Professional Documents

Culture Documents

Event-Driven KANBAN:: Replenishment When Maintaining The Control Cycle

Uploaded by

reddy pOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Event-Driven KANBAN:: Replenishment When Maintaining The Control Cycle

Uploaded by

reddy pCopyright:

Available Formats

In the event-driven KANBAN procedure, you can also use all the functions available in the

KANBAN module.

You must maintain separate control cycles for event-driven KANBAN.

In this procedure, a kanban is only created when required. That is, kanban creation is triggered

by a certain event. The system creates a kanban for every requested material quantity, which is

subsequently deleted on replenishment.

The event-driven kanban is created using a separate function. The quantity to be replenished is

defined directly in this function. In the control cycle, you can define the following restrictions for

the definition of the kanban:

You can enter a rounding quantity to round up the required quantity.

Reaching or exceeding the trigger quantity:

The procedure here is similar to the two procedures described above. However, the

difference here is that the kanban is set to EMPTY when the remaining quantity in the

kanban reaches or exceeds the trigger quantity. In this process, the parts are withdrawn

with the quantity signal. In this case, you must maintain the trigger quantity as well as the

logic in the control cycle. This process is particularly useful for parts that are not used on

a regular basis. Therefore, you can procure parts with KANBAN without having to keep

several containers in stock. However, a PDC system is required for this procedure.

4. Event-Driven KANBAN:

In event-driven KANBAN, material provision is not based on a predefined number of kanbans or

a predefined kanban quantity. Instead, it is based on actual material consumption. The material is

not continually provided and replenished at a supply area. It is only replenished when specifically

requested. In this procedure, the advantages of the KANBAN module are used to make the

material replenishment process even more simple.

In the one-card KANBAN procedure, you can also use all the functions available in the KANBAN

module.

Before you can use this procedure, you must select one of the processes in the field, Trigger

replenishment when maintaining the control cycle.

Triggering replenishment at status IN USE:

After the first container is reported full, the system proceeds as follows: The second

kanban is set to the status WAIT. If a new kanban is requested, the system sets the full

kanban to the status IN USE. With this status change the kanban with status WAIT is

automatically changed to status EMPTY and thus replenishment is triggered. When this

new kanban is delivered, it receives the status FULL. As soon as the kanban from which

material is still being withdrawn is set to EMPTY, the system automatically sets it to status

WAIT and the process is repeated.

This procedure is illustrated in the following graphic:

Triggering replenishment at status WAIT:

After the first container is reported full, the system proceeds as follows: When a new

kanban is requested, the full kanban is set to status EMPTY. With this status change the

kanban with status WAIT is automatically changed to status EMPTY and thus

replenishment is triggered. The kanban from which material is still being withdrawn

receives the status WAIT. When the new kanban is delivered, it receives the status FULL

and the process is repeated. As opposed to the logic with the status IN USE, you do not

have to work with an additional status here. On the other hand, you have no possibility in

the system of seeing whether a container is currently being emptied.

You might also like

- Event-Driven KANBAN:: Replenishment When Maintaining The Control CycleDocument1 pageEvent-Driven KANBAN:: Replenishment When Maintaining The Control Cyclereddy pNo ratings yet

- SAP KanBan Process PDFDocument48 pagesSAP KanBan Process PDFAvinash DondapatyNo ratings yet

- SAP KanBan ProcessDocument48 pagesSAP KanBan ProcessSelvaCelladurai100% (4)

- One-Card KANBAN System with Quantity SignalDocument1 pageOne-Card KANBAN System with Quantity Signalreddy pNo ratings yet

- Kanban Quantity Signal ExplainedDocument1 pageKanban Quantity Signal Explainedreddy pNo ratings yet

- Kanban Process: G.V.SHIVAKKUMAR Venkatesansivakumar@yahoo - Co.inDocument1 pageKanban Process: G.V.SHIVAKKUMAR Venkatesansivakumar@yahoo - Co.inreddy pNo ratings yet

- KANBAN PROCESS IN SAP for TOYOTADocument20 pagesKANBAN PROCESS IN SAP for TOYOTAShweta SinhaNo ratings yet

