Professional Documents

Culture Documents

Spur Gears-Lewis Formula

Uploaded by

Dedi KartiwaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spur Gears-Lewis Formula

Uploaded by

Dedi KartiwaCopyright:

Available Formats

ENGINEERING INFORMATION

SPUR GEARS

LEWIS FORMULA (Barth Revision) TABLE II–VALUES OF SAFE STATIC STRESS (s)

Gear failure can occur due to tooth breakage (tooth stress) or

surface failure (surface durability) as a result of fatigue and Material (s) Lb. per Sq. In.

wear. Strength is determined in terms of tooth-beam stresses Plastic ........................................................................ 5000

for static and dynamic conditions, following well established for- Bronze ........................................................................ 10000

mula and procedures. Satisfactory results may be obtained by Cast Iron ..................................................................... 12000

.20 Carbon (Untreated) ................................... 20000

{

the use of Barth’s Revision to the Lewis Formula, which consid-

ers beam strength but not wear. The formula is satisfactory for .20 Carbon (Case-hardened) .......................... 25000

commercial gears at Pitch Circle velocities of up to 1500 FPM. It Steel .40 Carbon (Untreated) ................................... 25000

is this formula that is the basis for all Boston Spur Gear ratings. .40 Carbon (Heat-treated)............................... 30000

.40 C. Alloy (Heat-treated) .............................. 40000

METALLIC SPUR GEARS

W = SFY 600

Max. allowable torque (T) that should be imposed on a gear

P 600 + V

W = Tooth Load, Lbs. (along the Pitch Line) will be the safe tooth load (W) multiplied by D or T = W x D

2 2

S = Safe Material Stress (static) Lbs. per Sq. In. (Table II) The safe horsepower capacity of the gear (at a given RPM) can

F = Face Width, In.

Y = Tooth Form Factor (Table I) be calculated from HP = T x RPM or directly from (W) and (V);

63,025

P = Diametral Pitch

HP = WV

D = Pitch Diameter

V = Pitch Line Velocity, Ft. per Min. = .262 x D x RPM 33,000

For NON-METALLIC GEARS, the modified Lewis Formula For a known HP, T = 63025 x HP

RPM

shown below may be used with (S) values of 6000 PSI for

Phenolic Laminated material.

W = SFY 150 + .25

P 200 + V

TABLE I TOOTH FORM FACTOR (Y)

14-1/2° Full 20° Full

Number of Teeth Depth Involute Depth Involute

10 0.176 0.201

11 0.192 0.226

12 0.210 0.245

13 0.223 0.264

14 0.236 0.276

15 0.245 0.289

16 0.255 0.295

17 0.264 0.302

18 0.270 0.308

19 0.277 0.314

20 0.283 0.320

22 0.292 0.330

24 0.302 0.337

26 0.308 0.344

28 0.314 0.352

30 0.318 0.358

32 0.322 0.364

34 0.325 0.370

36 0.329 0.377

38 0.332 0.383

40 0.336 0.389

45 0.340 0.399

50 0.346 0.408

55 0.352 0.415

60 0.355 0.421

65 0.358 0.425

70 0.360 0.429

75 0.361 0.433

80 0.363 0.436

90 0.366 0.442

100 0.368 0.446

150 0.375 0.458

200 0.378 0.463

300 0.382 0.471

Rack 0.390 0.484

Gear Catalog 139

®

You might also like

- Working of TransformerDocument48 pagesWorking of Transformersudhir100% (1)

- Polymer-Based Bearing Materials The Role of Fillers and Fibre ReinforcementDocument7 pagesPolymer-Based Bearing Materials The Role of Fillers and Fibre Reinforcementlessard1620No ratings yet

- Grebe - Capacitor Switching and Its Impact On Power Quality Draft Paper 0000 PDFDocument7 pagesGrebe - Capacitor Switching and Its Impact On Power Quality Draft Paper 0000 PDFrmendozaing100% (1)

- Drive Selection of Rolling MillsDocument4 pagesDrive Selection of Rolling MillsCihan OzturkNo ratings yet

- Billet Defects - Off-Corner Cracks Formation, Prevention and EvolutionDocument33 pagesBillet Defects - Off-Corner Cracks Formation, Prevention and EvolutionJorge Madias0% (1)

- Working Principle of DC MotorDocument6 pagesWorking Principle of DC MotorMosabNo ratings yet

- Mill Scale Safety Data SheetDocument7 pagesMill Scale Safety Data SheetNeni RahayuNo ratings yet

- Water Treatment Residuals Management Fact SheetDocument4 pagesWater Treatment Residuals Management Fact SheetWil OrtizNo ratings yet

- Everflow Turbine Leaflet 1Document2 pagesEverflow Turbine Leaflet 1Bidyapati BiswalNo ratings yet

