Professional Documents

Culture Documents

Quality Clinic Process Overview: L.A. Site

Uploaded by

Kristof MCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Clinic Process Overview: L.A. Site

Uploaded by

Kristof MCCopyright:

Available Formats

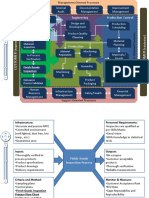

Quality Clinic Process Overview

L.A. Site

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 1

What is a Quality Clinic?

• The Quality Clinic is a place that encourages open communications around quality

issues (triage)

• Quality Clinics analyze product and process nonconformances, determine root

causes, and ensures changes to standard work, processes and/or designs

• Staffed by associates who have an in-depth knowledge of the products produced by

the Clinic business unit, the measurement instruments contained within the Clinic,

and problem solving skills

• Real-time triage investigations performed

• Alert notification system designed to provide immediate notice of nonconformance in

manufacturing areas

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 2

Document Structure

Control & Documentation of Quality Clinic Process

Nonconforming Product Enterprise Level

Nonconforming Material Control Quality Clinic Process

L.A. Site Level

Escape Management Process Quality Clinic Process

Standard Work Instructions

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 3

Key Elements

People

Review Visual and

And Structured

Analysis Process

Performance/Metrics

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 4

People

• Focal point leadership established

• Standard work developed

• Interface networking driven by Ops/Quality Tier II Correction

Action Board (CAB)

• Clear Instructions to Manufacturing Engineer, Process

Engineer, and Quality Engineer

• Drive the process forward – Daily routine

• Enterprise “Continuous Improvement” philosophy drives

employee engagement at all levels

Receiving Satellite Assembly Satellite Quality

Core Quality Clinic Quality Clinic Clinic

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 5

Nonconforming Material Flow

Event

Nonconformance Material Review Manger/Clinic

Nonconformance Generated In Inspection Notifies Engineer Completes Contact Natural

Happens System Manager and Clinic Pre-Disposition Work Team (NWT)

Hardware Tracked

NWT Completes

Part Moved To Aging

Corrective Action Monitored in

Appropriate Area Until Quality Clinic

NWT Completes Determination and

Disposition Is

Investigation Tier I Action

(If Appropriate) Complete

Pre-disposition through Corrective Action Determination Flow

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 6

Quality Clinic Process

Physical Visual Management

Quality Clinic Status Board

and Product Lanes

Cones, Lanes and Check Out Cards Color-Coded To Product

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 7

Process

Andon is derived from a Japanese term for a

type of paper lantern “warning”

• Andon system provides a visual feedback to the

manufacturing floor and support teams

• Indicates assistance is needed

• Empowers “stop the production” for quality issues

• Brings immediate attention to problems as they

occur in the manufacturing process

• Provides consistent communication to the shop floor

• Improves accountability of operators by increasing

their responsibility for “good” production and taking

action when problems occur

• Improves the ability of supervisors to quickly

identify and resolve manufacturing issues

Zone/machine where

nonconformance occurred

indicated on TV monitor map

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 8

Performance and Metrics

Managing Hardware Velocity - Quality Clinic Health

Types of nonconformances Types of nonconformances Quality Clinic

sent to Clinic sent to Clinic by Program Processing Backlog

Hardware Processed Corrective Action Current Clinic

Cycle Time Determination Closure Age Hardware Aging

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 9

Performance and Metrics

Managing Performance: Product and Process

Internal Nonconformance

Corrective

Escapes Action Rate

Cost of Poor Corrective Action Implementation

Quality In-House Plan Approval Cycle

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 10

Performance and Metrics

Analysis

Fabrication Internal

NCs

Supply

NCs

-NCs

-Turnbacks Function P-line

Type Cause

Issue Responsible Department

Supplier

Assembly Quality

Assurance Nonconformance

Material Review

Rework

Repair

Scrap

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 11

Analysis

• Quality Clinics leverage off a strong Root Cause Analysis (RCA) and tiered

corrective action board (CAB) structure

• Quality Clinic leadership are trained in incident investigation, RCA,

mistake proofing and have expertise in the facilitation of problem

resolution activity

• In addition, as part of the process structure, systemic identification, NC

trending and value stream interruption analysis is supported with the

utilization of:

• Concentration diagrams

• Concentration mapping

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 12

Concentration Diagram

• Designed to provide a visual of process

areas that hinder product and quality

• Repetitive

nonconformances

evident in the value

stream

• Seen over time or from

unit to unit

Assembly P

Assembly Process

rocess

Manufacturing

Warehousing Process in the product value

stream that requires attention

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 13

Concentration Mapping

• Designed to provide a

visual of processes

that hinder product

quality

• Factory map showing

the different processes

• High quantity of

nonconformances in an

individual process

Process Areas

Nonconformance Types

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 14

Summary

• Quality Clinic comprised of four elements

• People / Process / Performance-Metrics / Analysis

• Quality Clinic encourages open communications, analyzes product and

process nonconformances and facilitates the investigative process

• Staffed by experienced individuals with in-depth knowledge of product/ processes

• Typical focus areas: Core Manufacturing, Assembly and Supply Chain

• Designed as a Visual Management Tool

• Concentration diagrams and mapping

• Posted health and performances metrics

• Embedded in close proximity to operational activity

• Focused on real-time triage, containment and action response

Does not contain any ITAR or EAR Technical Information

Aerojet Rocketdyne 15

You might also like

- Ispe Reprint - Process - ValidationDocument5 pagesIspe Reprint - Process - ValidationFederico74No ratings yet

- Equipment ValidationDocument20 pagesEquipment ValidationPILLINAGARAJU100% (1)

- PLC ValidationDocument26 pagesPLC ValidationdesignselvaNo ratings yet

- Validation Master Plan SummaryDocument11 pagesValidation Master Plan SummaryAjay GangakhedkarNo ratings yet

- Disease Detectives NotesDocument5 pagesDisease Detectives NotesErica Weng0% (1)

- Quality System ManualDocument20 pagesQuality System ManualbhupendraNo ratings yet

- Checklist of Mandatory Documentation Required by IATF 16949 enDocument3 pagesChecklist of Mandatory Documentation Required by IATF 16949 enKristof MC100% (1)

- Policy Deployment X-MatrixDocument12 pagesPolicy Deployment X-MatrixKristof MC100% (1)

- Policy Deployment X-MatrixDocument12 pagesPolicy Deployment X-MatrixKristof MC100% (1)

- Iqoqpq RMG PDFDocument11 pagesIqoqpq RMG PDFsrinivas rNo ratings yet

- Black Belt Tollgate Checklist BBv1.1Document12 pagesBlack Belt Tollgate Checklist BBv1.1Kristof MCNo ratings yet

- State Art Practice Assessment Earthquake 16 NasDocument297 pagesState Art Practice Assessment Earthquake 16 NasInsan HanafiahNo ratings yet

- Qualification of HPLCDocument10 pagesQualification of HPLCmukeshjol89% (9)

- 2 Neo-Classical and Modern Management TheoriesDocument39 pages2 Neo-Classical and Modern Management TheoriesYASH SANJAY.INGLENo ratings yet

- Non Conformance ProcedureDocument1 pageNon Conformance ProcedureZharel AhmadNo ratings yet

- Leadership Today Practices For Personal and Professional PerformanceDocument412 pagesLeadership Today Practices For Personal and Professional PerformanceEstie100% (4)

- Special Characteristics PDFDocument11 pagesSpecial Characteristics PDFKristof MCNo ratings yet

- UGC MODEL CURRICULUM STATISTICSDocument101 pagesUGC MODEL CURRICULUM STATISTICSAlok ThakkarNo ratings yet

- ADVIA-2120i Hematology TrainingDocument73 pagesADVIA-2120i Hematology TrainingLoay TibiNo ratings yet