- KANBAN With Quantity SignalDocument1 pageKANBAN With Quantity Signalreddy pNo ratings yet

- How To Control A Production SystemDocument4 pagesHow To Control A Production SystemSashi PrabhuNo ratings yet

- JIT, Push/Pull, Mixed Model Scheduling, KanbanDocument6 pagesJIT, Push/Pull, Mixed Model Scheduling, KanbanShweta GoswamiNo ratings yet

- New CKMLCP in S - 4hana - Erp Financials - SCN WikiDocument8 pagesNew CKMLCP in S - 4hana - Erp Financials - SCN Wikisurya100% (1)

- Kanban in SapDocument47 pagesKanban in SapProjteklab Ranchi67% (3)

- Kanban System Proposed for Stirling Engine Manufacturing CellDocument21 pagesKanban System Proposed for Stirling Engine Manufacturing CellBayu SetiadiNo ratings yet

- Ch6-The Kanban SystemDocument23 pagesCh6-The Kanban SystemSaadAminNo ratings yet

- The Kanban SystemDocument5 pagesThe Kanban SystemAnil SinghNo ratings yet

- Repetitive manufacturing with KanbanDocument3 pagesRepetitive manufacturing with KanbanFarooq JamalNo ratings yet

- Specify Batch Level and Activate Status Management in SAPDocument4 pagesSpecify Batch Level and Activate Status Management in SAPMahesh M KoriNo ratings yet

- Kanban ProcessDocument45 pagesKanban ProcessAvinash DondapatyNo ratings yet

- Alternative Based ConfirmationDocument17 pagesAlternative Based ConfirmationKarthik BhiravajoshulaNo ratings yet

- Define Batch Specific Unit of MeasureDocument8 pagesDefine Batch Specific Unit of MeasurevenkatNo ratings yet

- Kanban External ProcessingDocument3 pagesKanban External ProcessingvikasbumcaNo ratings yet

- Kanban System ExplainedDocument9 pagesKanban System ExplainedMik NavasquezNo ratings yet

- Just-In-Time and Kanban: Push or Pull?Document43 pagesJust-In-Time and Kanban: Push or Pull?cristianpetriceanNo ratings yet

- Sap WM Kanban Master DataDocument11 pagesSap WM Kanban Master DataAbhijitNo ratings yet

- 5.5 Advantages: 5.4.7 The Alternative: Kanban EstimationDocument40 pages5.5 Advantages: 5.4.7 The Alternative: Kanban EstimationĐạt Nguyễn TiếnNo ratings yet

- Purifying MAB Crystal Using EBA Chromatography and Freeze DryingDocument6 pagesPurifying MAB Crystal Using EBA Chromatography and Freeze DryingFarah NajihahNo ratings yet

- Lec2 PDFDocument8 pagesLec2 PDFAmal GSNo ratings yet

- Kanbansystempresentationforblog2003 110725050616 Phpapp02Document18 pagesKanbansystempresentationforblog2003 110725050616 Phpapp02sulisjogjaNo ratings yet

- ET401 Lab Self-Regulating Single Tank Level Control: Modeling and Tuning Profs Sarnacki, Owen, Olivari, Tefft Fall 2019Document4 pagesET401 Lab Self-Regulating Single Tank Level Control: Modeling and Tuning Profs Sarnacki, Owen, Olivari, Tefft Fall 2019essameldinNo ratings yet

- AWS Autscaling Cheat Sheet ResearchDocument17 pagesAWS Autscaling Cheat Sheet ResearchabhinavsrivastavNo ratings yet

- Chapter 16 - Lean Systems Answers To Questions, Problems, and Case Problems Answers To QuestionsDocument13 pagesChapter 16 - Lean Systems Answers To Questions, Problems, and Case Problems Answers To QuestionsomkarNo ratings yet

- Accrual EngineDocument48 pagesAccrual Enginerajesh1978.nair2381100% (2)

- Accrual Engine in S4 HANA 1909Document29 pagesAccrual Engine in S4 HANA 1909Гульнар Кожикенова100% (2)

