Professional Documents

Culture Documents

Busbar Sizing Calculation-2

Uploaded by

daniel.cabasa25770 ratings0% found this document useful (0 votes)

17 views7 pagesbusbar sizing

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentbusbar sizing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views7 pagesBusbar Sizing Calculation-2

Uploaded by

daniel.cabasa2577busbar sizing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

ABR Siowar | ThrcePhaseBusbarssysiem | Toss ESSP-BARSIA

Tied by D- Caza do. VESONSBOSTOSO v.00 Pag. 157

SWITCHGEAR GT3-4

STUDY OF THE SIZING AND

OF THE ELECTRODYNAMIC EFFORTS:

OF THE THREE PHASE BUSBARS SYSTEM

‘TECHNICAL SPECIFICATION

me aan Ey

‘| oar Rae Dceaain |

[ABB Arorae | Three Phase Bashar System “TO-ESSP-BARS34

[sie by, Cazzaiga ‘vg. VCSOOOSTUOUU He. Pag. 2017

1. SUBJECT

Subject of the following technica peifiction i the study af the busbrs stem of prefabricated

boxes fr the Switchgear GT-4 plant

‘he purpose ofthis stay to highligh the ing ofthe busbar system to ensue the normal

operting conditions and any posible shor cre

2, BUSBARS SIZING

“The section ofthe bars hive been shed according to the ated cument and to the short-cut

‘tents of he pan.

“Th toe phase busbar sytem of the plat can be divided ito tre sections characterized by its

rated opting erent The following re the technical data ofthe plant

slic da

Rated voltage 138 1KV)

Frequency o (Ha)

‘Symmetrical soa -cireuitcurent 50 [KA the tee sets)

ration ofthe shot rut 1 ee}

Rated current section | 4000 (A)

Rated crent section 2 12504),

Rated current section 3 00 (A)

Ambien temperature ase

ABB Bioras | TieerhaseDusbarsytem | 7OBLESSP-BARSIA

ese hy D.Carzani ‘dg VESOO3B0STOADO Rev. 00 Pag. 3007

Capacity of Busbars

Section

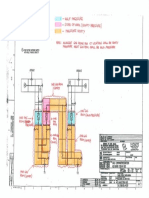

Forsecton 1s been chose formation of bars composed ofthe sub-conductors sie 12012

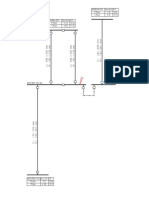

‘mm. The following statin shows wo pases ofthe ars system with hoxizontally place Hines

‘nd the longest section side in hrizontl postion

an cama

ea ae

Referng to standards CE UNEL O1433-72, the capacity ofa busbar system 120812 wn can be

approximated by using the eapacity of 3750 [A] for a section of 100112 mm aed 4560 [A] for 9

section of 125x12 tam. Therefore, the capacity of a busbar system 120x12 mm Ch")

proximaed to 4350 (A ith the folowing configurations and operating contons:

"> 3 subscondactrs fate br, with he longest section side in vertical poston

> ambient emperatur of 1" C;

> temperature rise of 30°C;

> frequency of 0 Hs

“The real capacity ofthe busbar system i auld using coefficients corrective depending onthe

configuration ofthe projet:

Tm Ie kL eRe RE = 4850 6 148 + 0,75 + 0,913 = 4200 1A]

with

~ KI =cametion fr for diferent values of ambient temperature 25 °C), temperature

ris (65°C elated tthe maximum operating temperature ofthe insulators (100°C),

= “Ka = conection fstoe for thermal load capacity variations duet differences in layout

‘he longest setion sein horizontal position

13 conection fico fo the diferent operating Frequency (60H.

Inthe setion 1, the capac ofthe ars stom 4260 [A] is higher than the ated utent of 4000,

1.

“Three Phase Busbars System {TOMESSP BARS

dv. VCSOOSEOSTOSUD Rev.00| Pag dat

For sections 2 and 3 has teen chosen a formation of bars composed of one conductor sized

10010 mm. The busbars stems hve diferent yous, the capacity is estimated forthe layout

tat leads to the its lowest vale: ovizontlly pice ines and the Jongest section sie in

horizontal postion.

