Professional Documents

Culture Documents

Extrusion Technology

Uploaded by

HEMANTKHERACopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Extrusion Technology

Uploaded by

HEMANTKHERACopyright:

Available Formats

Complete Extrusion

Lines for Plastic Pipes

Value Through Know-How

About U

Delivering Know-How:

Extrusion Lines by Pipe Manufacturer

The 50 years of experience in design Uponor Infra provides complete extrusion lines for

and manufacturing of plastic pipe PE-HD pipe manufacturing in dimensions ranging

extrusion lines ensures successful from 16 up to 1600 mm. In addition, we also supply PERT,

solutions for every customer. PP-r and PEX-pipe manufacturing equipment.

Being also a pipe manufacturer, we

constantly strive for new innovations

in terms of quality and productivity.

As we pass on this know-how to the customers. Who is not

only getting the best technology, but a business-ready,

complete production concept. Our heavy duty extrusion

lines enable the production of several different products

like tap water, gas, PE casing pipes, heating pipes, meaning

the capacity can be adopted to where needed at the time.

2 Complete Extrusion Lines for Plastic Pipes

Complete Extrusion Lines for Plastic Pipes 3

Technolog

Efficient Raw Material Handling

Raw material handling system is designed to transfer • An optional raw material dryer completed with a

raw materials to the feed hopper of the extruder and to vacuum conveyor, which transfers raw material

keep the manufacturing process continuous. The system granulate from the dryer to the feed hopper of the

comprises the following components: extruder. Tubes for transporting of raw material are of

stainless steel. Air ducts of the raw material transfer

• Vacuum conveyor, which transfers raw material system are of aluminum alloy.

granulate from the storage bunker to the feed hopper

of an extruder, or alternatively to an optional dryer.

Raw Material Handling System

TYPE Type 1 Type 2 Type 3 Type 4

Capacity kg / h 500 1000 1500 2000

Real-Time Monitoring,

Real-Time Value

Gravimetric control system (GCS) monitors the raw • PLC with single user interface

material consumption in real-time mode and compares • line speed measurement with closed loop control

it to the haul-off speed. If any deviation of actual metric • screw rotary speed measurement

weight from its calculated value occurs, GCS corrects the • measurement of screw output per one revolution (gr/r)

speed of the extruder or the speed of the haul-off unit. • interfaces for upper level control and printer (optional)

According to the Customer’s demand and requirements,

the GCS instrumentation and software are delivered either

for single-flow or multi-flow monitoring. A basic GCS is

comprised of following components:

• feed hopper

• weighing hopper

• metering valve and frame

4 Complete Extrusion Lines for Plastic Pipes

Single Screw Extruders

The pipe extruder is designed for the manufacturing of

polyolefin pipes. The product range comprises extruders

with screw diameters from 18 to 150 mm.

• Barrier screw: Nitrated steel, HV 950 – 1000

• Grooved feed bush: used with a barrier screw enables

high plastification rates and low melt temperatures

• Extruder barrel: Nitrated steel, HV 950 - 1000

• Temperature control zones, heating/cooling

• Heating zones of extrusion die flange.

Diversified Extrusion Tools

The Uponor Infra extrusion dies enable pipe extrusion of The Advantages:

polyolefin materials, such as PE (HDPE, MDPE) and PP. The • low head volume enables short dwell times and low

die-heads are of spiral distribution type. Dimensioning of thermal stress impressed upon the melt

the flow channels is based on the rheological characteristics • low pressure build-up even at high material throughput

of the most frequently used types of plastics. Optionally at low stock temperature

the die head can be equipped with Internal Cooling System • precise distribution of the melt which minimizes the

for shorten cooling length or increasing output. wall thickness deviations

• short self-cleaning time when changing the colour of

raw material

• high mechanical characteristics of the pipe.

Complete Extrusion Lines for Plastic Pipes 5

Technolog

Save Energy, Produce More:

High Performance 37 L/D Extruder

High output 37 L/D extruder series for the demands of Closed loop cooling system:

energy saving and constant distribution. • Extruders provided with closed cooling system have

water-cooled motor, drive, control cabin, gear and

Standard water-cooled AC -motor: barrel. Internal screw cooling as option.

• Excellent coefficient of efficiency (92,9 %). • The system is silent with no heat losses to the

• Low noise level <75 dB(A), without heat losses to the environment.

production hall. • It is easy to connect to the factory’s cooling system or

process water. Due to glycol composition the closed

Energy saving water-cooled drive: system remains clean and rustless.

• The intelligent frequency converter adjusts

magnetization according to the load, which means Movable operator control panel and Internet remote

improved efficiency. connection:

• Mobile control panel can be moved either side of the

Advanced barrel cooling: extruder or even near to pipe head.

