Professional Documents

Culture Documents

Amana BTM MNT FRZR Tech Sheet 16023133

Uploaded by

En VyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amana BTM MNT FRZR Tech Sheet 16023133

Uploaded by

En VyCopyright:

Available Formats

Service Specifications Bottom Mount RefrigeratorTechnical Information

AFD2535DEB AFD2535DEB0, AFD2535DEQ AFD2535DEQ0,

AFD2535DES AFD2535DES0, AFD2535DEW AFD2535DEW0,

! WARNING MFD2560HEB MFD2560HEB0, MFD2560HEQ MFD2560HEQ0,

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before

servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires MFD2560HES MFD2560HES0, MFD2560HEW MFD2560HEW0

removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization. Due to a possibility of personal injury or property damage, always contact an authorized technician for

3. Release the refrigerator door light switch. service or repair of this refrigerator.

4. The control will display Fd to confirm entry into the Forced Defrost Mode.

! CAUTION

Freezer Refrigerator

F

All safety information must be followed as provided in Service Manual 16022769.

5. Entry is confirmed by pressing the Refrigerator Down key once more. The unit is off and in the Defrost Mode.

Note: All control functions will be turned off (Compressor, Defrost, Evaporator Fan, the damper will

remain in its current position).

6. The control will default to the short run period test as shown here: ! WARNING

Freezer Refrigerator

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before

S servicing unless testing is required. Discharge capacitors through a 10,000 ohm resistor before handling. Wires

removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization.

Note: You can toggle between the (S)hort and (L)ong test mode by pressing the Refrigerator UP Key.

Long Test mode is used for factory test and should not be used in the field.

Freezer Refrigerator No-Load Performance, Controls in Normal Position

Refrigerator Center

L Compartment Freezer Compartment

Percent Run Time Cycles/24 hr Average Food Average Food

7. Once the desired mode is displayed, confirm the forced defrost by pressing the Refrigerator down Key once. Kw/24 hr ±0.4 ±10% Temperature ±3°F Temperature ±3°F

±25%

The defrost will begin immediately and the display will return to a normal operating display with set point values.

Freezer Refrigerator

Ambient °F 70° 90° 110° 70° 90° 110° 70° 90° 110° 70° 90° 110° 70° 90° 110°

25 cu ft 1.0 1.60 2.3 28 48 65 35 39 25 38 36 35 0 0 0

4 4

Temperature Relationship Test Chart

8. Close the Refrigerator door(s). You are in the defrost mode Suction

Note: Forced Defrost mode can be exited at any time prior to step 7 by closing the Refrigerator Door(s). Evaporator Evaporator Suction Line Average Total Pressure Head Pressure

Service Test Mode: Outlet Inlet ±7°F Wattage ±10% ±2 PSIG ± 5 PSIG

The service test functions are performed using the refrigerator display and keypad. Enter the Service Test Mode ±3°F ±3°F

by performing the following sequence of events: Ambient °F 70° 90° 70° 90° 70° 90° 70° 90° 70° 90° 70° 90°

25 cu ft -20 -17 -20 -17 85 105 135 140 6"(Vac.) 0 87 137

1. Hold the refrigerator door light switch closed.

2. Press the Refrigerator Temperature Up keypad 3 times consecutively. Schematic

Note: The 3 Keystrokes must be done consecutively and within 10 seconds.

3. Release the refrigerator door light switch.

4. The control will display SE to confirm entry into the service mode.

Freezer Refrigerator

S E

5. Entry to the Service Menu is confirmed by pressing the Refrigerator Up key once more.

6. The control will display its software version for 3 seconds.

Freezer Refrigerator

2 5

7. Following the software revision display the freezer display will read the first test number in the

diagnostic tree. The refrigerator display will be blank.

Freezer Refrigerator

1

Note: All control functions will be turned off (Compressor, Defrost, Evaporator Fan, the damper will

remain in its current position).

8. You are now in the SERVICES TEST operational mode and may use the diagnostic tests.

The Service Test Mode can be exited at any time by closing the Refrigerator Door(s).

