Professional Documents

Culture Documents

GMK 5100 Gear Control System

Uploaded by

المهندسوليدالطويلOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GMK 5100 Gear Control System

Uploaded by

المهندسوليدالطويلCopyright:

Available Formats

Deutsche Grove

Home page

1. GMK 5100 Gear Control System

1.1 GMK 5100 gearbox (transmission)

1.2 Overview of transmission

2. Gear and clutch selection

2.1 Gear and clutch selection with Telligent automatic gear change

2.2 Components of the Telligent automatic gear change

2.3 Operating conditions

2.3.1 Road drive (constant speed)

2.3.2 Starting

2.3.3 Gear shift

3. Gear selector

3.1 Gear selector

3.2 Starting

3.3 Selecting operating mode - Automatic operation

3.4 Manual operation

3.5 Gear selection by the electronics

3.6 Gear selection by driver

3.7 Emergency shift on transmission with Telligent shifting

3.8 Perform emergency shift

3.8.1 Emergency shift with emergency switch

3.8.2 Emergency shift when the vehicle is stationary

4. Programming Procedure

GMK 5100 Gear Control System April 2000 1

Deutsche Grove

1. GMK 5100 Gear Control System

1.1 The GMK 5100 is equipped with a pneumo-electronically operated 16-speed G240-16

gearbox. Gears can be preselected manually or automatically. During emergency

service, gears are selected pneumatically.

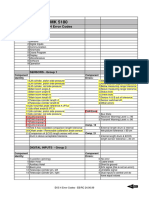

1.2 Overview of gears selection mechanical: Fig 1

Fig. 2

Fig. 3

Fig. 1

5

4

5

3 2

1 Central plug X 29

2 Solenoid GV Y29/Y30

3 Gate solenoid valve Y33/34

4 Sensor split B62

5 Sensor Range B63

6 Solenoid GP Y31/32

7 Sensor Gate B61

GMK 5100 Gear Control System April 2000 2

Deutsche Grove

Fig. 2

4

2 3

1 Gear sensor B 60

2 Gear solenoids Y35/Y36

3 Gear solenoids Y37/Y38

4 Countershaft speed sensor B 3

5 Sensor Clutch B2

Fig. 3

1 Output speed sensor B 57

GMK 5100 Gear Control System April 2000 3

Deutsche Grove

2. Gear and clutch

2.1 Gear and clutch with Telligent automatic gear change

The Telligent automatic gear change is a system, which allows the crane to be started and its

gears changed with the engine, dry clutch and gearbox without having to activate a clutch

pedal. The gears can either be shifted manually by the driver via a transmitter or automatically

by the electronic control system.

2.2 Components of the Telligent automatic gear change

• Telligent gear shift

• Telligent engine system comprising:

• drive control system FR (FMR) and

• engine control system MR (PLD) including unit pump cylinders

• clutch control system comprising

• clutch control KS(MKR) and

• clutch operation KB(EMK), which disengages the clutch

• automatic gear selection AG(AGE).

The electronics FMR, GS(EPS), KS and AG communicate equally via a high-speed bus (high-

speed CAN); FMR and PLD as well as KS and KB are connected to one another via separate

bus systems (low-speed CAN).

When emergency service is activated, the electrical operation of the clutch is switched off and

is activated directly via a clutch pedal via a safety valve.

2.3 Operating conditions

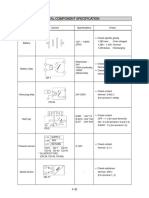

The KS electronics control the logical linking of the three components engine, clutch and

transmission depending on the travelling condition, with due regard to the input variables and

signals (from the transmitter, position of the accelerator, speeds, etc.). Fig. 1

2.3.1 Road drive (constant speed)

In this travel condition, during the on-road driving, the nominal value for the engine torque is

determined directly by the accelerator via the FMR, the clutch is closed.

2.3.2 Starting

The clutch is engaged in a controlled manner according to the torque setting of the

accelerator, during which time the engine is kept at idling speed. Please see fig. 2 for details

about the control operation.

