Professional Documents

Culture Documents

SI F500++ATC+reference+point+error+alarm

Uploaded by

Artūrs CeimersOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SI F500++ATC+reference+point+error+alarm

Uploaded by

Artūrs CeimersCopyright:

Available Formats

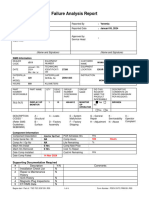

◐ Service Information ◑

Overseas Customer

Title Issued by

Service Team

Issue No. TCH2018040001

F500+_ATC reference point error alarm Issued on 2018. 04. 02

Prepared by Y.H. Park Approved

Applicable

□ Lathe ( ) ■ VMC ( ) □ HMC ( ) □ Others ( ) Reviewed by J.Y. Kwon Approved

models

□ Product Information □ Component Information

Category Approved by J.S. Kim Approved

□ Maintenance Information ■ Others

This is to advise the corrective measure for F500+ATC reference point irregularity alarm triggering.

- Below -

1. Applicable model : F500+

2. Description

▶ Description Before improvement

: It occurs during warming up after ATC reference point setting is

completed. ATC stop position varies in a random pattern.

- ATC servo home reference point position cannot be confirmed.

-> Machine ATC home X2.3(X), servo home X0.7(O)

▶ Cause

: Key is separate from the connection area between ATC

cambox and motor reducer.

-> The separation occurred due to size difference between the

reducer and cam box key.

(Cambox depth is two times the shaft length of the reducer (50 After improvement

㎜)

▶ Corrective Measures

: Fasten a washer designed to prevent the separation of key in

ATC motor reducer area.

3. Service Procedures (See corrective measures)

- Refer to this procedure to respond to the same problem.

■ Customer Support Team (Service Center) □ Sales Team □ Overseas Sales Team □ USA Affiliate □ EU

Distributed

Affiliate □ China Affiliate □ Production Department 1 □ Mass Production Engineering Team (Lathe Cutting,

to

Control, MC) □ Machine Quality Assurance Team of Quality HQs

Prepared by Y.H. Park Confirm

Accepted

Reviewed by J.Y. Kwon Confirm

by

References

Approved by J.S. Kim Confirm

Overseas Customer Service Team

You might also like

- FJ44 Service Bulletin - Fuel Flow Tube ReplacementDocument4 pagesFJ44 Service Bulletin - Fuel Flow Tube Replacementlong chenNo ratings yet

- Light FittingsDocument35 pagesLight FittingsAnandu AshokanNo ratings yet

- FJ44-72-129 - Feb. 6, 2015Document4 pagesFJ44-72-129 - Feb. 6, 2015mrboogie390No ratings yet

- Training SampleDocument43 pagesTraining SampleSpancerNo ratings yet

- RWRG0007 - Internal Heat Exchange (Cooler) Failure: Pre-Authorized Warranty Repair Guideline RWRG0007Document2 pagesRWRG0007 - Internal Heat Exchange (Cooler) Failure: Pre-Authorized Warranty Repair Guideline RWRG0007Bart JohnNo ratings yet

- Stress Calculation Stress Engineering Cover SheetDocument7 pagesStress Calculation Stress Engineering Cover SheetPappu Kishore KumarNo ratings yet

- Fj44 Service Bulletin: 1. Planning InformationDocument5 pagesFj44 Service Bulletin: 1. Planning InformationMaral HaghaniNo ratings yet

- SR B7509M22 Sa9190c444 Sa1041ct03 2023-06-04Document1 pageSR B7509M22 Sa9190c444 Sa1041ct03 2023-06-04Randy BuncabNo ratings yet

- Vibration Monitoring of Shipboard MachineryDocument8 pagesVibration Monitoring of Shipboard MachinerySarafianNo ratings yet

- Maintenance Transaction Record: Aircraft Identification and StatusDocument1 pageMaintenance Transaction Record: Aircraft Identification and StatusAlejandro BarradasNo ratings yet

- Certificate of Calibration: V. MartinezDocument2 pagesCertificate of Calibration: V. MartinezIng Guerrero CandiaNo ratings yet

- Hindalco Booster Fan SpecDocument9 pagesHindalco Booster Fan SpecMadhubalan ChinnasamyNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Certificate of Calibration: F. ViañaDocument2 pagesCertificate of Calibration: F. ViañaIng Guerrero CandiaNo ratings yet

