Professional Documents

Culture Documents

OSHA Regulations in Malaysia: Factories and Machinery Act Requirements

Uploaded by

WaizMuqrieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OSHA Regulations in Malaysia: Factories and Machinery Act Requirements

Uploaded by

WaizMuqrieCopyright:

Available Formats

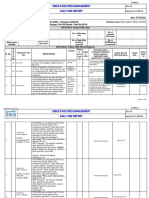

CHAP 2: OSHA IN MALAYSIA AND OCCUPATIONAL SAFETY AND HEALTH REGULATION Factories and Machinery Act (FMA) SAFETY

Factories and Machinery Act (FMA) - HEALTH To prevent accidents due to use and handling of machines

To prevent disease due to excessive use and exposure to To provide a standard minimum requirement for the protection of workers

1. Lead 3. Mineral dust REQUIREMENTS

2. Asbestos 4. Noise 1. STEAM BOILER -Safety valves (2 or more) -Feed check valve

AND UNFIRED -Water gauges (2 pcs) -Inspector's test pressure gauge

Reducing exposure limits (Hierarchy of Hazard Control) PRESSURE -Feed pumps (2pcs) OR Feed attachment

VESSEL pump + injector -Fusible plug

Remove the hazard -Steam pressure gauge -Low-water alarm

-Blow down valve or cock -Low-water fuel cut-out

Replace the hazard

Increase Effectiveness

-Main steam stop valve -Manufacturer's name plate

2. PERSON IN -Certificate of Competency

Isolate worker from hazard CHARGE -Machines:

(1) Steam boiler (3) Internal combustion engine

Change the way people work (2)Steam engine (4) Dredge

(e.g. safe work procedure)

3. ELECTRIC -Design, construction, installation, testing

Protect workers PASSENGER AND o Lifts load and capacity

GOODS LIFT o Lift safety equipment

o Operation and control

APPLY TO CONTROL -Approval for lift installation

1. LEAD All factories processes that use -Respiratory protection equipment o Information and dimension of lift

lead EXCEPT -Mechanical ventilation and o Drawing showing design and location of lift

construction sites or works of recirculation of air o Certificate from manufacturer

engineering construction -Job rotation o Certificate of lift safety equipment test

2. ASBESTOS All manufacturing process that -Respiratory protective equipment o Certificate of wire rope

use asbestos EXCEPT -Exhaust equipment -Maintenance

cleaning of premise, equipment -Protective clothing o Inspect lifts every 3 months

and factory facilities -Proper housekeeping o Conduct and maintain maintenance record for each lift

-Change room, lockers, shower 4. FENCING OF -Fence every dangerous part of machines

facilities MACHINERY -Constantly maintained and kept securely fastened in position at

-Substitution AND SAFETY all times

3. MINERAL All factories where there are -Clothing covers the whole body 5. SAFETY, HEALTH -Floor: level, good, non-slippery condition, no holes

DUST processes using mineral dust -Gloves, hats, shoes AND WELFARE -Stairway: guard rail & handrail

**Sandblasting process can be -Face shields, goggle -Working at a height: safety belts or ropes

used ONLY with written -Hygiene facilities -Firefighting appliances: provided, maintained, accessible

approval from the Chief -Disposal of clothing and equipment -Ventilation: natural ventilation, mechanical ventilation

Inspector -Water spray -Temperature: cool the air, create adequate air movement (reduce

4. NOISE All factories involving exposure -Hearing protection device the body temperature of employee)

< 90 dB to excessive noise level (e.g. -Job rotation -Lighting: intensity of illumination >2 fc (foot-candles)

steel, chemical, palm oil mill, -Drinking water: provided and maintained, suitable drinking cups

textile factory) -First aid: injury must have immediate first-aid treatment

6. NOTIFICATION, - Notify machine installation: machine other than electric To Persons Other Than Their Employees

CERTIFICATES OF passenger and goods lifts Conduct activities that does not endanger and expose them (person other than

COMPETENCY -Notify accidents: report to an Inspector in case of accident employees) to safety & health risks

AND -Certificate of fitness for machine: steam boiler, unfired pressure Provide necessary information to them on the manner of his actions that might

