Professional Documents

Culture Documents

Us 5927620

Uploaded by

100liv0 ratings0% found this document useful (0 votes)

12 views4 pagesasphalt

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentasphalt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views4 pagesUs 5927620

Uploaded by

100livasphalt

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

United States Patent 11»

Memon

[54] ACTIVATED METHOD FOR TREATING

CRUMB RUBBER PARTICLES

[75] Inventor: “Mohammed Memon, Sterling, Va.

[73] Assignee: Phaltech Corporation, Sterling, Va,

[21] Appl. No.: 08/988,949

[22] Filed: Dee. 11, 1997

(51) BO2C 19/00; BOC 19/12

(52) 241/17; 241/21; 241/23;

241/24.12; 241/24.17, 241/24.193 241/27;

24L/DIG. 31; 241/DIG. 37

[58] Field of Search 241/16, 17, 21,

2AL/23, 24.12, 24.13, 24.17, 24.19, 27,

DIG. 37, DIG. 3T

[56] References Cited

U.S. PATENT DOCUMENTS

4,240,587 12/1980 Letsch 24123,

'4625,922. 12/1985 Brubaker eal Dat

SLICE USED

TI

USO059276200,

(1) Patent Number:

[45] Date of Patent:

5,927,620

Jul. 27, 1999

244/D1G. 31 X.

2423

BaDIG, 37 x

4,789,272 12/1988 Matsubara et

8 3/1989 Moore et a

1/091 Hadermann et a

5.26440 11/1903 Plate 24L/DIG. 37 X

5286374 2/1904 Chen 208/400

51369215 11/1994 Platz 24U/D1G. 37 X.

5.524838 6/1996 Elers etal. aU

51634509 6/1907 Khas etal pais

Primary Examiner—Jobn M. Husar

Attorney, Agent, or Firm-—Laubscher & Laubscher

157] ABSTRACT

‘An improved method for eating crumb rubber particles for

use in asphalt compositions is characterized by activating

the particles to enhance the rheological properties thereof. A

slurry of crumb rubber particles is formed by adding water

thereto, The slurry is heated to a temperature of 85-90° C,

to release excess oils ancl chemicals from the particles into

the slurry. The slurry is dried to produce a fine mesh rubber

product with enhanced rheological properties.

10 Claims, 1 Drawing Sheet

“COOL TR

|ECES,

N LIQUID NITROGEN COOLER }-——4

SEPARATE CRUMB RUBBER | 5

AND CELLULOSIC FIBERS

19

2

i

yt Soh GROvE,RuBBER

corer) oan SE

“gees

av HEATED SLURRY SuLeoT ane

vo OF tlen Say |_| Gis wade

RuBbe SARTILES vannicees

COLLECT AND PACK

RESULTING FINE MESH 20

RUBBER PRODUCT

US. Patent

Jul. 27, 1999

SLICE USED 2

TIRES

ye

COOL TIRE PIECES

IN LIQUID NITROGEN COOLER

CELLULOS

FIBERS

COLLECT

PULVERIZE TIRE

PIECES

SEPARATE CRUMB RUBBER

AND CELLULOSIC FIBERS

SORT CRUMB RUBBER

PARTICLES BY SIZE

Ic

FORM HEATED SLURRY

OF SMALLER CRUMB

RUBBER PARTICLES

\8_-

DRY PARTICLES ]

COLLECT AND PACK

RESULTING FINE MESH

RUBBER PRODUCT

p+ 20

5,927,620

| -— 4

COLLECT LARGE

CRUMB _RUBBER

PARTICLES

5,927,620

1

ACTIVATED METHOD FOR TREATING

(CRUMB RUBBER PARTICLES

BACKGROUND OF THE INVENTION

Most ofthe asphalt produced in the United States does not

accommodate variable weather conditions to which the

asphalt is exposed. Accordingly, asphalt is modified in

various states 10 accommodate that slate’s weather co

tions and to qualify for standardized SUPERPAVE proto-

ccols. The present invention relates to an improved method

for creating eryogenically ground erumb rubber particles

used in asphalt compositions to improve the theological

properties thereof.