GMK 5100 Gear Control System April 2000 4

Deutsche Grove

2.3.3 Gear shift

After a gear request from the driver (with gear shift selector) or the system (automatic gear

selection), the combination – engine and clutch – is just controlled in time by the transmission

electronics. The output speed is automatically adjusted to the transmission input rate via the

output speed control, fig. 3.

The automatic gear selection determines the respective gear depending on the travel

condition, output speed, etc. The lowest possible fuel consumption is thereby striven for at

constant speed. Overspeeds and excessively low speeds as well as pendulum shifts are

avoided. Fig. 4 shows the basic course of this process.

If the “brakes” pilot lamp illuminates, the driver must activate the brake pedal, giving the

electronics a chance to change down.

The clutch subsystem

Fig. 1 Protection/Emergency system

Actuator

GMK 5100 Gear Control System April 2000 5

Deutsche Grove

Fig. 2 Low gear

Fig. 3 Gear shift

GMK 5100 Gear Control System April 2000 6

Deutsche Grove

Fig. 4

Automatic gear selection

Acquisition of

measuring data

(via CAN)

Accelerator Vehicle

Speed

Output speed

condition

FR Engine torque Shift

routines

Vehicle

weight Traction

Actual gear upshift Shift

Gradient

Input

of road

philosophy

GS speed

Clutch path Changing Delay in nominal

down gear Shifting

Nominal

gear

ABS signal Driver’s Thrust upshift Fade out of

BS ASR signal wish nominal gear

Speed VA

Thrust

downshift

Position of the

RS retarder lever

GMK 5100 Gear Control System April 2000 7

Deutsche Grove

3. Gear selector

3.1 Gear selector

2 5

3

6

1

8

4

7

1 Control key

2 Change down gear / reverse gear

3 Upshift gear / forward gear

4 Neutral key

5 Change down/Reverse gear

6 Upshift / forward gear

7 Splitter

8 Automatic/Manual operation switch

3.2 Starting

To start, only 1st to 4th gears can be selected from Neutral (N).

Low gears =

-1st gear = Press control key and move gearshift lever forwards.

-2nd gear = Move gearshift lever forwards.

-3rd gear = Move gearshift lever forwards and release. Press control key and

move gearshift lever forwards a second time.

-4th gear = Move gearshift lever forwards. Release gearshift lever and

move it forwards a second time

GMK 5100 Gear Control System April 2000 8

Deutsche Grove

Preselecting low gear:

- Activate gearshift lever, control key and splitter and release. The low gear selected will

flash on the display. If a low gear is preselected from Neutral (N) when the vehicle is

stationary or the service brake or parking brake is activated, the preselection will be stored

for 2 minutes (for 10 seconds if the service/parking brake is released). If the

service/parking brake is activated during the time the preselection is stored, the storage

time will be extended to 2 minutes.

- Disengage clutch, the gear is shifted to the selected low gear and this is shown on the

display. Reverse and Neutral cannot be preselected.

Changing low gear:

- If a low gear is to be changed, activate the Splitter (or control key and gearshift lever)

again from the mid-position (normal position).

Cancel preselection of low gear:

- Activate neutral key

Selecting operating mode

The driver can choose between two operating modes (automatic/manual).

3.3 Automatic operation

In automatic operation, the optimum gear at any one time is determined and selected

according to the travelling condition, the position of the accelerator and the operating

condition of the engine, etc. The Telligent automatic gear change automatically controls the

clutch operation and gear shift.

When the vehicle is stationary and the service brake or parking brake is activated:

- Press and hold the control key on the gearshift lever and move the gearshift lever forwards

or backwards (reverse).

1st - 4th gears can be selected.

- Release brakes and activate accelerator. The vehicle starts.

Upshift

- Replace with Light acceleration: Upshift at low output speed.

- Replace with heavy acceleration: Upshift at high output speed.

Changing down

Gear shifts in the low gears depend on the position of the accelerator.

