Professional Documents

Culture Documents

How Tower Cranes Work

Uploaded by

Scarlet ShweCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How Tower Cranes Work

Uploaded by

Scarlet ShweCopyright:

Available Formats

ctu

el

Stru re & Marshall, J Steel Struct Constr 2017, 3:2

DOI: 10.4172/2472-0437.1000133

Co

e

urnal of St

Journal of Steel Structures & Construction

nstructi on

Jo

ISSN: 2472-0437

Research

Short Article

Communication Open

OpenAccess

Access

How Tower Cranes Work

Marshall B*

Director of Engineering Entrepreneurs Program, North Carolina State University, North Carolina, USA

Tower Cranes The machinery arm contains the winch motor that lifts the load,

along with the control electronics that drive it and the cable drum, as

Tower cranes are a common fixture at any major construction shown in Figure 4.

site. They’re pretty hard to miss they often rise hundreds of feet into

the air, and can reach out just as far. The construction crew uses the The motors that drive the slewing unit are located above the unit s

tower crane to lift steel, concrete, large tools - like acetylene torches and large rotational gear (Figure 5).

generators, and a wide variety of other building materials (Figure 1). 3) And, the operators cab (Figure 6).

When you look at one of these cranes, what it can do seems nearly

impossible: Why doesn’t it tip over? How can such a long boom lift

so much weight? How is it able to grow taller as the building grows

taller? If you have ever wondered about how tower cranes work, then

this article is for you. Here, you will find out the answers to all of these

questions and more!

Parts of a Tower Crane

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the

crane.

2. The base connects to the mast (or tower), which gives the tower

crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-

gear and motor) that allows the crane to rotate.

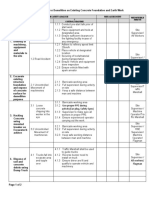

Figure 2: Slewing unit.

4. Attached to the slewing unit is the jib (or boom), the machinery

arm, the counterweights.

5. And, the Operators Cab.

On top of the slewing unit are three parts (Figure 2):

1) The long horizontal jib (or working arm), which is the

portion of the crane that carries the load. A trolley runs along the jib to

move the load in and out from the cranes center (Figure 3);

2) The shorter horizontal machinery arm, which contains

the cranes motors and electronics as well as the large concrete

counterweights.

Figure 3: The long horizontal jib.

*Corresponding author: Marshall Brain, Director of Engineering Entrepreneurs

Program, North Carolina State University, North Carolina, USA; Tel: +1 919-515-

2011; E-mail: marshalle@marshallbrain.com

Received June 08, 2017; Accepted September 28, 2017; Published October 04,

2017

Citation: Marshall B (2017) How Tower Cranes Work. J Steel Struct Constr 3: 133.

doi: 10.4172/2472-0437.1000133

Copyright: © 2017 Marshall B. This is an open-access article distributed under

the terms of the Creative Commons Attribution License, which permits unrestricted

Figure 1: Tower crane. use, distribution, and reproduction in any medium, provided the original author and

source are credited.

J Steel Struct Constr, an open access journal Volume 3 • Issue 2 • 1000133

ISSN: 2472-0437

Citation: Marshall B (2017) How Tower Cranes Work. J Steel Struct Constr 3: 133. doi: 10.4172/2472-0437.1000133

Page 2 of 3

Figure 4: The shorter horizontal machinery arm.

Figure 7: The operators cab.

Figure 5: The winch motor in machinery arm.

Figure 8: Large anchor bolts embedded deep into this pad support the base

of the crane.

members structure gives the mast the strength to remain upright.

So these cranes are essentially bolted / anchored to the ground

to ensure their stability. In the next section, you will learn how tower

cranes “grow.”

How Do They Grow?

Tower cranes arrive at the construction site on 10 to 12 tractor-

trailer rigs.

Figure 6: The motors that drive the slewing unit.

The crew uses a mobile crane to first assemble a 40-foot (12 m)

mast that consists of two vertical mast sections and the slewing gear.

Now, it would be a pretty big problem if one of these things fell over

on a jobsite. Let’s find out what keeps these massive structures standing Then the jib and the machinery sections are assembled.

upright (Figure 7).

The mobile crane then places these horizontal members on the pre-

Why Don’t They Fall Over? assembled mast sections.

When you look at a tall tower crane, the whole thing seems The counterweights are then added (Figures 9 and 10).

outrageous - why don’t these structures fall over, especially since they

To rise to its maximum height, the crane grows itself one mast

have no support wires of any kind?

section at a time! The crew uses a top climber or climbing frame

The first element of the tower crane s stability is a large concrete that fits between the slewing unit and the top of the mast. Here is the

pad that the construction company pours several weeks before the process:

crane arrives. This pad typically measures 30 feet by 30 feet by 4 feet (10

× 10 × 1.3 meters) and weighs 400,000 pounds (182,000 kg). These are a) The crew hangs a weight on the jib to balance the

the pad measurements for the crane shown here. counterweight.