- Kanban SystemDocument23 pagesKanban SystemSachin MaheshwarNo ratings yet

- KANBAN GUIDE TO CONTROL INVENTORY & IMPROVE FLOWDocument5 pagesKANBAN GUIDE TO CONTROL INVENTORY & IMPROVE FLOWsantosh kumarNo ratings yet

- Kanban System ExplainedDocument23 pagesKanban System ExplainedSlamet Dwi HaryantoNo ratings yet

- Kanban System ExplainedDocument23 pagesKanban System ExplainedSlamet Dwi HaryantoNo ratings yet

- Vf11 Cancel Not ClearedDocument3 pagesVf11 Cancel Not Clearedbinh0% (1)

- Kanban Pull Sequence and Kanban CardsDocument4 pagesKanban Pull Sequence and Kanban CardsPritesh MoganeNo ratings yet

- KANBANDocument16 pagesKANBANShreyasi RanjanNo ratings yet

- ACI WIPE OUT ProcedureDocument2 pagesACI WIPE OUT Proceduresachin giriNo ratings yet

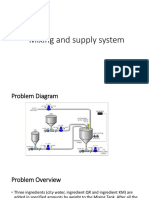

- Mixing and Supply SystemDocument5 pagesMixing and Supply SystemMOHAMMED ALSPITANNo ratings yet

- The Pull System Mystery ExplainedDocument5 pagesThe Pull System Mystery Explainedpg_menemNo ratings yet

- Batch ManagementDocument3 pagesBatch ManagementAbhijit GhodakeNo ratings yet

- Lect12 - Kanban SystemsDocument37 pagesLect12 - Kanban Systemsmaniea1990100% (1)

- RBA in Batch Backorder Processing: Rules-Based Availability CheckDocument2 pagesRBA in Batch Backorder Processing: Rules-Based Availability ChecksallyNo ratings yet

- Kanban: Presented byDocument12 pagesKanban: Presented byshrutesNo ratings yet

- Kanban InstructionsDocument17 pagesKanban InstructionsDũng TNNo ratings yet

- 5.4.1.5 Factors Influencing The Number of KanbansDocument40 pages5.4.1.5 Factors Influencing The Number of KanbansĐạt Nguyễn TiếnNo ratings yet

- 5600 SEmanualDocument28 pages5600 SEmanualyoucef88No ratings yet

- Drum Filling UnitDocument24 pagesDrum Filling Unitsathyanand tkNo ratings yet

- α=2∧that of feed back parameter is 1. α αDocument2 pagesα=2∧that of feed back parameter is 1. α αAnonymous AFFiZnNo ratings yet

- α=2∧that of feed back parameter is 1. α αDocument2 pagesα=2∧that of feed back parameter is 1. α αAnonymous AFFiZnNo ratings yet

- Revaluating at Actual PricesDocument2 pagesRevaluating at Actual PricesHeamanth Kkumar ChiittibommaNo ratings yet

- Search The Community Search SAP: Login RegisterDocument48 pagesSearch The Community Search SAP: Login RegisterAnil KumarNo ratings yet

- Interoperability of Batches Between ERP and EWMDocument28 pagesInteroperability of Batches Between ERP and EWMshailesh MishraNo ratings yet

- KANBAN: Streamlining Workflow for Effortless Efficiency (2023 Guide for Beginners)From EverandKANBAN: Streamlining Workflow for Effortless Efficiency (2023 Guide for Beginners)No ratings yet

- Your First Successes with Kanban: Understanding Kanban in a Knowledge-based Context and Implementing it in the CompanyFrom EverandYour First Successes with Kanban: Understanding Kanban in a Knowledge-based Context and Implementing it in the CompanyNo ratings yet

- Automotive Actuators and EVAP System TestingFrom EverandAutomotive Actuators and EVAP System TestingRating: 4.5 out of 5 stars4.5/5 (4)

- Highjump One Ui Basics 1.0Document35 pagesHighjump One Ui Basics 1.0reddy pNo ratings yet

- Quick Guide - EDIIDoc Interfacing To SAP ECC From External SystemDocument16 pagesQuick Guide - EDIIDoc Interfacing To SAP ECC From External SystemRicky DasNo ratings yet