Stopping

When the vehicle is stopping, the clutch is automatically disengaged shortly before the idle

speed is reached. When the vehicle is stationary, a suitable low gear is automatically selected.

GMK 5100 Gear Control System April 2000 9

Deutsche Grove

3.4 Manual operation

In manual operation the driver can choose whether to have gears selected by the electronics or

whether to select them himself. The Telligent automatic gear change automatically controls

the clutch operation and the gear shift.

When starting, only the 1st to 4th gears can be selected from Neutral (N).

If the vehicle is stationary and the service brake or parking brake is selected

- Press and hold control key on the gearshift lever and move gearshift lever forwards or

backwards (reverse). The gear is automatically shifted to the 2nd gear of the fast speed

group (every gear has a low speed and a fast speed group).

Changing low gear:

The low gear can be changed by activating the control key and gearshift lever, the

gearshift lever or the Splitter.

- Release brakes and activate accelerator. The vehicle starts.

Gear shift

3.5 Gear selection by the electronics (EPS selection)

The driver determines the shift direction by activating the gearshift lever. The electronics

determine the suitable gear level (nominal gear) for the shift direction selected. The nominal

gear depends on the operating conditions (travelling speed, vehicle loading, position of

accelerator, etc.)

Shift direction:

- Shift direction forwards = upshift

- Shift direction backwards = changing down

If a warning buzzer sounds, no downshift will be made. The permissible output speed has

been exceeded.

The gear can only be shifted in the selected shift direction.

Shift

- Operate gearshift lever. The shift is completed when the selected gear level is indicated on

the display.

3.6 Gear selection by driver

The driver determines the shift direction and the gear level by activating the gearshift lever

and control key or the Splitter.

Shift direction and speed level

Upshift:

By ½ gear = Move Splitter upwards.

- By 1 gear = Press and hold control key and move gearshift lever backwards.If the

warning buzzer sounds, no downshift or only a limited downshift will be made. The

permissible output speed has been exceeded.

GMK 5100 Gear Control System April 2000 10

Deutsche Grove

Neutral (N)

The gear can only be shifted to Neutral if the gearshift lever and Splitter are in the mid-

position (normal position).

- Confirm neutral button.

The shift is completed when “N” appears on the display.

Stopping

When the vehicle is stopping, the clutch is automatically disengaged shortly before the idle

speed is reached. The vehicle stays in the same gear, in which it is stopped.

Note

- If the vehicle is stopped when it is in 5th to 8th gear, it cannot start again in this gear. Select

a suitable low gear from 1st to 4th gear to start.

- If the vehicle stands for more than 90 seconds with the engine running, the gear is

automatically shifted to Neutral (N). After 60 seconds “Neutral” flashes on the display. If

the accelerator is touched briefly, the vehicle remains in the selected low gear for a further

90 seconds.

3.7 Emergency shift on transmission with Telligent shifting

Release emergency clutch pedal.

Pull release lever for

emergency clutch pedal.

Emergency clutch pedal (retracted)

???eingeklappt)

Release lever for

emergency clutch pedal

Emergency clutch pedal

(extended)

GMK 5100 Gear Control System April 2000 11

Deutsche Grove

3.8 Perform emergency shifts:

1

G

2

R

NL

NH

1 = Tilt lid upwards

G = Normal position (Neutral)

2 = 2nd gear

NL = Neutral (slow upshift group)

NH = Neutral (fast upshift group)

5. = 5th gear

R = Reverse

3.8.1 Emergency shift with emergency switch

Swing up cover of the emergency switch. The emergency switch is in the normal position and

is not operative:

- During travelling.

- If the key in the steering wheel lock is in the travelling position and no fault (emergency

clutch prompt symbol) is shown.

Note!

- If the display indicates a fault (prompt for emergency clutch), stop vehicle and perform

emergency shift.

3.8.2 Emergency shift when the vehicle is stationary:

- Press clutch pedal right down and hold.

- Start engine.

