POSITION

RANGING DIP SWITCH SETTING DETAIL

546213 REV D

4.18.11

DIESEL ENGINE MAGNETIC PICK-UP DIP SWITCH SETTING CHART OUTBOARD ENGINE ALTERNATOR INPUT

DIP SWITCH SETTING CHART

NUMBER OF TEETH NUMBER OF TEETH NUMBER OF TEETH

CLOSE SWITCH CLOSE SWITCH CLOSE SWITCH

ON FLYWHEEL ON FLYWHEEL ON FLYWHEEL NUMBER OF

- OPEN SWITCH

80 120 1,3,7,9 160 1,2,4,5,6,7,8,9 ALTERNATOR POLES

81 7,8 121 1,3,7,8,9,10 161 1,2,3,5,6,10 4 1,2

82 6,7,8 122 1,3,6,7 162 1,2,3,5,6,9,10 6 2,3

83 5,7,9 123 1,3,6,7,8,10 163 1,2,3,5,6,8,9,10 8 2

84 5,6,7,10 124 1,3,5,9 164 1,2,3,5,6,7,8,10 10 4,5

85 3,7 125 1,3,5,7,9 165 1,2,3,5,6,7,8,9,10 12 4

86 3,6,10 126 1,3,4 166 1,2,3,4,6,9 20 6

87 3,6,7,8,9 127 1,3,4,7 167 1,2,3,4,6,8,10

88 3,5,7,8 128 1,3,4,7,8 168 1,2,3,4,6,8,9,10 NON-OUTBOARD GAS ENGINE IGNITION

89 3,5,6,7 129 1,3,4,6,10 169 1,2,3,4,6,7,8,10 INPUT DIP SWITCH SETTING CHART

90 3,4,6,8 130 1,3,4,6,7 170 1,2,3,4,5,10

91 3,4,5 131 1,3,4,6,7,8 171 1,2,3,4,5,9,10 NUMBER OF

OPEN SWITCH

92 3,4,5,7,8 132 1,3,4,5,10 172 1,2,3,4,5,8,9 ENGINE CYLINDERS

93 2,7 133 1,3,4,5,7 173 1,2,3,4,5,7,9,10 4 1,2

94 2,6 134 1,3,4,5,7,8 174 1,2,3,4,5,7,8,9 6 2,3

95 2,6,7,8 135 1,3,4,5,6,10 175 1,2,3,4,5,6,10 8 2

96 2,5,8 136 1,3,4,5,6,7 176 1,2,3,4,5,6,9,10

97 2,4 137 1,3,4,5,6,7,8 177 1,2,3,4,5,6,8,9 PULSE GENERATOR INPUT

98 2,4,8,9,10 138 1,2,6,10 178 1,2,3,4,5,6,8,9,10

DIP SWITCH SETTING CHART

99 2,3,9 139 1,2,6,8 179 1,2,3,4,5,6,7,8,10

100 2,3,7,8,10 140 1,2,6,7,8 180 1,2,3,4,5,6,7,8,9,10 RATIO OF PTO SPEED

2,3,6,8 1,2,6,7,8,9,10 OPEN SWITCH

101 141 TO ENGINE RPM

102 2,3,6,7,8,9 142 1,2,5,9 .5 TO 1.0 1,2,3,4,5

103 2,3,5,7,10 143 1,2,5,7,10 1.0 TO 1.0 2,3

104 2,3,4 144 1,2,5,7,8,10 1.5 TO 1.0 3,4

105 2,3,4,7,9 145 1,2,5,6,10 2.0 TO 1.0 ALL CLOSED

106 2,3,4,6,10 146 1,2,5,6,8,10

107 2,3,4,6,7,9 147 1,2,5,6,7,9,10

108 2,3,4,5,10 148 1,2,5,6,7,8,9

109 2,3,4,5,7,9 149 1,2,4,6,9 SWITCH POSITIONS

110 2,3,4,5,6,10 150 1,2,4,6,8,9 1 THRU 8 ARE

111 2,3,4,5,6,7,9 151 1,2,4,6,7,9,10 SHOWN IN THE

112 1,6,10 152 1,2,4,6,7,8,9,10 OPEN POSITION

113 1,6,7,10 153 1,2,4,5,9

114 1,5 154 1,2,4,5,8,9

115 1,5,7,10 155 1,2,4,5,7,9,10

116 1,5,7,8,9 156 1,2,4,5,7,8,9,10

117 1,4,7 157 1,2,4,5,6,9 SWITCH POSITIONS

118 1,4,7,8,10 158 1,2,4,5,6,8,10 9 AND 10 ARE

119 1,3,9 159 1,2,4,5,6,7,9,10 SHOWN IN THE

CLOSED POSITION

RANGING DIP SWITCH SETTING DETAIL

546213 REV D

4.18.11

You might also like

- Kenwood KD 65F InstructionManualDocument11 pagesKenwood KD 65F InstructionManualdjr01749No ratings yet

