Professional Documents

Culture Documents

Sandvik DD2710

Uploaded by

lorenzo henerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sandvik DD2710

Uploaded by

lorenzo henerCopyright:

Available Formats

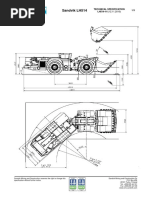

DD2710

DEVELOPMENT DRILL

TECHNICAL SPECIFICATION

Sandvik DD2710 is a compact and flexible single- KEY FEATURES

boom electro-hydraulic jumbo for development Coverage area 34 m

drilling in narrow vein and mass mining as well as in Hydraulic rock drill 1 x HLX5 (20 kW)

tunneling, in cross sections up to 34 m. Drill feed 1 x TF500-12 (12 rods)

Boom 1 x B26F

Sandvik DD2710 is equipped with Sandvik HLX5 Hole length 3 440 mm (12 rods)

hydraulic rock drill, which delivers 20 kW of T-section width in turning 2 750 mm

percussion power for high penetration rates and Transport width 1 600 mm

good rock tool service life in varying rock conditions. Transport height 2 535 mm / 2 750 mm

The universal B26F boom is fitted with 360 feed Transport length 10 065 mm (TF512)

rotation, automatic parallelism and a large and Operating weight 11 600 kg

optimally shaped coverage, for fast and accurate

face drilling and versatility. The direct controlled IBC

control system has added automatic functions that

allow the operator to concentrate safely on fast and

accurate drilling.

Sandvik DD2710 is mounted on a 4-wheel drive

frame-steered and diesel powered carrier, which

features a FOPS-approved safety canopy, and layout

designed for good visibility and stability in tramming

in small mining drifts and tunnels. The operating and

maintenance interface are designed for easy access,

safe operation and all service points are accessible

from ground level.

Scan or click to see the video.

1. SANDVIK DD2710 - DEVELOPMENT DRILL

HYDRAULIC ROCK DRILL ELECTRIC SYSTEM

Type of rock drill HLX5 (TS2-232) Standard voltages 380 - 690 V ( 10%)

Percussion power 20 kW Total installed power 70 kW

Percussion pressure Max. 220 bar Main switch gear NSX160N/38

Percussion rate 67 Hz IP classification Specification TS2-132

Rotation speed Max. 250 rpm (with OMS 80) Starting method Star delta starter 380 - 660 V

Rotation torque 400 Nm (with OMS 80) Automatic cable reel CR with tramming interlock

Hole diameter (face drilling) 43 - 64 mm Cable reel control At the operator station

Hole diameter (reaming) 76 -127 mm Phase inversor detector Automatic

T38 - Hex 35 - R32 Front lights

4 x 48 W LED (24 V)

Recommended rod T38 - Hex 35 - Alpha 330 (combined working and driving)

T38 - Hex 35 -R35 Rear tramming lights 2 x 48 W LED (24 V)

Shank adapter (male) T38 Operator station light 1 x 5 W (24V)

Weight 210 kg Amber flashing light LED (24 V)

Length 955 mm Batteries 2 x 12 V, 80Ah

Profile height 87 mm

AIR AND WATER SYSTEM

DRILLING FEED Flushing of holes By water

Type TF500-10 TF500-12 TF500-14 TFX6/12 Water booster pump type WBP1 (3 kW )

Feed force kN Max. 25 Max. 25 Max. 25 Max. 25 kN 40 l/min at 12 bar

Water pump capacity

Total length mm 4 660 5 270 5 880 3 540 / 5370 (inlet pressure = 4 bar)

1 830 (6) / Water pump inlet pressure 2 - 5.4 bar

Rod length mm 3 090 (10) 3 700 (12) 4 305 (14)

3 700 (12) Flushing water pressure 10 - 12 bar

Hole length mm 2 830 3 440 4 050 1 610 / 3 440 Shank lubrication device SLU-1 (air / oil mist)

Weight (with- Air compressor CTN10 (1.0 m/min, 7 bar)

kg 470 500 530 620

out hoses) Rock drill oil consumption 180 - 250 g/h

Rock drill air consumption 250 - 350 l/min

BOOM

Type of boom B26F (TS2-259) OPERATORS SAFETY CANOPY

Face drilling coverage 29 m2 (parallel holes) Canopy certification FOPS (ISO 3449)

