Professional Documents

Culture Documents

55 Ni CR Mo V7

Uploaded by

ananda_beloshe75Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

55 Ni CR Mo V7

Uploaded by

ananda_beloshe75Copyright:

Available Formats

Licensed Copy: sheffield un sheffi~ un , na, Sun Nov 19 1o:U1:11LllVI1 +uu:uu 'f.?l}Jo , u 11 1.,,u11 l1v11 cu 'VVtJJ• ,..

,, ~~·

......

Nl

~

r:r

;-'

'

00-

~

1 cc

::r ::r

II>

Cl

°'

...:)

~

QI 8 cc

a;:;·

::s

cc

II>

QI

-

cc

"' I")

Chemical composition a, b, (% mlm) Hardness Hardening test "'::s 0

8

(annealed) c Hardening Quenching Tempering Hardness

Steel name c SI Mn Cr Mo v w Others +A temperature mediumd temperature HRC ::r

- "C0

II> "'

HB ~ ::;.-

max. "C (± 10"C) "C (± 10°C) min. c: o·

' - ) II> ::s

• ,...55NiCrMoV78 0,50 to 0,60 0, 10 to 0,40 0,60 to 0,90 0,80 to 1, 20 0,35to 0.55 0,05 to 0,15 Ni: 1,50 to 1,80 2481 850 r1 0 500 429 ::s ,.-.,

I") I")

::r QI

32CrMoV 12·28 0,28 to 0,35 0, 10 to 0,40 0,15 to 0,45 2,70 to 3,20 2,50 to 3,00 0,40 to 0,70 - 229 1040 0 550 46

II> "'

Q. -

X37C rMoV5·1 0,33 to 0,41 0.80 to 1,20 0,25 to 0,50 4,80 to 5,50 1,10to1,50 0,30 to 0,50 - 229 1020 0 550 48 QI

::s ::s

QI

X38CrMoV5·3 0.35 to 0,40 0,30 to 0,50 0,30 to 0,50 4,80 to 5,20 2,70 to 3,20 0,40 to 0,60 - 229 1040 0 550 50 c. a

X40CrMoV 5·1 0,35 to 0,42 0,80 to 1,20 0,25 to 0,50 4,80 to 5,50 1,20to1,50 0,85to 1,15 - 229 1020 0 550 50 - '<

8II> "'v;·

50CrMoV13·1 5 0.45 to 0,55 0,20 to 0,80 0,50 to 0,90 3,00 to 3,50 1,30 to 1,70 0,15 to 0,35 - 248 1010 0 5 10 56 "C '::;-'

II> QI

X30WC rV9·3 0,25 to 0,35 o, 10 to 0.40 0, 15 to 0,45 2,50 to 3,20 - 0,30 to 0,50 8,50 to 9,50 - 241 1150 0 600 48 ti! ::s

X35CrWMoV5 0,32 to 0,40 0,80 to 1,20 0,20 to 0 ,50 4,75 to 5,50 1,25 to 1,60 0,20 to 0,50 1,10to 1,60 - 229 1020 0 550 48

Q. ::sII>

I") QI

38C rCoW V1 8· 17·17 0,35 to 0,45 0,15 to 0,50 0,20 to 0,50 4,00 to 4,70 0,30 to 0,50 1,70 to 2, 10 3,80 to 4,50 Co 4,00 to 4,50 260 1120 0 600 48 0 II>

::s -

Q. Q.

a Elements not quoted in !his table shall not be intentionally added to the steel without the agreement of the purchaser, other tha n lor the purpose of finishing the heat. AU reasonable preca utions shall be taken to proven! the addition from scrap or ;::','. ::r

other matedals used in manufacture. of such elements which affect the hardenabltily, mecha nical properties and applicability. - · QI

b

~a

For all steels (unless o1herwise specified) . phosphorus " 0 ,030 % and sulfur ..;; 0.020 %.

Q' ;;

c Hardness in the cold drawn condition (+A +C) may be 20 HB higher tha n fn the annealed condilion (+A) . ., "'

d

::r

0 ~"'

Quenching medium: 0 a Oil. Usual Quenching media lor tools are air, gas or salt bal h.

7" ;-

e The sulfur content for thi s grade is .; 0,030 %. :;! 8

f

0 "C

For grea1er dimension s, this steel is n orma lly supplied in the quenched and tempered condilion with a hardness of approximately 380 HB. ~II>

- :a

g This value applies for smaller dimensions only.