BACKGROUND OF THE INVENTION

Different asphalt modification processes are currently

available to enhiance the rheological properties of the asphait

at various temperatures, These processes includes polymer

modification, crumb rubber modification, chemical

modification, and the production of asphalt flux. Polymer

modification enhances the high temperature rheological

properties of asphalt, whereas asphalt ux improves only the

low temperature theological properties. Crumb rubber and

‘chemical modification processes provide improvements at

high and low temperatures, but chemical modification is

‘more expensive,

‘Crumb rubber modification is most economical when fine

mesh crumb rubber particles such as those obtained from

used tires are used, Crumb rubber produced by a eryogenic

grinding process can be used to modify asphalt but does not

significantly enhance the theological properties of the

asphalt as compared with crumb rubber produced by an

ambient grinding process.

“The present invention was developed in order to improve

the crumb rubber modification to enhance the theological

properties of crumb rubber modified asphalt. The improve~

ment is the result of activating fine mesh erumb rubber

produced from a eryogenie grinding process.

SUMMARY OF THE INVENTION

Accordingly, it is a primary object ofthe present invention

to provide a method for treating crumb rubber particles in

Which water is added to a quantity of crumb rubber particles

to form a slurry thereof. The slurry is heated to between 85°

C. and 90° C. fora period of atleast five minutes to release

‘excess oils and chemicals from the crumb rubber particles

into the slurry. The heavier crumb rubber particles are then

removed from the slurry following which the slury is dried

resulting in enbanced rheological properties owing 10 the

removal of excess oils and chemicals

‘According to a more specific object ofthe invention, the

‘crumb rubber particles are formed as the result of grinding

used tires under cryogenic coaditions, ‘The resulting par-

ticles of crumb rubber ate sorted by size and the larger

particles, which are laden with metals, are separated either

‘magnetically or in a eyelone separator

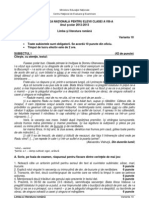

BRIEF DESCRIPTION OF THE FIGURE

Other objects and advantages of the invention will

become apparent from a study of the following specification

‘when viewed in the light of the accompanying drawing, in

whieh:

‘The FIGURE is a block diagram illustrating the steps

according to the improved method for eating crumb rubber

particles according to the invention,

0

as

os

ss

4s

ss

6s

2

DETAILED DESCRIPTION

‘The activated method for treating crumb rubber particles

according to the invention will be described with reference

to the FIGURE. The most economical source of rubber

material is [rom used tires. Crumb rubber particles. are

obiained trom used tires by a exyogenie grinding process.

Specifically, « quantity of used tires are sliced into small

pieces 2 which are then eryogenically cooled in a liquid

nitrogen cooler 4 until they become rigid and brittle. The

pieces are then ground into smaller particles such as by

pulverizing the rigid and brite tire pieces 6.

AS a result of the cryogenic cooling and pulverizing

processes, the tire pieces are reduced to a mixture of crumb

rubber particles and cellulosic fibers. The cellulosic fibers

are then separated from the crumb rubber particles 8 A

preferred method for this separating step is to place the

‘mixture in a cyclone separator where the fibers are removed

from the crumb rubber particles by centrifugal force. The

cellulosic fibers are collected 10 and packed for recycling

purposes,

‘The remaining crumb rubber particles are then sorted by

size 12, This sorting step can be implemented using filter

screens and/or a magnetic separator. Because many of the

tires used as the rubber source contain steel belts, the heavier

rubber panicles are laden with metal. By passing a large

magnet over the crumb rubber particles, the metal laden

particles can be collected 14,

‘The lighter crumb rubber particles are then activated or

treated for purification, More particularly, a quantity of

water is added to the particles to form a slurry 16. The

preferred ratio of crumb rubber particles to water in the

slurry is 1:2. The slurry is heated to an clevated temperature,

preferable in the range of 85-90" C, The addition of water

and the elevated temperature causes the particles o expand

which enables excess oils and chemicals in the rubber

particles to be released into the slurry. The temperature is

elevated for a sufficient period of time, generally five

‘minutes or more, to enable the release of oils, chemicals and

some residual metals, from the slurry.