- Pioneer - Receiver VSX-D711 - Service ManualDocument82 pagesPioneer - Receiver VSX-D711 - Service ManualRenatoMaia100% (1)

- Manual Kenwood 615Document40 pagesManual Kenwood 615cemeloNo ratings yet

- Sony Ps2 SCPH 39000 Series Service Manual GH 022Document28 pagesSony Ps2 SCPH 39000 Series Service Manual GH 022RenatoNo ratings yet

- ZL50H ManualDocument77 pagesZL50H Manualjeckohimo89% (18)

- Essex ManualDocument107 pagesEssex Manuali_tiberius_m8153100% (2)

- 335 02 0905 GBDocument98 pages335 02 0905 GBigarijo100% (5)

- User'S Guide: Downloaded From Manuals Search EngineDocument32 pagesUser'S Guide: Downloaded From Manuals Search EngineFrancisco J Rojas GNo ratings yet

- GDM 5403Document59 pagesGDM 5403Flaviano SaccàNo ratings yet

- GR-SXM260: Compact Vhs CamcorderDocument32 pagesGR-SXM260: Compact Vhs CamcorderMinnie Sue JusticeNo ratings yet

- Panasonic-PVD4745-enDocument72 pagesPanasonic-PVD4745-engensipaoNo ratings yet

- Home Theater Sony-Str-K850p-ManualDocument52 pagesHome Theater Sony-Str-K850p-ManualDouglas SantosNo ratings yet

- VG 4250Document56 pagesVG 4250Kevin DrakeNo ratings yet

- NSB enDocument28 pagesNSB enPablo GonzalezNo ratings yet

- PD-M403 PD-M423: R Lla.Document16 pagesPD-M403 PD-M423: R Lla.miguel_olmos_18No ratings yet

- 0632 Ac2000 Owners ManualDocument42 pages0632 Ac2000 Owners ManualBeltazor HellboyNo ratings yet

- Pioneer BDP-140 - Manual de ServiçoDocument72 pagesPioneer BDP-140 - Manual de Serviçokdantas574No ratings yet

- Installation Considerations When Applying Variable Frequency DrivesDocument49 pagesInstallation Considerations When Applying Variable Frequency DrivesAravind HVNo ratings yet

- Touch Tester - Operation, Installation and Calibration InstructionsDocument2 pagesTouch Tester - Operation, Installation and Calibration InstructionsMarcoNo ratings yet

- GR-SXM250: Compact Vhs CamcorderDocument32 pagesGR-SXM250: Compact Vhs CamcorderkuqinasooNo ratings yet

- m800 ManualDocument2 pagesm800 ManualÁgost VitaNo ratings yet

- JBL CS60.2 ManualDocument8 pagesJBL CS60.2 ManualDarioGTINo ratings yet

- Pioneer CDJ-800 Service ManualDocument78 pagesPioneer CDJ-800 Service ManualAdrian DuMay100% (1)

- Sony-Ps2-Scph-50000 Series Service Manual PDFDocument25 pagesSony-Ps2-Scph-50000 Series Service Manual PDFOrdileyNo ratings yet

- Universal Kit Installation ManualDocument70 pagesUniversal Kit Installation Manualnelutuanv-1No ratings yet