- Shift gear

Neutral:

If a gear is selected, push emergency switch down from “G” position and hold for approx. 1

second. Release emergency switch.

GMK 5100 Gear Control System April 2000 12

Deutsche Grove

2nd gear:

Push emergency switch down from “G” position, turn clockwise to the 2 nd gear marker and

hold for approx. 1 second. Release emergency switch.

5th gear:

Push emergency switch down from the “2nd gear” position, turn clockwise to the “NL” marker

and hold for approx. 2 seconds. Release emergency switch.

Push emergency switch down from the “NL” position, turn clockwise to the “NH” marker and

hold for approx. 2 seconds. Release emergency switch.

Push emergency switch down from the “NH” position, turn clockwise to the “5th gear” marker

and hold for approx. 1 second. Release emergency switch.

Reverse:

Push emergency switch down from the “G” position, turn clockwise to the „r. gear“ marker

and hold for approx. 1 second. Release emergency switch.

- Slowly release clutch pedal.

Gear shift

Shifting from 2 nd to 5th gear (while travelling on a level road):

- Press clutch pedal right down and hold.

Push emergency switch down from the “2nd gear” position, turn clockwise to the “NL” marker

and hold for approx. 2 seconds. Release emergency switch.

Push emergency switch down from the “NL” position, turn clockwise to the “NH” marker and

hold for approx. 2 seconds. Release emergency switch.

Push emergency switch down from the “NH” position, turn clockwise to the “5th gear” marker

and hold for approx. 1 second. Release emergency switch.

- Slowly release clutch pedal.

Shifting from 5th to 2nd gear:

Only when the vehicle is stationary with the engine running (idling speed)

- Press clutch pedal right down and hold.

Push emergency switch down from the “5th gear” position, turn clockwise to the “NH” marker

and hold for approx. 2 seconds. Release emergency switch.

Push emergency switch down from the “NL” position, turn clockwise to the “NH” marker and

hold for approx. 2 seconds. Release emergency switch.

Push emergency switch down from the “NL” position, turn clockwise to the “2nd gear” marker

and hold for approx. 1 second. Release emergency switch.

- Slowly release clutch pedal.

GMK 5100 Gear Control System April 2000 13

Deutsche Grove

4. GMK 5100

Transmission

Programming Procedure

The programming is necessary, if the following items are exchanged:

Direction sensors, master cylinder, slave cylinder, protection valve, KB (EMK), electronic KS

(MKR)

• Ignition off

• Press both buttons (function and neutral button) with left hand

• Switch on ignition with right hand

• If „N“ flashes, start engine, 02K21 is to be operated by hand

• If „N“ lights up again, the programming procedure is finished.

During the entire programming procedure, the buttons are to be pressed !!

If the programming procedure cannot be carried out, the emergency pedal

is to be turned out.

• Ignition off

• Press emergency pedal

• Press both buttons (function and neutral button) with left hand

• Switch on ignition with right hand

• If „N“ flashes, start engine, 02K21 is to be operated by hand

• If buzzer sounds, release emergency pedal

• If buzzer sounds, press emergency pedal

• Repeat this press and release procedure until “N” lights up again

• Now the programming procedure is finished.

Programming of electronic KS with Minidiag 2

• Connect Minidiag 2

• Select electronic KS and call “Routine“

• Follow the on-screen instructions

Attention: The vehicle moves !

For that reason, at least 5m space is necessary in

front of the vehicle!