INSPECTION vessel affect their safety or health

-Regular inspection: 15 36 months An Occupier of a Place of Work to Persons Other Than His Employees

7. BUILDING -Slipping Hazards: remove slippery footing caused by oil, grease Premise is made available to use by the other person

OPERATION -Dust and Gases: controlled by ventilation Any material provided for use there is safe and without risk to health

AND WORKS OF -Corrosive Substances: store alkalis, acid, toxic, hazardous Penalty

ENGINEERING substances, provide suitable PPE RM 50, 000 max or

CONSTRUCTION -Protective Apparel: safety helmet, waterproof boots, safety vest Imprisonment 2 years max or both

-Disposal of Debris: method that will not endanger persons

2. DUTIES OF DESIGNERS, MANUFACTURERS AND SUPPLIERS

OSH Act 1994 Plant

To promote and encourage occupational safety and health Plant is of safe design and construction and without risk to health when properly

To secure the safety, health and welfare of persons at work against risks used

Apply to sectors: Arrange/carry out necessary test/examination

1. Manufacturing 8. Wholesale and Provision of adequate information of plant

Sector Retail Trades Substances

2. Mining and 9. Hotel and Substance is of safe and without risk to health when properly used

Quarrying Restaurant Arrange/carry out necessary test/examination

3. Construction 10. Finance Provision of adequate information of substances

4. Agriculture 11. Insurance Penalty

5. Forestry and 12. Real Estate and

RM20,000 max

Fishing Business

Imprisonment 2 years max or both

6. Utilities Service Sector

7. Storage and 13. Public Services

3. DUTIES OF EMPLOYEES

Comm

General

Reasonable care for safety and health of himself and others;

1. DUTIES OF EMPLOYER AND SELF-EMPLOYED PERSONS (>5 EMPLOYEES)

Cooperate with employer and others;

General

Wear and use PPE

Ensure practice of the safety, health and welfare at work

Comply with instructions on OSH

Provide and maintain working environment that is safe and without health risks

Not to Interfere with Or Misuse Things Provided

Ensure safety of worker and absence of risk during operation, handling, storage

Dont intentionally, recklessly or negligently interferes with or misuses anything

and transport of plant and substances

provided

Provide information, instruction, training and supervision

Discrimination

Provide adequate facilities for workers welfare at work

Employer cant dismiss, injure employee or alter his position unless he complaints

Formulate Safety & Health Policy

Prepare a written general OSH Policy (revise when appropriate)

Acknowledge his/her employees on any revision of the policy

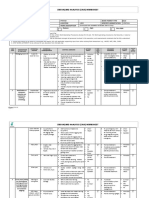

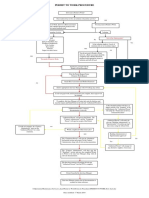

OSHA Regulations 3. NOTIFICATION OF ACCIDENT, DANGEROUS OCCURRENCE, OCCUPATIONAL

1. CLASSIFICATION, LABELLING AND SAFETY DATA SHEET OF HAZARDOUS CHEMICALS POISONING AND OCCUPATIONAL DISEASE

2. CLASSIFICATION, PACKAGING AND LABELLING OF HAZARDOUS' CHEMICALS

Serious injury

Duties of Supplier Notify Send report

(cant work more

To Classify Chemicals DOSH within 7days

than 4 days)

To Ensure Chemicals Supplied in Good Packaging

To Label Packages

To Furnish Chemical Safety Datasheet

Notify Poisoning/

Death

Director Sick

Chemical Classification

4. USE AND STANDARDS OF EXPOSURE OF CHEMICALS HAZARDOUS TO HEALTH

Register of chemicals hazardous to health (employer identify and record)

Exposure does not exceed 8 hours

Follow permissible exposure limit

Control the exposure

o Eliminate o Safe work o Modify process parameters

o Substitute practices o Local exhaust ventilation

o Enclosure o Approved PPE

Label & Re-labelling, Chemical Safety Data Sheet

Information, instruction and training

Supervision

Labelling Exposure monitoring

Warning sign

5. SAFETY AND HEALTH OFFICER

Purpose of Regulation

To provide legal framework for registration & notification of Safety & Health

Officer

To lay down duties of SHO

Duties of Safety and Health Officer (SHO)