April 2004 4 16023133 April 2004 1 16023133

© 2004 Maytag Services © 2004 Maytag Services

Component Specifications Service Specifications

! WARNING ! WARNING

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before

servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires

servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires

removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization.

removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization.

Programming Mode:

Component Specifications all parts Note: The Program Code is located on the Serial Plate on this unit after the word Code.

115VAC/60HZ unless noted

Compressor run capacitor Volt..................................................... 220 VAC 1. Open the Fresh Food door and hold the Fresh Food door light switch closed while pushing the Freezer

Capacitance ...................................... 15 µfd ± 10% Temperature Down Key pad 3 times consecutively.

Compressor BTUH ................................................. 730 BTUH

Watt ................................................... 60 Hz / 125 watts Note: The 3 Keystrokes must be done consecutively and within 10 seconds.

Current Lock rotor .............................. 19.0 amps± 15% 2. Release the Fresh Food door light switch.

Current Full load ................................ 1.09 amps± 15%

Resistance Run windings .................. 3.33 ohms± 15%

3. The control will display PE to confirm entry into the programming mode.

Freezer Refrigerator

Resistance Start windings ................. 4.28 ohms± 15%

Electric damper control Maximum closing time 36 seconds P E

Temperature Rating 20°F- 110°F

RPM 1

4. Entry is confirmed by pressing the Freezer Down key once more.

Thermistor Temperature Resistance

77°F.................................................... 10,000 ohms Note: All control functions will be turned off (Compressor, Defrost, Evaporator Fan, the damper will

36°F ................................................... 29,500 ohms remain in its current position)

0°F...................................................... 86,300 ohms

Condenser motor Rotation (facing end opposite shaft) Clockwise 5. The control will display the current Program Code. This value should be validated with the Program Code

RPM 1250 RPM printed on the unit serial plate.

Watt.................................................... 4.2 watts±15%@115VAC Freezer Refrigerator

Current ............................................... 0.63 amps± 15%@115VAC

2 5

Note: If the Program Code is correct, the Programming Mode is exited by closing the Refrigerator door(s).

Evaporator fan motor Rotation (facing end opposite shaft) Clockwise 6. To set the desired Program Code number press the Freezer and Refrigerator UP keys. The

RPM…………………………………… 2940 RPM

Watt……………………………………. 4.6 ±15% watts@115VAC corresponding digit will be advanced with each key press.

Overload/Relay Ult. trip amps @ 158°F (70°C) ........... 2.67 amps± 15% 7. Once the desired Program Code is displayed, press the Freezer DOWN Key until the Program Code

Close temperature ........................... 142°F ±16° begins flashing indicating it has been saved.

Open temperature............................ 284°F ±9° Note: If you attempt to enter an invalid Program Code the control will not save the new code, but will flash the old

Short time trip (seconds).................... 10 seconds ±5

Short time trip (amps @77°F (25°C).. 11 amps ±2amps

code and this will be displayed. (The unit will NOT run with a Program Code of 00).

Control board Volt..................................................... 120VAC, 60 HZ

8. Once the Program Code has been saved the Programming Mode is exited by closing the Refrigerator

See Control Board section for door(s). If the new code is incorrect this process should be repeated after closing the Refrigerator door(s).

diagnostics

Thermostat (Defrost) Volt .................................................... 120/240 VAC

The Programming mode can be exited at any time by closing the Refrigerator Door(s).

Watt ................................................... 495 watts

Current ............................................... 10/5 amps Defrost Operation:

Resistance across terminals: The Control Board adapts the compressor run time between defrosts to achieve optimum defrost intervals by

Above 42°F ±5°.................................. Open monitoring the length of time the defrost heater is on.

Below 12°F ±7° .................................. Closed After initial power up, defrost interval is 4 hours compressor run time. Defrost occurs immediately after the 4 hours.

Evaporator heater Volt..................................................... 115 VAC

Wattage.............................................. 435 ±5% watts @ 115VAC

Note: Once unit is ready to defrost there is a 4 minute wait time prior to the beginning of the defrost cycle.