- Pilot Plant Scale Up TechniqueDocument84 pagesPilot Plant Scale Up Techniquedimendra100% (8)

- Radiopharmaceutical Production: Process ValidationDocument13 pagesRadiopharmaceutical Production: Process ValidationVinay PathakNo ratings yet

- 1 - Introduction To Computerized Systems Validation - For ReviewDocument41 pages1 - Introduction To Computerized Systems Validation - For Reviewpate malabananNo ratings yet

- ISO/GMP/FDA Training Validation: Topic: Date: 2/23/2012 Facility: SS White India Trainer: Hollie JohnsonDocument17 pagesISO/GMP/FDA Training Validation: Topic: Date: 2/23/2012 Facility: SS White India Trainer: Hollie JohnsonMitulNo ratings yet

- Business Ethics PDFDocument37 pagesBusiness Ethics PDFtubuiNo ratings yet

- Cleaning Validation For Medical Device ManufacturingDocument12 pagesCleaning Validation For Medical Device ManufacturingDCG CandyNo ratings yet

- Bqs Asq Lpa Overview 2 3 2017 Rev 11 PDFDocument48 pagesBqs Asq Lpa Overview 2 3 2017 Rev 11 PDFelyesNo ratings yet

- Halonix Technologies Private Limited Supplier Audit Check SheetDocument1 pageHalonix Technologies Private Limited Supplier Audit Check Sheetatul sachanNo ratings yet

- Qualification - Validation CPOB 2018 PDFDocument145 pagesQualification - Validation CPOB 2018 PDFmela milaniNo ratings yet

- ISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKDocument20 pagesISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKroelly100% (2)

- Job Analysis and Job EvaluationDocument35 pagesJob Analysis and Job EvaluationHoney RoyNo ratings yet

- Akashi Demand LetterDocument1 pageAkashi Demand LetterKristof MCNo ratings yet

- Technology Transfer Plan & Exhibit TJDocument19 pagesTechnology Transfer Plan & Exhibit TJTejashreeNo ratings yet

- Practical Approach To Managing Safety Critical Equipment and Systems in Process PlantsDocument10 pagesPractical Approach To Managing Safety Critical Equipment and Systems in Process PlantsMuhammad Danish AmanNo ratings yet

- 5S Guide: An Introduction To The 5S Method and Practical Tips For Implementation in Any FacilityDocument25 pages5S Guide: An Introduction To The 5S Method and Practical Tips For Implementation in Any FacilityAndré Luiz LimaNo ratings yet

- SAP QM Introduction DeckDocument22 pagesSAP QM Introduction DeckVikash RanjanNo ratings yet

- Laboratory Quality/Management: A Workbook with an Eye on AccreditationFrom EverandLaboratory Quality/Management: A Workbook with an Eye on AccreditationRating: 5 out of 5 stars5/5 (1)

- 2017 - Develop A Roadmap For The Implementation of A Global CSV ProgramDocument74 pages2017 - Develop A Roadmap For The Implementation of A Global CSV Programkaka**No ratings yet

- Introducing SIRE 2.0 Industry Associations Awareness Session - 6 MayDocument21 pagesIntroducing SIRE 2.0 Industry Associations Awareness Session - 6 Maysureen123100% (2)

- Sample Consent-Form PDFDocument4 pagesSample Consent-Form PDFJe KirsteneNo ratings yet

- Attribute Gage RR RidgwayDocument50 pagesAttribute Gage RR RidgwayPradeepNo ratings yet

- Feleffektsanalys/Failure Mode and Effect Analysis Konstruktion/DesignDocument12 pagesFeleffektsanalys/Failure Mode and Effect Analysis Konstruktion/DesignKristof MCNo ratings yet

- Product Process ValidationDocument13 pagesProduct Process ValidationJayant Kumar JhaNo ratings yet

- 5S Handbook PDFDocument20 pages5S Handbook PDFAnonymous iMq2HDvVqNo ratings yet