0

0

=

ti!

"'II>i;-

Q'

.,

VJ'" ::r

QI

a

II>

::s

s·

~

QI

::sQ.

You might also like

- Blade Runner Souvenir MagazineDocument61 pagesBlade Runner Souvenir Magazinepalomitachan86% (7)

- Physiologic Obstetrics by APMCDocument1,091 pagesPhysiologic Obstetrics by APMCKatrina Cajigal100% (8)

- Rules of Thumb for Mechanical EngineersFrom EverandRules of Thumb for Mechanical EngineersRating: 3.5 out of 5 stars3.5/5 (3)

- Ain T Misbehavin Arr Lennie Niehaus AATB Saxophone Quartet PDF Scribd Aus Dem Internet 01Document1 pageAin T Misbehavin Arr Lennie Niehaus AATB Saxophone Quartet PDF Scribd Aus Dem Internet 01StephanBuehhler0% (2)

- STP DrawingsDocument100 pagesSTP DrawingsStephen Rajkumar JayakumarNo ratings yet

- The CamperVan and Motorhome BookDocument74 pagesThe CamperVan and Motorhome Bookdevil fixitNo ratings yet

- Salesforce Platform Developer 1Document15 pagesSalesforce Platform Developer 1Kosmic PowerNo ratings yet

- Ab Initio Interview Questions - HTML PDFDocument131 pagesAb Initio Interview Questions - HTML PDFdigvijay singhNo ratings yet

- Over Head Gantry 1Document1 pageOver Head Gantry 1darshanNo ratings yet

- Asme II D Subsection 3 - Table TMDocument62 pagesAsme II D Subsection 3 - Table TMyar_nlNo ratings yet

- Column Interaction Diagram PlotsDocument8 pagesColumn Interaction Diagram PlotsptdcaliguidNo ratings yet

- MCQs on Defence Audit Code Chapter 9 and 10Document2 pagesMCQs on Defence Audit Code Chapter 9 and 10Rustam SalamNo ratings yet

- Contract of Lease-Water Refilling StationDocument4 pagesContract of Lease-Water Refilling StationEkeena Lim100% (1)

- Ain T Misbehavin Arr Lennie Niehaus AATB Saxophone Quartet PDF Scribd Aus Dem Internet 02Document1 pageAin T Misbehavin Arr Lennie Niehaus AATB Saxophone Quartet PDF Scribd Aus Dem Internet 02StephanBuehhler0% (2)

- Susan Abbotson - Critical Companion To Arthur Miller - A Literary Reference To His Life and Work-Facts On File (2007) PDFDocument529 pagesSusan Abbotson - Critical Companion To Arthur Miller - A Literary Reference To His Life and Work-Facts On File (2007) PDFTaha Tariq0% (1)

- Motion For Bill of ParticularsDocument3 pagesMotion For Bill of ParticularsPaulo Villarin67% (3)

- CEMEX Global Strategy CaseDocument4 pagesCEMEX Global Strategy CaseSaif Ul Islam100% (1)

- ASTM A106 Seamless Carbon Steel Pipe For High Temperature Service PDFDocument9 pagesASTM A106 Seamless Carbon Steel Pipe For High Temperature Service PDFsingaravelan narayanasamyNo ratings yet

- Soil Nailing and Rock Anchors ExplainedDocument21 pagesSoil Nailing and Rock Anchors ExplainedMark Anthony Agnes AmoresNo ratings yet

- 100 Days, - 100 HoursDocument64 pages100 Days, - 100 HourssalbeNo ratings yet

- Santa Lucla: Valse AndantinoDocument2 pagesSanta Lucla: Valse AndantinoLukas HöflingNo ratings yet

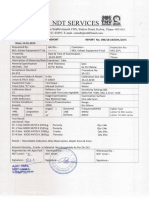

- Quality Certificate for SAIL Discharging Door AssemblyDocument1 pageQuality Certificate for SAIL Discharging Door Assemblyananda_beloshe75No ratings yet

- Quality Certificate for SAIL Discharging Door AssemblyDocument1 pageQuality Certificate for SAIL Discharging Door Assemblyananda_beloshe75No ratings yet

- Summer Training Report On HCLDocument60 pagesSummer Training Report On HCLAshwani BhallaNo ratings yet

- BIM and AM to digitally transform critical water utility assetsDocument20 pagesBIM and AM to digitally transform critical water utility assetsJUAN EYAEL MEDRANO CARRILONo ratings yet