Packaging seal properly To advise employer on safety and health

Safety Data Sheet To inspect place of work to determine any hazard liable to cause bodily injury

To investigate any accident, near miss, dangerous occurrence, poisoning or disease

To assist employer or S&H committee in organising and implementing OSH

programme &inspections

To collect, analyse & maintain statistics

To assist any officer in carrying his duty under the act and regulations

To carry out any other instruction made by the employer on safety & health at

workplace matter

SHO Qualification Functions

Diploma in OSH or equivalent approved by Minister Assist in development of rules and systems

Completed a course of training in OSH & passed any examination or equivalent Assist in development and review of programmes

approved by Minister & has minimum 3 years experience in OSH Perform analysis of incident trends and statistic

(SHO Course conducted by NIOSH is one of the approved course) Review and recommend amendments to safety and health policy

Been working in OSH for at least 10 years Perform inspections and recommend preventive measures

Holds other qualification or has received training as prescribed by Minister Perform immediate investigation of accidents and recommend corrective measure

Investigate complains of unsafe practices and recommend corrective measure

Difference Site Safety Supervisor (SSS) & Safety and Health Officer (SHO) Assist in development of promotional and education programmes

Site Safety Supervisor (SSS) Safety and Health Officer (SHO) Discuss reports and matters from safety officer, enforcement officers, etc

Comply to FMA Comply to OSHA Advise employer on safety and health matters

Appointed by the main contractor Appointed by occupier/employer

Helps the main contractor to meet the Total project cost >RM20 million 7. CONTROL OF INDUSTRIAL MAJOR ACCIDENT HAZARDS

requirements of FMA Helps the occupier/ employer to meet Identification and notification of an industrial activity and changes

Promote the safe conduct of work the requirements of OSHA Demonstration of safe operation for non-major hazard installation

generally within the worksite Promote safe conduct of work at the Registration of competent person

place of work Report on industrial activity.

On-site emergency plan keep updating

6. SAFETY AND HEALTH COMMITTEE Notification of major accident

A group of responsible people committed in their all-out effort to provide a safe and Penalty

healthy workplace

Objective

To promote consultation and cooperation between management and workers in

upgrading safety & health at work

To provide a two-way communication channel for dissemination of information on

safety & health issues

To enhance interest and motivation of all groups of management and workers at

workplace of work in safety & health

EMPLOYERS EMPLOYEES

CHAIRMAN SECRETARY

REPRESENTATIVES REPRESENTATIVES

Employer or his Safety and health Division managers Representatives

authorised officer / directors from various

manager Sections section

supervisors

You might also like

- Job Safety Analysis Worksheet: JGC Penthouse Extension BLDGDocument2 pagesJob Safety Analysis Worksheet: JGC Penthouse Extension BLDGCherry BetonioNo ratings yet

- Hand-Operated Power Tool SafetyDocument2 pagesHand-Operated Power Tool SafetySanthoshKumarNo ratings yet

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaNo ratings yet

- Daily HSE ReportDocument5 pagesDaily HSE ReportSayeed MalikNo ratings yet

- Sharjah Waterfront City-Sector 2 & Sun IslandDocument2 pagesSharjah Waterfront City-Sector 2 & Sun IslandCaptainNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument20 pagesSafety Data Sheet: 1. Product and Company IdentificationPubcrawlNo ratings yet

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- Assessment For CCTV System Testing & CommissioningDocument5 pagesAssessment For CCTV System Testing & CommissioningAnonymousNo ratings yet

- Risk Assessment TrainingDocument32 pagesRisk Assessment TrainingAmodhya vikumshanNo ratings yet

- JHA Construction of Drain and SumpDocument6 pagesJHA Construction of Drain and SumpSamsiah TolaNo ratings yet

- Risk Assessment For Installation of Enclosed Switches IsolatorsDocument7 pagesRisk Assessment For Installation of Enclosed Switches IsolatorsADIL AL-AQABYNo ratings yet

- Initial & Re-CertificationDocument107 pagesInitial & Re-CertificationSatya PrabhatNo ratings yet

- Chemical Register Chec MacfeamDocument2 pagesChemical Register Chec MacfeamBekmengNo ratings yet