GMK 5100 Gear Control System April 2000 14

You might also like

- Carrier Malfunctions - EU PDFDocument44 pagesCarrier Malfunctions - EU PDFrenat100% (1)

- EKS 5 Sensor Adjustment GuideDocument17 pagesEKS 5 Sensor Adjustment Guideemail4mobile100% (9)

- DC G240 eDocument14 pagesDC G240 eHany Mohamed100% (11)

- ECOS Training NotesDocument13 pagesECOS Training Notesazamen100% (3)

- ECOS Error Codes 5130-1Document23 pagesECOS Error Codes 5130-1Benjamín Sancho Contreras100% (4)

- Ecos System Description GMK 4075: Error CodesDocument31 pagesEcos System Description GMK 4075: Error CodesMohamed RashedNo ratings yet

- ECOS 1 PresentationDocument87 pagesECOS 1 PresentationLuis Jose Lloban100% (1)

- Superstructure Malfunctions - EUDocument78 pagesSuperstructure Malfunctions - EUazamenNo ratings yet

- ECOS Data Report 3063Document13 pagesECOS Data Report 3063Sarra Chouchene0% (1)

- ErrorCodes 5220 V01 06Document24 pagesErrorCodes 5220 V01 06Sarra Chouchene100% (1)

- Service Technicians Information Supplement: Revised January 1997Document48 pagesService Technicians Information Supplement: Revised January 1997Lucas Romero50% (2)

- BMK 1055 1 enDocument82 pagesBMK 1055 1 enDavidVazquez100% (8)

- Eks 83Document4 pagesEks 83leo100% (4)

- Grove GMK Training PDFDocument297 pagesGrove GMK Training PDFnurfathoni100% (4)

- DS350 Error CodesDocument12 pagesDS350 Error Codesefrain revillaNo ratings yet

- GMK 5100 ECOS Error Codes V2Document9 pagesGMK 5100 ECOS Error Codes V24g lite100% (1)

- EKS4 Simulation - DINDocument16 pagesEKS4 Simulation - DINazamen0% (2)

- ECOS Error Codes - 5220Document24 pagesECOS Error Codes - 5220Benjamín Sancho Contreras100% (3)

- Home Page Error Code GuideDocument31 pagesHome Page Error Code GuideArsène TIA MANNo ratings yet

- EKS 3 - Programming: Step 1: Press The ConfirmDocument4 pagesEKS 3 - Programming: Step 1: Press The ConfirmCarlos Leonardo Rojas Campiño100% (1)

- Allison - MD - 3066 - P V2Document38 pagesAllison - MD - 3066 - P V2ncir67% (3)

- AC - 300 Training ManualDocument632 pagesAC - 300 Training ManualPrakash Vasudevan100% (1)

- EKS4 Error CodesDocument6 pagesEKS4 Error Codesvivek kashyapNo ratings yet

- Lec 002527108 EngDocument248 pagesLec 002527108 EngIvailo Zapryanov100% (1)

- Wiring Carrier - ENDocument118 pagesWiring Carrier - ENFarai Chamisa100% (3)

- GMK 5220 ManualDocument3 pagesGMK 5220 ManualCarlos Riffo100% (3)

- ATF110G-5 EM4 1 Specifications 022015Document52 pagesATF110G-5 EM4 1 Specifications 022015Mulatua Sirait100% (1)

- SuspensionDocument14 pagesSuspensionDaniel Castillo Peña100% (2)

- Changing EST units and removing telescope cylinderDocument4 pagesChanging EST units and removing telescope cylinderrodolfof_31100% (1)

- GMK Schematic HandbookDocument55 pagesGMK Schematic HandbookYukki Badamgarav100% (10)

- LTM 1070 - 1Document655 pagesLTM 1070 - 1Cristyan GabrielNo ratings yet

- دائرة المشحمة لونش مانتوكDocument138 pagesدائرة المشحمة لونش مانتوكMohamed Rashed100% (1)

- ECOS System Error Code GuideDocument23 pagesECOS System Error Code Guidemohamed100% (1)

- LTM 1200 Liebherr Cranes: 1.1 Fill Quantities For Crane ChassisDocument1 pageLTM 1200 Liebherr Cranes: 1.1 Fill Quantities For Crane ChassispurushmicroNo ratings yet

- Tadano AML M1 M2-TR (MkII Connection Instructions)Document5 pagesTadano AML M1 M2-TR (MkII Connection Instructions)Daniel AguirreNo ratings yet

- 12as2302 - 3002 - 16as2602so - enDocument2 pages12as2302 - 3002 - 16as2602so - enStanislav Sultanov67% (6)

