Professional Documents

Culture Documents

Hufcor 632 Paired F4149F

Uploaded by

doody.dpujaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hufcor 632 Paired F4149F

Uploaded by

doody.dpujaCopyright:

Available Formats

632 SERIES SPECIFICATIONS

Paired Panels

PRODUCT OVERVIEW:

Select for Value: Series 632 panels offer a wide choice of finish options,

accessories, and sound control levels.

Standard Features: The panels are nominally 3” [76] thick, and have a frame of

16 ga. steel. The top horizontal sound seal is of multi-finger vinyl, and the

bottom sound seal is retractable and provides up to 2” [50] floor clearance (to

accommodate out-of-level floors). The retractable seals are Quick-Set™ which

means they are easily extended or retracted with only a 1/2 turn of the

removable handle. The faces may be covered from a wide selection of vinyl

colors and patterns. The face substrate varies by the level of sound control

required (STC rating).

Paired Panels: Select for wall-to-wall space division. Panels are hinged in pairs

allowing fast setup. They may be stacked at either or both ends of the track or

in a "pocket". One or more pair of panels may also be placed anywhere along

the track for use as sight dividers.

Top Supported How to Obtain: Hufcor partitions are sold, installed, and serviced by factory-

Center Stack trained local authorized Distributors in the United States and by Licensees and

Paired Panels Distributors outside the U.S.A.

Manually Operated

Maximum Opening Height: 24’3" [7391] Delivery: Panels are custom built for your specific project. Lead times vary due

Maximum Opening Width: Unlimited to seasonal fluctuations. Check with your Distributor for the current schedule. If

STC Ratings: 41, 43, 47, 49, 51 fast shipment is required, quick ship programs are available.

Warranty: Track and panels are guaranteed for two years against defects in

material and workmanship.

"Standard" Product Features and Benefits:

Look for these features when comparing similar products.

1. Feature: Protective vertical trim (Available option: 5. Feature: Waist high seal activator for quick set

no protective vertical face trim.) retractable seals.

Benefit: Trim protects the panel edges and faces Benefit: Fast, easy seal activation without bending or

plus it provides a handhold when moving panels. stooping.

2. Feature: Quick-Set™ Retractable Seals 6. Feature: Removable operating handle.

. Benefit: The retractable seals are Quick-Set™ Benefit: Prevents unauthorized operation.

which means they are easily extended or 7. Feature: Expanding Jamb Closure (Lever Closure) Panel

retracted with only a 1/2 turn of the removable Benefit: Exerts 250 lbs [113.4 kg] of force against the

handle. No tedious cranking needed to set the fixed wall. The compression creates tight panel joints

seals. for optimum sound control.

3. Feature: 2” [50] retractable bottom seals 8. Feature: Interlocking vertical seals

Benefit: Retractable seals accommodate out-of- Benefit: Ensures panel-to-panel alignment and prevents

level floor conditions. When retracted, nothing sound leaks between panels.

drags on the floor when the panels are moved. 9. Feature: Low profile hinges

Panels can be “locked” in place. Benefit: Safety and aesthetics - no unsightly hinges

4. Feature: Retractable bottom seals exert downward protruding from the panel faces.

seal force

Benefit: Provides constant force against floor for

optimum acoustics even on carpet or other

porous floor materials. Maintains panel stability

when the seals are set.

Optional track systems, seals, and accessories enable the standard product to

be modified for optimum versatility. See details provided or ask your Hufcor

representative for the features you want.

F-4149F Figures in brackets [ ] are in millimeters unless otherwise noted. 1

GENERAL SPECIFICATIONS/SERIES 632

Paired Operable Partitions provide no protective vertical face trim.

4. Vertical sound seals shall be of tongue and groove configuration,

PART 1 - GENERAL

ensure panel-to-panel alignment and prevent sound leaks between

1.01 DESCRIPTION

panels.