Parallelism Automatic hydraulic Unit height in tramming 2 750 mm

Boom extension 1 200 mm Operator station: 102 dB(A)

Sound pressure level EN 791

Boom weight (without hoses) 1 850 kg Emitted: 124 dB(A)

Feed roll-over 360 For working / tramming

Operators seat

Adjustable with seat belt

HYDRAULIC SYSTEM

Powerpack HPP 555 (55 kW)

Operating principle Direct hydraulic control

Percussion, rotation, feed 65 cc + 35 cc + 33 cc

and boom pump (Triple pump)

Filtration (pressure / return) 10 / 10

Oil tank volume 200 liters

Filling pump for hydraulic oil Electric

Cooler for hydraulic oil OW30 oil-to-water (30 kW)

Level indicator and automatic

Low oil level indication

switch-off

DRILLING CONTROL SYSTEM

Type of control system IBCQF, hydraulic

Full percussion and collaring

Feed and rotation

Adjustable parameters

Fast rock drill return and forward

Flushing

Stop and return

Automatic features

Anti-jamming

2. SANDVIK DD2710 - DEVELOPMENT DRILL

CARRIER OPTIONAL FEATURES AND PACKAGES

Type of carrier MERCURY (frame steered) Drilling feed

Carrier articulation 35 *Feed length TF510 (10 rods) or TF514 (14 rods)

Rear axle oscillation 6 *Telescopic feed TFX6/12

Ground clearance 295 mm Cleaning system

Diesel engine Deutz TCD3.6 L4 (74 kW, Tier 3, China III) LP system with reel Up to 15 bar (TS2-343)

Exhaust catalyzer Standard HP system with reel Up to 180 bar (TS2-343)

Transmission Hydrostatic, automotive Electric system

Wheel motors 4 x radial piston *Multi-voltage 550 or 1 000 V (50 / 60 Hz)

*Electric cables Specification TS2-121

Tires 10.00 - 15

Ground fault and overcurrent VYK

Service brakes Hydrostatic and positive braking protection

Parking and Battery jump start Optional

SAHR fail safe type wet disc brakes

emergency brakes Air and water system

8 km/h (Horizontal) *Air mist flushing With External water / internal air

Tramming speed CTN16 with 1 x 60L air receiver

4 km/h (14%=1:7=8)

*End-of-hole flushing With 1 x 60L air receiver

Gradeability / sideways tilt Max. 15 / 5 Air mine connection IP5 air cleaner

Fuel tank 60 liters *Dry drilling CTN16 with 1 x 60L air receiver, air / oil

cooler, dust hood on feed, readiness

2 x Telescopic (front) for hydraulic supply onboard dust

Carrier stabilization

2 x Vertical (rear) collector

Brake release Manual hand pump Hooks for water / air hose 2 hooks

Centralized greasing points Carrier Greasing system

Hand held fire extinguisher 1 x 6 kg (type ABC) Manual system Greasing unit with pump, reel and

Tramming alarm Standard nozzle (Spec. 5-2110)

Colour scheme Sandvik Operators safety canopy

2 x Operators manual Operator protection Safety grill

2 x Maintenance manual

Fire suppression system

Documentation 2 x Technical manual (in English only)

Manual system Ansul, 6 nozzles (Spec. 5-9800)

2 x Parts manual (in English only)

2 x CD of manuals (PDF files)

Carrier

*Foam filled tires 4 pcs

Wheel chocks and holders 2 Sets

Extra items

Berg plug and socket

Spare rock drill HLX5

Spare wheel assembly Standard or foam filled tires

Special tools for rock drill Complete set (Spec. 2-1861)

Field kit (Spec. 2-1862)

Documentation Extra manuals

Package: Country specific SAS (cluster lights, reflective taps and

options wheel chocks and holders)

*Package: Harsh water Advanced (TS2-049)

*) replaces standard feature

3. SANDVIK DD2710 - DEVELOPMENT DRILL

Coverage manual override = 34 m

Coverage autoparellel = 29 m

R2

R1

35

TS2-075:06/ENG/METRIC Sandvik Mining and Rock Technology 2016 SANDVIK is a registered trademark owned by Sandvik Intellectual Property AB in Sweden and other countries.

