Professional Documents

Culture Documents

B 2800649 DD

Uploaded by

sppOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B 2800649 DD

Uploaded by

sppCopyright:

Available Formats

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

.

ne pu

ow ion

ht ct

:.

ig pe

yr ns

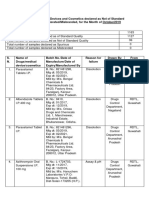

Attachment No. H.1

op r i

f c Fo

Raw Materials,

to

en

Intermediates and Product

ns

Co

Handling

‘, A&&nent No ti.1 - Main Textdoc

EPA Export 25-07-2013:15:03:40

Attachment H.l Material Handling

Schwarz Pharma Ltd. Revised IPCL Application

CONTENTS

Section Page No

I. MATERIAL STORAGE .................................................................................................... 1

1.1 Raw Materials and Intermediates ............................................................ 1

1.2. Waste storage.. ................................................................................................................. 2

2. MANAGEMENT OF MATERIALS ................................................................................... 2

3. MOVEMENT OF MATERIALS . .. .. . . ... . . .. .. . .. . . .. .. . .. .. .. . . ... . .. . .. .. . .. . .. . .. .. . ...m................s........... 3

4. BUND MANAGEMENT .*.......................................,...........,.......................,.................*.... 3

.

se

ru

he

ot

ny

fo y.

d nl

ra

Appendix H.l .I Supply Chain Management

re o

ui es

eq os

r r rp

Appendix H.l.2 chemical Storage

ne pu

ow ion

Appendix H.1.3 Bund Integrity Testing

ht ct

ig pe

yr ns

op r i

Appendix H.1.4 Bund Management

f c Fo

Appendix H.1.5 Bund Locations

to

en

ns

Co

Appendix H.l.6 Material Flow

Appendix H.l.7 Bund upgrade program

AttachmentNo H.1- MainText.doc Pagei

EPA Export 25-07-2013:15:03:40

Attachment H.1 Material Handling

Schwarz Pharma Ltd. Revised IPCL Application

1. MATERIAL STORAGE

The methodology for the storage of materials (separation and segregation) is addressed

in SOP 400.010 Supply Chain Management, which is contained in Appendix H.I.I. A

regular review of the methodology behind the storage procedures of materials is carried

out. This ensures a proper system of storage is implemented.

Materials at Schwarz Pharma Limited are stored in discrete locations depending on the

nature/status of the material. The Health & Safety Officer must be informed of all new

materials as per SOP 610.014, in order that the correct storage location for the material

may be determined based on the chemical properties of the material. Locations of

storage areas within the main facility are contained in Appendix H.1.2 Chemical

Storage, Site Map.

1.1. Raw Material and Intermediate

There are two main bulk chemical storage areas. The Nitration tank farm is located

.

se

immediately to the west of the Plant and is approximately 208m’ in area. It holds 8

ru

he

storage tanks for solvents and each ranges in size from 15 to 30m3. The tanks are fully

ot

ny

fo y.

bunded and closed so that any accidental spillages or leaks are contained. The

d nl

ra

re o

associated transfer pumps are located within the bunded area. The solvents are hard-

ui es

eq os

r r rp

piped via a modified pipe rack to the Nitration Plant. The over ground pipe is detailed in

ne pu

ow ion

Appendix H.1.6 Material Flow

ht ct

ig pe

yr ns

An additional storage tank farm is located at the Main Production Building (BPC) which

op r i

f c Fo

holds a further 13 tanks. The nature and quantity of material is detailed in storage areas

within the main facility are contained in Appendix H.1.2 - Chemical Storage. To minimise

to

en

air emissions, treatment/abatement equipment was installed on vessels in the BPC that

ns

Co

hold substances classified as Class I under the TA Luft 1986 Organics classification

system. This equipment comprises acidic/basic scrubbers for emissions from reactors.

Raw material and packaging for use in pharmaceutical manufacturing, Work in Progress

(WIP) & all finished goods are stored in the Pharma Warehouse. The Chemical

Warehouse is used for the storage of solid raw materials, intermediates & packaging for

use in API manufacture, which require storage indoors.

The Covered drum store, Drum store has two racks and ground level storage. This area

is used for storage of the corrosive Sodium Hydroxide (pearl) & compatibles e.g.

Sodium Chloride. The Open Drum has 6 racks and a number of ground level storage

areas. It is used for storage of drummed solvents/liquid reagents & API work in

progress.

As material is required for manufacturing it is transferred to the Production Supply

Areas (SOP 400.053) where short-term storage occurs while -awaiting usage. All

incoming GMP materials are received to IM Location 902 for short-term staging,

awaiting ‘put away’. Physically the materials may reside in the Pharma Lobby, the floor

area of the Chemical W/H or the roadway.

AttachmentNo H.l - Main Text.doc Page1

EPA Export 25-07-2013:15:03:40

Attachment H.1 Material Handling

Schwarz Pharma Ltd. Revised IPCL Application

Due to the hazardous & water sensitive nature of Lithium Amide, n-Butyl Lithium &

Vilsmeier Reagent, they have a unique storage location in the ‘Lithamide’ store.

Cylinders of Gas used in processing, maintenance & laboratories are stored in a

dedicated area. There is one rail container used as temporary storage area for

recyclable fibreboard drums.

1.2. Waste storage

A dedicated Waste Management Area is in operation at the site. All measures have been

taken to ensure adequate storage space is provided and the area is of suitable

construction to prevent a risk of surface and groundwater pollution. All waste stored is

clearly labelled and marked. A procedure for collection, storage and disposal of waste oils

and scrap metal is employed at the site. Waste Oil control procedures have been put in

place and a dedicated waste oil storage area has been created in the drum storage area.