- LTM 1080 PT2Document20 pagesLTM 1080 PT2William VillanuevaNo ratings yet

- Suspension Presentation PDFDocument98 pagesSuspension Presentation PDFALI MHWA100% (3)

- Super HydraulicDocument17 pagesSuper HydraulicDaniel Castillo Peña100% (2)

- Training Information LTM 1300-1Document94 pagesTraining Information LTM 1300-1Raphael92% (13)

- ECOS Display FunctionsDocument95 pagesECOS Display FunctionsAhmed Hassan Abo Asem100% (11)

- Liccon II Components: Progress in MotionDocument25 pagesLiccon II Components: Progress in MotionAly AbdelhamedNo ratings yet

- ECOS Components Identity, Function and DescriptionDocument25 pagesECOS Components Identity, Function and DescriptionEduardo Alves80% (5)

- Carrier Hyd Schematic - 1 - With GraphicsDocument1 pageCarrier Hyd Schematic - 1 - With GraphicsAhmed Hassan Abo AsemNo ratings yet

- AC100 Training Manual Ver 2 0 PDFDocument382 pagesAC100 Training Manual Ver 2 0 PDFما ضاقت الا لتفرج80% (5)

- Users Manual: SN1676-1CB Canbus Control SystemDocument26 pagesUsers Manual: SN1676-1CB Canbus Control Systemابراهيم حافظNo ratings yet

- GMK5220 Super Pressure AdjustmentsDocument9 pagesGMK5220 Super Pressure AdjustmentsAngel Dlsg100% (2)

- SHB LTM 1030-2 Uw-09 899500808 enDocument36 pagesSHB LTM 1030-2 Uw-09 899500808 enHoracio Berni100% (2)

- Grove Master Tech PubsDocument7 pagesGrove Master Tech PubsDenNo ratings yet

- Manual TransmissionDocument9 pagesManual TransmissionKatu2010No ratings yet

- Errorcodes EKS5 enDocument20 pagesErrorcodes EKS5 engrineldo8480% (5)

- Wheel Alignment Spur Einstellen Netviewer EnglischDocument31 pagesWheel Alignment Spur Einstellen Netviewer EnglischMTK2016No ratings yet

- GMK5100 OperationDocument666 pagesGMK5100 Operationvasil313100% (1)

- Funcionamieno TransmisionDocument9 pagesFuncionamieno TransmisionOrestes Ram100% (1)

- 09ab 2 PDFDocument73 pages09ab 2 PDFAnonymous muN2iBLJBNo ratings yet

- AllisonDocument9 pagesAllisonDaniel Castillo Peña100% (5)

- 22B Automated Manual TransmissionDocument10 pages22B Automated Manual TransmissionmanhNo ratings yet

- GS DescDocument4 pagesGS DescCostel CaramanNo ratings yet

- 350 GB 0102Document106 pages350 GB 0102silenkodmitrij33No ratings yet

- Sistemul SIMOS 3 4 Motor ALZ PDFDocument37 pagesSistemul SIMOS 3 4 Motor ALZ PDFAngel Julian HernandezNo ratings yet

- Getting Started PDFDocument14 pagesGetting Started PDFCeliz MedinaNo ratings yet

- Transmicion Hyundai H439CDocument17 pagesTransmicion Hyundai H439CYoel Flores LipaNo ratings yet

- GROUP 2 CHECKS AND TROUBLESHOOTINGDocument8 pagesGROUP 2 CHECKS AND TROUBLESHOOTINGthierrylindoNo ratings yet

- WX185 Ir1328ccgbDocument20 pagesWX185 Ir1328ccgbالمهندسوليدالطويلNo ratings yet

- CAT 345 B AGS 01 Up Hydraulic SchematicDocument7 pagesCAT 345 B AGS 01 Up Hydraulic SchematicGanapati Hegde100% (6)