- National Safety Week Program AgendaDocument3 pagesNational Safety Week Program AgendaDJadee Anuppur AmlaiNo ratings yet

- Hirarc Training IADC EqivalentDocument45 pagesHirarc Training IADC EqivalentNorman AinomugishaNo ratings yet

- Present Perfect.Document1 pagePresent Perfect.Leidy DiazNo ratings yet

- Behavior Based Safety (BBS) : Emco QatarDocument29 pagesBehavior Based Safety (BBS) : Emco QatarparthaNo ratings yet

- Awning Install JhaDocument2 pagesAwning Install JhafatimahNo ratings yet

- E HIRARC TemplateDocument43 pagesE HIRARC TemplateJohn Kurong100% (1)

- Safe Work Practice: Title General Application Protective MechanismsDocument1 pageSafe Work Practice: Title General Application Protective Mechanismssriset100% (1)

- PR 15 Hira Procedure Bim& Tim r1Document17 pagesPR 15 Hira Procedure Bim& Tim r1Purna Chandra BaruaNo ratings yet

- Permit to Work Procedure FlowchartDocument1 pagePermit to Work Procedure FlowchartRenatoNo ratings yet

- Schedule For Inspection Feb 2020Document2 pagesSchedule For Inspection Feb 2020Siddharth RanaNo ratings yet

- Facebook Facing Off Againt TencentDocument6 pagesFacebook Facing Off Againt TencentWai Shan Lee0% (1)

- Osh Legis Topic 1 2 and 3Document44 pagesOsh Legis Topic 1 2 and 3SUHAILI BINTI BOHORI STUDENTNo ratings yet

- Dokumen - Tips Contoh-Hirarc PDFDocument4 pagesDokumen - Tips Contoh-Hirarc PDFtenry_03No ratings yet

- Hirarc Kerja Membuat JalanDocument3 pagesHirarc Kerja Membuat JalanNoralbaniah Ahmadul100% (2)

- Hirarc JKKP ClosingDocument40 pagesHirarc JKKP ClosingThegym le Greene100% (1)

- The Unseelie Prince Maze of Shadows Book 1 by Kathryn AnnDocument267 pagesThe Unseelie Prince Maze of Shadows Book 1 by Kathryn Annanissa Hri50% (2)

- Safety Everyday Safety Pep - Talk: Wrigley BangaloreDocument34 pagesSafety Everyday Safety Pep - Talk: Wrigley Bangaloreramkumardotg_5807772No ratings yet

- Health & Safety: Workplace Inspection Checklist - Workshop AreasDocument6 pagesHealth & Safety: Workplace Inspection Checklist - Workshop AreasMuhammad Alif ZauharNo ratings yet

- First Aid Box Monthly ChecklistDocument1 pageFirst Aid Box Monthly Checklistpurushottam JhariyaNo ratings yet

- Unsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentDocument5 pagesUnsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentTayyab Hasnain Saadat JanjuaNo ratings yet

- 6.4 Accident Investigation 6 Edit BDocument100 pages6.4 Accident Investigation 6 Edit BHilmyZulkifliNo ratings yet

- Organic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiDocument1,212 pagesOrganic Evolution (Evolutionary Biology) Revised Updated Ed by Veer Bala RastogiTATHAGATA OJHA83% (6)

- Near Miss Report Form DetailsDocument1 pageNear Miss Report Form Detailskkalvi100% (1)

- Hiradc Merentang KabelDocument3 pagesHiradc Merentang KabeladelenaNo ratings yet

- Non-Routine Hazards and Risk Assessment SummaryDocument42 pagesNon-Routine Hazards and Risk Assessment SummaryGanesh Murugesan0% (1)

- HIRARCDocument7 pagesHIRARCWong TonyNo ratings yet

- GRP-SHQ-FOR-001-08 Visitor Supplier SHE Induction Briefing FormDocument2 pagesGRP-SHQ-FOR-001-08 Visitor Supplier SHE Induction Briefing FormgrantNo ratings yet

- Children & Young People's Services RISK ASSESSMENTDocument2 pagesChildren & Young People's Services RISK ASSESSMENThaziq ziqNo ratings yet