- IqpqoqDocument5 pagesIqpqoqShiva KrishnaNo ratings yet

- ValidationDocument1 pageValidationriwanbadarNo ratings yet

- Operator's Training Program and Certification SchemeDocument7 pagesOperator's Training Program and Certification SchemeAJAY SRIVASTAVANo ratings yet

- SEMI Supply Chain Co-optimization critical to drive Moore's law forwardDocument15 pagesSEMI Supply Chain Co-optimization critical to drive Moore's law forwardjaonnNo ratings yet

- Presentation On: Software Engineering Quality Assurance and TestingDocument54 pagesPresentation On: Software Engineering Quality Assurance and TestingMese AKNo ratings yet

- SOP in Use QualificationDocument4 pagesSOP in Use QualificationDharmesh PatelNo ratings yet

- T06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Document66 pagesT06002.006 Viva E System Onsite Training Workbook Eff Date 09-13-21Zitouni LamineNo ratings yet

- Drilling Rig Inspection and Workover FundamentalsDocument23 pagesDrilling Rig Inspection and Workover Fundamentalslearn offshore drillingNo ratings yet

- Fundamentos de Inspección y Reacondicionamiento de Plataformas de PerforaciónDocument23 pagesFundamentos de Inspección y Reacondicionamiento de Plataformas de PerforaciónABRAHAM NERY LLORENTY ROJASNo ratings yet

- Reduce Risks and Costs of Laboratory Equipment QualificationDocument29 pagesReduce Risks and Costs of Laboratory Equipment Qualificationzfo302No ratings yet

- Electrical Control Cabinet (TAG22T3 100B) 7 Mar 2023 Sierra BlassingameDocument10 pagesElectrical Control Cabinet (TAG22T3 100B) 7 Mar 2023 Sierra BlassingameMohamed AminNo ratings yet

- ISO Accredited Training and Certification: VCAT I - Vibration AnalysisDocument3 pagesISO Accredited Training and Certification: VCAT I - Vibration AnalysisPraveenNo ratings yet

- Ag Devicediagnostics PDFDocument22 pagesAg Devicediagnostics PDFAnonymous cXjAZTNo ratings yet

- Schletter-Brochure-Service_Ground_Mounted_SystemsDocument3 pagesSchletter-Brochure-Service_Ground_Mounted_Systemsf789sgacanonNo ratings yet

- Qualification of Equipments: A Systematic Approach: International Journal of Pharmaceutical Sciences May 2018Document10 pagesQualification of Equipments: A Systematic Approach: International Journal of Pharmaceutical Sciences May 2018HamidNo ratings yet

- Ebccsp16AutomaticControl FutureChallengesSolutionsandSystems RevDocument57 pagesEbccsp16AutomaticControl FutureChallengesSolutionsandSystems RevGlauco SantiagoNo ratings yet

- 2012 Calibrations in Process Control and AutomationDocument11 pages2012 Calibrations in Process Control and AutomationLALIT RAAZPOOTNo ratings yet

- 01 7341026 Rev E - IntroductionDocument6 pages01 7341026 Rev E - IntroductionPhong LeNo ratings yet

- Regulatory BrochureDocument8 pagesRegulatory BrochureJEYA KUMARANNo ratings yet

- Process Validation and Revalidation in Medical Device ProductionDocument7 pagesProcess Validation and Revalidation in Medical Device ProductionBREWSKINo ratings yet

- Reference ArticleDocument5 pagesReference ArticleZiaNo ratings yet

- Chapter 34 Conducting Info Sys AuditDocument72 pagesChapter 34 Conducting Info Sys AuditamirNo ratings yet

- Orange HRM: System Test PlanDocument8 pagesOrange HRM: System Test Planvictor othugadi100% (1)

- 2.seamless Integration Daniel NilssonDocument20 pages2.seamless Integration Daniel Nilssonleon tagoreNo ratings yet