All dimensions in mm

Feed R1 R2 C L

TF500-10 2 900 mm 4 980 mm 2 630 mm 9 485 mm

TF500-12 2 900 mm 5 100 mm 2 750 mm 10 065 mm

TF500-14 2 900 mm 5 235 mm 2 880 mm 10 285 mm

2 750 SANDVIK

2 535

DD2710

1 810 1 480

15 16

2 090 2 350

5 150

L

SANDVIK

2 900

DD2710

1 630

150

All dimensions in mm

Sandvik Mining and Rock Technology reserves the right to make changes to the information on this data sheet without prior notification to users.

Please contact a Sandvik representative for clarification on specifications and options.

MINING.SANDVIK.COM

4. SANDVIK DD2710 - DEVELOPMENT DRILL

You might also like

- Cycle Car With Moto WheelDocument83 pagesCycle Car With Moto Wheelsapientwon7712100% (1)

- Tool Engineering Jig and Fixture BookDocument261 pagesTool Engineering Jig and Fixture Bookaashishyogesh95100% (3)

- 6991 5005 01 DIAMEC 232 ManualDocument76 pages6991 5005 01 DIAMEC 232 ManualОлег100% (1)

- Machine Tools - Made Easy PDFDocument320 pagesMachine Tools - Made Easy PDFAmrinder Singh90% (10)

- Drilling ProblemsDocument38 pagesDrilling ProblemsChukwuma LystanNo ratings yet

- 8997 6091 00 Diagrams and Drawings PDFDocument127 pages8997 6091 00 Diagrams and Drawings PDFpiratax31100% (1)

- Rock Drill PDFDocument94 pagesRock Drill PDFfurkan84No ratings yet

- DS311 8 - 3040-ADocument4 pagesDS311 8 - 3040-AsanamehNo ratings yet

- Shaft SinkingDocument70 pagesShaft SinkingHalo Zeus100% (1)

- ASTT - Guidelines For Horizontal DirectiDocument45 pagesASTT - Guidelines For Horizontal DirectiFerdie TolosaNo ratings yet

- DD310 26Document94 pagesDD310 26Raphael Ruiz RamosNo ratings yet

- DE700 Series PDFDocument5 pagesDE700 Series PDForlando chullo llave100% (1)

- EXPANSO - Rock and Concrete Breaking Non Explosive Mortar - Call - 7676001100Document14 pagesEXPANSO - Rock and Concrete Breaking Non Explosive Mortar - Call - 7676001100CA JamesNo ratings yet

- Ulotka Face Master 2.5NVDRDocument2 pagesUlotka Face Master 2.5NVDRlorenzo henerNo ratings yet

- 8991 4813 00 Diagrams and Drawings PDFDocument94 pages8991 4813 00 Diagrams and Drawings PDFphong100% (1)

- Product Catalogue ROBELDocument110 pagesProduct Catalogue ROBELAlberth Mauricio Casteblanco GomezNo ratings yet

- 9851 3586 01 COP MD20 BrochureDocument4 pages9851 3586 01 COP MD20 BrochureEduardo MassainiNo ratings yet

- Sandvik DL311Document4 pagesSandvik DL311Anonymous Dm7iMmtNo ratings yet

- Mori Seiki G Codes and M CodesDocument9 pagesMori Seiki G Codes and M CodesAsh BetchumNo ratings yet

- Rocket Boomer L2 C: Next GenerationDocument63 pagesRocket Boomer L2 C: Next GenerationArturo Pedro Salgado Medina100% (2)

- Dev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishDocument4 pagesDev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishBBBBBBNo ratings yet

- Sandvik RH550 Manuel OperatingDocument106 pagesSandvik RH550 Manuel OperatingAdil DouziNo ratings yet

- SANDVIK DD422iEDocument4 pagesSANDVIK DD422iElorenzo henerNo ratings yet

- DS310 (New Electric Box) - GDocument122 pagesDS310 (New Electric Box) - GIrvinDiazOscategui100% (2)

- Jumbo Dd421Document4 pagesJumbo Dd421Anonymous Iu8A4JC100% (2)