[As with section 1 refetngo standards CE UNE 01433-72 the capacity of the busbar eytem

Pa Tne M2 eb = 1670 «1,48 = 0,85 = 0,013

00

Inthe sections 2 and 3, the sapacty ofthe bars system 1850 [A] is higher than the ated currents

(of 1250-800 [A

Caleulation of short-cireult withstand

Refetng to standards CEL 11-17 and CEI EN 60439-1 to determin the minim ie of bat 0

‘ensue the withstand of tena effects caused by shot ict current, one can use the Following

formula:

ee; symmetia shor: cet eument

“Tee: dation of he sot ical

(C eonstant dependent from the miei (copper), fom the operating temperature ad fom

the maxima tempantire of the bars in cas of short ciel By set

temperature ofthe busin case of short iret of 250°C, the valu constant °C" is 143,

“The sections ofthe bars equal to 10D04320 mm therefore sty the condition ofthe stances.

ABB Svorae | Three Phase Busbars Sytem TOBLESSP BARSA

sed by D-Cazzn aug VCSOORRDSTOSOO Re. ag 517

3. ELECTRODYNAMICS EFFORTS,

“The evaluation of eletodssamics efforts as examined by eaeulsing the maximam fores of

ration and repulsion between the bars in cae of shor-clcul, avoning to the following

expression (1.

anieltpeeaef]

>> Fin: maximum valteof dynamic fot that could develop in a single athe phase system

tu in ease of short

> lac: vale ofthe syttical shor circuit caren [A]

> Asymmetty factor: this factor takes flo account the peak short circuit cument 1h the

‘exprestion above, ths value was set equa 016

> S:distance between as (mm)

> factor which takes nto aecouut the space enfguration ofthe tree bs

“To cone the mechanical strength of te busbar system in ease of shor-cicit the wlimate

bending tes of he isolator mast be grater than the fore “Pm ® alle.

“The tio “Fan” allows te calle the stess on the single insulator. The ent

‘he distance ofthe insulator on the bar

M1." epesens

[1fe“Industral Power Englacerng and Applications Handbook” K.C. Agrawal

Verification

“The pant was designed to vithsand a short cliuit symmetrical curentof SOKA for 5.

“The insulators installed in the plant have the following mechanical characteristics: vlimate

beading tess (respect othe heud of insulator) sequal to 12500 N; ereepage distance of 300mm;

height of insiatr of 210 rm.

Ihe sexton fy according tothe configuration of the projet the slstynamic effort wil te

applied at an height of 30mm above the Head of th insulator. So the effort bearable fom the

insulators equal to 11000 ¥.

Inthe sections 2 the eletdynsmic effort wil be apliod at an height of 50 or Sm above the

head of the instr, aceding the horizontal or vertical postion of the longest side ofthe

section, So the effort bearable fon the inelstor i ua 10000 N with a vert poston, or

12200 with hovizontl position of the lnges side ofthe section.

[ABB Asonu Three Phase Busbars System. OM-ESSP-BARSS4

Tsiued by D.Cazzaiga ov. VES 10000 Kev.00| Pag. 67

Seti

‘The mest steal contons

‘> S-=minimm distance bxween conductor ofthe plants equal to 300mm.

> L-=maximum distance tween insulators is equal 6450 mn,

“The maxi vl of the electodynamiesefot it

nels ses ene EBIO reson]

With equal to 12

‘Theeffor an thesingleinwstoris: Fin* Le 16090 045 =7200N

Sections 2

“The most tel contons

2S =misinum distance baween condor of the plants equal to 230mm.

‘> L.=maximum distance tetwee slates qual 6400 mm,

With a horizontal posiin of longest side of the section, the maximum value of the

lectrdynamic effort is

Fawbelt tera as. 12S000%. se aco fA

With Kequalto 1

‘The effort on the single instr:

With & vertical poston of the longest side of the section, the maximum value of the

esr ynumie efforts is

so000t

s+ sr]

With Kequa

“The effort on the single slat

Fin #L= 17400 #0, = 7000.8

ABB iorar | Tiveetinetotarsynten | TOs SsP-BARSSE

Tested by D,Carzaniga ‘dg. VESTS 10000 Kev.00| Pag. 707

1 summary

“+ tot naar eton 7200 1N}

“+ Effet saab owe inslators 11000

ith orion position ofthe longest side af he section

‘lot instore setions 2-3 0100 (NI

+ fort besable fom thensulators —— 12200(N]

‘with vertical postion of th: longest side ofthe setion

“© Effort saat setions 2-3 7000 8)

“+ fort bearable fromthe insators 10000 INI

“The results above shows a proper desi of the busbas system 10 withstand the electrodynamics

effets in ease of short-circuit.