2. MANAGEMENT OF MATERIALS

.

se

A tool for the procurement of chemicals, inventory management, manufacturing, release

ru

he

and shipment of products called Systems, Applications and Products for Data Processing

ot

ny

fo y.

(SAP) is employed at Schwarz Pharma Ltd. This indirectly benefits environmental

d nl

ra

re o

ui es

management through improved chemical classification for storage and better tracking of

eq os

r r rp

hazardous waste in storage and for disposal off-site.

ne pu

ow ion

ht ct

SAP controls storage at two different levels, Inventory Managed (IM) and Warehouse

ig pe

yr ns

Managed CJVM):

op r i

f c Fo

n WM storage allows the storage in discrete ‘bins’ & the exact quantity of material in

to

en

each bin can be seen;

ns

Co

. IM storage shows the total quantity of material stored in a particular location but

does not display storage to bin level.

The SAP system takes into account the properties & classification of the substance to be

stored, & uses this to dictate the storage location of material. SAP will not allow the

storage of different batches of the same material in a bin nor will it allow the storage of

two different types of material in the same bin. The only exception is the open drum store,

which allow a mixing of different materials due to the availability of bin spaces. The

system will not chose to supply a material to any production process if the material is in

l Quarantine (represented as letter Q on SAP);

l Blocked stock (represented as letter S on SAP).

When QC passes the material on the SAP system it becomes available to be utilised by

production. The SAP system will only supply material to production in the absence of any

letter after the batch number selected.

Attachment

NoH.1-MainTextdoc Page2

EPA Export 25-07-2013:15:03:40

Attachment H.1 Material Handling

Schwarz Pharma Ltd. Revised IPCL Application

A programme of ongoing Vendor Environmental Appraisal has been in place at Schwarz

Pharma Ltd for a number of years. This involves the evaluation of the top 20 suppliers of

raw materials, from an environmental viewpoint, using key performance indicators. In

addition, the annual vendor appraisal has been extended to incorporate the key indicators

by which all Raw Material suppliers should be assessed. If a supplier is being listed as an

approved supplier they receive a copy of the Schwarz Pharma Ltd. Environmental Survey

prior to commencement of business. The evaluation of suppliers is incorporated into the

standard vendor appraisal procedure.

It is planned to extend the Vendor Environmental Appraisal to a greater number of raw

material suppliers and environmentally significant contractors and consultants such as

waste contractors and suppliers of abatement/measuring equipment.

3. MOVEMENT OF MATERIALS

Solid materials are received at the facility in either steel/fibre drums fitted with tamper

proof closures or bags and are unloaded directly in the warehouse. The materials are

.

se

firstly subject to quarantine and following satisfactory quality control checks, then stored

ru

he

in the warehouse, until requisitioned by the production department for processing.

ot

ny

fo y.

Movement of solid material externally on-site is by pallet truck or fork truck. Internal

d nl

ra

re o

ui es

move-ments of the material is via lifts for floor to floor transfer or charged via stainless

eq os

r r rp

steel charge chute for transfer to equipment systems,

ne pu

ow ion

ht ct

Liquid materials are transported on-site in steel drums and plastic containers, similar to

ig pe

yr ns

the movements of solid materials. Within processing buildings, drums are charged from

op r i

f c Fo

dedicated areas. Such areas incorporate closed drains for collection and containment

purposes, which may be accessed to facilitate cleanup of any spillages.

to

en

ns

Co

The movement of materials across the site is shown in Appendix H.1.6 Material Flow. All

physical movements of material and quantity will be reflected immediately on the SAP

system once the transfer orders created for movement of material to required locations

are confirmed. See SOP 400.053 Transfer of Material to Production.

4. BUND MANAGEMENT

All bunds at the Schwarz Pharma Ltd. facility, including Drum stores, Scrubbers, WWTP

and Glycol bunds, are lined. A map indicating the locations of all bund locations is

included in Appendix H.l.5. The Drum storage area has been tested for its resilience to

forklift and truck traffic. Full integrity tests of bunds takes place at a maximum frequency

of 3 years and records relating to the testing are held by the Engineering Department at

Schwarz Pharma. A copy of the most recent bunding report for the Schwarz Pharma Ltd.

facility is included in Attachment H.1.3. This also includes a report on non-compliant

bunds. A summary of the outcome of the testing is included in Appendix H.1.7.

Schwarz Pharma Ltd. has defined a process whereby containment bunds are routinely

inspected and drained of their contents in such a manner as to prevent any possibility of

Affachment

NoH-1-MainText.doc Page3

EPA Export 25-07-2013:15:03:40

Attachment H.l Material Handling

Schwarz Pharma Ltd. Revised IPCL Application

environmental damage either through spillage, leakage or the improper discharge of

material to surface water drains or groundwater.

Schwarz Pharma Ltd. has implemented a programme for the provision of satisfactory

containment at the facility. The main aims of the programme included the bunding of tank

and drum storage areas. A preliminary risk assessment of material storage at the facility

identified those areas requiring primary action and those storage areas requiring

impervious surfaces to materials stored therein. In total, 29 bunds were identified for the

purposes of this programme (3 bunds located at Bay 130 are now no longer in use and

are therefore not included within the 29 bunds).

All materials drained from bunds are discharged directly to the drainage network, which

brings the effluent to the wastewater treatment plant. The only exception to this rule is the

discharge of nitration bunds. The contents of the nitration plant bunds are normally

discharged to surface water and are only discharged to the wastewater treatment plant if

contaminated. Before discharging liquid from the tank farm bunds, the bunds are checked

for pH to ensure acidity is not a concern. Before discharging from the Mother Liquor

Bunds, the liquid must be checked to ensure it does not contain solids or odour.