• Cooling fins and ceramic heaters ensures accurate melt • Multilingual selected by push button.

temperature. Internal cooling of the screw is optionally • The PLC includes Ethernet for the remote connection

available. by VPN router or internet connection with customer’s

accessible I.P. Address.

Constant output:

Mixer (Option):

• Spiral grooved feed section creates circumstances for

formation of even constant and homogenous high • The mixer ensures huge increase of output and

output of the melt flow. homogenous melt with even distribution for different

kind of master batches. The hemispherical cavities

of the mixer force the raw material travelling along

the barrel continuously changing direction, causing

shearing and cutting action to the melt.

6 Complete Extrusion Lines for Plastic Pipes

Complete Extrusion Lines for Plastic Pipes 7

Technolog

Advanced Calibration Tools

Calibration gives the pipe its final shape and size. Haul-off unit

Uponor Infra provides complete range of calibration sleeves The haul-off unit grips the pipe over a long length and

for vacuum and pressure calibration. Our long experience pulls it at a constant speed. The haul-off consists of a

in pipe manufacturing allows precise designing of the number of pulling belts around the pipe. The pulling belts,

sleeves that optimizes production. High quality calibration which are located under the extrusion axis, are mechanically

tools ensure round pipes with excellent surface and lower adjustable and upper ones are driven pneumatically.

overweight of the pipe products.

Pipe cutting equipment

Pipe Calibration Tanks

Pipes with a diameter over Ø 160 mm are usually cut to the

The calibration tank can be either of single or double standard length.

chamber construction. The bottom part of the unit is used

as a water reservoir, which ensures precise temperature Circular saws

control in the calibration tank. The temperature of

Circular saws for cutting pipes of outer diameter up to Ø

the calibration tank is kept on the desired level by a

250 mm.

thermostat. The calibration tank is installed on the rail

tracks, anchored to the workshop’s floor. The longitudinal

Planetary saws

movement of the calibration tank is motorised.

The planetary saw is delivered as a single cut unit. By

request any planetary saw can be equipped with two-step

cutting heads. The initial cut is executed by disk saws and

the final operation by cutting blades. In that way ingress of

sawdust inside the pipe is prevented.

Vacuum Calibration Tanks

VCA VCA VCA VCA VCA VCA VCA

TYPE

63-6 110-6 250-6 400-6 630-6 800-6 1200-6

Pipe diameter Ø, mm 10 - 63 20 - 110 50 - 250 63 - 400 110 - 630 250 - 800 630 - 1200

Spray Cooling Baths

SB 110- SB 250- SB 400- SB 630- SB 800- SB 1200- SB-1600-

TYPE SB 63-10(6)

10(6) 10(6) 10(6) 10(6) 10(6) 10(6) 6(4)

Pipe diameter Ø, mm 10 - 63 20 - 110 50 - 250 63 - 400 110 - 630 250 - 800 630-1200 710-1600

Pressure Calibration Tanks

PCA PCA

TYPE

1200 1600

Pipe diameter Ø, mm 400 - 1200 710-1600

Haul-Off Units

PVL

TYPE PVL 110/3 PVL 250/4 PVL 400/6 PVL 630/6 PVL 800/6 PVL 1200/10 PVL 1600/12

1000/8

Pipe diameter Ø, mm 16 - 110 50 - 250 40 - 400 110 - 630 140 - 800 160 -1000 315 - 1200 710 - 1600

8 Complete Extrusion Lines for Plastic Pipes

Complete Extrusion Lines for Plastic Pipes 9

Technolog

Full Process Control

The control system constantly monitors the manufacturing Wall thickness ultrasonic measure control (UMC)

process on its every stage and corrects current production The wall thickness ultrasonic measure control is to maintain

parameters to the set value. Basic control system provides the high and stable product quality and to minimize

following services to the manufacturing process: consumtion of specific raw materials. The core of the

ultrasonic measure control system is the high-speed

• Speed control of all installed drives of the production ultrasonic evaluation electronics and the sensor system.

line The processed data is displayed on the UMC output screen

• Temperature control and adjusting to the set point and used by the process control system to correct the

• Control of water level in calibration tanks and spray performance of the extrusion line.

cooling baths

• Pressure control of raw material melt The UMC controls the following operations

• Raw material flow control and related parameters:

• Alarm reporting and diagnostics.

• metric weight (haul-off / extruder)

• minimum wall thickness (haul-off)

Integrating the gravimetric control into the basic control

• wall thickness profile (die head centering)

system enables enhanced process monitoring and run mode

• diameter (vacuum)

optimization, saving raw materials and other resources.

• extruder/start-up ramps

• component dosing

Extended operation control system

• co-extrusion.

The operation control system of a single extrusion line

can be connected to the PC-based upper level control

system, which integrates and administers control systems

of all installed production lines of the factory. This enables

effective and comprehensive process control, including

operation security and co-ordination. The extended

operation control system allows the manufacturing process

automation.