- Dokumen - Tips - Sandvik Mining Offering Guide (001 092)Document92 pagesDokumen - Tips - Sandvik Mining Offering Guide (001 092)Jose luis Sarayse cruz100% (1)

- LH 514 Technical Specification Sandvik LH514-10Document3 pagesLH 514 Technical Specification Sandvik LH514-10Emanuel Nicolas Villarruel100% (1)

- 311 Range Tramming: Maintenance ManualDocument28 pages311 Range Tramming: Maintenance ManualjoseNo ratings yet

- DD311 40Document154 pagesDD311 40luis naupari100% (1)

- 1.DL210 Presentation PDFDocument43 pages1.DL210 Presentation PDFCristian Sepulveda100% (1)

- 8795988107.1 en Easer L Maintenance ScheduleDocument36 pages8795988107.1 en Easer L Maintenance ScheduleAngel Bernachea100% (2)

- Sandvik LH410 (TORO 7) (10t) - 2017 PDFDocument10 pagesSandvik LH410 (TORO 7) (10t) - 2017 PDFДмитрий АсташонокNo ratings yet

- Leaflet Face Master 2.3-1BDocument2 pagesLeaflet Face Master 2.3-1Blorenzo henerNo ratings yet

- Leaflet Face Master 2.3-1BDocument2 pagesLeaflet Face Master 2.3-1Blorenzo henerNo ratings yet

- Syntec Programming v7Document125 pagesSyntec Programming v7Damree EmirNo ratings yet

- DS312 Specification Sheet EnglishDocument4 pagesDS312 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- Service Manual Air Flushing CircuitDocument14 pagesService Manual Air Flushing CircuitrolandNo ratings yet

- Espec DL311-7 7 - 6328-EDocument4 pagesEspec DL311-7 7 - 6328-EFranklin LabbeNo ratings yet

- Drilling & BlastingDocument7 pagesDrilling & BlastingVikram SharmaNo ratings yet

- Sandvik DE710: Heavy Duty Core DrillDocument3 pagesSandvik DE710: Heavy Duty Core DrillHenry Contreras100% (1)

- Core BarrelsDocument15 pagesCore BarrelsfededaNo ratings yet

- SIMBA 1354 Pag 1-2 - 4Document4 pagesSIMBA 1354 Pag 1-2 - 4lorenzo hener100% (1)

- Ds311-Ficha Tecnica PDFDocument4 pagesDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyNo ratings yet

- DL301 Series - Product Presentation - Low Res PDFDocument58 pagesDL301 Series - Product Presentation - Low Res PDFlido100% (1)

- Simba E7-SeriesDocument8 pagesSimba E7-SeriesVictor BalboaNo ratings yet

- Sandvik DD310-26X MediumDocument2 pagesSandvik DD310-26X Mediumjuancaf773557No ratings yet

- 01 Component LocationDocument10 pages01 Component Locationyeya1963tito100% (1)

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDocument73 pagesMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريNo ratings yet

- HidraulicoDocument114 pagesHidraulicosergio manuel delgado pobleteNo ratings yet

- Carrusel RHS17 Actualizado, Simba 1254Document44 pagesCarrusel RHS17 Actualizado, Simba 1254Pancho ArriazaNo ratings yet

- DL331-5 Con CanopyDocument4 pagesDL331-5 Con CanopyLeonardo Luis Gomez QuipuzcoaNo ratings yet

- Caboltec Atlas PDFDocument40 pagesCaboltec Atlas PDFNeilNo ratings yet

- Sandvik DD320-40Document4 pagesSandvik DD320-40david100% (3)

- dd210 Specification Sheet English PDFDocument4 pagesdd210 Specification Sheet English PDFGerson Dario Rojas TorresNo ratings yet

- Quasar 1FDocument4 pagesQuasar 1FMiguel CalderónNo ratings yet

- Scooptram&Minetruck 9851 2450 01eDocument36 pagesScooptram&Minetruck 9851 2450 01elidoNo ratings yet

- DS421 8-4301-ADocument4 pagesDS421 8-4301-AchristianNo ratings yet

- Sandvik DD210Document4 pagesSandvik DD210Lener Elvin Lopez LavadoNo ratings yet