Large anchor bolts embedded deep into this pad support the base b) The crew detaches the slewing unit from the top of the mast.

of the crane (Figure 8): Large hydraulic rams in the top climber push the slewing unit up 20

feet (6 m) (Figures 11 and 12).

The mast rises from this firm foundation. The mast is a large, lattice

structure, typically 10 feet (3.2 meters) square. The triangulated cross- The crane operator uses the crane to lift another 20 foot mast

J Steel Struct Constr, an open access journal Volume 3 • Issue 2 • 1000133

ISSN: 2472-0437

Citation: Marshall B (2017) How Tower Cranes Work. J Steel Struct Constr 3: 133. doi: 10.4172/2472-0437.1000133

Page 3 of 3

section into the gap opened by the climbing frame. Once bolted in

place, the crane is 20 feet taller!

Once the building is finished and it is time for the crane to come

down, the process is reversed - the crane disassembles its own mast and

then mobile cranes disassemble the rest.

How Much Weight Can They Lift?

A typical tower crane has the following specifications:

1. Maximum unsupported height: 265 feet (80 meters) - The

crane can have a total height much greater than 265 feet if it is tied into

the building as the building rises around the crane.

Figure 9: Mobile crane.

2. Maximum reach: 230 feet (70 meters).

3. Maximum lifting power: 19.8 tons (18 metric tons).

4. Counterweights: 20 tons (16.3 metric tons).

The maximum load that the crane can lift is 18 metric tons (39,690

pounds), but the crane cannot lift that much weight if the load is

positioned at the end of the jib. The closer the load is positioned to the

mast (center of rotation), the more weight the crane can lift safely.

Alternatively, the crane may be rated as having capacity of 300

tonne-meters. The 300 tonne-meter rating tells you the relationship.

For example, if the operator positions the load 30 meters (100 feet)

Figure 10: The counter weights.

from the mast, the crane can lift a maximum of 10.1 tonnes (i.e., 300

tonne divided by 30 meters).

The crane uses two limit switches to make sure that the operator

does not overload the crane:

a) The maximum load limit switch monitors the pull on the

cable and makes sure that the load does not exceed 18 tonnes.

b) The load moment limit switch makes sure that the operator

does not exceed the tonne-meter rating of the crane as the load moves

out on the jib. A cat head assembly in the slewing unit can measure

the amount of collapse in the jib and sense when an overload condition

occurs.

Renting a Tower Crane

Most construction companies rent their tower cranes from another

company.

This separate organization would mobilize the crane to the jobsite,

assemble it and charge a monthly fee while the crane is on the site.

Figure 11: Climbing frame.

The typical fee for installation and disassembly runs around

US$60,000. This price includes shipping the crane to the site, renting

the mobile crane used to assemble the tower crane, the cost of the crew

that handles the assembly, etc.

A typical monthly rental fee for a 150-foot-tall tower crane is

approximately US$15,000, with an additional charge to rent the

climbing frame and extra mast sections.

Citation: Marshall B (2017) How Tower Cranes Work. J Steel Struct Constr 3:

Figure 12: Tower crane. 133. doi: 10.4172/2472-0437.1000133

J Steel Struct Constr, an open access journal Volume 3 • Issue 2 • 1000133

ISSN: 2472-0437

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- BCN 3224 - Exam 3 ReviewDocument34 pagesBCN 3224 - Exam 3 Reviewmgwin17No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Tank FoundationsDocument83 pagesTank Foundationsdroates100% (17)

- ULSADO-JSA-Demolation Existing Concrete FoundationDocument2 pagesULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- Chapter 7 - Transient Heat Conduction PDFDocument64 pagesChapter 7 - Transient Heat Conduction PDFhaqjmiNo ratings yet

- Pipe SupportDocument19 pagesPipe SupportScarlet Shwe50% (2)

- Lifetime Extension Steam TurbineDocument10 pagesLifetime Extension Steam Turbineramakantinamdar100% (1)

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjNo ratings yet

- AtmDocument2 pagesAtmJegan RichardNo ratings yet

- Architectural SpecificationDocument16 pagesArchitectural SpecificationScarlet ShweNo ratings yet

- Architectural SpecificationDocument16 pagesArchitectural SpecificationScarlet ShweNo ratings yet

- Komatsu SAA6D114E-3D Engine ManualDocument634 pagesKomatsu SAA6D114E-3D Engine ManualLuzioNetoNo ratings yet