- Effect of Harmonics On Power FactorDocument5 pagesEffect of Harmonics On Power FactorRamalingeswar JtNo ratings yet

- Screw Size Allen Key Size, S A BDocument3 pagesScrew Size Allen Key Size, S A BНикола КолаковићNo ratings yet

- Twenty-Five Years of Experience in Discussing Rolls and Rolling Technology PDFDocument12 pagesTwenty-Five Years of Experience in Discussing Rolls and Rolling Technology PDFfahrgeruste3961No ratings yet

- Motor Duty TypesDocument3 pagesMotor Duty TypesVijay KumarNo ratings yet

- Predictive Maintainance Using Thermal ImagingDocument28 pagesPredictive Maintainance Using Thermal ImagingGeetha_Sulaksh_9338No ratings yet

- ABB-DMI Type DC Machines Operating and Maintenance InstructionsDocument48 pagesABB-DMI Type DC Machines Operating and Maintenance InstructionsElafanNo ratings yet

- Abrasive ProcessesDocument63 pagesAbrasive ProcessesmohdhmNo ratings yet

- GOLDEN Deep Well Turbine PumpsDocument3 pagesGOLDEN Deep Well Turbine PumpskfctcoNo ratings yet

- NTS TESCO Junior Engineer - SDO Test - 2019 PDFDocument11 pagesNTS TESCO Junior Engineer - SDO Test - 2019 PDFjunaid ahmedNo ratings yet

- Wire Rod Surface DefectsDocument11 pagesWire Rod Surface DefectsNicolas ValleNo ratings yet

- Thermal Analysis of MaterialsDocument17 pagesThermal Analysis of MaterialsHamzahSardar100% (1)

- Differential Pressure TransmitterDocument14 pagesDifferential Pressure TransmitterZainab KadhemNo ratings yet

- Roll Breakage DetectionDocument7 pagesRoll Breakage Detectionzubair ahmadNo ratings yet

- Failure Analysis of Sheared Shaft of A Brine Recycle Pump...Document12 pagesFailure Analysis of Sheared Shaft of A Brine Recycle Pump...Pd RarNo ratings yet

- Grinding Wheel Selection FactorsDocument15 pagesGrinding Wheel Selection Factorsmaulikgadara100% (1)

- Society For Maintenance and Reliability Professionals Body of Knowledge Guided StudyDocument1 pageSociety For Maintenance and Reliability Professionals Body of Knowledge Guided StudyBruno Saracol VenturaNo ratings yet

- The Complete Guide to Hot Rolling of SteelDocument13 pagesThe Complete Guide to Hot Rolling of SteelAndréNo ratings yet

- Professor Induction Column on Induction Coil FailuresDocument6 pagesProfessor Induction Column on Induction Coil FailuresajaydevbNo ratings yet

- Reheating Furnace.3Document8 pagesReheating Furnace.3Zulfa Ilham BasyarahilNo ratings yet

- Fuels and CombustionDocument13 pagesFuels and CombustionHamza Amin100% (1)

- Bearing HeaterDocument5 pagesBearing HeaterAnand KatariyaNo ratings yet

- Scanning probe microscopy techniques and principlesDocument4 pagesScanning probe microscopy techniques and principlesbabakNo ratings yet

- Spur Gear Design 1Document16 pagesSpur Gear Design 1Nagu SriramaNo ratings yet

- Continuous Casting TheoryDocument12 pagesContinuous Casting Theoryyash_ganatra100% (1)

- Principle Angle Single Point Cutting ToolsDocument16 pagesPrinciple Angle Single Point Cutting ToolsSoumik DasNo ratings yet

- SKF Thermal Imager TMTI 2Document2 pagesSKF Thermal Imager TMTI 2Catanescu Alexandru-LaurentiuNo ratings yet

- Types of GearsDocument22 pagesTypes of GearsAnonymous 2RbW9dNo ratings yet

- Harmonics and How They Relate To Power Factor - POWERFACDocument8 pagesHarmonics and How They Relate To Power Factor - POWERFACtatacpsNo ratings yet

- Guidelines for selecting flangesDocument6 pagesGuidelines for selecting flangesMohit BauskarNo ratings yet

- 03 - Rolling of MetalsDocument61 pages03 - Rolling of MetalsAbhishek SinhaNo ratings yet

- AC Drives Reliance ElectricDocument12 pagesAC Drives Reliance ElectricnmvikramNo ratings yet

- Complete CatalogDocument651 pagesComplete CatalogFernando EscriváNo ratings yet

- Basic Rolling Bearing TechnologyDocument75 pagesBasic Rolling Bearing TechnologyRobert Reyes100% (1)