10 Complete Extrusion Lines for Plastic Pipes

Aftersales

Uponor Infra provides services by our skilled and professional

staff. Our customer service offers original spare parts with

flexible and short delivery times.

Customers’ staff is trained in Finland and during the start

up at the customers’ premises. Our experienced technicians

assists and helps you to maintain best quality products in your

manufacturing line.

We invest time in understanding the customer and provide

top-class service from start to finish. Our customers’ success is

our success

Complete Extrusion Lines for Plastic Pipes 11

11

Professional Solutions for

Plastics Industry

Uponor Infra is a joint venture between the Uponor Since the 1960´s, the Technology

Corporation and the KWH Group established in 2013 by department of Uponor Infra has been

merging the two owners´ infrastructure businesses. The supplying equipment and technology

company has a leading position in the infrastructure pipe solutions for customers worldwide. Uponor

systems markets in northern Europe, with operations also Infra offers a wide range of high quality

in North America and Asia. The technology and licensing products and services and carries out

department, formerly known as KWH Pipe Ltd, Technology, is complete turnkey factory projects.

based in Vaasa, Finland.

Uponor Infra Ltd T +358(0)20 129 211

Pointer / FRAM 11.2014 200.

P.O. Box 21 F +358(0)20 129 2099

FI-65101 Vaasa W www.uponor.fi/technology

Finland E machinery.vaasa@uponor.com

You might also like

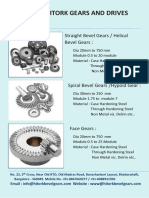

- Nomenclature of Spur GearDocument1 pageNomenclature of Spur GearHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 12Document1 pageChapter 11 - Gear - 12HEMANTKHERANo ratings yet

- Fundamental Law and Involute Curve: R / R Constant (Constant Speed Ratio)Document1 pageFundamental Law and Involute Curve: R / R Constant (Constant Speed Ratio)HEMANTKHERANo ratings yet

- Type of Gear - 2Document1 pageType of Gear - 2HEMANTKHERANo ratings yet

- Type of Gear - 3Document1 pageType of Gear - 3HEMANTKHERANo ratings yet

- Gear Pitch Diameter, Circular Pitch and Center Distance CalculationDocument1 pageGear Pitch Diameter, Circular Pitch and Center Distance CalculationHEMANTKHERANo ratings yet

- Gear 2 PDFDocument1 pageGear 2 PDFHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 9Document1 pageChapter 11 - Gear - 9HEMANTKHERANo ratings yet

- Type of GearDocument1 pageType of GearHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 6Document1 pageChapter 11 - Gear - 6HEMANTKHERANo ratings yet

- Gear 1 PDFDocument1 pageGear 1 PDFHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 10Document1 pageChapter 11 - Gear - 10HEMANTKHERANo ratings yet

- Moktrans - SRC Helical Gearbox PDFDocument32 pagesMoktrans - SRC Helical Gearbox PDFHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 7Document1 pageChapter 11 - Gear - 7HEMANTKHERANo ratings yet

- Chapter 11 - Gear - 5Document1 pageChapter 11 - Gear - 5HEMANTKHERANo ratings yet

- Gears Design Principles and ApplicationsDocument1 pageGears Design Principles and ApplicationsHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 8Document1 pageChapter 11 - Gear - 8HEMANTKHERANo ratings yet

- Chapter 11 - Gear - 2Document1 pageChapter 11 - Gear - 2HEMANTKHERANo ratings yet

- Gear Pitch Diameter, Circular Pitch and Center Distance CalculationDocument1 pageGear Pitch Diameter, Circular Pitch and Center Distance CalculationHEMANTKHERANo ratings yet

- Chapter 11 - Gear - 3Document1 pageChapter 11 - Gear - 3HEMANTKHERANo ratings yet

- Rotor Gear Box WPA WPS WPX WPO WPDA WPDSDocument20 pagesRotor Gear Box WPA WPS WPX WPO WPDA WPDSHEMANTKHERA100% (1)

- .QM 23e Ppap Level 1Document26 pages.QM 23e Ppap Level 1Eb Mohamed TahaNo ratings yet

- High-Speed Gear DrivesDocument12 pagesHigh-Speed Gear DriveswillalizadeNo ratings yet

- Moktrans - SRC Helical Gearbox PDFDocument32 pagesMoktrans - SRC Helical Gearbox PDFHEMANTKHERANo ratings yet

- Hirork Gearsand Drive ProfileDocument1 pageHirork Gearsand Drive ProfileHEMANTKHERANo ratings yet

- Characteristics Of: Corrugated Hdpe PipeDocument17 pagesCharacteristics Of: Corrugated Hdpe PipeHEMANTKHERANo ratings yet