- Treinamento Delta V BrasilDocument33 pagesTreinamento Delta V BrasilJefferson da rocha silvaNo ratings yet

- DVCon Europe 2015 T07 PresentationDocument98 pagesDVCon Europe 2015 T07 PresentationJon DCNo ratings yet

- 0594-0598 (1058) Analytical Instrument QualificationDocument5 pages0594-0598 (1058) Analytical Instrument QualificationRaf RafNo ratings yet

- Approach For Establishing A World Class Test LaboratoryDocument4 pagesApproach For Establishing A World Class Test LaboratoryPreeti KashyapNo ratings yet

- Failure Mode and Effects AnalysisDocument5 pagesFailure Mode and Effects AnalysisSamantha IsabelNo ratings yet

- PID Advances in Industrial Control PID Advances in Industrial ControlDocument41 pagesPID Advances in Industrial Control PID Advances in Industrial Controllucz xiomiNo ratings yet

- Inspection and Test: Submitted To: Prepared By: Dr. Archana Gandhi Shrey Sharma Anmol JainDocument17 pagesInspection and Test: Submitted To: Prepared By: Dr. Archana Gandhi Shrey Sharma Anmol JainAnmol JainNo ratings yet

- Engineering System Analysis Identifies Root Cause and Systemic GapsDocument2 pagesEngineering System Analysis Identifies Root Cause and Systemic Gapsgeorge moyoNo ratings yet

- ValidationGuideline TharwatMokalledDocument14 pagesValidationGuideline TharwatMokalledKevin HilaresNo ratings yet

- Amer Gamal Pres Session11Document54 pagesAmer Gamal Pres Session11iabureid7460No ratings yet

- 01 Review of The Auditing ProcessDocument34 pages01 Review of The Auditing ProcessGwyneth Ü ElipanioNo ratings yet

- 5Ss 1615573784Document20 pages5Ss 1615573784Kristof MCNo ratings yet

- Potential Causes of Quality Issues in Composite ManufacturingDocument23 pagesPotential Causes of Quality Issues in Composite ManufacturingKristof MCNo ratings yet

- Lean Six Sigma Leadership 1615402359Document1 pageLean Six Sigma Leadership 1615402359Kristof MCNo ratings yet

- 5Ss 1615573743Document48 pages5Ss 1615573743Kristof MCNo ratings yet

- Effective Root Cause Analysis with 3 Legged 5 WhyDocument42 pagesEffective Root Cause Analysis with 3 Legged 5 WhySerchecko JaureguiNo ratings yet

- Dmaic Roadmap PDFDocument1 pageDmaic Roadmap PDFKristof MCNo ratings yet

- 5 Ss Visual ControlDocument57 pages5 Ss Visual ControlR.BALASUBRAMANINo ratings yet

- LSS Templates - M Cox - v4 Aug 08Document139 pagesLSS Templates - M Cox - v4 Aug 08Kristof MCNo ratings yet

- TPS - The Four Elements of Built in QualityDocument5 pagesTPS - The Four Elements of Built in QualityKristof MCNo ratings yet

- Yield GE Wekk48 - 52Document10 pagesYield GE Wekk48 - 52Kristof MCNo ratings yet

- Development and Implementatio A Remote Audit Tool For HighDocument92 pagesDevelopment and Implementatio A Remote Audit Tool For HighKristof MCNo ratings yet

- External Auditing and QualityDocument351 pagesExternal Auditing and QualityKristof MC100% (1)

- Learn To SeeDocument67 pagesLearn To SeeKristof MCNo ratings yet

- LSSBBDocument35 pagesLSSBBKristof MCNo ratings yet

- LSSBBDocument35 pagesLSSBBKristof MCNo ratings yet

- Plantilla Modelo Hoshin KanriDocument8 pagesPlantilla Modelo Hoshin KanriJavier NumpaqueNo ratings yet