- Specific Risk Assessment For Civil Work - Kijitonyama Shule SiteDocument5 pagesSpecific Risk Assessment For Civil Work - Kijitonyama Shule SiteemnelNo ratings yet

- Mechanic HirarcDocument17 pagesMechanic Hirarcfauzi5878No ratings yet

- Centre For Diploma Studies: Occupational Safety & HealthDocument7 pagesCentre For Diploma Studies: Occupational Safety & HealthCik Mizza MijotNo ratings yet

- Pathophysiology of Cardiogenic Pulmonary EdemaDocument8 pagesPathophysiology of Cardiogenic Pulmonary EdemaLili Fiorela CRNo ratings yet

- Securing Obligations Through Pledge and MortgageDocument4 pagesSecuring Obligations Through Pledge and MortgagePrincessAngelaDeLeon100% (1)

- Power Distribution HIRARC Risk AssessmentsDocument76 pagesPower Distribution HIRARC Risk AssessmentsNazri100% (1)

- Portable Fire Extinguisher Safety: Facilities Planning and ManagementDocument18 pagesPortable Fire Extinguisher Safety: Facilities Planning and ManagementAnnisa ZaririmaNo ratings yet

- Fma PDFDocument25 pagesFma PDFasyraf_zamanNo ratings yet

- Safety SignageDocument14 pagesSafety SignageChef ShaneNo ratings yet

- Evacuation Drill Details 7-2018Document5 pagesEvacuation Drill Details 7-2018Mustafa Adel100% (3)

- OSH & Fundamental of OSHDocument22 pagesOSH & Fundamental of OSHIbnu SulaimnNo ratings yet

- Safety and Health Officer Regulations 1997Document25 pagesSafety and Health Officer Regulations 1997Mohd Khairol JambliNo ratings yet

- Consist OSH KPIs Workshop ProposalDocument20 pagesConsist OSH KPIs Workshop ProposalAhmad Nazri MokhtarNo ratings yet

- TABLE OF CONTENTS ANALYSISDocument12 pagesTABLE OF CONTENTS ANALYSISFairuza MNasirNo ratings yet

- Security measures for 12 Rabi ul Awal eventsDocument2 pagesSecurity measures for 12 Rabi ul Awal eventsZain Iqbal100% (1)

- FIELD ERECTION OF 15000 BBLs TANK (IK-2545) PROJECT: PAINTING WORK IN CONFINED SPACE JSADocument2 pagesFIELD ERECTION OF 15000 BBLs TANK (IK-2545) PROJECT: PAINTING WORK IN CONFINED SPACE JSAJohnNo ratings yet

- Air Pollution Control-AeeDocument2 pagesAir Pollution Control-AeedungdvNo ratings yet

- OSHA Training and Reference Materials Library - PPE AssessmentDocument10 pagesOSHA Training and Reference Materials Library - PPE AssessmentOluwafemi Samuel AdesanmiNo ratings yet

- OSH Audit Checklist V1 0Document10 pagesOSH Audit Checklist V1 0johnoo7No ratings yet

- Ra1 - General Risk Assessment Form 2015Document3 pagesRa1 - General Risk Assessment Form 2015api-349297013No ratings yet

- Job Safety Analysis (Rms Project)Document9 pagesJob Safety Analysis (Rms Project)Ahmad MensaNo ratings yet

- C&C-EHS-P-017 Legal and Other RequirementDocument17 pagesC&C-EHS-P-017 Legal and Other RequirementNajman HamdiNo ratings yet

- Hazard Risk Assessment Light Bulb ChangeDocument1 pageHazard Risk Assessment Light Bulb ChangePHH9834No ratings yet

- HSE STATSDocument1 pageHSE STATSPT. ANUGRAH MIRAN MANDIRINo ratings yet

- Fan ASA - Series NewDocument43 pagesFan ASA - Series Newalban fejzolliNo ratings yet

- APK Series: Propeller FansDocument4 pagesAPK Series: Propeller FansWaizMuqrieNo ratings yet

- Double Inlet Centrifugal FAN: With Airfoil WheelsDocument43 pagesDouble Inlet Centrifugal FAN: With Airfoil WheelsWaizMuqrieNo ratings yet

