Professional Documents

Culture Documents

Begg Cousland Tower Internals

Uploaded by

HavocFireCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Begg Cousland Tower Internals

Uploaded by

HavocFireCopyright:

Available Formats

World Class Process Engineering Solutions

Equipment for (Petro)Chemicals

& Metallurgical Industries

Equipment for Industrial

Pollution Control

As well as our Filtration Equipment (e.g. ‘Becoil’ CECEBE ‘SMART’ Type

Demisters & ‘Becofil’ Candle Filters) we supply

also the Tower Internals range as shown below. Begg Cousland has also supplied customers with tower

internal packages including CECEBE ‘SMART’ type of

ACID DISTRIBUTORS distributor.

This distributor is almost a mixture of the other 2 types,

Begg Cousland can offer a wide range of acid distributor maximising the benefits of each in terms of :

styles and materials, for new towers or to retrofit old Even flow through all orifices

ones. Even distribution

Avoidance of spray generation

Pipe Type Avoidance of leveling problems

In addition it offers :

Personnel Safety and ease of inspection

(Inspection from outside of tower)

The Pipe type distributor is well known and can be made

to suit all tower sizes and designs. Using special HD2

grade Cast Iron, the pipe materials have a life equal to

Mondi type.

Inspection ports at the ends of each main header pipe

Trough Type

allow access to the inside of the pipe without the need to

enter the tower.

This is a safety feature and means minimised risk of acid

flow blockage.

The Trough type distributor has liquid troughs fed from a

header pipe, and the troughs are fitted with distribution

pipes of different length and orientation, to ensure an

even and equal liquid flow to the tower packing. Various design geometries to suit each tower

Special alloy materials can be used for this type.

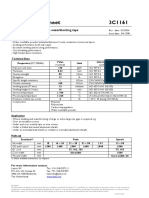

Ceramic Random Tower Packings Standard Data - Saddles

Begg Cousland supply high quality ceramic packings for Size Bulk No. of Surface Percent

Drying and Absorbing Towers. We have a very good and (nominal) Density Pieces Area Void

experienced supply from China for these products, which kg/m3 per m3 m2/m3 Space %

are distributed by us, with our guarantees. 25 mm 650 84,000 250 78

They have been widely used outside China, many times 38 mm 630 25,000 164 84

by major contractors and end users. 50 mm 620 9,400 142 81

75 mm 550 1,870 92 80

Standard Data – Super Intalox Saddles

Size Bulk No. of Surface Percent

(nominal) Density Pieces Area Void

kg/m3 per m3 m2/m3 Space %

25 mm 705 84,000 255 77

38 mm 670 25,000 195 80

50 mm 760 9,400 118 79

75 mm 590 1,870 92 80

Typical Specifications of Ceramic Saddles & Rings

Temperature resistance, 1460

Water Absorption: 0.11-0.15%

Porosity: 0.25-0.35%

Standard Data - Rings

Losses in Sulphuric acid by ASTM C-279: 0.07-0.23%

Real density: 2300kg/m3 Size Bulk No. of Surface Percent

O/Dia. x Density Pieces Area Void

Heat Conductivity: 1.412W/(m.K) at 200 Wall kg/m3 per m3 m2/m3 Space %

1.427 W/(m.K) at 500 Thickness

Thermal Expansion, mm/mm. 4.7-5.6x10-6 15 mm 880 378,000 370 64

Hardness: HM 7.2 x 2mm

25 mm 670 47,700 190 74

x 2.5mm

38 mm 740 13,500 120 68

x 4 mm

50 mm 660 5,800 92 74

x 5 mm

75 mm 590 1,700 62 75

x 8 mm

100 mm 580 700 46 80

x 10 mm

150 mm 680 320 50 80

x 15mm

Standard Data – Cross Partition Rings

Typical Chemical Composition (%)