- Vsx305 Om-Pioneer TextDocument28 pagesVsx305 Om-Pioneer TextMarcos MartinsNo ratings yet

- Compact Disc Player ManualDocument48 pagesCompact Disc Player ManualShannon Rgb100% (1)

- Stereo Cassette Deck: TC-WE435Document20 pagesStereo Cassette Deck: TC-WE435angel33guitarNo ratings yet

- Install Stewart Warner gaugesDocument2 pagesInstall Stewart Warner gaugesHanNo ratings yet

- VSX-609 709 RRV2274Document64 pagesVSX-609 709 RRV2274sollersNo ratings yet

- Read Service Manual Carefully Before ServicingDocument21 pagesRead Service Manual Carefully Before Servicinganjan chatterjeeNo ratings yet

- 2000.1D EVO Owner's Manual IntroductionDocument8 pages2000.1D EVO Owner's Manual IntroductionALINUX SOUNDNo ratings yet

- Compact Disc Player ManualDocument80 pagesCompact Disc Player ManualIgor Alves De SouzaNo ratings yet

- CS300.1 CS60.4 CS60.2: The Official Brand of Live MusicDocument8 pagesCS300.1 CS60.4 CS60.2: The Official Brand of Live MusicLuis RodriguezNo ratings yet

- Pioneer CDJ-800mk2 Service ManualDocument228 pagesPioneer CDJ-800mk2 Service ManualAdrian DuMay100% (2)

- ManualDocument76 pagesManualOscar CastañedaNo ratings yet

- Amp BP - OmDocument8 pagesAmp BP - OmRoma RomaNo ratings yet

- KD-SR80BT: Instruction Manual Manual de Instrucciones Manuel D'InstructionsDocument76 pagesKD-SR80BT: Instruction Manual Manual de Instrucciones Manuel D'InstructionsViktor TorresNo ratings yet

- Active Servo Subwoofer Owner's ManualDocument12 pagesActive Servo Subwoofer Owner's ManualJansen SouzaNo ratings yet

- TK-780 (E - E3) Revised - B51-8523-10Document66 pagesTK-780 (E - E3) Revised - B51-8523-10Gerardo HernándezNo ratings yet

- Pioneer sc-68 sc-67Document276 pagesPioneer sc-68 sc-67cutolodanielNo ratings yet

- Sony TCWE835S enDocument24 pagesSony TCWE835S enAndrew MorrisNo ratings yet

- Sony CDP-CX57-ENG PDFDocument32 pagesSony CDP-CX57-ENG PDFBernard MarreauNo ratings yet

- AKA304 (Akai-S3200XL) PDFDocument318 pagesAKA304 (Akai-S3200XL) PDFJh CtNo ratings yet

- 193 - 0301 Ac1000 Owners Manual Pre 7 1 09Document30 pages193 - 0301 Ac1000 Owners Manual Pre 7 1 09Juan José VelázquezNo ratings yet

- Nad 712 ManualDocument68 pagesNad 712 ManualdadejaNo ratings yet

- Stereo CD Cassette Deck Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Document78 pagesStereo CD Cassette Deck Receiver: This Manual Is Applicable To The Following Model (S) and Type (S)Claudelino ToffolettiNo ratings yet

- VSX-D812 D912 RRV2732Document93 pagesVSX-D812 D912 RRV2732Reynaldo AlvaradoNo ratings yet

- LG Fe-M200e Ffh-M200aDocument20 pagesLG Fe-M200e Ffh-M200ajoseto_441No ratings yet

- Owner'S Manual: Audio SystemDocument19 pagesOwner'S Manual: Audio SystemCuauhtemoc HernandezNo ratings yet

- Pioneer VSX-D712-K (RRV2731)Document91 pagesPioneer VSX-D712-K (RRV2731)angel quinteroNo ratings yet

- Camera Operations Guide: DCR-PC330Document136 pagesCamera Operations Guide: DCR-PC330knockcontrolNo ratings yet

- Sony-Ps2-Scph-39000 Series Service Manual gh-022 PDFDocument28 pagesSony-Ps2-Scph-39000 Series Service Manual gh-022 PDFHotel WijayaNo ratings yet