- Tata 1-1 PDFDocument5 pagesTata 1-1 PDFManoj kumarNo ratings yet

- Reverse Osmosis and Ultra Filtration Class LectureDocument7 pagesReverse Osmosis and Ultra Filtration Class Lecturenabil100% (1)

- Engineering Drawing II Tutorial PDFDocument38 pagesEngineering Drawing II Tutorial PDFskumaranspNo ratings yet

- TESCO Junior Engineer TestDocument20 pagesTESCO Junior Engineer Testuzair ahmad100% (1)

- Induction Heating Parameters On Forging BilletDocument85 pagesInduction Heating Parameters On Forging BilletAnonymous VRspXsmNo ratings yet

- Coupling: Presentation by - Riyaz RafiqueDocument32 pagesCoupling: Presentation by - Riyaz RafiqueRiyazRobotics100% (2)

- Thermal AnalysisDocument18 pagesThermal AnalysisamitNo ratings yet

- Polymers in Sensor ApplicationsDocument68 pagesPolymers in Sensor ApplicationsAbc_scribdNo ratings yet

- Different Types of FlangesDocument11 pagesDifferent Types of Flangessambhav metalNo ratings yet

- The Iron Puddler My life in the rolling mills and what came of itFrom EverandThe Iron Puddler My life in the rolling mills and what came of itNo ratings yet

- Experimento Queda LivreDocument1 pageExperimento Queda LivrefelipeNo ratings yet

- Libro 1Document5 pagesLibro 1alonsninja10No ratings yet

- Flow Rate and Pressure Drop AnalysisDocument4 pagesFlow Rate and Pressure Drop Analysiskarla alcazar valenciaNo ratings yet

- Binder4 PDFDocument5 pagesBinder4 PDFMohamad RifaiNo ratings yet

- Grafik Hubungan Antara Regangan Dan Tegangan GeserDocument18 pagesGrafik Hubungan Antara Regangan Dan Tegangan GeserIvan HamdanyNo ratings yet

- Konversi Satuan HardnessDocument9 pagesKonversi Satuan HardnessFaiz NaufalNo ratings yet

- Software Exercise 1Document14 pagesSoftware Exercise 1MeraNo ratings yet

- 282 kW Glycol Chiller Package Budgetary QuotationDocument4 pages282 kW Glycol Chiller Package Budgetary QuotationDedi KartiwaNo ratings yet

- Progress Drawing 19 Des 2019Document1 pageProgress Drawing 19 Des 2019Dedi KartiwaNo ratings yet

- Cross Tee PDFDocument1 pageCross Tee PDFDedi KartiwaNo ratings yet

- Spek UboltDocument2 pagesSpek UboltRafiazis75No ratings yet

- Sheet Metal and Fiberglass Duct Fabrication TechniquesDocument71 pagesSheet Metal and Fiberglass Duct Fabrication TechniquesAnirudhreddy SafalNo ratings yet

- Form Registrasi Confined SpaceDocument1 pageForm Registrasi Confined SpaceDedi KartiwaNo ratings yet

- Form Registrasi Confined SpaceDocument1 pageForm Registrasi Confined SpaceDedi KartiwaNo ratings yet

- Why Not WyeDocument4 pagesWhy Not WyeDavid S. CastNo ratings yet

- Cross Tee PDFDocument1 pageCross Tee PDFDedi KartiwaNo ratings yet

- Mip-1900 Wing Seal Windlass Pusher Tensioner With Shear: Safety WarningsDocument2 pagesMip-1900 Wing Seal Windlass Pusher Tensioner With Shear: Safety WarningsDedi KartiwaNo ratings yet

- MicroVerb 4 - Program Chart PDFDocument2 pagesMicroVerb 4 - Program Chart PDFjokokompNo ratings yet

- Operation Manual: - 33 Immediately Usable EffectsDocument16 pagesOperation Manual: - 33 Immediately Usable EffectsDedi KartiwaNo ratings yet

- TDocument12 pagesTDedi KartiwaNo ratings yet

- Nas 1638Document2 pagesNas 1638ak_thimiriNo ratings yet

- Sound System Interconnection PDFDocument8 pagesSound System Interconnection PDFfsarkNo ratings yet

- Painting System UenoDocument1 pagePainting System UenoDedi KartiwaNo ratings yet

- QTN 005 TSRT PDFDocument1 pageQTN 005 TSRT PDFDedi KartiwaNo ratings yet

- TDocument12 pagesTDedi KartiwaNo ratings yet

- Modif Support Screw Conv 110-665 ModelDocument1 pageModif Support Screw Conv 110-665 ModelDedi KartiwaNo ratings yet

- Diagram Electrical HomeDocument1 pageDiagram Electrical HomeDedi KartiwaNo ratings yet