Size Bulk No. of Surface Percent

SiO2 70.21-74.51 O/Dia. x Density Pieces Area Void

Al2O3 19.79-23.13 Thickness kg/m3 per m3 m2/m3 Space %

Fe2O3 0.38-1.15 50 mm 830 5800 132 68

CaO .01-0.52 x 5 mm

MgO 0.27-0.88 75 mm 1140 1950 120 56

K2O 1.32-3.40 x 8 mm

Na2O 0-0.20 100 mm 1025 1000 110 53

Ti2O 0.01- 0.15 x 10 mm

150 mm 1035 290 60 58

x 15mm

Ceramic Dome Packing Support Other Internals / Equipment Available :

Acid Resistant Brick Lining for Towers

Refractory Brick Linings

The highest manufacturing quality standards are used for

the production of ceramic domes for the support of Ceramic Grid Bars

random ceramic packings in process towers.

These domes are self supporting, strong, and have an Ceramic Balls for catalyst support / hold-down

excellent free area to minimize pressure loss.

The gas distribution is very even with his design, which is

a key to good packing performance above it.

For further information, please contact us at

Begg Cousland has used these dome supports in many Begg Cousland & Co. Ltd.

towers and there has been 100% customer satisfaction

636 Springfield Road

Including Sulphuric Acid plants in China there are more

than 200 reference installations in the last 20 years, with

Glasgow G40 3HS

diameters ranging from 1360mm to 8000mm.

United Kingdom

Tel + 44 141 556 5288

Fax + 44 141 554 7447

E-mail : sales@beggcousland.com

3 Towers in Russia with internals by Begg Cousland

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- BCE - H2SO4 Tower InternalsDocument3 pagesBCE - H2SO4 Tower InternalsDũng LêNo ratings yet

- Tubing PDFDocument20 pagesTubing PDFTheEdgeNo ratings yet

- Kristeel CatalogueDocument52 pagesKristeel CatalogueRam TejaNo ratings yet

- Sika® Carbodur® S: Product Data SheetDocument4 pagesSika® Carbodur® S: Product Data SheetMohammed FarhanNo ratings yet

- Brochure KuterlexDocument8 pagesBrochure KuterlexT KelvinNo ratings yet

- HSS80 Heat Shrink Sleeve: Features & BenefitsDocument2 pagesHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- A World Class Manufacturer: of Induction BendsDocument10 pagesA World Class Manufacturer: of Induction BendsClarkFedele27No ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Eddyfi Technologies Tubing ProbesDocument34 pagesEddyfi Technologies Tubing ProbesJesus E ContrerasNo ratings yet

- Strenx Tube 700QLH: General Product DescriptionDocument2 pagesStrenx Tube 700QLH: General Product Descriptionflastrico832No ratings yet

- Qatar Catalogue Comb in TedDocument34 pagesQatar Catalogue Comb in TedAnonymous 2Dz4Kq9M7No ratings yet

- Wire & Cable 202312261659586681900588413Document24 pagesWire & Cable 202312261659586681900588413Amir IqbalNo ratings yet

- Torelief - : Ultra High ResolutionDocument1 pageTorelief - : Ultra High ResolutionRizwan KhanNo ratings yet

- Global Roofing Solutions Bond-Dek Composite Deck: The Smart Decking PeopleDocument12 pagesGlobal Roofing Solutions Bond-Dek Composite Deck: The Smart Decking PeopleMedi YuhendraNo ratings yet

- Pipe Wrap Tape BrochureDocument8 pagesPipe Wrap Tape BrochureRamadon BernalNo ratings yet

- Regaduct AcousticDocument14 pagesRegaduct AcousticEdward GuestNo ratings yet

- Hra Panel SpecDocument4 pagesHra Panel SpecMuhammad Arslan Khurshid BhattiNo ratings yet

- Data Sheet AluminaDocument10 pagesData Sheet AluminaXin EnNo ratings yet

- CE 201 Engineering Materials AggregatesDocument17 pagesCE 201 Engineering Materials AggregatesMahadi HasanNo ratings yet

- Atlantic - Civil - Multi-Plate - Brochure Tot PDFDocument12 pagesAtlantic - Civil - Multi-Plate - Brochure Tot PDFLulu IluNo ratings yet