- Rcs454: Python Language Programming LAB: Write A Python Program ToDocument39 pagesRcs454: Python Language Programming LAB: Write A Python Program ToShikha AryaNo ratings yet

- TachometerDocument51 pagesTachometerKiran SugandhiNo ratings yet

- Planning - THERM - Timber - H-I - H-V - 2016 (RAICO)Document542 pagesPlanning - THERM - Timber - H-I - H-V - 2016 (RAICO)AnrStukNo ratings yet

- Hager Protection Devices TechnicalDocument70 pagesHager Protection Devices TechnicalerreagaaNo ratings yet

- Application Examples American: Example ProblemsDocument4 pagesApplication Examples American: Example ProblemsScarlet ShweNo ratings yet

- Plane Frame With Steel Design - Staad ProDocument11 pagesPlane Frame With Steel Design - Staad ProScarlet ShweNo ratings yet

- Methods For Achieving and Measuring Soil Compaction - tcm45-341155Document6 pagesMethods For Achieving and Measuring Soil Compaction - tcm45-341155Tan Yi LiangNo ratings yet

- Continuous Spouting NZMRM Capacity CalculationDocument9 pagesContinuous Spouting NZMRM Capacity CalculationScarlet ShweNo ratings yet

- Network Scanner Tool User's GuideDocument42 pagesNetwork Scanner Tool User's GuideScarlet ShweNo ratings yet

- Seismic Loads ExplainedDocument11 pagesSeismic Loads ExplainedScarlet ShweNo ratings yet

- Wind DesignDocument1 pageWind DesignScarlet ShweNo ratings yet

- Manual Check Using STAADPRODocument31 pagesManual Check Using STAADPRODenden DermawanNo ratings yet

- Read MeDocument1 pageRead MeScarlet ShweNo ratings yet

- Critical Path Method Construction SchedulingDocument19 pagesCritical Path Method Construction SchedulingScarlet ShweNo ratings yet

- Steel Note PDFDocument28 pagesSteel Note PDFScarlet ShweNo ratings yet

- General Civil NoteDocument18 pagesGeneral Civil NoteScarlet ShweNo ratings yet

- Vend RegDocument49 pagesVend RegProcaeHexdofNo ratings yet

- Spec Oem National 300qDocument2 pagesSpec Oem National 300qJose Javier GamaNo ratings yet

- Actividad 5 TermodinamicaDocument4 pagesActividad 5 TermodinamicaAngel EncastinNo ratings yet

- Coils TransponderDocument4 pagesCoils TransponderGuadalajara JaliscoNo ratings yet

- Geotech Final ReportDocument38 pagesGeotech Final Reportapi-320590292No ratings yet

- MC Lab Manual ModifiedDocument64 pagesMC Lab Manual ModifiedBaswamy CseNo ratings yet

- Westinghouse Manuals PDFDocument38 pagesWestinghouse Manuals PDFCarl HensonNo ratings yet

- Unit One: Wind LoadsDocument67 pagesUnit One: Wind Loadsabdu yimerNo ratings yet

- FRL GoyenDocument12 pagesFRL GoyenAbigael92No ratings yet

- Nylatron GSM Technical Data SheetDocument1 pageNylatron GSM Technical Data SheetgovindsrNo ratings yet

- Ktu Laca Solved Question PaperDocument22 pagesKtu Laca Solved Question PaperSofiyaNo ratings yet

- RtosDocument78 pagesRtossekinNo ratings yet

- ITU Rec. BT.709-5 Defines Parameters for HDTV StandardsDocument31 pagesITU Rec. BT.709-5 Defines Parameters for HDTV StandardsHarold Coila VillenaNo ratings yet

- Ce1a3q E1a3qDocument5 pagesCe1a3q E1a3qapi-239041842No ratings yet

- What Is Transmission Channel ?Document12 pagesWhat Is Transmission Channel ?tusharNo ratings yet

- RCP-15 Drilling Fluid Agitator Parts ListDocument5 pagesRCP-15 Drilling Fluid Agitator Parts ListwaleedNo ratings yet

- Durehete 1055Document5 pagesDurehete 1055alextentwenty100% (1)

- Introduction To Soil MechanicsDocument20 pagesIntroduction To Soil MechanicsMaeen AhmedNo ratings yet

- Fluid Mechanics Subjective QuestionsDocument3 pagesFluid Mechanics Subjective QuestionsCrewdex ProNo ratings yet

- Lars Part Ix - Safety Managment System Requirements-SmsDocument24 pagesLars Part Ix - Safety Managment System Requirements-SmssebastienNo ratings yet