- SAP Hybris Products For CommerceDocument1 pageSAP Hybris Products For Commercereddy pNo ratings yet

- Ale Idoc GuideDocument11 pagesAle Idoc GuideVenkateswara Reddy KolagotlaNo ratings yet

- Add coding in sectionDocument2 pagesAdd coding in sectionreddy pNo ratings yet

- Return Po PDFDocument7 pagesReturn Po PDFreddy pNo ratings yet

- Improve Supply Chain Visibility with SAP SNCDocument40 pagesImprove Supply Chain Visibility with SAP SNCreddy pNo ratings yet

- HybrissDocument1 pageHybrissreddy pNo ratings yet

- SAP acquires hybris ecommerce platform in 2013Document1 pageSAP acquires hybris ecommerce platform in 2013reddy pNo ratings yet

- SAP PO ConfirmationsDocument18 pagesSAP PO Confirmationsarrowxen8396100% (1)

- TyuDocument3 pagesTyureddy pNo ratings yet

- TyuDocument7 pagesTyureddy pNo ratings yet

- Training Manual SAP SNC v1.1Document47 pagesTraining Manual SAP SNC v1.1reddy pNo ratings yet

- Select Field That Would Be Display by This Query. Started by Choosing The Field GroupDocument8 pagesSelect Field That Would Be Display by This Query. Started by Choosing The Field Groupreddy pNo ratings yet

- SAP Integration Consulting PDFDocument2 pagesSAP Integration Consulting PDFreddy pNo ratings yet

- A Case ScenarioDocument1 pageA Case Scenarioreddy pNo ratings yet

- Out of Scope: The Following Areas Are Out of Scope For This Project: Point 1 Point 2 Point 3 Point 4 Point 5Document2 pagesOut of Scope: The Following Areas Are Out of Scope For This Project: Point 1 Point 2 Point 3 Point 4 Point 5reddy pNo ratings yet

- Creating ABAP QueryDocument2 pagesCreating ABAP Queryreddy pNo ratings yet

- What Is ABAP QueryDocument1 pageWhat Is ABAP Queryreddy pNo ratings yet

- Configuration in SAP: 1. Import Standard SAP CharacteristicsDocument1 pageConfiguration in SAP: 1. Import Standard SAP Characteristicsreddy pNo ratings yet

- Goods Receipt & Batch Creation in SAPDocument1 pageGoods Receipt & Batch Creation in SAPreddy pNo ratings yet

- 1 Project Description: 2.1 in ScopeDocument1 page1 Project Description: 2.1 in Scopereddy pNo ratings yet

- YuiDocument1 pageYuireddy pNo ratings yet

- Creation of A Batch Search Strategy: Automatic Batch Determination Based On Shelf LifeDocument1 pageCreation of A Batch Search Strategy: Automatic Batch Determination Based On Shelf Lifereddy pNo ratings yet

- Kanban Process: G.V.SHIVAKKUMAR Venkatesansivakumar@yahoo - Co.inDocument1 pageKanban Process: G.V.SHIVAKKUMAR Venkatesansivakumar@yahoo - Co.inreddy pNo ratings yet

- TesDocument1 pageTesreddy pNo ratings yet

- YuiDocument1 pageYuireddy pNo ratings yet

- Example TextDocument1 pageExample Textreddy pNo ratings yet

- TesDocument1 pageTesreddy pNo ratings yet

- TesDocument1 pageTesreddy pNo ratings yet

- 2390A Series Spectrum AnalyzersDocument6 pages2390A Series Spectrum AnalyzersElizabeth FaulknerNo ratings yet

- Computational Methods For Fracture PDFDocument135 pagesComputational Methods For Fracture PDFDiego PinoNo ratings yet

- Stellarisware Release Notes: Sw-Rln-6852Document160 pagesStellarisware Release Notes: Sw-Rln-6852Akio TakeuchiNo ratings yet

- Meltdown: The New Normal Call of The Wild Gear of The YearDocument93 pagesMeltdown: The New Normal Call of The Wild Gear of The YearAppaeommasaranghaeNo ratings yet