- Zf2515 Zoi 4bzw Nach0umt3muccnDocument26 pagesZf2515 Zoi 4bzw Nach0umt3muccnraulNo ratings yet

- Check 3 Điểm MatchingDocument61 pagesCheck 3 Điểm MatchingNgọc Thiện BùiNo ratings yet

- Repair ContractDocument2 pagesRepair ContractGarantias ChireyNo ratings yet

- Indicador de Altura #Id 600201804Document2 pagesIndicador de Altura #Id 600201804Emily Hernandez CincoNo ratings yet

- FAR_ZBN41205Document4 pagesFAR_ZBN41205yeremia kristianNo ratings yet

- Compaction Inspection Report for Emily-1 ProjectDocument9 pagesCompaction Inspection Report for Emily-1 Projectmuhammad sauqiNo ratings yet

- Eo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofDocument7 pagesEo Atr42-72-21001 R00 Ata 72 - Engine - Igniter Plug With Incorrect Terminal - Inspection ofVince Renier RamosNo ratings yet

- Calibration Certificate for Valve Safety Model SB75-NPT 3/4Document2 pagesCalibration Certificate for Valve Safety Model SB75-NPT 3/4Ing Guerrero CandiaNo ratings yet

- Quote Labor PartsDocument2 pagesQuote Labor PartsOno Jr ArazaNo ratings yet

- Bms SystemDocument58 pagesBms SystemAnandu AshokanNo ratings yet

- VT ReportDocument1 pageVT ReportBauyrzhanNo ratings yet

- XZB (36B) Rotating Cups-Installation Technique and Inspection RecordDocument23 pagesXZB (36B) Rotating Cups-Installation Technique and Inspection RecordPercy ChenNo ratings yet

- Failure Analysis Report AFA 1Document5 pagesFailure Analysis Report AFA 1bartanto59No ratings yet

- 故障分析报告 30112022Document15 pages故障分析报告 30112022Jimmy ManagaraNo ratings yet

- Eaton Warranty FlowchartDocument1 pageEaton Warranty FlowchartQuispe IvanNo ratings yet

- MRADocument1 pageMRAChristine RucklinNo ratings yet

- PTW For DAM AreaDocument2 pagesPTW For DAM AreaAmigoz PearlNo ratings yet

- Gearbox Reconditioning & Repair: Solutions in MotionDocument24 pagesGearbox Reconditioning & Repair: Solutions in MotionMohamed ElfeilNo ratings yet

- Generator Manual 1Document392 pagesGenerator Manual 1Gopal Radhakrishnan100% (5)

- Dimensional Inspection Report: Rapport de Contrôle DimensionnelDocument3 pagesDimensional Inspection Report: Rapport de Contrôle DimensionnelZouhair BenmabroukNo ratings yet

- Ec 1811338 EcDocument25 pagesEc 1811338 EcChuck AnsphilNo ratings yet

- Technical Specification for Loop Seal BlowersDocument5 pagesTechnical Specification for Loop Seal BlowersJKKNo ratings yet

- Dist W300_0100 claim detailsDocument1 pageDist W300_0100 claim detailsLEONARDO DIEGO ALBINAGORTA PAREDESNo ratings yet

- MDR List of Content for PIPEDocument1 pageMDR List of Content for PIPED S Sagar TripuramalluNo ratings yet

- EP0220A 156 No's CR DEV-010229Document6 pagesEP0220A 156 No's CR DEV-010229nethajinet10No ratings yet

- Dealer Home Service and Incentive Program: Total Customer Satisfaction - Field Quality Assurance (FQA)Document9 pagesDealer Home Service and Incentive Program: Total Customer Satisfaction - Field Quality Assurance (FQA)danica gojo cruzNo ratings yet

- Eg5008 0 1Document2 pagesEg5008 0 1Victor SanchezNo ratings yet

- QuotDocument1 pageQuotnatty nigussieNo ratings yet

- DaimlerChrysler Ford GM Part Submission WarrantDocument4 pagesDaimlerChrysler Ford GM Part Submission WarrantEly SaldivarNo ratings yet

- V-2154-101-A-111 - 0A Method Statement Stairway Tank InstallationDocument24 pagesV-2154-101-A-111 - 0A Method Statement Stairway Tank InstallationWidya PrasetyaNo ratings yet