Resistance ......................................... 29 ±5% ohms Optimum defrost is 15 minutes. Each additional minute the defrost thermostat remains closed, 1 hr. is subtracted from

Mullion Assembly w/ Heater Volt……………………………………… 120 VAC

the previous defrost interval. Each minute the thermostat opens prior to optimum defrost, it extends the next defrost

Wattage.............................................. 10±.5 watts @ 120VAC interval 1 hr. When defrost thermostat opens there is a 4-6 minute drip time before compressor restarts or Control

Resistance ......................................... 1440 ±5% ohms Board will terminate defrost at 25 minutes if defrost thermostat has not opened and will reset the defrost interval to the

Resistance checked at leads at center of hinged side of Fresh 8 hr. minimum setting.

Food door. 4 hours of continuous compressor run resets the next defrost interval to 8 hours and will initiate a defrost, if 8 hours of

Water valve, dual Volt……………………………………… 120 VAC

Watt.................................................... 35 watts (Brown coil) compressor run time has also occurred.

20 watts (Yellow coil) Forced Defrost Mode:

Light switch Type…………………………………….. SPST NC Power up Refrigeration mode will occur unless both the cold control and defrost terminator are open, in that case the

Volt……………………………………… 125/250 VAC

Current………………………………….. 8 / 6 amps

defrost mode will occur for 2 minutes.

The forced defrost function is performed using the refrigerator display and keypad. Enter the Forced Defrost

Light switch / Interlock Type…………………………………….. SPDT NO/NC

Volt……………………………………… 125/250 VAC

Mode by performing the following sequence of events:

Current………………………………….. 5 / 2.5 amps 1. Hold the refrigerator door light switch closed.

Energy Saver switch Type…………………………………….. SPST NO

Volt……………………………………… 125/250 VAC 2. Press the Refrigerator Temperature Down keypad 3 times consecutively.

Current………………………………….. 16 / 8 amps Note: The 3 keystrokes must be consecutive and within 10 seconds.

April 2004 2 16023133 April 2004 3 16023133

© 2004 Maytag Services © 2004 Maytag Services

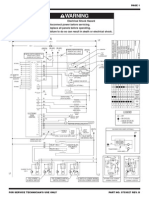

Wiring Diagram Service Specifications

! WARNING ! WARNING

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before

servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires

removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization. removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization.

See Note below

about alternate wiring Service Test 1 – Defrost Thermostat & Defrost Circuit Test

of Refrigerator door harness When selected this test will display the state of the defrost thermostat. In order to perform this test the defrost heater will

be energized. The test is activated and deactivated using the Refrigerator Up key. Once activated, this test must be

Note: When energy switch is in the “Off” position the fresh food mullion heater is energized and when the de-activated to move to another test number. The Freezer Up / Down keys allow selection of the test to be

energy switch is in the “On” position the fresh food mullion heater is not powered. To avoid moisture from performed.

condensing on the fresh food mullion the energy switch should always be in the “Off” position. This test also allows observation and measurement of proper defrost function. You can observe defrost heat and voltages

while the test is activated.

Freezer Refrigerator

1 O

DEFROST THERMOSTAT OPEN

Freezer Refrigerator

1 S

DEFROST THERMOSTAT SHORTED (CLOSED)

Service Test 2 – Compressor/Condenser Fan Test

When selected and activated this test will operate the Compressor/Condenser Fan circuit. You should evaluate proper

operation of the compressor and condenser fan. The Refrigerator Up key will toggle between “O” / “F” (ON & OFF)

the compressor drive circuit. The test must be “deactivated” or in the OFF position to move to another test selection.

Freezer Refrigerator

2 O

Freezer Refrigerator

2 F

OBSERVE COMPRESSOR & CONDENSER FAN FUNCTION

Service Test 3 – Evaporator/Freezer Fan Test

When selected and activated this test will operate the freezer fan. The Refrigerator Up key will toggle between “O” /

“F” (ON & OFF) the fan drive circuit. You will have to inspect the fan for proper function. The test must be “deactivated” or

in the OFF position to move to another test selection.