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

AttachmentNo H.l -Main Text.doc Page4

EPA Export 25-07-2013:15:03:40

Attachment H.l Material Handling

URS Schwatz Pharma Ltd. Revised IPCL Application

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

Supply Chain Management

op r i

f c Fo

to

en

ns

Co

EPA Export 25-07-2013:15:03:40

Page 1 of 7

SUPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATERIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

1.0 PURPOSE

To outline the procedure for the storage of all materials (including Packing Materials) to ensure the

proper separation and segregation of chemicals at SCHWARZ PHARMA Limited.

2.0 RESPONSIBILITY

* 2.1 It is the responsibility of the Supply Chain Manager to ensure that the concerned individuals

are familiarised with this SOP in accordance with SOP No. 103.001.

2.2 It is the responsibility of the Materials Technologist & the Warehouse Team Facilitator to

.

ensure that material is stored in a safe and controlled maturer.

se

ru

2.3 It is the responsibility of the Materials Technologist in consultation with the Environmental

he

ot

and Health Safety Department to provide guidance in the safe storage of materials and that the

ny

fo y.

d nl

ra

information created on the SAP system is correct.

re o

ui es

eq os

r r rp

3.0 APPROWL

ne pu

ow ion

ht ct

ig pe

This SOP and any future changes must be approved by the Supply Chain Manager, the API Manager,

yr ns

the Health and Safety Offtcer, Pharma Manager, and the Head of QA and Support Services.

op r i

f c Fo

4.0 SCOPE

to

en

ns

Co

This SOP is in effect in the Supply Chain Management and Manufacturing Departments.

5.0 PROCEDURE

l 5.1 There are several warehouse storage locations & types in SCHWARZ PHARMA Limited and

these are listed in Attachment I and maps showing all the Storage areas

(Attachments III-VI).

5.2 For safety/regulatory purposes, materials at SCHWARZ PHARMA Limited are stored in

discrete locations depending on the nature/status of the material. The Health & Safety Officer

must be informed of all new materials as per SOP 610.014, in order that the correct storage

location for the material may be determined based on the chemical properties of the material.

Written By: Approved By: Approved By: Approved By: Approved By Approved By:

S. O’Donoghue M Dohmam J. O’Halloran D. Mullins Pat Quirke I. Wills

Materials Technologist Supply Chain Mgr. Prod. Manager Health &Safety Phama Mmuf. Mgr. Head of QA &

OfflW Support Services

Date: Date: Date: Date: Date: Date:

EPA Export 25-07-2013:15:03:40

’

Page 2 of 7

SUPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATERIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

5.3 Under no circumstances must drums of flammable liquids be stacked more than two pallets

high. The maximum stack height for fibreboard drums is three pallets high

Note: Material locations and contents areprinted once on a weekly basis and the copy is

supplied to the Security Oj?cer every Thursday.

5.4 A computerised system; SAP is used to control the storage and selection of materials

throughout all storage locations at SCHWARZ PHARMA Limited.

5.5 SAP controls storage at two different levels, Inventory Managed (IM) and Warehouse

.

se

Managed (WM) - See Attachment I.

ru

he

ot

5.5.1 WM storage allows the storage in discrete ‘bins’ & the exact quantity of material

ny

fo y.

d nl

ra

in each bin can be seen.

re o

ui es

eq os

5.5.2 IM storage shows the total quantity of material stored in a particular location but

r r rp

ne pu

does not display storage to bin level.

ow ion

ht ct

ig pe

5.6 The SAP system takes into account the properties & classification of the substance to be

yr ns

op r i

stored, & uses this to dictate the storage location of material (Attachment II).

f c Fo

to

5.7 SAP will not allow the storage of different batches of the same material in a bin nor will it

en

ns

allow the storage of two different types of material in the same bin. The only exception is

Co

the open drum store, which allow a mixing of different materials due to the availability of

bin spaces.

5.8 The system will not chose to supply a material to any production process if the material is

in

Quarantine (represented as letter Q on SAP)

Blocked stock (represented as letter S on SAP).

5.9 When QC passes the material on the SAP system it becomes available to be consumed by

production. The SAP system will only supply material to production in the absence of any

letter after the batch number selected.

Note: All physical movements of material and quantity will be reflected immediately on the

SAP system once the transfer orders createdfor movement of material to required

locations are con$rmed See SOP 400.053 Transfer of Material to Production

EPA Export 25-07-2013:15:03:40

Page 3 of 7

SUPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATFRIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

5.10 Storage Locations

5.10.1 TankFarm

5.10.1.1 Bulk solvents/reagents are stored in dedicated tanks in the tank farms.

There are two distinct tank farms at; SCHWARZ PHARMA Limited

Main tank farm (SOP 400.011) & Nitrates Tank farm (SOP 400.052)

both of which are treated as IM storage location 0061 in SAP.

5.10.1.2 Nitric acid for Bay130 is stored in a bulk tank (SOP 400.014) under

IM storage location; 0130.

5.10.1.3 Tank 14 in the main tank farm is used for the storage of bulk waste

.

se

solvent for disposal and is assigned a separate storage in SAP; IM

ru

he

location 0014.

ot

ny

fo y.

d nl

ra

re o

5.10.2 Gas Storage

ui es

,. Cylinders of Gas used in processing, maintenance & laboratories are stored in a

eq os

r r rp

ne pu

dedicated area; IM location 0063.

ow ion

ht ct

ig pe

5.10.3 Pharma Warehouse

yr ns

op r i

5.10.3.1 Raw materials & packaging for use in Pharmaceutical manufacturing,

f c Fo

Pharma Work in Progress (WIP) & all finished goods are stored in the

Pharma Warehouse (WM 050).

to

en

5.10.3.2 Capsule Shells, Finished Product Capsules and Tablets are not stored on the

ns

Co

high levels near the fan heaters.

5.10.3.3 This warehouse consists of high level racking; A to J for the storage

of Class 4.1 & non-hazardous materials.