- Aniruddha CharitraDocument81 pagesAniruddha CharitraNaren G SuryaNo ratings yet

- Supersonic,': (Turbulencei, in .. /), GAMMA-,R'AY .'.Document39 pagesSupersonic,': (Turbulencei, in .. /), GAMMA-,R'AY .'.janiklp1337No ratings yet

- La8633xx La76814 STRG6653 3y03Document2 pagesLa8633xx La76814 STRG6653 3y03Cesar RodriguezNo ratings yet

- PB243645Document166 pagesPB243645Ibrahim DanishNo ratings yet

- Telefono Panasonic KX-T2365Document4 pagesTelefono Panasonic KX-T2365Bilier Diaz CabreraNo ratings yet

- DC DB Proposed Interface As Per Site Spare of Future MCBs AvailableDocument1 pageDC DB Proposed Interface As Per Site Spare of Future MCBs AvailableengrandyNo ratings yet

- Encrypted Data File ContentsDocument2 pagesEncrypted Data File Contentsisabel aguirreNo ratings yet

- Rear level sensor replacement guideDocument1 pageRear level sensor replacement guideNicolas PaezNo ratings yet

- Our Town June 5, 1947Document8 pagesOur Town June 5, 1947narberthcivicNo ratings yet

- Montacarga Eléctrico 25bt HyundaiDocument24 pagesMontacarga Eléctrico 25bt HyundaimichaelshelterNo ratings yet

- Journal of Comparative Literature and Aesthetics, Vol. 1, No. 1, Summer 1978Document48 pagesJournal of Comparative Literature and Aesthetics, Vol. 1, No. 1, Summer 1978Viraj ShuklaNo ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1895-48Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1895-48Fornvald TamasNo ratings yet

- Our Town November 12, 1942Document4 pagesOur Town November 12, 1942narberthcivicNo ratings yet

- Hameg hm504 1004 Oscilloscope SCHDocument4 pagesHameg hm504 1004 Oscilloscope SCHMarco PeltzerNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Kuffner - Op87 Doce-DuosDocument9 pagesKuffner - Op87 Doce-Duosluimiranda48No ratings yet

- 2022-09-13 Cajas Electricidad Domoticas X Wifi - AMAZONDocument4 pages2022-09-13 Cajas Electricidad Domoticas X Wifi - AMAZONmr. guyNo ratings yet

- O Modern Indian HistoryDocument1 pageO Modern Indian HistorymarepalliNo ratings yet

- New PassportDocument2 pagesNew PassportShamsurahman ShamsiNo ratings yet

- Math 2Document2 pagesMath 2api-463578527No ratings yet

- Uinu:!I1 H " !uif: 1 I !lltlii I Ui!I!!! F' F!NDocument4 pagesUinu:!I1 H " !uif: 1 I !lltlii I Ui!I!!! F' F!Nlewisw.stiNo ratings yet

- HP Pdp124pDocument1 pageHP Pdp124pefremofe100% (2)

- Gya Ary: ,......, Gyan Bhart, High ChoolDocument1 pageGya Ary: ,......, Gyan Bhart, High ChoolNikhil ShankarNo ratings yet

- Analyzing trends in biometric data over timeDocument6 pagesAnalyzing trends in biometric data over timeisabel aguirreNo ratings yet

- 1948 B-29 Lake Mead Crash Accident ReportDocument9 pages1948 B-29 Lake Mead Crash Accident ReportMystery WireNo ratings yet

- Maths 3 Assignment BasisDocument5 pagesMaths 3 Assignment Basiscanilaky97No ratings yet

- Maceda SulingDocument4 pagesMaceda Sulingmusic.comp09No ratings yet

- ML20101Q417Document65 pagesML20101Q417muhamad.elhosiny21No ratings yet

- Lyudkevich S - Album LeafDocument3 pagesLyudkevich S - Album LeafblastilNo ratings yet

- 1961 OsmDocument319 pages1961 Osmsatish kadamNo ratings yet

- Our Town November 5, 1942Document4 pagesOur Town November 5, 1942narberthcivicNo ratings yet

- 2007 Mathe I Klausur 07Document2 pages2007 Mathe I Klausur 07ajaNo ratings yet

- Knauf - Ceiling PDFDocument31 pagesKnauf - Ceiling PDFAbdelmuneimNo ratings yet