Freezer Refrigerator

3 O

Freezer Refrigerator

3 F

OBSERVE FAN OPERATION

Note: In the event of excessive moisture on fresh food door mullion. The red and blue cabinet wires to door

harness can be reversed to power fresh food door mullion heater continuously. This will help to reduce

moisture on fresh food door mullion. See wiring alternate above for wiring in mullion heater for continuous

operation. When powered continuously Energy Switch is no longer in heater circuit.

April 2004 8 16023133 April 2004 5 16023133

© 2004 Maytag Services © 2004 Maytag Services

Service Specifications Service Specifications

! WARNING ! WARNING

To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before To avoid risk of electrical shock that can cause death or severe personal injury, disconnect unit from power before

servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires servicing unless tests require power. Discharge capacitors through a 10,000-ohm resistor before handling. Wires

removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization. removed during disassembly must be replaced on correct terminals to ensure proper grounding and polarization.

Service Test 6 – Open Damper Test

Service Test 4 – Fresh Food Thermistor Test When selected this test will indicate the current position “O” / “C” (OPEN / CLOSED) of the refrigerator damper. The

When selected and activated this test will display Pass, Open, Short result for a test on the Fresh Food Thermistor Refrigerator Up key will toggle the damper open and closed. You must allow 1 minute for each attempt to change

circuit as show below. The test is activated and de-activated via the Refrigerator Up key, and must be the damper position. You should observe proper damper function.

Freezer Refrigerator

de-activated to move to another test selection.

Freezer Refrigerator 6 O

4 P Freezer Refrigerator

PASS RESULT 6 C

Freezer Refrigerator OBSERVE DAMPER FUNCTION

4 O ! CAUTION

Adjustments of Service Test 7 or Service Test 8 will alter the performance of the unit.

OPEN RESULT

Service Test 7 – FF Performance Adjustment

Freezer Refrigerator

This test will allow adjustment of the control performance points. Each step will incrementally change the Refrigerator

performance warmer (towards 1) or colder towards (9) as adjusted. The default value is 5.

4 S

The refrigerator / Up/Down keys are used to adjust the Performance Offset value.

SHORT RESULT WARMER Í(1 2 3 4 (5) 6 7 8 9) Î COLDER.

Freezer Refrigerator

Service Test 5 – Freezer Thermistor Test

When selected this test will display Pass, Open, Short result for a test on the Freezer Thermistor circuit as 7 5

show below. The test is activated and de-activated via the Refrigerator Up key, and must be de-activated DEFAULT

to move to another test selection. Freezer Refrigerator

Freezer Refrigerator

7 6

5 P COLDER

The last FF Performance Offset value displayed before leaving test 7 will be saved when the refrigerator door(s) is

PASS RESULT closed.

Freezer Refrigerator Service Test 8 – FZ Performance Adjustment

This test will allow the adjustment of the control performance points. Each step will incrementally change the Freezer

5 O performance warmer (towards 1) or colder towards (9) as adjusted. The default value is 5.

The refrigerator / Up/Down keys are used to adjust the Performance Offset value.

OPEN RESULT WARMER Í(1 2 3 4 (5) 6 7 8 9) Î COLDER

Freezer Refrigerator

Freezer Refrigerator

8 5

5 S

DEFAULT

SHORT RESULT Freezer Refrigerator

8 4

WARMER

The last FZ Performance Offset value displayed before leaving test 8 will be saved when the refrigerator door(s) is

closed.

April 2004 6 16023133 April 2004 7 16023133

© 2004 Maytag Services © 2004 Maytag Services

You might also like

- Rsg257 Fast TrackDocument7 pagesRsg257 Fast Trackdan theman100% (1)

- Samsung Nevera Serie RB PDFDocument62 pagesSamsung Nevera Serie RB PDFAlexander NarvaezNo ratings yet

- Service Data Sheet 240389646Document2 pagesService Data Sheet 240389646Arianna IsabelleNo ratings yet

- Fast Track Troubleshooting: Demo MODE / Cooling Off Mode Load Mode Diagnostic ModeDocument12 pagesFast Track Troubleshooting: Demo MODE / Cooling Off Mode Load Mode Diagnostic ModeAshton TyreeNo ratings yet