- Certificado de Luxometro (Radiometro)Document4 pagesCertificado de Luxometro (Radiometro)Jhonny BarberoNo ratings yet

- ® Maintenance: Ctros TelligentDocument5 pages® Maintenance: Ctros TelligentBishoo ShenoudaNo ratings yet

- BOP Plate VisualDocument1 pageBOP Plate VisualRanjithNo ratings yet

- Part Submission Warrant (PSW)Document8 pagesPart Submission Warrant (PSW)api-980604No ratings yet

- C-0659 R08-CR-RCD - Rev.B - Dimensional Inspection Record Form For Compressor RotorDocument4 pagesC-0659 R08-CR-RCD - Rev.B - Dimensional Inspection Record Form For Compressor RotorHimanyu RafiqNo ratings yet

- 1.mechanical - Electrical Completion Inspection Checklist - E20812Document3 pages1.mechanical - Electrical Completion Inspection Checklist - E20812Lulu ChaniagoNo ratings yet

- 3RN10112CB00 Datasheet en PDFDocument3 pages3RN10112CB00 Datasheet en PDFvishadkapadiaNo ratings yet

- FG Wilson India Operator (2 Cyl) PDFDocument69 pagesFG Wilson India Operator (2 Cyl) PDFviraj arjun ghadageNo ratings yet

- Ngg. YO UN G: Calibration Services PVT LTDDocument2 pagesNgg. YO UN G: Calibration Services PVT LTDchitranjan4kumar-8No ratings yet

- XZB (36B) Rotating Cups-Installation Technique and Inspection RecordDocument26 pagesXZB (36B) Rotating Cups-Installation Technique and Inspection RecordPercy ChenNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Audel Guide to the 2005 National Electrical CodeFrom EverandAudel Guide to the 2005 National Electrical CodeRating: 4 out of 5 stars4/5 (1)

- Stylus dimension by tool sizeDocument5 pagesStylus dimension by tool sizeArtūrs CeimersNo ratings yet

- Heidenhain TNC 151 AP Service InstructionsDocument78 pagesHeidenhain TNC 151 AP Service InstructionsArtūrs CeimersNo ratings yet

- Mastercam Natively Supported Import & Export File TypesDocument2 pagesMastercam Natively Supported Import & Export File TypesArtūrs CeimersNo ratings yet

- Formulas For MillingDocument5 pagesFormulas For MillingArtūrs CeimersNo ratings yet

- Programmable Logic Controllers Basic Level TextbookDocument18 pagesProgrammable Logic Controllers Basic Level TextbookAhmed Shehab AliNo ratings yet

- Installation and Operating InstructionsDocument20 pagesInstallation and Operating InstructionsArtūrs CeimersNo ratings yet

- Suggested Tapping SpeedsDocument1 pageSuggested Tapping SpeedsArtūrs CeimersNo ratings yet

- Cutting Data Corrax EngDocument5 pagesCutting Data Corrax Engstanalina00No ratings yet

- FESTO Hydraulics CourseDocument236 pagesFESTO Hydraulics Coursemadmax2222100% (17)

- Red Waste of MetalworkingDocument44 pagesRed Waste of MetalworkingArtūrs CeimersNo ratings yet

- CNC Turning Coordinate SystemDocument1 pageCNC Turning Coordinate SystemArtūrs Ceimers100% (1)

- SIEMENS SINUMERIK 802D Programming and Operating Manual For TurningDocument504 pagesSIEMENS SINUMERIK 802D Programming and Operating Manual For TurningArtūrs Ceimers100% (2)

- Machine Shop Fluid MaintenanceDocument5 pagesMachine Shop Fluid MaintenanceArtūrs CeimersNo ratings yet

- Q&A Manual Guide 16i 18i 21iDocument23 pagesQ&A Manual Guide 16i 18i 21ivrpatel1No ratings yet

- Checklist Mobile App Testing 0Document11 pagesChecklist Mobile App Testing 0Sana Khan100% (1)

- Transition To F90Document17 pagesTransition To F90Gowtham ReddyNo ratings yet

- Impact of Computer Security System On The Job Performance of The Office TechnologistDocument10 pagesImpact of Computer Security System On The Job Performance of The Office TechnologistIjasini Banga GabrielNo ratings yet