- Sandvik DD321Document4 pagesSandvik DD321Anonymous Dm7iMmt0% (2)

- Maintenance Manual: Original InstructionsDocument32 pagesMaintenance Manual: Original InstructionsElber Luis Chavez Barrios100% (1)

- Boomer S1 L: Low Profile Face Drilling Rig For Drifts and Tunnels With Cross Sections Up To 29 MDocument8 pagesBoomer S1 L: Low Profile Face Drilling Rig For Drifts and Tunnels With Cross Sections Up To 29 MDiegoAndresJofreVillablanca100% (1)

- Samlingsspec Atlas Copco ROCDocument4 pagesSamlingsspec Atlas Copco ROCCarlos Andres Campos TorresNo ratings yet

- Technical Specification Sandvik LH514-14Document3 pagesTechnical Specification Sandvik LH514-14enriquerojoperez_539100% (2)

- 9851 3543 01a - Simba S7 - Technical Specification - EnglishDocument8 pages9851 3543 01a - Simba S7 - Technical Specification - EnglishMiguel Angel Otiniano ParedesNo ratings yet

- Acuñador Scaletec MC Atlas CopcoDocument4 pagesAcuñador Scaletec MC Atlas CopcoMichael de la BarraNo ratings yet

- Perforadora Montabert HC 50: ReseminDocument12 pagesPerforadora Montabert HC 50: ReseminAdolfo MarcosNo ratings yet

- Boomer 282.PDF PerforaoDocument4 pagesBoomer 282.PDF Perforaoperfo 49r67% (3)

- DD310 26 PDFDocument94 pagesDD310 26 PDFmegamNo ratings yet

- Powerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentDocument5 pagesPowerroc T35 E: Surface Drill Rig For Construction, Road Construction and Urban DevelopmentElgi Alam PangestuNo ratings yet

- Boomer104 SpecDocument4 pagesBoomer104 SpecLucho MoraNo ratings yet

- 10-01 Boltec S - Electrical System 24VDocument47 pages10-01 Boltec S - Electrical System 24VALVARO ANTONIO SILVA DELGADONo ratings yet

- Sandvik Du311-Tk Underground Drill: Technical SpecificationDocument4 pagesSandvik Du311-Tk Underground Drill: Technical SpecificationGabriel Ulloa100% (2)

- D25KS - D245S Blasthole DrillDocument4 pagesD25KS - D245S Blasthole DrillDarling Jerard Vera BriceñoNo ratings yet

- Pit Viper 235 High Resolution US Tcm1241-3515574Document4 pagesPit Viper 235 High Resolution US Tcm1241-3515574Mackarena Isabel Santander Alegre100% (1)

- Frontonero SANDVIK DD311Document4 pagesFrontonero SANDVIK DD311Arturo And100% (1)

- Sandvik Dd321 Development Drill: Technical SpecificationDocument4 pagesSandvik Dd321 Development Drill: Technical SpecificationFERNANDO INOCENTE TRINIDAD GUERRANo ratings yet

- dd321 Specification Sheet EnglishDocument4 pagesdd321 Specification Sheet Englishgkqztsy9skNo ratings yet

- SpecificationsDocument4 pagesSpecificationsSebastian VasquezNo ratings yet

- Atlas Copco Rocket Boomer GuideDocument2 pagesAtlas Copco Rocket Boomer GuideBrayean Silva SánchezNo ratings yet

- Boomer S 1D PDFDocument4 pagesBoomer S 1D PDFlorenzo henerNo ratings yet

- BoomerDocument2 pagesBoomerlorenzo henerNo ratings yet

- Ulotka Face Master 1.7L PDFDocument2 pagesUlotka Face Master 1.7L PDFlorenzo henerNo ratings yet

- Broshure Face Master 1.7 2 PDFDocument2 pagesBroshure Face Master 1.7 2 PDFlorenzo henerNo ratings yet

- DR 580Document3 pagesDR 580lorenzo henerNo ratings yet

- Simba m6 Pag 1 5 6 7Document8 pagesSimba m6 Pag 1 5 6 7lorenzo henerNo ratings yet