- Eddyfi Technologies Tubing Probes 01Document36 pagesEddyfi Technologies Tubing Probes 01abdNo ratings yet

- Threaded Mechanical Branch TeeDocument2 pagesThreaded Mechanical Branch TeeJulian RiverosNo ratings yet

- Medio Filtrante KLC Mini-Pleat 65%-95%Document1 pageMedio Filtrante KLC Mini-Pleat 65%-95%Caro VelezNo ratings yet

- R5T Capped Roof Panels Product DescriptionDocument4 pagesR5T Capped Roof Panels Product DescriptionAgonNo ratings yet

- MiscellaneousDocument49 pagesMiscellaneousjrsvalenzuelaNo ratings yet

- Utility Cable Single Core in Triplex Formation - 1642522171Document2 pagesUtility Cable Single Core in Triplex Formation - 1642522171Madhan raj VenkatachalamNo ratings yet

- Compact and transport screenings with VODATECH screw presses and conveyorsDocument2 pagesCompact and transport screenings with VODATECH screw presses and conveyorsMariusCapraNo ratings yet

- Datasheet LiYCY CableDocument1 pageDatasheet LiYCY CableResaKandhyNo ratings yet

- Datasheet LiYCY Cable PDFDocument1 pageDatasheet LiYCY Cable PDFResaKandhy100% (1)

- Qatar Steel - Metal DeckDocument4 pagesQatar Steel - Metal DeckkarthickNo ratings yet

- Datasheet TBUT000400 enDocument2 pagesDatasheet TBUT000400 enpetkoNo ratings yet

- LMIB9 SeriesDocument2 pagesLMIB9 Seriesaras aliNo ratings yet

- To BiniDocument53 pagesTo BiniMehari GebreyohannesNo ratings yet

- Tech Guide in Wire SelectionDocument7 pagesTech Guide in Wire SelectionLowell ValienteNo ratings yet

- Resistance WireDocument16 pagesResistance Wirets01759No ratings yet

- LS Copper Wire Rod: Leading SolutionDocument12 pagesLS Copper Wire Rod: Leading SolutionhuynhvanquynhNo ratings yet

- Water Swallable TapeDocument1 pageWater Swallable TapeSanthosh V RaajendiranNo ratings yet

- HDSF2 Large Diameter Seals With PTFE Excluder Lip: Excluder Lip Provides Extra Line of Defence Against Abrasive DustDocument2 pagesHDSF2 Large Diameter Seals With PTFE Excluder Lip: Excluder Lip Provides Extra Line of Defence Against Abrasive DustHeryanto SyamNo ratings yet

- Untitled Spreadsheet - Sheet1Document3 pagesUntitled Spreadsheet - Sheet1Civil Engineering by Ankur GuptaNo ratings yet

- Data Teknis Hive Honeycomb KoreaDocument70 pagesData Teknis Hive Honeycomb KoreailhamhanafyNo ratings yet

- Cabone Lorraine Sintering Brochure 2008Document6 pagesCabone Lorraine Sintering Brochure 2008Varun DodhiaNo ratings yet

- Hardox 400 TubeDocument2 pagesHardox 400 TubeSubodh ShindeNo ratings yet

- New Separators For Industrial and Specialty Lead Acid BatteriesDocument6 pagesNew Separators For Industrial and Specialty Lead Acid BatteriesCustomer Tech Support / Product Development Sales/CCT Dept. AECPLNo ratings yet

- Brochure Sieve Shakers enDocument4 pagesBrochure Sieve Shakers enjesusNo ratings yet

- gts1 2012Document2 pagesgts1 2012Maira VieiraNo ratings yet

- C1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileDocument8 pagesC1.1.0 Ajiya - 2018 - Roofing Catalogue Clip Lock ProfileFahmi YusoffNo ratings yet

- Bore-Well Pipes PDFDocument6 pagesBore-Well Pipes PDFNikita KadamNo ratings yet