“The sty ends by caultng the safety Factors, fr section 1 is equal 1100077200 = 1,52 while

for sections 23 ve 1220011900 = 120 and 100007000 = 1.4,

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Industrial Solutions: Paralleling SwitchgearDocument1 pageIndustrial Solutions: Paralleling Switchgeardaniel.cabasa2577No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mirat PV Plant RMU Installation ScheduleDocument1 pageMirat PV Plant RMU Installation Scheduledaniel.cabasa2577No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- HV Intake 1 Mark Up - 071218Document1 pageHV Intake 1 Mark Up - 071218daniel.cabasa2577No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Technical Specification for 17.5kV Metal-Clad SwitchgearDocument5 pagesTechnical Specification for 17.5kV Metal-Clad Switchgeardaniel.cabasa2577No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Single Line Diagram - High Voltage Power Distribution Rev ADocument1 pageSingle Line Diagram - High Voltage Power Distribution Rev Adaniel.cabasa2577No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Mission Vision SCEDocument5 pagesMission Vision SCEdaniel.cabasa2577No ratings yet

- Ayban Scope of WorkDocument38 pagesAyban Scope of Workdaniel.cabasa25770% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Remote RelaysDocument1 pageRemote Relaysdaniel.cabasa2577No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Annual Safety Summary Report for Central Region Operations SectionDocument2 pagesAnnual Safety Summary Report for Central Region Operations Sectiondaniel.cabasa2577No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- HV Intake 2 Mark Up - 071218Document1 pageHV Intake 2 Mark Up - 071218daniel.cabasa2577No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- UPEEP 1st General Assembly 2018Document1 pageUPEEP 1st General Assembly 2018daniel.cabasa2577No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Transformer Electrical Connection SCLB 1250-22-0.415 ModelDocument1 pageTransformer Electrical Connection SCLB 1250-22-0.415 Modeldaniel.cabasa2577No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Revised National Plumbing Code of The Philippines 1Document225 pagesRevised National Plumbing Code of The Philippines 1daniel.cabasa2577No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Relay SettingDocument7 pagesRelay Settingdaniel.cabasa2577No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Electrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 SpecificationDocument1 pageElectrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 Specificationdaniel.cabasa2577No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PRC Application GuideDocument2 pagesPRC Application Guidedaniel.cabasa2577100% (1)

- Logic Diagram for Acceleration Trip Coordination SchemeDocument1 pageLogic Diagram for Acceleration Trip Coordination Schemedaniel.cabasa2577No ratings yet

- 3-Phase Fault AnalysisDocument11 pages3-Phase Fault Analysisdaniel.cabasa25770% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Electrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 SpecificationDocument1 pageElectrical Characteristics: Aluminium Conductors Steel Reinforced (Acsr) To Astm B:232-86 Specificationdaniel.cabasa2577No ratings yet

- ETAP Report (Modified - 4pages) PDFDocument4 pagesETAP Report (Modified - 4pages) PDFdaniel.cabasa2577No ratings yet

- Tower Details Double CKTDocument1 pageTower Details Double CKTdaniel.cabasa2577No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ETAP Short-Circuit Report AnalysisDocument4 pagesETAP Short-Circuit Report Analysisdaniel.cabasa2577No ratings yet

- Room Layout 7701-ModelDocument1 pageRoom Layout 7701-Modeldaniel.cabasa2577No ratings yet

- RX DiagramDocument1 pageRX Diagramdaniel.cabasa2577No ratings yet

- ABB CT and VT Application Guide Ed3Document128 pagesABB CT and VT Application Guide Ed3Andrej Černe100% (4)

- Acceleration FinalDocument1 pageAcceleration Finaldaniel.cabasa2577No ratings yet

- PUTT SchemeDocument1 pagePUTT Schemedaniel.cabasa2577No ratings yet

- SLD Updtd Hail ProjectDocument1 pageSLD Updtd Hail Projectdaniel.cabasa2577No ratings yet

- Ad Dayir - LayoutDocument1 pageAd Dayir - Layoutdaniel.cabasa2577No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)