5.10.3.4 Pure ISDN (class 1) is stored in 4 bins in Rack I at level 1, a

maximum of 600Kgs may be stored at any time (SOP 400.061).

5.10.3.5 WIP material (including Intermediate bulk containers - Matcons) is

stored on racks B & C (WM 055).

5.10.3.6 Packaging material is stored at high levels on the above two racks &

rack E.

5.10.3.7 Equipment may also be stored at high levels on Rack E.

5.10.3.8 There is a designated area in the Pharma Warehouse for the storage of

returned finished product, awaiting disposition, this is located on I

Rack I-OS-01 to I-08-09 (WM904) (SOP 400.058).

EPA Export 25-07-2013:15:03:41

Page 4 of 7

STJPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATERIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

5.10.3.9 The Lobby area of the Pharma Warehouse is designated as an

incoming & outgoing area for the receipt of Raw materials/

Intermediates & for the staging of Finished goods awaiting shipment

(IM 916). If required dividers into Incoming & Outgoing areas will

segregate the area (e.g. a delivery arrives while a shipment is awaiting

collection).

5.10.4 Chemical Warehouse

5.10.4.1 The Chemical Warehouse is managed at WM level & is used for the

storage of Solid Raw Materials, Intermediates & packaging for use in

.

se

API manufacture, which require storage indoors (WM 00 1).

ru

5.10.4.2 The storage is on racking, A to M, primarily for the storage of Class

he

ot

4.1 & non-hazardous materials.

ny

fo y.

d nl

ra

5.10.4.3 Classes 5,6.1,8 & non-hazardous are stored on Rack H.

re o

ui es

eq os

,’ 5.10.4.4 Packaging material & miscellaneous items are stored on Rack M.

r r rp

ne pu

5.10.4.5 Fibreboard drums are stored in the Chemical Warehouse &

ow ion

distributed to other locations as required their storage is however

ht ct

ig pe

reflected in SAP IM location W055 (Pharma WIP area).

yr ns

op r i

5.10.4.6 Plastic drums are stored over the Office in the Chemical Warehouse.

f c Fo

5.10.4.7 The controlled substance Midazolam (SOP 400.03 1) is stored in the

safe in the Chemical Warehouse ( WM 008).

to

en

5.10.4.8 Rejected Material (SOP 400.059) is stored in a specially designated &

ns

Co

locked area on J & L Racks (WM 011 Container). RX Material from

Pharma is also stored in this area.

5. IO.5 Lithamide Store (002)

Due to the hazardous & water sensitive nature of Lithium Amide, n-Butyl

Lithium & Vilsmeier Reagent, they have a unique storage location in the

‘Lithamide’ store (WM 002).

5.10.6 Drum Storage Area

5.10.6.1 The Covered drum store, Drum store 1 (WM 004) has two racks

(A&B) & Ground level storage (C). This area is used for storage of

the corrosive Sodium Hydroxide (pearl) & compatibles e.g. Sodium

Chloride.

5.10.6.2 Dimethyl Sulphate is also stored in the covered drum store (SOP

400.045).

EPA Export 25-07-2013:15:03:41

Page 5 of 7

SUPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATERIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

5.10.6.3 The Open Drum store (WM 003) has 6 racks & a number of ground

level storage areas (A to L) & is used for storage of Drummed

solvents/liquid reagents & API work in progress (Rack B).

5.10.6.4 Rejected/ Waste material is stored on Racks A & F in this area in

location WM 005.

5.10.6.5 Oil, Sodium Hypochlorite & Bromine have dedicated bunded storage

areas within this location.

5.10.6.6 An additional waste management area is denoted by location WM

007.

.

se

5.10.7 Production Areas

5.10.7.1 ru

Material which is required for manufacturing is transferred to the

he

ot

Production Supply Areas (SOP 400.053) where short term storage

ny

fo y.

d nl

ra

occurs while awaiting usage to planned processes:

re o

ui es

,C BPC Production Supply area (WM 020)

eq os

r r rp

Nitration PSA (WM 060)

ne pu

ow ion

Pharma Dispensing PSA (WM 051)

ht ct

ig pe

Pharma Palletising PSA (WM 052)

yr ns

Material produced by the manufacturing facilities will be confirmed

op r i

5.10.7.2

f c Fo

on SAP to the appropriate WIP areas, these may be either IM

managed or WM managed:

to

en

BPC WlP areas; WM 021 or IM WO21

ns

Co

Nitration WIP areas; WM 03 1 or IM W03 1

Pharma WlP areas; WM 055 or IM WO55

This material may either be used in the process immediately or

transferred to a Warehouse location.

Note: The roadway may be usedfor short term staging of material

awaiting transfer to racks.

5.10.7.3 Non-GMP materials used in the WasteWater Treatment Plant

(WWTP) are stored in the Effluent Supply area (WM 051), additional

IBCs may be stored within the Drum store bund.

5.10.8 Goods Receipt area

All incoming GMP materials are received to IM Location 902 for short-term

staging, awaiting ‘put away’. Physically the materials may reside in the Pharma

Lobby, the floor area of the Chemical W/H or the roadway.

EPA Export 25-07-2013:15:03:41

Page 6 of 7

SUPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATERIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

5. IO. 9 Rail Containers

There is one rail container used as temporary storage area for recyclable fibre

board drums :

Container 1: Fibreboard Drums for reuse with Work In Progress material.

5.10.10 Bay 130

5.10.10.1 Due to the fact that Bay 130 is situated off-site, material must be

transferred to & from this facility (SOP 400.056) & storage facilities

are provided on the B 130 site in IM location 0130.

.