- Ductile Iron Pipes: Company ProfileDocument10 pagesDuctile Iron Pipes: Company ProfileSurendra ElayathambyNo ratings yet

- MI Thickwall Thermocouple: Normal ApplicationsDocument1 pageMI Thickwall Thermocouple: Normal Applicationsmohan babuNo ratings yet

- Ac-700 SpecificationDocument10 pagesAc-700 SpecificationTarek Abuzene100% (1)

- LSM 80 (Lamella Settler Module 80 MM) : DesignDocument2 pagesLSM 80 (Lamella Settler Module 80 MM) : DesignJulio TovarNo ratings yet

- Fabrication of Large GRP Storage TanksDocument60 pagesFabrication of Large GRP Storage TanksjoekaledaNo ratings yet

- PoliMac Coated Gabion Mattress SpecDocument2 pagesPoliMac Coated Gabion Mattress SpecworkatarNo ratings yet

- RT Projector: Portable and Mini Film ViewersDocument5 pagesRT Projector: Portable and Mini Film ViewersesltirchyNo ratings yet

- Grade 3 PresspaperDocument2 pagesGrade 3 PresspaperSunil GurubaxaniNo ratings yet

- Rockwool SeriesDocument12 pagesRockwool SeriesUsamah AhmadNo ratings yet

- Cast Resin Straight-Through Joint: M-EurolineDocument1 pageCast Resin Straight-Through Joint: M-EurolineWisam ShabanNo ratings yet

- THHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDocument1 pageTHHN - THWN 90°C 600V - Columbia Wire & Cable CorporationDanilo BabolNo ratings yet

- The Pall Ring Company Virtual BrochureDocument30 pagesThe Pall Ring Company Virtual Brochurepippo2378793No ratings yet

- Distillation Tower DesignDocument66 pagesDistillation Tower DesignHavocFireNo ratings yet

- ReadmeDocument1 pageReadmeOscar FelicianoNo ratings yet

- Kinetic Characterisation of Catalysts For Methanol Synthesis PDFDocument10 pagesKinetic Characterisation of Catalysts For Methanol Synthesis PDFestudio91No ratings yet

- Distillation Tower DesignDocument66 pagesDistillation Tower DesignHavocFireNo ratings yet

- Methanol Manufacturing ProcessDocument2 pagesMethanol Manufacturing ProcessDaniil GhilescuNo ratings yet

- SweetFX - Settings - Mass Effect - 4K Effects - FinalDocument10 pagesSweetFX - Settings - Mass Effect - 4K Effects - FinalHavocFireNo ratings yet

- Cs - Methenex - 2005 - enDocument5 pagesCs - Methenex - 2005 - enJahangir MalikNo ratings yet

- James DysonDocument17 pagesJames DysonHavocFireNo ratings yet

- ReadmeDocument1 pageReadmeOscar FelicianoNo ratings yet

- Experimental and Theoretical Study of Dryout in Annular Ow in Small Diameter ChannelsDocument20 pagesExperimental and Theoretical Study of Dryout in Annular Ow in Small Diameter ChannelsHavocFireNo ratings yet

- Problem Sheet 2Document3 pagesProblem Sheet 2HavocFireNo ratings yet

- Luyben Process Dynamics and ControlDocument3 pagesLuyben Process Dynamics and ControlRazleen RashidiNo ratings yet

- No Notes For This One, Just Bring Your Lecture Notes From The Previous 6 LecturesDocument1 pageNo Notes For This One, Just Bring Your Lecture Notes From The Previous 6 LecturesHavocFireNo ratings yet

- 1 - Introduction To AggregateDocument22 pages1 - Introduction To AggregateFatin HazwaniNo ratings yet

- Energies 14 02463Document17 pagesEnergies 14 02463RoberticoZeaNo ratings yet

- Decking (Composite & 2 Layers Reinf)Document41 pagesDecking (Composite & 2 Layers Reinf)Than Than SoeNo ratings yet