- Xl44 ERC Diagnostic TestDocument2 pagesXl44 ERC Diagnostic TestSamurai Appliance Repair Man100% (8)

- LG BD550 Service ManualDocument141 pagesLG BD550 Service ManualPaul KupasNo ratings yet

- WP Im Tech SheetDocument53 pagesWP Im Tech Sheetdan themanNo ratings yet

- Miele NavodilaDocument60 pagesMiele NavodilamitjajNo ratings yet

- MSA VMW PP PresentationDocument65 pagesMSA VMW PP PresentationplasmapeteNo ratings yet

- LG Wm2277hw ManualDocument44 pagesLG Wm2277hw ManualmaildaveNo ratings yet

- Electric & Gas Dryer: Service ManualDocument41 pagesElectric & Gas Dryer: Service ManualLaura Cecilia MaggioNo ratings yet

- G8066 Miele Casi ManualDocument64 pagesG8066 Miele Casi ManualAndonLazaNo ratings yet

- Whirlpool Calypso Service ManualDocument68 pagesWhirlpool Calypso Service ManualBrian D Smith100% (1)

- Fast Track Troubleshooting: Model: WF461ABP/XAA WF461ABW/XAADocument9 pagesFast Track Troubleshooting: Model: WF461ABP/XAA WF461ABW/XAAMaugrys CastilloNo ratings yet

- Service Manual Zanussi FCS 872CDocument32 pagesService Manual Zanussi FCS 872Cdean_alexandru100% (1)

- Rs265 SRVC ManDocument92 pagesRs265 SRVC Mandan themanNo ratings yet

- Frid Ffhs26 Tech SheetDocument2 pagesFrid Ffhs26 Tech Sheetdan themanNo ratings yet

- LG Canada HVAC Technical Support Ductless HVAC & PTAC Error CodesDocument9 pagesLG Canada HVAC Technical Support Ductless HVAC & PTAC Error CodesJeremiasPereiraNo ratings yet

- Refrigerator Product Feature: Twin X Airflow Xtra Space Door Alarm Vegetable CrisperDocument95 pagesRefrigerator Product Feature: Twin X Airflow Xtra Space Door Alarm Vegetable CrisperhinkxxNo ratings yet

- LG LWD3081ST 30" ELECTRIC CONVECTION BUILT-IN OVEN Sm.Document64 pagesLG LWD3081ST 30" ELECTRIC CONVECTION BUILT-IN OVEN Sm.tunet1106No ratings yet

- Whirlpool Dishwasher Motor-Pump Assembly ReplacementDocument3 pagesWhirlpool Dishwasher Motor-Pump Assembly ReplacementSamurai Appliance Repair ManNo ratings yet

- Ka MW SM - Khms1850sDocument68 pagesKa MW SM - Khms1850sdan themanNo ratings yet

- RF 265 266 Ab Samsung RefriDocument49 pagesRF 265 266 Ab Samsung RefriaderlochNo ratings yet

- LG Lrg30 30 RangeDocument78 pagesLG Lrg30 30 Rangedan themanNo ratings yet

- LGE WM3632HW Service ManualDocument43 pagesLGE WM3632HW Service ManualJeffrey JimenezNo ratings yet

- AQV12VBE - AQV12VBE Service Manual PDF Inverter Samsung PDFDocument96 pagesAQV12VBE - AQV12VBE Service Manual PDF Inverter Samsung PDFAnonymous ajQr0qXNo ratings yet

- KitchenAid Range KESC3008WH11 - Service ManualDocument6 pagesKitchenAid Range KESC3008WH11 - Service ManualplasmapeteNo ratings yet

- Coleman Mach 8 Ac ManualDocument12 pagesColeman Mach 8 Ac Manualgcannon3No ratings yet

- LFD25860STDocument47 pagesLFD25860STJames LeeNo ratings yet

- 3 LG Steam WasherDocument93 pages3 LG Steam Washeracostaricci100% (1)

- RF 267 AeDocument118 pagesRF 267 Aebeltranreal6162100% (1)