5.10.10.2 Storage is provided for both API & Pharmaceutical materials.

se

5.10.10.3 ru

API liquid raw materials are stored in racks in the open store (Racks

he

ot

I-l to I-20)

ny

fo y.

d nl

ra

5.10.10.4 Racks A & B in the B130 warehouse are used as a Pharma production

re o

ui es

supply area & for the short term staging of Pharma finished products

eq os

r r rp

(maximum staging time 48hr.s).

ne pu

ow ion

5.10.10.5 Racks C & D are used as an API production supply area & for the

ht ct

ig pe

short term staging of API finished products (maximum staging time

yr ns

48hrs).

op r i

f c Fo

5.10.10.6 Packaging materials (Liners, fibreboard drums & 200L plastic drums)

are also stored in location 0130.

to

en

5.10.10.7 API work in progress is stored in the production area.

ns

Co

5.11 Damaged Material/Packaging

In the event of material which has been Passed becoming damaged/contaminated in

any way, or the label becoming detached, the container must be placed to a block

bin on the SAP and then into blocked stock on the SAP SYSTEM, and repackaged

(if necessary) and re-inspected. Once a usage decision is made the material is either

released for consumption or disposal.

5.12 Documentation

Attachment I: List of Warehouse Locations (IM & WM locations)

Attachment II: List of Classification.

Attachment III: Map of the Drum Store areas of the Main Plant.

Attachment IF Map of Pharma Warehouse Locations.

Attachment k Map of Chemical Warehouse Location.

Attachment Y7; Map of Bay 130 Store.

Attachment WI: Site Map.

EPA Export 25-07-2013:15:03:41

:

Page 7 of 7

SUPPLY CHAIN MANAGEMENT PROCEDURE SOP

Effective Date:

Title: STORAGE OF MATERIALS 400.010 Revision No: 20 Date: 10.02.04

Prev Rev No: 19 Dated: 02.10.02

6.0 FtEWISION

This SOP is reviewed annually according to SOP 100.007. Any necessary changes will be

documented in a new revision of this SOP

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

EPA Export 25-07-2013:15:03:41

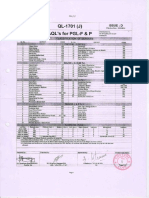

SUPPLY CHAIN MANAGEMENT PROCEDURE

SOP Page 1 of 1

ATTACHMENT I Effective Date:

4OO-sblO Revision No: 20 Date: 10.02.04

Title: LIST OF WARESHOUSE LOCATIONS (IM & WM LOCATIONS) Prev Rev No: 19 Dated: 02.10.02

r Ma,teri&.Storatie Locations at. sCm= p&&R&&i LIMITED b

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

Returns area Pharma Warehouse

ui es

Pharma Warehouse

eq os

050 904

r r rp

ne pu

ow ion

ht ct

ig pe

- Chemical Warehouse Chemical Warehouse safe

yr ns

008

op r i

f c Fo

to

en

ns

Co

Open Drum store Covered Drum Waste material rack Open Backyard storage

003 store 005 007

BPC Production Supply Area (PSA) Nitration PSA Pharma Dispensing Pharma Effluent Supply

020 060 PSA Pellitising PSA area

051 052 054

BPC Work in Progress Area (WIP) Nitration WIP area Pharma WIP area

021 031 055

Rail Containers

011

EPA Export 25-07-2013:15:03:41

SOP Page 1 of 1

SUPPLY CHAIN MANAGEMENT PROCEDURE

ATTACHMEXW II 400.010

Effective Date:

Revision No: 20 Date: 10.02.04

Title: LIST OF CLASSIFICATION Prev Rev No: 19 Dated: 02.10.02

Non Hazardous NH Non: Hazardous

1 Explosive Materials

:I LIQ 1 Explosive Materials

:lsoL 1 Explosive Materials

12.1 IFlammable Gas I

12.2 INon-Flammable, non-toxic aas I

12.3 IToxic Gas

C:ZGAS 12 IGases

.

C3LIQ 3 Flammable Liquids

se

c4-I SOL 4.1 Flammable Solid ru

he

ot

CX-2GAS 4.2 Subs. liable to spontaneous combustion

ny

fo y.

I

d nl

IC4-2LK.a 14.2 ISubs. liable to spontaneous combustion

ra

re o

I

ui es

IC4-2SOL 14.2 ISubs. liable to spontaneous combustion

eq os

I

r r rp

IC45GAS 14.3 IFlammable when in contact with water

ne pu

IC4-3LlQ 14.3 IFlammable when in contact with water I

ow ion

ht ct

C43SOL 4.3 Flammable when in contact with water

ig pe

yr ns

C4SOL 4 Flammable Solids

op r i

f c Fo

C5-1 GAS 5.1 Oxidizer

c5-1 LIQ 5.1 Oxidizer

to

cs-ISOL 5.1 Oxidizer

en

ns

C5-2LIQ 5.2 Organic Peroxides

Co

CSGAS 5 Oxidizing Subs. And Organic Peroxide

1C5LlQ 15 loxidizina Subs. And Oroanic Peroxide I

C5SOL (5 IOxidizing Subs. And Organic Peroxide

C&l GAS 16.1 IToxic Substances I

C6-1 LIQ 6.1 Toxic Substances

C6-I SOL 6.1 Toxic Substances

C6-2GAS 6.2 Infections Substances

C6-2LIQ 6.2 Infections Substances

IL 16.2 llnfections Substances I

SAS 1’5 IToxic and Infectious Substances I

-IQ 16 IToxic and Infectious Substances I

SOL 16 IToxic and Infectious Substances I

:7GAS 17 IRadioactive Substances I

:7LIQ

IC7SOL

k

7

7

Radioactive

Radioactive

Substances

Substances --I

--I

GAS 8 Corrosives

:tlQ 8 Corrosives

CISOL 8 Corrosives

CSGAS 9 Mb rcellaneous Dangerous Goods-

ItsLIQ I9 IMiscellaneous Dangerous Goods I

lC9SOL I9 IMiscellaneous Danaerous Goods I

EPA Export 25-07-2013:15:03:41

SOP Page 1 of 1

SUPPLY CHAIN MANAGEMENT PROCEDURE

ATIACHMENT lII 400.010

Effective Date:

Revision No: 20 Date: 10.02.04

Title: MAP OF DRUM STORE AREAS OF Prev Rev No: 19 Dated: 02.10.02

THX MAIN PLANT

i A B E C DGJHKILI 003 i

DRUMSTORE 2

AT

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

DRUMSTORE 1

B

op r i

f c Fo

A

to

en

ns

Co

EPA Export 25-07-2013:15:03:41

”

5

SOP Page 1 of 1

SUPPLY CHAIN MANAGEMENT PROCEDURE

ATTACHMENT IV 400.010

Effective Date:

Revision No: 20 Date: 10.02.04

Title: MAP OF PHARMA WAREHOUSE Prev Rev No: 19 Dated: 02.10.02

LOCATIONS

.

se

ru

he

_._~___ .--~---__

ot

IB

,..c -...._-_._

ny

fo y.

--. . -../

d nl

ra

re o

ui es

eq os

r r rp

ne pu

[!I r-F---- -- -7

ow ion

Iji

LF-.- -. ~/I

ht ct

ali

ig pe

yr ns

op r i

f c Fo

--._-_-_------_-- ----

-_

ixI _-____-._ --..

to

en

WAREHOUSE

ns

Co

EPA Export 25-07-2013:15:03:41

.

SOP Page 1 of 1

SUPPLY CHAIN MANAGEMENT PROCEDURE

ATTACHMENT V 400.010

Effective Date:

Revision No: 20 Date: 10.02.04

Title: MAP OF CHEMICAL WAREHOUSE Prev Rev No: 19 Dated: 02.10.02

LOCATIONS

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

EPA Export 25-07-2013:15:03:41

SOP Page 1 of 1

SUPPLY CHAIN MANAGEMENT PROCEDURE

A’ITACHMENT VI 400.016’ Effective Date:

Revision No: 20 Date: 10.02.04

Title: MAP OF BAY 130 STORE Prev Rev No: 19 Dated: 02.10.02

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

Last Modified

Drawing No. O%%%+,

(1 pi-k--j

\I

Production storage

EPA Export 25-07-2013:15:03:41

SOP Page 1 of 1

SUPPLY CHAIN MANAGEMENT PROCEDURE

ATTACHMENT VI 400.010

Effective Date:

Revision No: 20 Date: 10.02.04

Title: SITE MAP Prev Rev No: 19 Dated: 02.10.02

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

‘_ EPA Export 25-07-2013:15:03:41

@@q@@~-fi@

/

/. ./ ^_ . ‘,

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

l To include: 5.3.2.3 “Storage of Ametolam and

f c Fo

to

en

ns

Co

. To include new Warehouse locations and new

. To include responsibilities of Safety &

Environmental Department.

n To describe the storage of Returned Material (5.5)

and Capsule Shells (5.10).

. To include the Pharma Manager as a signatory.

. To update 5.10 Pharma Storage

ote after 5.2 stating that Material

Locations and Contents are printed on a daily basis.

EPA Export 25-07-2013:15:03:41

:. ~“@qq#“~~~

.’ ( ‘y‘i. _*.j i ..

I.. . . :ic. ‘. ,V‘. A * “.

SOP TiTLE: STORAGE OF Mii&IALS ’ SOP NUMB&: 400.010

REVISION REQUESTED REASON FOR REVISION EFFECTIVE

VO. BY: DATE

13 GT l SOP modified to detail locations by 04.09.00

MAC individual Warehouse.

l To update Pharma storage locations in

5.9

l To include Section 5.11

l To update Drawings.

l Change title of ‘Warehouse Team

Leader’ to ‘Warehouse Team

Facilitator’.

.

To include Section 5.13

se

l

ru

To include the maps revised and

he

l

ot

updated on 17.08.00

ny

fo y.

d nl

ra

To update section 5.8 on Pharmaceutical

re o

14 GT 17.10.00

ui es

eq os

r* Warehouse.

r r rp

ne pu

15 GT To specify that Bay 130 is only a staging 09.07.01

ow ion

areas for Finished Goods

ht ct

ig pe

16 GT To reflect the revised storage locations in 19.09.01

yr ns

op r i

the Chemical and Pharma Warehouses and

f c Fo

to reflect the Nitrates Tank Farm.

to

17 S.0.D l To significantly change the storage 26.08.02

en

ns

philosophy & therefore the physical

Co

locations resulting from the

implementation of SAP.

l Including the removal of all

references to Passed & Quarantined

locations.

l To include a listing of hazard

classifications & storage locations &

SAP types (attachments I and II).

l To update Maps (attachments III and

IV).

l Remove reference to the fridge as a

storage location.

l Include a returns area in Pharma

W/H

18 S.O.D. l 510.8 The goods receipt area had 13.12.02

been incorrectly described as 101

instead of 902.

EPA Export 25-07-2013:15:03:42

,,;’ j:,

.,:3: . ,.’

REVISION REQUESTED REASONFORREVISION EFFECTIVE

NO. BY: DATE

19 A. C. l To include in 5.10.4.8 that RX Material 12.03.03

from Pharma is also stored in this area.

l To remove references to Rail Containers

2 & 3 as they are no longer in use in

5.10.9.

l To change Department title from

“Materials” to “Supply Chain

Management”.

.

se

l To update list of signatories and

ru

he

department changes.

ot

ny

fo y.