- CD/DPF-R Series: Instruction ManualDocument28 pagesCD/DPF-R Series: Instruction Manuallilo6romeroNo ratings yet

- Instruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineDocument20 pagesInstruction Manual Mode D'Emploi Manual de Instrucciones: Register OnlineLauraNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Electronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesFrom EverandElectronic Connection Techniques and Equipment 1968-69: Pergamon Electronics Data SeriesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- York County Court Schedule 5/27Document16 pagesYork County Court Schedule 5/27rugbyprodigy824No ratings yet

- Conectores Iso CarAudioDocument38 pagesConectores Iso CarAudioMoisés Francisco100% (2)

- Monster 821 EUR enDocument146 pagesMonster 821 EUR enChethan K. ReddyNo ratings yet

- CHE 453 Transport PhenomenaDocument10 pagesCHE 453 Transport PhenomenaTanvir Ahmed100% (1)

- Supply Chain Localization Strategies For The FutureDocument162 pagesSupply Chain Localization Strategies For The FutureConstantine CucciNo ratings yet

- Directory - Ontario Federation of AgricultureDocument69 pagesDirectory - Ontario Federation of Agriculturearwid vasilevNo ratings yet

- Wmfun - E05 v0 - Wm-Im InterfaceDocument19 pagesWmfun - E05 v0 - Wm-Im Interfacechandra9000100% (1)

- Source Container QG 020-QG100Document20 pagesSource Container QG 020-QG100hendraNo ratings yet

- Engine Scania1 PDFDocument74 pagesEngine Scania1 PDFMarek MaciążekNo ratings yet

- 4 - Stair Case - Dead LoadsDocument4 pages4 - Stair Case - Dead Loadsraghav abudhabiNo ratings yet

- Drainage design detailsDocument1 pageDrainage design detailsAnal BiswasNo ratings yet

- Kit HD Profesional 2021: On Sale Hard Disk With Installers and Keygen (Complete)Document1 pageKit HD Profesional 2021: On Sale Hard Disk With Installers and Keygen (Complete)JozefNo ratings yet

- Between Permeability and IsolationDocument24 pagesBetween Permeability and IsolationYassir El aidouniNo ratings yet

- Senior Logistics Executive in Dallas TX Resume Thomas JonesDocument3 pagesSenior Logistics Executive in Dallas TX Resume Thomas JonesThomasJones1No ratings yet

- Bel Geddes ProfileDocument7 pagesBel Geddes ProfileLewis PuntonNo ratings yet

- Requirements for Existing Chemical TankersDocument6 pagesRequirements for Existing Chemical Tankersir_azlan_aziz860No ratings yet

- Private Standard: Shahram GhanbarichelaresiDocument2 pagesPrivate Standard: Shahram Ghanbarichelaresiarian tejaratNo ratings yet

- Camp Coxcomb HistoryDocument345 pagesCamp Coxcomb HistoryCAP History Library100% (1)

- Botswana Jde MappingDocument7 pagesBotswana Jde MappingKiran KagitapuNo ratings yet

- Product Sheet Damen FCS 4008 08 2018Document2 pagesProduct Sheet Damen FCS 4008 08 2018Genesis Lissette Loyola OrtizNo ratings yet

- ResumeDocument3 pagesResumechavanshital855No ratings yet

- Pacific Military Bases (1945)Document274 pagesPacific Military Bases (1945)CAP History Library100% (6)

- Sr. EngineerDocument4 pagesSr. Engineerapi-121320726No ratings yet

- Global Passenger Survey 2021 HighlightsDocument19 pagesGlobal Passenger Survey 2021 HighlightsKurtulus OzturkNo ratings yet

- QuingDocument48 pagesQuinglulughoshNo ratings yet

- Bus Bays - S-R-SH-10 R2Document6 pagesBus Bays - S-R-SH-10 R2Stephen Rajkumar JayakumarNo ratings yet

- POB Pekerja Demobilisasi Rip 1500 HP - 061121Document3 pagesPOB Pekerja Demobilisasi Rip 1500 HP - 061121didikhartadiNo ratings yet