- Guia Modem Zyxel VMG862 3T50BDocument4 pagesGuia Modem Zyxel VMG862 3T50BJosé AntonioNo ratings yet

- Applications Highlights: - Manufacturing, Electronics and Automotive: - Medical - Clinical Lab AutomationDocument2 pagesApplications Highlights: - Manufacturing, Electronics and Automotive: - Medical - Clinical Lab AutomationWarkaNo ratings yet

- Techknowlogia Journal 2002 Jan MacDocument93 pagesTechknowlogia Journal 2002 Jan MacMazlan ZulkiflyNo ratings yet

- Signal Generator With Arduino Using DDS and Pico - Hackster - IoDocument9 pagesSignal Generator With Arduino Using DDS and Pico - Hackster - IoAhmed Abdel AzizNo ratings yet

- Str-X67xxseries An en PDFDocument19 pagesStr-X67xxseries An en PDFRenn PaculanangNo ratings yet

- PFB2N60/PFF2N60 DatasheetDocument7 pagesPFB2N60/PFF2N60 DatasheetCostel CojocaruNo ratings yet

- Data Sheet - iSH Servo Drive SystemDocument34 pagesData Sheet - iSH Servo Drive Systemm.etNo ratings yet

- PF Lecture 4Document63 pagesPF Lecture 4yaseen ejazNo ratings yet

- DCRS 5960 28F DCDocument7 pagesDCRS 5960 28F DCPhạm Văn ThuânNo ratings yet

- Comptia Security Sy0 701 Exam Objectives (5 0)Document21 pagesComptia Security Sy0 701 Exam Objectives (5 0)Erick Camilo50% (4)

- Dashboard Design LayoutDocument6 pagesDashboard Design Layoutluis anchayhua pradoNo ratings yet

- Querying The Schema's Using Xspath in XML Language: T. Vamsi Vardhan Reddy, D.V. Subbaiah. M.Tech, (PH.D)Document5 pagesQuerying The Schema's Using Xspath in XML Language: T. Vamsi Vardhan Reddy, D.V. Subbaiah. M.Tech, (PH.D)IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- 1.2.2 Lab - Linux ReviewDocument31 pages1.2.2 Lab - Linux ReviewMARY MAE MAGDALENE GREGORENo ratings yet

- Software Project Management 4th Edition: Selection of An Appropriate Project ApproachDocument14 pagesSoftware Project Management 4th Edition: Selection of An Appropriate Project ApproachSudha KarNo ratings yet

- Appid Yahoo Mail Neo&wssid EZ7 MR Zti M4 J&ymreqid Bec 69Document10 pagesAppid Yahoo Mail Neo&wssid EZ7 MR Zti M4 J&ymreqid Bec 69Juliana R. B. AlmeidaNo ratings yet

- 8251 PciDocument14 pages8251 PciSoham ChatterjeeNo ratings yet

- Piping DownloadsDocument11 pagesPiping DownloadsAnkit ChughNo ratings yet

- F6TesT EnglishDocument270 pagesF6TesT EnglishHamylto PamoNo ratings yet

- SSED - Solved Problems For Chapter 5Document7 pagesSSED - Solved Problems For Chapter 5MINH NGUYỄN THẾNo ratings yet

- Optimal Control System Company Profile PDFDocument9 pagesOptimal Control System Company Profile PDFkarna patelNo ratings yet

- ASaP LNG Sampler Brochure 01-2018Document5 pagesASaP LNG Sampler Brochure 01-2018Arfan NNo ratings yet

- 114 CodeInspectorDocument28 pages114 CodeInspectorAbhishek KumarNo ratings yet

- Serial Code Number Tinta L800Document5 pagesSerial Code Number Tinta L800awawNo ratings yet

- Freemake Software For YoutubeDocument5 pagesFreemake Software For YoutubeVickfor LucaniNo ratings yet

- The Best Web App To Convert JPG To PDFDocument1 pageThe Best Web App To Convert JPG To PDFJekly MoningkaNo ratings yet

- MSI MS-953500aDocument1 pageMSI MS-953500aFERNANDO R. RNo ratings yet

- JembatanCableTray02 ModelDocument1 pageJembatanCableTray02 ModelMas DiqiNo ratings yet