- America00Ogil BWDocument796 pagesAmerica00Ogil BWMirko SvirkoNo ratings yet

- Pages From Dorman Longs - Handbook For Constructional Engineers - 1895-31Document1 pagePages From Dorman Longs - Handbook For Constructional Engineers - 1895-31Fornvald TamasNo ratings yet

- Cynthia-c-davidson-23-Diagram WorkDocument59 pagesCynthia-c-davidson-23-Diagram WorkFilippo Maria DoriaNo ratings yet

- No. H46W6: Scale 1:50,000Document1 pageNo. H46W6: Scale 1:50,000Priya GautamNo ratings yet

- Our Town October 10, 1946Document12 pagesOur Town October 10, 1946narberthcivicNo ratings yet

- 14a TrenchC-SET-201607-Signed&Stamped Ammended For WeldingDocument15 pages14a TrenchC-SET-201607-Signed&Stamped Ammended For WeldingiplaruffNo ratings yet

- WWII 101st Cavalry GroupDocument55 pagesWWII 101st Cavalry GroupCAP History LibraryNo ratings yet

- 'R' (J!JLLH: Njelasan Batas TanahDocument2 pages'R' (J!JLLH: Njelasan Batas Tanahjas lineNo ratings yet

- .... ::P S::JVT::L F - I.. L - ,-R-I - 1::::P::: : :J : .... :J:) - # t.LI LL-I+-2 - F+ - ( - L..:: - ::1-:i: - 1-. .-2 - IDocument1 page.... ::P S::JVT::L F - I.. L - ,-R-I - 1::::P::: : :J : .... :J:) - # t.LI LL-I+-2 - F+ - ( - L..:: - ::1-:i: - 1-. .-2 - IMohammed H SaeedNo ratings yet

- Tyrone Ayham Rasul BeyDocument1 pageTyrone Ayham Rasul BeyTyrone Ayham Rasul BeyNo ratings yet

- Recipientes A PresionDocument1 pageRecipientes A Presionabddut0condoriNo ratings yet

- Back and front views of a structureDocument4 pagesBack and front views of a structureDynamic Power Solutions GhaziabadNo ratings yet

- Our Town November 20, 1947Document6 pagesOur Town November 20, 1947narberthcivicNo ratings yet

- TrigonometryDocument2 pagesTrigonometrypatNo ratings yet

- CRN 3493990263Document3 pagesCRN 3493990263ananda_beloshe75No ratings yet

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDocument24 pagesPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishNo ratings yet

- Purchase Orders for Engineering EquipmentDocument122 pagesPurchase Orders for Engineering Equipmentananda_beloshe75No ratings yet

- Weekly Report-NovDocument8 pagesWeekly Report-Novananda_beloshe75No ratings yet

- ISH Check List - EK288Document1 pageISH Check List - EK288ananda_beloshe75No ratings yet

- Dissimilar Metal WeldabilityDocument1 pageDissimilar Metal Weldabilityananda_beloshe75No ratings yet

- Synergia Inspected List-23.5.2019Document1 pageSynergia Inspected List-23.5.2019ananda_beloshe75No ratings yet

- Comparison EN8D - IS 2062Document1 pageComparison EN8D - IS 2062ananda_beloshe75No ratings yet

- Macro Requirement As Per CodeDocument3 pagesMacro Requirement As Per Codeananda_beloshe75No ratings yet

- Dissimilar Metal Weldability Concepts Alber SadekDocument45 pagesDissimilar Metal Weldability Concepts Alber SadekMohammad AliNo ratings yet

- Comparison EN8D - Is 2062Document1 pageComparison EN8D - Is 2062ananda_beloshe75No ratings yet

- Standard Working Procedure - System 1Document6 pagesStandard Working Procedure - System 1ananda_beloshe75No ratings yet

- Steelwork Preparation S 2 EepvDocument6 pagesSteelwork Preparation S 2 Eepvananda_beloshe75No ratings yet

- Preferred Tol and FitsDocument9 pagesPreferred Tol and Fitsananda_beloshe75No ratings yet

- COC - Entry and Exit Saddle Assembly.Document2 pagesCOC - Entry and Exit Saddle Assembly.ananda_beloshe75No ratings yet

- C Channel Length Extension WeldingDocument1 pageC Channel Length Extension Weldingananda_beloshe75No ratings yet

- Testrep - Lock NutDocument2 pagesTestrep - Lock Nutananda_beloshe75No ratings yet