- Respharma Company BrochureDocument7 pagesRespharma Company BrochureHiteshi Parekh100% (1)

- Holiday Homework - CommerceDocument3 pagesHoliday Homework - CommerceBhavya JainNo ratings yet

- Vestige Frequently Asked QuestionsDocument2 pagesVestige Frequently Asked Questionsmadhu77No ratings yet

- SChedule VIDocument88 pagesSChedule VIbhushan2011No ratings yet

- The Mechanisms of Alloxan-And Streptozotocin-Induced DiabetesDocument11 pagesThe Mechanisms of Alloxan-And Streptozotocin-Induced DiabetesOktaviani Fitria Susanti SusantiNo ratings yet

- Mazda2 Brochure August 2009Document36 pagesMazda2 Brochure August 2009Shamsul Zahuri JohariNo ratings yet

- ACCT601 Australian Auditing and Assurance Services 201660Document15 pagesACCT601 Australian Auditing and Assurance Services 201660Rafayel MarufNo ratings yet

- MK84SUSDocument2 pagesMK84SUSali mortezaNo ratings yet

- Zkihel Ilaye Efera: EducationDocument3 pagesZkihel Ilaye Efera: EducationezkihelNo ratings yet

- Google Inc 2014Document19 pagesGoogle Inc 2014Archit PateriaNo ratings yet

- IM-100 IM-202 IM-300 IM-400 IM-500 Operating and Programming - TOCDocument6 pagesIM-100 IM-202 IM-300 IM-400 IM-500 Operating and Programming - TOCRudinHarianto0% (1)

- Effects of Job Evaluation On Workers' Productivity: A Study of Ohaukwu Local Government Area, Ebonyi State, NigeriaDocument6 pagesEffects of Job Evaluation On Workers' Productivity: A Study of Ohaukwu Local Government Area, Ebonyi State, Nigeriafrank kipkoechNo ratings yet

- OBURE Understanding How Reits Market WorksDocument3 pagesOBURE Understanding How Reits Market WorksJohn evansNo ratings yet

- Local Budget Memorandum No. 75 PDFDocument21 pagesLocal Budget Memorandum No. 75 PDFArnold ImbisanNo ratings yet

- Ahmad Hassan Textile MillsDocument52 pagesAhmad Hassan Textile Millsmakymakymaky007100% (4)

- FINAL REPORT WV Albania Buiding Futures PotentialDocument30 pagesFINAL REPORT WV Albania Buiding Futures PotentialVasilijeNo ratings yet

- Political Internet Memes On Corruption Issue Surrounding The Philippine Health Insurance CorporationDocument9 pagesPolitical Internet Memes On Corruption Issue Surrounding The Philippine Health Insurance CorporationFeline Joy SarinopiaNo ratings yet

- Phys234h Lecture03Document29 pagesPhys234h Lecture03Jessa Balanay GalaponNo ratings yet

- Kimwa Compound, Baloy 04/01/2023 03/27/2023 LYL Development Corporation 006430292000Document1 pageKimwa Compound, Baloy 04/01/2023 03/27/2023 LYL Development Corporation 006430292000Maricel IpanagNo ratings yet

- III International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaDocument8 pagesIII International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaIshita KotakNo ratings yet

- G.R. No. 173637 - Speedy TRial and Double JeopardyDocument3 pagesG.R. No. 173637 - Speedy TRial and Double Jeopardylr dagaangNo ratings yet

- Visual Design-Composition and Layout PrinciplesDocument5 pagesVisual Design-Composition and Layout PrinciplesRadyNo ratings yet

- Huawei Switch Configuration CommandDocument10 pagesHuawei Switch Configuration CommandMohamed Khalil RouissiNo ratings yet

- Informatica Administrator Interview Questions and AnswersDocument3 pagesInformatica Administrator Interview Questions and Answersatoztarget100% (2)

- Training MatrixDocument4 pagesTraining MatrixJennyfer Banez Nipales100% (1)

- Admissions To MUNDocument2 pagesAdmissions To MUNImran KamalNo ratings yet