- UiTM MEC651 Mechanics and Thermodynamics AssignmentDocument1 pageUiTM MEC651 Mechanics and Thermodynamics AssignmentWaizMuqrieNo ratings yet

- Unit 5 - BlueprintDocument33 pagesUnit 5 - BlueprintWaizMuqrieNo ratings yet

- Law and Acts NotesDocument66 pagesLaw and Acts NotesWaizMuqrieNo ratings yet

- EIS NoteDocument4 pagesEIS NoteWaizMuqrieNo ratings yet

- COP Grease BrochureDocument4 pagesCOP Grease Brochured86299878No ratings yet

- A Short Example Presentation On Molecules Slash Molecular Chemistry in LatexDocument8 pagesA Short Example Presentation On Molecules Slash Molecular Chemistry in LatexintangibilidadeNo ratings yet

- Living in a digital age unit review and digital toolsDocument1 pageLiving in a digital age unit review and digital toolsLulaNo ratings yet

- Key Personnel'S Affidavit of Commitment To Work On The ContractDocument14 pagesKey Personnel'S Affidavit of Commitment To Work On The ContractMica BisaresNo ratings yet

- Wicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of QualityDocument1 pageWicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of Qualityalfdjole0% (1)

- Securifire 1000-ExtractedDocument2 pagesSecurifire 1000-ExtractedWilkeey EstrellanesNo ratings yet

- BS en 1044-1999 - Brazing Filler MetalsDocument26 pagesBS en 1044-1999 - Brazing Filler MetalsBorn ToSinNo ratings yet

- ReadingDocument6 pagesReadingakhyar sanchiaNo ratings yet

- GTA Max Profit Bunker Locations Update v1.4Document1 pageGTA Max Profit Bunker Locations Update v1.4Sam FarrelNo ratings yet

- I. Specifikacija Opreme Sa Ugradnjom R.Br. Opis JM KomDocument4 pagesI. Specifikacija Opreme Sa Ugradnjom R.Br. Opis JM KomAleksandar VidakovicNo ratings yet

- List of OperationsDocument3 pagesList of OperationsGibs_9122100% (3)

- Data Structures LightHall ClassDocument43 pagesData Structures LightHall ClassIwuchukwu ChiomaNo ratings yet

- 01 Lab ManualDocument5 pages01 Lab ManualM Waqar ZahidNo ratings yet

- Degrees of Comparison: When We Compare Two Nouns: Comparative. When We Compare Three or More Nouns: SuperlativeDocument6 pagesDegrees of Comparison: When We Compare Two Nouns: Comparative. When We Compare Three or More Nouns: SuperlativeMerlina AryantiNo ratings yet

- Sheet Metal FormingDocument13 pagesSheet Metal FormingFranklin SilvaNo ratings yet

- Texas LS Notes 19-20Document2 pagesTexas LS Notes 19-20Jesus del CampoNo ratings yet

- Generic Strategies: Lessons From Crown Cork & Seal and Matching DellDocument16 pagesGeneric Strategies: Lessons From Crown Cork & Seal and Matching DellavaNo ratings yet

- Product Data Sheet: Eas Configurator: Easy Online Configuration Ekv1+1 120 Vg4Gxhq (Vg4Gxhq)Document1 pageProduct Data Sheet: Eas Configurator: Easy Online Configuration Ekv1+1 120 Vg4Gxhq (Vg4Gxhq)Attila HorvathNo ratings yet

- 09 Lift Cylinder Drift (Bulldozer) - CheckDocument2 pages09 Lift Cylinder Drift (Bulldozer) - CheckFredy Manrique AstoNo ratings yet

- Electronic Throttle ControlDocument67 pagesElectronic Throttle Controlmkisa70100% (1)

- Axis Bank Placement Paper Interview Questions 48072Document3 pagesAxis Bank Placement Paper Interview Questions 48072Ravi RanjanNo ratings yet

- 45 - Altivar 61 Plus Variable Speed DrivesDocument130 pages45 - Altivar 61 Plus Variable Speed Drivesabdul aziz alfiNo ratings yet

- Chapter 5Document11 pagesChapter 5XDXDXDNo ratings yet

- Explosive Loading of Engineering Structures PDFDocument2 pagesExplosive Loading of Engineering Structures PDFBillNo ratings yet