- Tightening Torque for Excavator ComponentsDocument3 pagesTightening Torque for Excavator ComponentsالمهندسوليدالطويلNo ratings yet

- Cs533e BzeDocument2 pagesCs533e Bzellesli1778% (9)

- Grgroup 2oup Engine Speed & Stall RPMDocument1 pageGrgroup 2oup Engine Speed & Stall RPMالمهندسوليدالطويل100% (1)

- Group 3 Tests and AdjustmentsDocument2 pagesGroup 3 Tests and AdjustmentsYoel Flores LipaNo ratings yet

- 1. الخطوط العرضيهDocument3 pages1. الخطوط العرضيهالمهندسوليدالطويلNo ratings yet

- Komatsu AcronymsDocument7 pagesKomatsu Acronymsالمهندسوليدالطويل100% (4)

- Plano Hydo InteractivoDocument11 pagesPlano Hydo InteractivoalexNo ratings yet

- Efficiently Remove and Install a Group 8 Turning JointDocument5 pagesEfficiently Remove and Install a Group 8 Turning Jointdeniden2013No ratings yet

- Rexroth A2VDocument20 pagesRexroth A2VالمهندسوليدالطويلNo ratings yet

- Section 8 Disassembly and AssemblyDocument4 pagesSection 8 Disassembly and Assemblydeniden2013No ratings yet

- HD 2 109c Caterpillar 3406eDocument2 pagesHD 2 109c Caterpillar 3406eالمهندسوليدالطويلNo ratings yet

- Komatsu PW130 PDFDocument24 pagesKomatsu PW130 PDFالمهندسوليدالطويلNo ratings yet

- Maintenance IntervalsDocument67 pagesMaintenance IntervalsHector Sanchez GarciaNo ratings yet

- 3406E 550hpDocument2 pages3406E 550hpالمهندسوليدالطويلNo ratings yet

- Group 3 Electrical Component SpecificationDocument8 pagesGroup 3 Electrical Component Specificationdeniden2013No ratings yet

- Pegj0039 00Document12 pagesPegj0039 00Okto SuyonoNo ratings yet

- BP 2632 GBDocument24 pagesBP 2632 GBالمهندسوليدالطويلNo ratings yet

- Advantages of Gradall excavators over conventional modelsDocument1 pageAdvantages of Gradall excavators over conventional modelsالمهندسوليدالطويلNo ratings yet

- Komatsu PW130 PDFDocument24 pagesKomatsu PW130 PDFالمهندسوليدالطويلNo ratings yet

- PowerShot D30 Spec Sheet EM FINAL Tcm84-1130924Document3 pagesPowerShot D30 Spec Sheet EM FINAL Tcm84-1130924المهندسوليدالطويلNo ratings yet

- BSF52 XXDocument2 pagesBSF52 XXالمهندسوليدالطويلNo ratings yet

- Putzmeister Wareparts Offer UAEDocument1 pagePutzmeister Wareparts Offer UAEالمهندسوليدالطويلNo ratings yet

- Section 1 GeneralDocument10 pagesSection 1 GeneralالمهندسوليدالطويلNo ratings yet

- ZF SolenoidsDocument4 pagesZF SolenoidsDavid Rosado100% (3)

- BSF52 XXDocument2 pagesBSF52 XXالمهندسوليدالطويلNo ratings yet

- TBEM CII Exim Bank Award ComparisonDocument38 pagesTBEM CII Exim Bank Award ComparisonSamNo ratings yet

- Appetizers Fire-Grilled Gourmet Burgers: Red Robin'S Finest Burgers Red'S Tavern MenuDocument2 pagesAppetizers Fire-Grilled Gourmet Burgers: Red Robin'S Finest Burgers Red'S Tavern MenufruitfuckNo ratings yet

- Populist Movement (Anant)Document7 pagesPopulist Movement (Anant)Siddhi JoshiNo ratings yet

- Plastic RecyclingDocument14 pagesPlastic RecyclingLevitaNo ratings yet

- What Is InterpolDocument5 pagesWhat Is InterpolJimmy Jr Comahig LapeNo ratings yet