20 SOD l Update any reference of SIFA LTD

d nl

ra

re o

to SCHWARZ PHRAMA LTD

ui es

eq os

Remove any reference to WM

r r rp

l

ne pu

storage 006

ow ion

To remove any reference to Nitric

ht ct

l

ig pe

yr ns

Acid in BAY 130

op r i

f c Fo

l To reflect changes to Procedure form

SAP R3 to SAP ENTERPRISE

to

Update signatories

en

l

ns

Co

EPA Export 25-07-2013:15:03:42

SOP RECEIPT COh!FI& hiN ’

SOP TITLE: STORAGE OF MATERIALS

I acknowledge receipt of the above SOP.

.

se

ru

he

Copvc.

ot

For All Csni

ny

fo y.

d nl

ra

re o

ui es

I have destroyed (returned in the case of BMI’s) the superceded revision of the SOP.

eq os

r r rp

ne pu

ow ion

Signed: Department:

ht ct

Date:

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

EPA Export 25-07-2013:15:03:42

Attachment H.l Material Handling

Schwarz Pharma Ltd. Revised IPCL Application

.

se

ru

Appendix H.l.2

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

Chemical Storage,

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

Site Map

f c Fo

to

en

ns

Co

EPA Export 25-07-2013:15:03:42

Co

ns

en

to

f c Fo

op r i

yr ns

ig pe

ht ct

ow ion

ne pu

r r rp

eq os

ui es

re o

d nl

fo y.

ra

ny

ot

he

ru

se

.

EPA Export 25-07-2013:15:03:42

‘. , .I

--_ .i_~---I’ -’ /

; /

i

‘I

llci

i ----.-.-~ I/i 1 -

-

RAW

WASTE

M,mR!AL IN/OUT

- ,NTERh,EDli\TE / PiiODUCT

L: UQUID WASTE

9: SOLID WSTE

,_._..___-.-- - ---

,’ BOUNDARY

,/”

.

se

ru

he

ot

ny

fo y.

d nl

ra

re o

ui es

eq os

r r rp

ne pu

ow ion

ht ct

ig pe

yr ns

op r i

f c Fo

to

en

ns

Co

a 22/7/04 CC 04/??. Enviro Mods

7 25/5/04 CC 04/189,Monitaring F

6 13/1/04 ,nclude NPD Portocobin

5 26/T/02 Updoted

4 13/5/02 Updated

3 28/8/01 Includes conteen

‘\ i 2 24/g/99 ,ncludes Nitration

\V

1 29/4/99 ,d”&S WWTP oncl

Worehause

R 20/2/97 Phormo Building Include,

EPA Export 25-07-2013:15:03:42

You might also like

- ECDD 37th Report FINAL PrelayoutDocument45 pagesECDD 37th Report FINAL PrelayoutsppNo ratings yet

- Guideline For Stability StudiesDocument44 pagesGuideline For Stability StudiesboddarambabuNo ratings yet

- DPS 2012 3 2 300 304Document5 pagesDPS 2012 3 2 300 304sppNo ratings yet

- CN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentsDocument3 pagesCN103239461A - Vitamin B Complex Injection and Preparation Method Thereof - Google PatentssppNo ratings yet

- US8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentsDocument10 pagesUS8809393B2 - Injectable Preparations of Diclofenac and Its Pharmaceutically Acceptable Salts - Google PatentssppNo ratings yet

- Zhang Asu 0010E 15975Document148 pagesZhang Asu 0010E 15975sppNo ratings yet

- Formulation 2Document38 pagesFormulation 2sppNo ratings yet

- CN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentsDocument3 pagesCN103169756B - Pharmaceutical Composition of Water-Soluble Vitamins For Injection, Fat-Soluble Vitamin Injection and Fat Emulsion Injection - Google PatentssppNo ratings yet

- Agilent ASMS 2019 ThP762 PosterDocument4 pagesAgilent ASMS 2019 ThP762 PostersppNo ratings yet

- PERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFDocument5 pagesPERFORMANCE QUALIFICATION PROTOCOL AUTOMATIC SIX HEAD LIQUID FILLING AND SEALING MACHINE - PDFsppNo ratings yet

- KB003Document4 pagesKB003sppNo ratings yet

- Optimization and Use of Talc in Direct Compression Tablet FormulaDocument307 pagesOptimization and Use of Talc in Direct Compression Tablet FormulasppNo ratings yet

- Rapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductsDocument12 pagesRapid and Efficient High-Performance Liquid Chromatography Analysis of N-Nitrosodimethylamine Impurity in Valsartan Drug Substance and Its ProductssppNo ratings yet

- Dareoct 19Document6 pagesDareoct 19sppNo ratings yet

- Risk Assessments and Sourcing Strategies For Excipients and ApisDocument2 pagesRisk Assessments and Sourcing Strategies For Excipients and ApissppNo ratings yet

- Regulatory Supplier QualificationDocument5 pagesRegulatory Supplier QualificationelmiraNo ratings yet

- AQL For PGL F&PDocument1 pageAQL For PGL F&PsppNo ratings yet

- Validation of BetalactamDocument18 pagesValidation of BetalactamsppNo ratings yet

- ASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFDocument3 pagesASEAN TMHS GMP Training Chapter 4 Annex 8 SOP On Cleaning of Equipment and Acce PDFAnuradha yadavNo ratings yet

- List of Units Indore SEZ PithampurDocument4 pagesList of Units Indore SEZ PithampursppNo ratings yet

- QA PharmaceuticalDocument413 pagesQA Pharmaceuticalalhalili100% (9)

- Guidance Documents APIDocument83 pagesGuidance Documents APIAmit NagareNo ratings yet

- LAB 075 Stability and Trial Testing Procedure SampleDocument2 pagesLAB 075 Stability and Trial Testing Procedure SamplesppNo ratings yet