- Liquid Penetrant Inspection 35 Question Quiz: First Name Last NameDocument6 pagesLiquid Penetrant Inspection 35 Question Quiz: First Name Last NameDedi Kartiwa100% (1)

- SR13204 PDFDocument1 pageSR13204 PDFDedi KartiwaNo ratings yet

- Zick AnalysisDocument12 pagesZick AnalysisrksahayNo ratings yet

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraNo ratings yet

- Stainless steel tank specification and comparison chartDocument1 pageStainless steel tank specification and comparison chartDedi KartiwaNo ratings yet

- Piezometer Ring Flyer PDFDocument1 pagePiezometer Ring Flyer PDFDedi KartiwaNo ratings yet

- F. Dimensional Report MMC SCRUB PUMPDocument5 pagesF. Dimensional Report MMC SCRUB PUMPDedi KartiwaNo ratings yet

- (Process Industry Practices) Design of ASME B31.3Document24 pages(Process Industry Practices) Design of ASME B31.3aguiarv88100% (1)

- Engineering & Technical Ebooks CollectionDocument4 pagesEngineering & Technical Ebooks CollectionDedi KartiwaNo ratings yet

- 13 Fashion Studies Textbook XIDocument158 pages13 Fashion Studies Textbook XIMeeta GawriNo ratings yet

- NOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationDocument10 pagesNOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationNur AfiqahNo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet

- All Associates Warning Against ChangesDocument67 pagesAll Associates Warning Against Changesramesh0% (1)

- TransistorDocument1 pageTransistorXhaNo ratings yet

- GIS Arrester PDFDocument0 pagesGIS Arrester PDFMrC03No ratings yet

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Document11 pagesSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaNo ratings yet

- Elmeasure Solenoid Ates CatalogDocument12 pagesElmeasure Solenoid Ates CatalogSEO BDMNo ratings yet

- Cold Forging Process TutorialDocument28 pagesCold Forging Process TutorialpanyamnrNo ratings yet

- Victron MultiPlus 48 1200-13-16 Datasheet enDocument1 pageVictron MultiPlus 48 1200-13-16 Datasheet enBAHJARI AMINENo ratings yet

- ROPE TENSIONER Product-Catalog-2019Document178 pagesROPE TENSIONER Product-Catalog-2019jeedanNo ratings yet

- DSE61xx Configuration Suite Software Manual PDFDocument60 pagesDSE61xx Configuration Suite Software Manual PDFluisNo ratings yet

- National Advisory Committee For AeronauticsDocument36 pagesNational Advisory Committee For AeronauticsSamuel ChristioNo ratings yet

- Philips DVD Player SpecificationsDocument2 pagesPhilips DVD Player Specificationsbhau_20No ratings yet

- Lanegan (Greg Prato)Document254 pagesLanegan (Greg Prato)Maria LuisaNo ratings yet

- Statement of Compulsory Winding Up As On 30 SEPTEMBER, 2008Document4 pagesStatement of Compulsory Winding Up As On 30 SEPTEMBER, 2008abchavhan20No ratings yet

- SEMICONDUCTORS AssignmentDocument8 pagesSEMICONDUCTORS AssignmentMaryam MuneebNo ratings yet

- SEO Design ExamplesDocument10 pagesSEO Design ExamplesAnonymous YDwBCtsNo ratings yet

- Application D2 WS2023Document11 pagesApplication D2 WS2023María Camila AlvaradoNo ratings yet

- Drafting TechnologyDocument80 pagesDrafting Technologyong0625No ratings yet

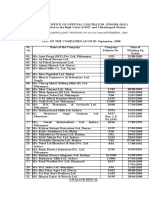

- Fong vs. DueñasDocument2 pagesFong vs. DueñasWinter Woods100% (3)

- Chapter 1: The Critical Role of Classroom Management DescriptionDocument2 pagesChapter 1: The Critical Role of Classroom Management DescriptionJoyce Ann May BautistaNo ratings yet

- Lecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022Document10 pagesLecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022MANAS RANJAN MISHRANo ratings yet

- 2016 Mustang WiringDocument9 pages2016 Mustang WiringRuben TeixeiraNo ratings yet

- SWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PDocument4 pagesSWOT Analysis of Solar Energy in India: Abdul Khader.J Mohamed Idris.PSuhas VaishnavNo ratings yet

- Antiquity: Middle AgesDocument6 pagesAntiquity: Middle AgesPABLO DIAZNo ratings yet

- AAU5243 DescriptionDocument30 pagesAAU5243 DescriptionWisut MorthaiNo ratings yet

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Document19 pagesHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeNo ratings yet

- Ks3 Science 2008 Level 5 7 Paper 1Document28 pagesKs3 Science 2008 Level 5 7 Paper 1Saima Usman - 41700/TCHR/MGBNo ratings yet