- Rakusa Simona PDFDocument147 pagesRakusa Simona PDFjames007spyNo ratings yet

- AluminiumDocument16 pagesAluminiumVigneswaranNo ratings yet

- Investors Preference in Commodities MarketDocument7 pagesInvestors Preference in Commodities MarketMuthu9751No ratings yet

- Introduction To Biostatistics1Document23 pagesIntroduction To Biostatistics1Noha SalehNo ratings yet

- Explainable AI in The Context of Data Engineering: Unveiling The Black Box in The PipelineDocument6 pagesExplainable AI in The Context of Data Engineering: Unveiling The Black Box in The PipelineInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Brownsville Learn Phase ReportDocument28 pagesBrownsville Learn Phase ReportJennifer LeeNo ratings yet

- Leija Et Al 2023 JFO-2023-259Document16 pagesLeija Et Al 2023 JFO-2023-259savaba8669No ratings yet

- Distance 6 User's GuideDocument358 pagesDistance 6 User's Guidecretinusmaximus100% (1)

- Analisis Tokoh Dan Penokohan Pada Drama RT Nol RW: Nol Karya Iwan SimatupangDocument10 pagesAnalisis Tokoh Dan Penokohan Pada Drama RT Nol RW: Nol Karya Iwan SimatupangDian MarlinaNo ratings yet

- SKF PDFDocument112 pagesSKF PDFAlvaro IgnacioNo ratings yet

- Rwanda International Conference On Technology in Education (RICTE) - Enhance Learning Through TechnologyDocument88 pagesRwanda International Conference On Technology in Education (RICTE) - Enhance Learning Through TechnologyNorman SchräpelNo ratings yet

- IALA Guideline 1018 Ed.3 Risk Management - May2013Document43 pagesIALA Guideline 1018 Ed.3 Risk Management - May2013songkkNo ratings yet

- British Journal of Marketing Studies Vol.2, No.6, pp.52-67, October 2014 Published by European Centre For Research Training and Development UKDocument16 pagesBritish Journal of Marketing Studies Vol.2, No.6, pp.52-67, October 2014 Published by European Centre For Research Training and Development UKAbay ShiferaNo ratings yet

- EVANGELISTA - Assignment #2Document4 pagesEVANGELISTA - Assignment #2Gabrielle EvangelistaNo ratings yet

- Tutorial Interpolation in QGISDocument3 pagesTutorial Interpolation in QGISMarcos José Falcão De Medeiros FilhoNo ratings yet

- Gantt Chart Masters DissertationDocument8 pagesGantt Chart Masters DissertationProfessionalPaperWritingServiceVirginiaBeach100% (1)

- Automatic Dismissal Alarm for Time AwarenessDocument54 pagesAutomatic Dismissal Alarm for Time AwarenessArnie John P. MendozaNo ratings yet

- STS Module 2Document44 pagesSTS Module 2TERRIUS AceNo ratings yet

- MB Criteria Effect on BPJS Patient SatisfactionDocument9 pagesMB Criteria Effect on BPJS Patient SatisfactionilaNo ratings yet

- Measuring Dimensions and Density with CalipersDocument3 pagesMeasuring Dimensions and Density with CalipersDorinneBarretto75% (4)

- What Is Strategic Management and Why Is It Important?Document3 pagesWhat Is Strategic Management and Why Is It Important?Marco RegunayanNo ratings yet

- In An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product RepresentationDocument34 pagesIn An Assembly Model, Components Are Brought Together To Define A Larger, More Complex Product Representationpalaniappan_pandianNo ratings yet

- Equity Theory: The Recent Literature, Methodological Considerations, and New DirectionsDocument10 pagesEquity Theory: The Recent Literature, Methodological Considerations, and New DirectionsZelia FreriaNo ratings yet

- First Reading RMDocument7 pagesFirst Reading RMBasim AhmedNo ratings yet

- TM Deliver A Short Oral Presentation in English RefinedDocument74 pagesTM Deliver A Short Oral Presentation in English RefinedYohanes ArifNo ratings yet