- SGN 160 PR: Diesel Genset ModelDocument4 pagesSGN 160 PR: Diesel Genset ModelHEMANTKHERANo ratings yet

- SLRCDocument32 pagesSLRCHEMANTKHERANo ratings yet

- Lift and Escalator Motor Sizing Methods ExplainedDocument22 pagesLift and Escalator Motor Sizing Methods ExplainedHEMANTKHERA100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pellet PotatoDocument24 pagesPellet PotatoArchit Agarwal100% (1)

- Final Report For Industrial Training Done at Mukwano IndustriesDocument62 pagesFinal Report For Industrial Training Done at Mukwano IndustriesOrtega IanNo ratings yet

- Nexans CableDocument8 pagesNexans CableQwerty1992ABCNo ratings yet

- Recent Advances in Surimi Technology: Uricml@uriacc - Uri.eduDocument7 pagesRecent Advances in Surimi Technology: Uricml@uriacc - Uri.eduNhi HoNo ratings yet

- Research Note On Aluminium Alloy Property PDFDocument80 pagesResearch Note On Aluminium Alloy Property PDFpenghzNo ratings yet

- FB Extruders Ex1021 Datasheet en DataDocument2 pagesFB Extruders Ex1021 Datasheet en DatafarshidNo ratings yet

- Skgd2000 CeDocument98 pagesSkgd2000 CeRafael GiraldoNo ratings yet

- Calendering Process Produces Plastic SheetsDocument14 pagesCalendering Process Produces Plastic SheetsMuhammad ChawlaNo ratings yet

- Autodesk Inventor 2014 Tutorial BookDocument27 pagesAutodesk Inventor 2014 Tutorial BookOnline InstructorNo ratings yet

- Practical Guide To Blow Moulding PDFDocument216 pagesPractical Guide To Blow Moulding PDFSuri Kens Michua100% (3)

- Tech Data Sheet IMPAXX™ 700 Energy Absorbing Foam: Product InformationDocument2 pagesTech Data Sheet IMPAXX™ 700 Energy Absorbing Foam: Product InformationChris DoukasNo ratings yet

- Application of Extrusion Technology in Plant Food Processing Byproducts: An OverviewDocument29 pagesApplication of Extrusion Technology in Plant Food Processing Byproducts: An OverviewParveen Mohammed AliNo ratings yet

- FieldTurf ComplaintDocument71 pagesFieldTurf ComplaintJepuertoNo ratings yet

- Polymer Diverter Valve Gala 2S EN SDocument2 pagesPolymer Diverter Valve Gala 2S EN SDiegoNo ratings yet

- TALAT Lecture 3501: Alloys and PropertiesDocument8 pagesTALAT Lecture 3501: Alloys and PropertiesCORE MaterialsNo ratings yet

- Catalogo - Seals Hidraulic HALLITE CasdelDocument321 pagesCatalogo - Seals Hidraulic HALLITE CasdelCarlos Alberto Coaguila Torres100% (1)

- CW March 2020 PDF For Download PDFDocument68 pagesCW March 2020 PDF For Download PDFАлексей СюкринNo ratings yet

- Abu Dhabi Oil Refining Doors and Windows SpecDocument16 pagesAbu Dhabi Oil Refining Doors and Windows SpecHalim KazdarNo ratings yet

- Desk Lamp DFM Analysis and RedesignDocument125 pagesDesk Lamp DFM Analysis and RedesignNur' AyuniNo ratings yet

- DIN English - Aircraft and Space Vehicle Engineering Collection - IHSDocument3 pagesDIN English - Aircraft and Space Vehicle Engineering Collection - IHSprashant.acharyahnrNo ratings yet

- Polypropylene: Product Data SheetDocument2 pagesPolypropylene: Product Data Sheet李万福No ratings yet

- Manufacturing TechnologyDocument6 pagesManufacturing TechnologyKarim HeshamNo ratings yet

- Pipeline Coating Specification UpdatesDocument15 pagesPipeline Coating Specification UpdatesDevam RajNo ratings yet

- Conversion of Degrees to Inches ChartDocument48 pagesConversion of Degrees to Inches ChartShibnathLahiri100% (1)

- Thermomechanical Streaking Defects in Architectural Aluminium ExtrusionsDocument250 pagesThermomechanical Streaking Defects in Architectural Aluminium ExtrusionszhaomingbaoNo ratings yet

- Intership Report FinalDocument48 pagesIntership Report FinalChandraksha PutturNo ratings yet

- HFDB-4202 Natural ECDocument3 pagesHFDB-4202 Natural ECShubham BaderiyaNo ratings yet

- Metal-Forming Machines PDFDocument31 pagesMetal-Forming Machines PDFdaha333No ratings yet

- 3D Printing Third Edition - Christopher Barnatt PDFDocument191 pages3D Printing Third Edition - Christopher Barnatt PDFEmilio Vicente100% (1)