Preferably, the heavier crumb rubber particles in the slurry

are separated from the remaining particles. This separation

‘can be accomplished using the eyclone separator andor an

electromagnet. The remaining smaller activated particles are

removed from the slurry by gravitational separation, These

particles are dried 18, resulting ina fine mesh rubber product

which is collected and packed 20 for use in making asphalt

‘The vulcanization of curing of rubber with other ingre-

dients such as carbon black used in the manufacturing of

tires. produces cross-links in the molecular structure

De-vuleanization of rubber occues during fine mesh grind-

ing, However, there is no activation of the carbon black or

rubber, Which includes extender oils and the other tir.

ingredients. It has already been determined that the fine

‘mesh rubber obtained by a cryogenic grinding process will

‘not produce the same rheological results on interaction with

asphalt as with ambiently ground eubbee, With the activation

ff the crumb rubber particles according to the invention,

enhanced rheological properties are ebtained.

Set forth in Table 1 are the test results for eryogenically

‘ground crumb rubber (CRM), ambient ground crumb eubber,

and activated eryogenically crumb rubber.

5,927,620

3

TABLE 1

‘Toul Fan Fiat

Asphalt Aspalt Asphalt

sureec “High “High Taw Separation

Grading Temp. Ten Tepe

Gyogeie GaP aee we

eM

Ambient TS ac,

kw

Adhd FO WC WR

Coyoenic

eM

‘As shown in the test results, the improved method of the

invention produces an activated fine mesh erumb rubber

which enhances the rheological properties of asphalt for

both high and low temperature simultaneously. The acti

vated fine mesh crumb rubber also improves the homoge-

neity in the asphalt system with the requisite separation.

While in accordance with the provisions of the patent

Statute the preferred forms and embodiments have been

illustrated and described, it will become apparent to those of

‘ondinary skill in the art that various changes and modifica-

tions may be made without deviating from the invention

‘concepts set forth above.

‘What is claimed is:

1. An activated method for treating eramb rubber particles

for use in asphalt compositions, comprising the steps of

(2) grinding used tires under exyogenie conditions to form

‘crumb rubber particles;

(®) adding water to the crumb rubber particles to form a.

‘crumb rubber slurry;

(6) heating the crumb rubber slurry to release excess oils

‘and chemicals from the crumb rubber particles into the

slurry; and

4

(@) drying the slurry to produce a fine mesh rubber

product with enhanced rheological properties resulting

from the removal of excess oils and chemicals from the

‘crumb rubber particles, whereby the rubber product is

5 used to modify asphalt for pavement

2. Amethod as defined in laim 1, and further comprising

the step of separating lager meial-laden crumb rubber

particles from the sluery prior to said drying step.

3. Amethod as defined in claim 2, wherein said separating

step comprises applying a magnetic force to the sluery to

remove ceumb rubber particles containing metals therefcom.

4. Amethod as defined in claim 2, wherein said separating

step comprises spinning the slurry in a eyclone separator

'5. Amethod as defined in claim 2, wherein said eryogenie

arinding step comprises

(1) Slicing a plurality of used tires into small pieces;

(2) cooling the pieces until they become rigid and brite;

and

(@) pulverizing the cooled pieces to form particles of

‘crumb rubber and cellulose fibers

66. Amethod as defined in claim §, and further comprising

the step of separating the crumb rubber particles trom the

cellulosic fibers.

7. A method as defined in claim 6, and further comprising

the step of sorting the erumb rubber particles by size.