- Sandvik Ds210l VDocument4 pagesSandvik Ds210l Vlorenzo henerNo ratings yet

- 6-9660-F (DD320-40) PDFDocument4 pages6-9660-F (DD320-40) PDFlorenzo henerNo ratings yet

- Broshure Face Master 2.3Document2 pagesBroshure Face Master 2.3lorenzo henerNo ratings yet

- D25KS D245S Blasthole Drill PDFDocument4 pagesD25KS D245S Blasthole Drill PDFlorenzo henerNo ratings yet

- Robbins 123rh C Pag 1-2-3Document4 pagesRobbins 123rh C Pag 1-2-3lorenzo henerNo ratings yet

- Broshure Face Master 1.4Document3 pagesBroshure Face Master 1.4lorenzo henerNo ratings yet

- Ulotka Face Master 1.7L PDFDocument2 pagesUlotka Face Master 1.7L PDFlorenzo henerNo ratings yet

- Boomer E1 C-DHDocument4 pagesBoomer E1 C-DHlorenzo henerNo ratings yet

- Holmen Leaflet Rango en CONCEREALDocument2 pagesHolmen Leaflet Rango en CONCEREALlorenzo henerNo ratings yet

- 9851348301b - Simba M4 Technical SpecificationDocument8 pages9851348301b - Simba M4 Technical Specificationlorenzo henerNo ratings yet

- DD210 6110 G PDFDocument4 pagesDD210 6110 G PDFlorenzo henerNo ratings yet

- Robbins 91/123: Large-Size Raise Boring Machines For Holes Ranging From 2.4 To 6.0 M (8-20 FT.) in DiameterDocument8 pagesRobbins 91/123: Large-Size Raise Boring Machines For Holes Ranging From 2.4 To 6.0 M (8-20 FT.) in Diameterlorenzo henerNo ratings yet

- 6-9660-F (DD320-40) PDFDocument4 pages6-9660-F (DD320-40) PDFlorenzo henerNo ratings yet

- Tool Wear in Friction Drilling: Scott F. Miller, Peter J. Blau, Albert J. ShihDocument10 pagesTool Wear in Friction Drilling: Scott F. Miller, Peter J. Blau, Albert J. Shihjuan carlosNo ratings yet

- Dgms All Circular 2003Document23 pagesDgms All Circular 2003imaduddinshaNo ratings yet

- PLL - 2149 Cavities PDFDocument35 pagesPLL - 2149 Cavities PDFMiguel VlntìnNo ratings yet

- Chapter 15Document17 pagesChapter 15assaNo ratings yet

- Termeni Si Expresii UzualeDocument4 pagesTermeni Si Expresii UzualeToader AlexNo ratings yet

- Kaban-SB 3011-EnDocument6 pagesKaban-SB 3011-EnMiguel Angel KhazandjianNo ratings yet

- MagDrill Catalog PDFDocument68 pagesMagDrill Catalog PDFolomizanaNo ratings yet

- SEI BasicDocument146 pagesSEI BasicYuthia Aulia Riani100% (1)

- EN WOOD 03 Holders-Copying-Jig PDFDocument2 pagesEN WOOD 03 Holders-Copying-Jig PDFÁngel Escamilla ÁvilaNo ratings yet

- PTechReview 18 1956 - 57 325Document11 pagesPTechReview 18 1956 - 57 325HANDRI TIRTA LIANDANo ratings yet

- Console Remote Control Installation InstructionsDocument18 pagesConsole Remote Control Installation InstructionsJoswyn LopesNo ratings yet

- 136 Boltec Mechanized Bolting RigsDocument3 pages136 Boltec Mechanized Bolting RigsKenny CasillaNo ratings yet

- Composite p715g PDFDocument44 pagesComposite p715g PDFAlexandre SouzaNo ratings yet

- Maintenance Task On Drilling MachineDocument8 pagesMaintenance Task On Drilling MachineRonak PatelNo ratings yet

- DBF 630 800 enDocument9 pagesDBF 630 800 enShady MohamedNo ratings yet

- Mach4 Mill GCode Manual PDFDocument60 pagesMach4 Mill GCode Manual PDFDao - Ngoc LamNo ratings yet

- GBH 8 45 D SheetDocument2 pagesGBH 8 45 D SheetchinitnNo ratings yet