- PIC/S Assessment & Joint Reassessment ProgrammeDocument15 pagesPIC/S Assessment & Joint Reassessment ProgrammesppNo ratings yet

- Registering drugs in MadagascarDocument2 pagesRegistering drugs in MadagascarsppNo ratings yet

- Dpco Price List April 2015Document82 pagesDpco Price List April 2015sppNo ratings yet

- Mapping Storage Areas Final Sign Off ADocument25 pagesMapping Storage Areas Final Sign Off Ahandayani100% (2)

- ECA PQG GDP Guideline Chapter 3 Appendix 2 Temp Map Report Template Feb2016Document13 pagesECA PQG GDP Guideline Chapter 3 Appendix 2 Temp Map Report Template Feb2016RICHARD FABIAN DURANNo ratings yet

- Levofloxacin: The International PharmacopoeiaDocument7 pagesLevofloxacin: The International PharmacopoeiasppNo ratings yet

- MICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratoryDocument11 pagesMICLAB 150 Initial Investigation of Out of Specification (OOS) Results in Microbiological LaboratorysppNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Capacity Utilisation Analysis Through TDABCDocument25 pagesCapacity Utilisation Analysis Through TDABCJames DonovanNo ratings yet

- SR - SC.G Dispatch of Goods To Shops From WarehouseDocument6 pagesSR - SC.G Dispatch of Goods To Shops From Warehousemirzamohsinjaved000No ratings yet

- S.Y.BMS Semester 3Document15 pagesS.Y.BMS Semester 3Pratiksha MutalNo ratings yet

- COOP MART QUẬN 7Document11 pagesCOOP MART QUẬN 7ĐẠT NGUYỄN ĐÌNH QUỐCNo ratings yet

- HIK RObotDocument20 pagesHIK RObotdocteur stringoNo ratings yet

- Case Studies 1 8 PDFDocument28 pagesCase Studies 1 8 PDFNina CeaNo ratings yet

- IFS Applications 10 - Warehouse Data Collection and Aurena Scan It Overview and Demo (Iraj)Document21 pagesIFS Applications 10 - Warehouse Data Collection and Aurena Scan It Overview and Demo (Iraj)venkikashyapNo ratings yet

- Company Case StudyDocument3 pagesCompany Case StudyAnand KrishnaNo ratings yet

- Limitations of ERPDocument6 pagesLimitations of ERPAshu TuliNo ratings yet

- Green Logistics Solutions in Vietnam: Case: Macnels Shipping Co - LTDDocument52 pagesGreen Logistics Solutions in Vietnam: Case: Macnels Shipping Co - LTDTrương Ái NhiNo ratings yet

- Containerization in Shipping Execution: An Oracle Topical Essay Created April 2000Document19 pagesContainerization in Shipping Execution: An Oracle Topical Essay Created April 2000Babu ChalamalasettiNo ratings yet

- Warehouse Manager Resume ExamplesDocument6 pagesWarehouse Manager Resume Examplesafiwfbuoy100% (2)

- Lazada S Last Mile Where No e Commerce Company in Vietnam Had Gone BeforeDocument10 pagesLazada S Last Mile Where No e Commerce Company in Vietnam Had Gone BeforesepehrNo ratings yet

- PGDMLM PapersDocument10 pagesPGDMLM PapersAakash Singh0% (1)

- O Level Commerce Through Questions and AnswersDocument30 pagesO Level Commerce Through Questions and AnswersBradley Muganyi100% (2)

- Project - Report - On ORDNANCE - FACTORY - NALANDADocument10 pagesProject - Report - On ORDNANCE - FACTORY - NALANDASantosh KumarNo ratings yet

- Improving Efficiency in A Hybrid Warehouse: A Case Study Improving Efficiency in A Hybrid Warehouse: A Case StudyDocument11 pagesImproving Efficiency in A Hybrid Warehouse: A Case Study Improving Efficiency in A Hybrid Warehouse: A Case StudyIbrahim SkakriNo ratings yet

- Oracle RetailDocument25 pagesOracle RetailMaddox SquareNo ratings yet

- CH 02Document39 pagesCH 02enamislamNo ratings yet

- Macdonald's Pakistan Supply ChainDocument35 pagesMacdonald's Pakistan Supply ChainTaha Durrani0% (1)

- Using Teams at Evans RV CompanyDocument6 pagesUsing Teams at Evans RV CompanyShubhangi KesharwaniNo ratings yet

- Tieman Dkk. 2012. Principles in Halal Supply Chain ManagementDocument28 pagesTieman Dkk. 2012. Principles in Halal Supply Chain Managementmuhammad taufikNo ratings yet

- Sap AfsDocument105 pagesSap Afstucu23456100% (2)

- Trip Generation RatesDocument3 pagesTrip Generation Rateshosny ahmedhosnyNo ratings yet

- Strategic Significance of Inventory Management for Customer ServiceDocument42 pagesStrategic Significance of Inventory Management for Customer ServiceAmir sabir100% (1)

- WMS Guide to Mobile Data Entry FeaturesDocument116 pagesWMS Guide to Mobile Data Entry FeaturesLoveNo ratings yet

- Plant Layout and Material Handling: Anoop Pandey Sr. Assistant Professor ABES Engineering College, GhaziabadDocument53 pagesPlant Layout and Material Handling: Anoop Pandey Sr. Assistant Professor ABES Engineering College, GhaziabadanoooppandeyeckNo ratings yet

- Questionnaire - RetailDocument11 pagesQuestionnaire - RetailNikhil MallviyaNo ratings yet

- International Marketing Channels: Mcgraw-Hill/IrwinDocument35 pagesInternational Marketing Channels: Mcgraw-Hill/IrwinIzatti AyuniNo ratings yet

- Mhra Temp MappingDocument11 pagesMhra Temp MappingvijayNo ratings yet