- Rf265aars Rf266aars Rf26nbrs1rf265aabp Rf266aabp Rf26nbbp1rf265aawp Rf266aawp Rf26nbsh1rf265aash Rf266aash PDFDocument126 pagesRf265aars Rf266aars Rf26nbrs1rf265aabp Rf266aabp Rf26nbbp1rf265aawp Rf266aawp Rf26nbsh1rf265aash Rf266aash PDFAlexNo ratings yet

- MHC Service Training GuideDocument36 pagesMHC Service Training GuideJim HarmkeNo ratings yet

- Manual LG LSC27910Document208 pagesManual LG LSC27910allwise35515No ratings yet

- Service Manual w11169652 Reva 27in Front Load WashersDocument94 pagesService Manual w11169652 Reva 27in Front Load WashersSunny SonawaneNo ratings yet

- G7881 Fault CodDocument16 pagesG7881 Fault CodMai Doan Nhu ThuanNo ratings yet

- Refrigerator: Service ManualDocument19 pagesRefrigerator: Service ManualCesar Calderon GrNo ratings yet

- GE Refigerator PFSS9PKY-PFSS9SKY Rervice-ManualDocument88 pagesGE Refigerator PFSS9PKY-PFSS9SKY Rervice-Manualdan theman100% (1)

- MXG 30 50 Manual Usa Etl 09-07Document77 pagesMXG 30 50 Manual Usa Etl 09-07Sanu PhilipNo ratings yet

- Usa Dishwasher Tech. TrainingDocument68 pagesUsa Dishwasher Tech. TrainingJostin Castillo Hurtado50% (2)

- Rs22hd Fast TrackDocument9 pagesRs22hd Fast Trackdan themanNo ratings yet

- CAE2743BQ0 Technical Info SheetDocument40 pagesCAE2743BQ0 Technical Info SheetNicholas KaminskiNo ratings yet

- Ge Wall Oven Touchpad Ohm TestDocument1 pageGe Wall Oven Touchpad Ohm TestSamurai Appliance Repair ManNo ratings yet

- LG Refrigerator Service ManualDocument72 pagesLG Refrigerator Service ManualFrancisco ParraNo ratings yet

- WM2688 Training Manual PDFDocument64 pagesWM2688 Training Manual PDFJavier Gonzalez BarronNo ratings yet

- Control board troubleshooting and diagnostics guideDocument2 pagesControl board troubleshooting and diagnostics guideEdison EspinalNo ratings yet

- Zic36on SeriesDocument59 pagesZic36on SeriesKale ArbroughNo ratings yet

- Manual de Servicio SXD Refrigerator LGDocument113 pagesManual de Servicio SXD Refrigerator LGfredy guevara oNo ratings yet

- Fast Track Troubleshooting: Model: WF331ANW/XAA WF331ANR/XAADocument6 pagesFast Track Troubleshooting: Model: WF331ANW/XAA WF331ANR/XAAIves WUNo ratings yet

- Sam rs2545Document80 pagesSam rs2545vee8power100% (5)

- Repair Manual Neptune Maytag Mah7500awwDocument26 pagesRepair Manual Neptune Maytag Mah7500awwgruvinonu33% (3)

- DLEX3001 TrainingManualDocument100 pagesDLEX3001 TrainingManualequus43No ratings yet

- Basic Service Training: Cooling Circuit R600a and R134aDocument64 pagesBasic Service Training: Cooling Circuit R600a and R134aKyaw San OoNo ratings yet

- LavDocument93 pagesLavPamela RodriguezNo ratings yet

- Quick Test Mode: Spin + Soil Level + POWER: Fast Track TroubleshootingDocument10 pagesQuick Test Mode: Spin + Soil Level + POWER: Fast Track TroubleshootingMaugrys CastilloNo ratings yet

- LG GC 181 ManualDocument15 pagesLG GC 181 ManualadijayptNo ratings yet

- Install and use your new refrigerator safelyDocument26 pagesInstall and use your new refrigerator safelyAna RodriguezNo ratings yet

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideFrom EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo ratings yet