- Human PhysiologyDocument4 pagesHuman Physiologyshahzain92No ratings yet

- Dof Omm Ss Skirting Sk-02Document8 pagesDof Omm Ss Skirting Sk-02Ideal DesignerNo ratings yet

- 14.4 Demonstration of Leak Before Break Design Criteria For Pipes of PHT System PHWRDocument2 pages14.4 Demonstration of Leak Before Break Design Criteria For Pipes of PHT System PHWRRoman KrautschneiderNo ratings yet

- Adverse Drug Reactions in A ComplementaryDocument8 pagesAdverse Drug Reactions in A Complementaryrr48843No ratings yet

- Eslit-Vinea-LA 03 Task #1-4Document11 pagesEslit-Vinea-LA 03 Task #1-4darkNo ratings yet

- Toyota-HiAce 2011 EN Manual de Taller Diagrama Electrico 4fdf088312Document4 pagesToyota-HiAce 2011 EN Manual de Taller Diagrama Electrico 4fdf088312Oscarito VázquezNo ratings yet

- Watson Studio - IBM CloudDocument2 pagesWatson Studio - IBM CloudPurvaNo ratings yet

- Lista 30 JulioDocument2 pagesLista 30 JulioMax Bike MartinezNo ratings yet

- Vào 10 - Sở L NG Sơn 2022-2023Document5 pagesVào 10 - Sở L NG Sơn 2022-2023Lan HuongNo ratings yet

- Underpinning Methods, Procedure and ApplicationsDocument10 pagesUnderpinning Methods, Procedure and ApplicationsShivaun Seecharan0% (1)

- Boast 98Document19 pagesBoast 98jghleivaNo ratings yet

- CT2003 LevelMeasurementP1 TechReport1 1Document27 pagesCT2003 LevelMeasurementP1 TechReport1 1Vignesh RajanNo ratings yet

- L5 Isomerism 3Document16 pagesL5 Isomerism 3Cheng FuNo ratings yet

- Easa Ad 2023-0133 1Document6 pagesEasa Ad 2023-0133 1Pedro LucasNo ratings yet

- Praveen Verma Auto CAD IntershipDocument15 pagesPraveen Verma Auto CAD IntershipPraveen vermaNo ratings yet

- User Manual With FAQs - Sales Invoice For Petrol PumpsDocument10 pagesUser Manual With FAQs - Sales Invoice For Petrol PumpsRavindra MittalNo ratings yet

- Revised Pharmacophore Model For 5 HT2A Receptor Antagonists Derived From The Atypical Antipsychotic Agent RisperidoneDocument14 pagesRevised Pharmacophore Model For 5 HT2A Receptor Antagonists Derived From The Atypical Antipsychotic Agent RisperidoneLUCAS OYANEDERNo ratings yet

- Vandergrift - Listening, Modern Theory & PracticeDocument6 pagesVandergrift - Listening, Modern Theory & PracticeKarolina CiNo ratings yet

- Volume Meters Models 962 and 963 Series CDocument8 pagesVolume Meters Models 962 and 963 Series CVictor Edy Facundo DelzoNo ratings yet

- Manual For Master Researchpproposal - ThesisDocument54 pagesManual For Master Researchpproposal - ThesisTewfic Seid100% (3)

- Physics Chapter on Motion and Force EquationsDocument2 pagesPhysics Chapter on Motion and Force EquationsMalikXufyanNo ratings yet

- Technology Unit 1 UTUDocument19 pagesTechnology Unit 1 UTUDaNo ratings yet

- W17155 PDF EngDocument7 pagesW17155 PDF Engluis alfredo lachira coveñasNo ratings yet

- Neem Oil Insect Repellent FormulationDocument12 pagesNeem Oil Insect Repellent FormulationnityaNo ratings yet

- Strategies and Methods For Cloud MigrationDocument10 pagesStrategies and Methods For Cloud MigrationVel_stNo ratings yet