'8. A method a defined in claim 7, wherein said heating

step comprises heating the slurry to a temperature in the

range of 85-90" C. for a period of at leat five minutes

'9.Amethod as defined in claim 8, wherein said separating

step comprises applying a magnetic force to the sluery to

remove erumb rubber particles containing metal therefrom,

10. A method as defined in elaim 9, wherein said sepa-

rating step comprises spinning the slurry in a cyclone

5. Separator

0

as

os

You might also like

- Material Test Report: Sample Details Particle Size DistributionDocument2 pagesMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- Material Test Report: Sample Details Particle Size DistributionDocument1 pageMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- Material Test Report: Sample Details Particle Size DistributionDocument1 pageMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- 162 PaliukaiteDocument7 pages162 PaliukaitePuneet SharmaNo ratings yet

- Ekingen eDocument192 pagesEkingen e100livNo ratings yet

- Material Test Report: Sample Details Particle Size DistributionDocument1 pageMaterial Test Report: Sample Details Particle Size Distribution100livNo ratings yet

- Us 3338849 ADocument6 pagesUs 3338849 A100livNo ratings yet

- 02 MAnderson MSCR ImplementationDocument39 pages02 MAnderson MSCR Implementation100liv100% (1)

- RILEM Recommended Test Method AAR-0: Detection of Alkali-Reactivity Potential in Concrete - Outline Guide To The Use of RILEM Methods in Assessments of Aggregates For Potential Alkali-ReactivityDocument8 pagesRILEM Recommended Test Method AAR-0: Detection of Alkali-Reactivity Potential in Concrete - Outline Guide To The Use of RILEM Methods in Assessments of Aggregates For Potential Alkali-Reactivity100livNo ratings yet

- RILEM Recommended Test Method AAR-1: Detection of Potential Alkali-Reactivity of Aggregates - Petrographic MethodDocument17 pagesRILEM Recommended Test Method AAR-1: Detection of Potential Alkali-Reactivity of Aggregates - Petrographic MethodAlvaro Pazmiño RomanNo ratings yet

- Technical White Paper FP 08 - 4-Mm DSRDocument71 pagesTechnical White Paper FP 08 - 4-Mm DSR100livNo ratings yet

- Calculation of Measurement Uncertainty For Stiffness Modulus of Asphalt MixtureDocument9 pagesCalculation of Measurement Uncertainty For Stiffness Modulus of Asphalt Mixture100livNo ratings yet

- Perpetual Pavements in Delivering Smooth RoadDocument37 pagesPerpetual Pavements in Delivering Smooth Road100livNo ratings yet

- Wo 2013163009 A 1Document307 pagesWo 2013163009 A 1100livNo ratings yet

- Asphalt Paper DSRDocument4 pagesAsphalt Paper DSRyazqaNo ratings yet

- ER926SB70ADocument2 pagesER926SB70A100livNo ratings yet

- Limba Romana Capacitate 2013Document2 pagesLimba Romana Capacitate 2013Ioana NicolescuNo ratings yet

- 992041Document47 pages992041100livNo ratings yet

- 020-Pap 017Document17 pages020-Pap 017100livNo ratings yet

- Development Crumb Rubber BitumenDocument10 pagesDevelopment Crumb Rubber Bitumen100livNo ratings yet

- AAPAs Asphalt Pavement Solutions - For Life ProjectDocument12 pagesAAPAs Asphalt Pavement Solutions - For Life Project100livNo ratings yet

- 25351Document8 pages25351100livNo ratings yet

- Online Users Guide en enDocument166 pagesOnline Users Guide en en100livNo ratings yet

- Jsir 68 (9) 812-816Document5 pagesJsir 68 (9) 812-816100livNo ratings yet

- 152Document6 pages152100livNo ratings yet

- Bitumen Viscosity Testing Equipment and Test ProceduresDocument6 pagesBitumen Viscosity Testing Equipment and Test ProceduresProf. Prithvi Singh Kandhal75% (4)

- 7 Hines AMAP SavannahDocument57 pages7 Hines AMAP Savannah100livNo ratings yet

- US6764542B1Document7 pagesUS6764542B1100livNo ratings yet

- Agpt T103 06 - RtfoDocument20 pagesAgpt T103 06 - Rtfo100livNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)