- 0 - Tech Sheet - 8208304 PDFDocument8 pages0 - Tech Sheet - 8208304 PDFBob Derrick0% (1)

- Amana Refrig ARB2214 Tech Sheet 12642402 PDFDocument2 pagesAmana Refrig ARB2214 Tech Sheet 12642402 PDFlibertyplusNo ratings yet

- Camp Buddy Choice GuideDocument28 pagesCamp Buddy Choice GuideM. Isra al miradNo ratings yet

- OPENBOX X810 Digital Satellite ReceiverDocument22 pagesOPENBOX X810 Digital Satellite Receiverbecstu7168No ratings yet

- Allyza Diane SauzaDocument60 pagesAllyza Diane SauzaAllyza Diane SauzaNo ratings yet

- Syllabus: Cambridge IGCSE® Food & Nutrition 0648Document23 pagesSyllabus: Cambridge IGCSE® Food & Nutrition 0648Tadiswa ChloeNo ratings yet

- Implants and Their Use in Beef Cattle Production Oklahoma State UniversityDocument26 pagesImplants and Their Use in Beef Cattle Production Oklahoma State UniversitysegurahNo ratings yet

- The SeafarerDocument3 pagesThe SeafarerBogdan AndreiNo ratings yet

- Roc ScienceDocument2 pagesRoc ScienceCamilo Espinoza CáceresNo ratings yet

- Chiller Cooling Tower AHUDocument9 pagesChiller Cooling Tower AHUAli Hassan RazaNo ratings yet

- Dont Destroy The ArchivesDocument10 pagesDont Destroy The ArchivesSeva David Louis Ball100% (1)

- Hydrology and Hydraulic calculations for Minor BridgeDocument16 pagesHydrology and Hydraulic calculations for Minor BridgeKunjesh LunagariyaNo ratings yet

- Ornithology Center Thesis SynopsisDocument6 pagesOrnithology Center Thesis SynopsisprasannaNo ratings yet

- DowsingDocument76 pagesDowsingBacean Aurel IoanNo ratings yet

- Ea (Dyn)Document9 pagesEa (Dyn)Dr.Biswajit jenaNo ratings yet

- Predictive MaintenanceDocument17 pagesPredictive Maintenancejimmy_d_nasutionNo ratings yet

- HSN Codan TransceiverDocument22 pagesHSN Codan TransceiverMinh VuNo ratings yet

- HSE Procedure Manual: Safety FormatsDocument20 pagesHSE Procedure Manual: Safety FormatsPavan KumarNo ratings yet

- Memory InterfacingDocument29 pagesMemory Interfacingabhi198808No ratings yet

- Brown Eyes Caramel ThighsDocument4 pagesBrown Eyes Caramel ThighsFremille MartinezNo ratings yet

- Macroinvertebrates LessonDocument2 pagesMacroinvertebrates Lessonapi-497946823No ratings yet

- Unit 1Document15 pagesUnit 1shubham WadhaneNo ratings yet

- Maths Chapter on Circles ExercisesDocument38 pagesMaths Chapter on Circles ExercisesHemant KumarNo ratings yet

- Treatment Planning and Computer SystemsDocument4 pagesTreatment Planning and Computer SystemsAnugrah SukmaNo ratings yet

- P 702eDocument31 pagesP 702eSAFETY FIRSTNo ratings yet

- Mathematics QuizDocument18 pagesMathematics QuizIyarna YasraNo ratings yet

- Sectional LayoutDocument7 pagesSectional LayoutNickol Hardway100% (1)

- Jung, Carl Gustav - Volume 9 - The Archetypes of The Collective UnconsciousDocument26 pagesJung, Carl Gustav - Volume 9 - The Archetypes of The Collective UnconsciousKris StarrNo ratings yet

- Developing The Whole PersonDocument17 pagesDeveloping The Whole PersonDaphne LavardoNo ratings yet

- Cutting Tools and Essentials GuideDocument6 pagesCutting Tools and Essentials GuideCaleb ArbouetNo ratings yet

- Tpde r13 Aprilmay 15Document4 pagesTpde r13 Aprilmay 15P S HARSHITANo ratings yet