- Is 13311.2.1992 PDFDocument12 pagesIs 13311.2.1992 PDFTayyab AnwarNo ratings yet

- Work Instructions For Blasting PaintingDocument2 pagesWork Instructions For Blasting Paintingananda_beloshe75No ratings yet

- Guarantee Certificate For SRDocument1 pageGuarantee Certificate For SRananda_beloshe75No ratings yet

- Letter To Elca - 16 - 17 NewDocument89 pagesLetter To Elca - 16 - 17 Newananda_beloshe75No ratings yet

- Digital Lab OvenDocument3 pagesDigital Lab Ovenananda_beloshe75No ratings yet

- Journal International SDLC 15 HalDocument15 pagesJournal International SDLC 15 HalAmandhaEarlyNo ratings yet

- Status Report of Saddle AsslyDocument2 pagesStatus Report of Saddle Asslyananda_beloshe75No ratings yet

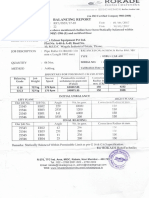

- Balancing ReportDocument2 pagesBalancing Reportananda_beloshe75No ratings yet

- TC For AVM WasherDocument4 pagesTC For AVM Washerananda_beloshe75No ratings yet

- Motor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BDocument4 pagesMotor Controllers AC Semiconductor Motor Controller Types RSE 22 .. - B, RSE 4. .. - B, RSE 60 .. - BAbdul Aziz KhanNo ratings yet

- Rodriguez, Joseph Lorenz Ceit-08-402ADocument7 pagesRodriguez, Joseph Lorenz Ceit-08-402AJOSEPH LORENZ RODRIGUEZNo ratings yet

- Manual Centrifugadora - Jouan B4i - 2Document6 pagesManual Centrifugadora - Jouan B4i - 2Rita RosadoNo ratings yet

- Capital Asset Pricing ModelDocument11 pagesCapital Asset Pricing ModelrichaNo ratings yet

- Questions For ReviewDocument2 pagesQuestions For ReviewJoemar JavierNo ratings yet

- Virtual Content SOPDocument11 pagesVirtual Content SOPAnezwa MpetaNo ratings yet

- Lab Equipment Catalog Research Concept LabDocument40 pagesLab Equipment Catalog Research Concept LabSeetanshu AwasthiNo ratings yet

- Application For Freshman Admission - PDF UA & PDocument4 pagesApplication For Freshman Admission - PDF UA & PVanezza June DuranNo ratings yet

- TV/VCR Tuner Ic With DC/DC Converter: FeaturesDocument21 pagesTV/VCR Tuner Ic With DC/DC Converter: FeaturesEdsel SilvaNo ratings yet

- An-7004 IGBT Driver Calculation Rev00Document8 pagesAn-7004 IGBT Driver Calculation Rev00Raghuram YaramatiNo ratings yet

- Master List of Approved Vendors For Manufacture and Supply of Electrical ItemsDocument52 pagesMaster List of Approved Vendors For Manufacture and Supply of Electrical ItemsBhoopendraNo ratings yet

- Infineon ICE3BXX65J DS v02 - 09 en PDFDocument28 pagesInfineon ICE3BXX65J DS v02 - 09 en PDFcadizmabNo ratings yet

- $$TR Sas 114 AllDocument384 pages$$TR Sas 114 Allctudose4282No ratings yet

- UE Capability Information (UL-DCCH) - Part2Document51 pagesUE Capability Information (UL-DCCH) - Part2AhmedNo ratings yet

- Ganbare Douki Chan MALDocument5 pagesGanbare Douki Chan MALShivam AgnihotriNo ratings yet

- Table of Forces For TrussDocument7 pagesTable of Forces For TrussSohail KakarNo ratings yet

- IT ManagementDocument7 pagesIT ManagementRebaz Raouf Salih MohammedNo ratings yet

- New Markets For Smallholders in India - Exclusion, Policy and Mechanisms Author(s) - SUKHPAL SINGHDocument11 pagesNew Markets For Smallholders in India - Exclusion, Policy and Mechanisms Author(s) - SUKHPAL SINGHRegNo ratings yet

- Example Italy ItenararyDocument35 pagesExample Italy ItenararyHafshary D. ThanialNo ratings yet

- E85001-0646 - Intelligent Smoke DetectorDocument4 pagesE85001-0646 - Intelligent Smoke Detectorsamiao90No ratings yet