- Ansi b36.10 Seamless Pipe SizesDocument2 pagesAnsi b36.10 Seamless Pipe SizesmohitNo ratings yet

- Support Issues at AEP Lawrenceburg and Waterford PlantsDocument11 pagesSupport Issues at AEP Lawrenceburg and Waterford Plantsfaizan abbasiNo ratings yet

- What Is A Glass Transition Temperature - Definition From CorrosionpediaDocument1 pageWhat Is A Glass Transition Temperature - Definition From CorrosionpediaCTPNo ratings yet

- Housekeeping ScheduleDocument2 pagesHousekeeping ScheduleZeyya Nikka Cordova Pingad100% (1)

- Barrier Performance of Common Plastic FilmDocument1 pageBarrier Performance of Common Plastic FilmAriane Victoria DantesNo ratings yet

- Transformer Inspection Monthly ReportDocument11 pagesTransformer Inspection Monthly ReportIbnu RozaqNo ratings yet

- ASME B31.3 Straight PipesDocument2 pagesASME B31.3 Straight Pipesjame11inNo ratings yet

- Nitoproof 600: Liquid Applied, Elastomeric, One Coat Waterproofing MembraneDocument3 pagesNitoproof 600: Liquid Applied, Elastomeric, One Coat Waterproofing MembraneFarah HaseenahNo ratings yet

- Air Cooled Heat Exchnger FormatedDocument43 pagesAir Cooled Heat Exchnger FormatedMustafa Anwar50% (2)

- Shenzhen Copperled Technology Co. LTD: F/UTP 4pairs cable-category5E-PE SheathDocument2 pagesShenzhen Copperled Technology Co. LTD: F/UTP 4pairs cable-category5E-PE SheathmelacorptelecomNo ratings yet

- ASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteDocument5 pagesASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteOmid DeldarNo ratings yet

- 10.0.9.1 As6052-53-54-55Document1 page10.0.9.1 As6052-53-54-55Gopinath SekarNo ratings yet

- Particle Reinforced and Fiber Reinforced Composites OverviewDocument29 pagesParticle Reinforced and Fiber Reinforced Composites OverviewJoy SueltoNo ratings yet

- AC PRICE QUOTEDocument4 pagesAC PRICE QUOTEFaizal Septia HadiNo ratings yet

- Las 9Document14 pagesLas 9HisokaNo ratings yet

- Monopole 30 M (Tubular)Document9 pagesMonopole 30 M (Tubular)jonni pangaribuanNo ratings yet

- WWW - Galpaexport.com Products-View - PHP Id GQP407K PDFDocument1 pageWWW - Galpaexport.com Products-View - PHP Id GQP407K PDFdovaleramosNo ratings yet

- Numerical Study of Stretch-Blow Molding of PET Bottles: January 2010Document7 pagesNumerical Study of Stretch-Blow Molding of PET Bottles: January 2010Anas AlbasarhNo ratings yet

- NortonCatalog PortableBeltsDocument2 pagesNortonCatalog PortableBeltsherysyam1980No ratings yet

- Rudawska 2016Document33 pagesRudawska 2016MochammadDzulFiqarNo ratings yet

- Sigma Marine Coatings Manual - Part8Document2 pagesSigma Marine Coatings Manual - Part8EngTamerNo ratings yet

- Concrete Strength Testing ExplainedDocument32 pagesConcrete Strength Testing ExplainedMinn LwinNo ratings yet

- Sans 10292Document31 pagesSans 10292leandroNo ratings yet

- GTX BeamDocument6 pagesGTX BeamSanjay SudhakaranNo ratings yet

- ASTM STP538 - Cleaning Stainless SteelDocument11 pagesASTM STP538 - Cleaning Stainless SteelPeter FowlesNo ratings yet

- Circuit Breaker Configuration of LTB245E1-1PDocument2 pagesCircuit Breaker Configuration of LTB245E1-1PThành Danh100% (1)

- Chimney FoundationDocument19 pagesChimney Foundationamass esmNo ratings yet