A. General

5. Horizontal top seals shall be fixed continuous contact dual 4-finger

1. Furnish and install operable partitions and suspension system. Provide

vinyl.

all labor, materials, tools, equipment, and services for operable walls in

(Option: Horizontal top seals shall be retractable, provide 1” [25]

accordance with provisions of contract documents.

nominal operating clearance, and exert upward force when

1.02 RELATED WORK BY OTHERS extended. All panels, including pass door panels and lever closure

A. Preparation of opening will be by General Contractor. Any deviation of site panels must have retractable top and bottom seals. Not available

conditions contrary to approved shop drawings must be called to the with automatic bottom seals.)

attention of the architect. 6. Horizontal bottom seals shall be retractable, provide up to 2” [50]

B. All header, blocking, support structures, jambs, track enclosures, nominal operating clearance, and exert downward force when

surrounding insulation, and sound baffles as required in 1.04 Quality extended.

Assurance. Optional Seals:

C. Prepunching of support structure in accordance with approved shop (a) Horizontal bottom seals shall be automatic and provide up to 2”

drawings. [50] nominal operating clearance. (Consult your Hufcor

D. Paint or otherwise finishing all trim and other materials adjoining head and Distributor for more information.)

jamb of operable partitions. (b) Horizontal bottom seals shall be fixed continuous contact dual

4-finger vinyl.

1.03 SUBMITTALS 7. Horizontal trim shall be of aluminum.

A. Complete shop drawings are to be provided prior to fabrication indicating 8. Low profile hinges on basic panels shall be of steel and project no

construction and installation details. Shop drawings must be submitted more than 1/4” [6] beyond panel faces. Each pair of panels to have

within 60 days after receipt of signed contract. a minimum of three hinges.

B. Weight of the panels shall be 5.7-10.2 lbs. per sq. ft. [27.8-49.8kg/sq.m]

1.04 QUALITY ASSURANCE

based on options selected.

A. Preparation of the opening shall conform to the criteria set forth per ASTM

C. Suspension system:

E557 Standard Practice for Architectural Application and Installation of

1. Track shall be of clear anodized architectural grade extruded

Operable Partitions

aluminum alloy 6063-T6. Track design shall provide precise

B. The partition STC (Sound Transmission Classification) shall be achieved

alignment at the trolley running surfaces and provide integral support

per the standard test methods ASTM E90.

for adjoining ceiling, soffit, or plenum sound barrier. Track shall be

C. Noise isolation classifications shall be achieved per the standard test

connected to the structural support by pairs of minimum 3/8” [10] dia.

methods ASTM E336 and ASTM E413.

threaded steel hanger rods. Guide rails and/or track sweep seals

D. Noise Reduction Coefficient (NRC) ratings shall be per ASTM C423.

shall not be required.

E. Rack testing for 10 years. (tensional strength stress test)

a. Each panel shall be supported by one 4-wheeled carrier. Wheels

F. The manufacturer shall have a quality system that is registered to the ISO

to be of hardened steel ball bearings encased with molded

9001 standards.

polymer tires.

1.05 PRODUCT DELIVERY, STORAGE, AND HANDLING

2. Plenum closure (by others): Design of plenum closure must permit

A. Proper storage of partitions before installation and continued protection

lifting out of header panels to adjust track height. Plenum closure

during and after installation will be the responsibility of the General

required for optimum sound control of partition.

Contractor.

3. Option (available for select layouts-consult your Hufcor Distributor):

1.06 WARRANTY The panels shall be supported by the Unispan pre-engineered truss

A. Partition system shall be guaranteed for a period of two years against and post system fabricated of steel and aluminum. Unispan is

defects in material and workmanship, excluding abuse. attached to the building structure for lateral support only. The load of

the truss and partition is supported by end columns. The columns

PART 2 - PRODUCTS are connected to floor plates that distribute the load of the system at

2.01 ACCEPTABLE MANUFACTURERS the floor.

A. Upon compliance with all of the criteria specified in this section, D. Finishes

Manufacturers wishing to bid products equal to the product specified must 1. Face finish shall be: (select as required):

submit to the architect 10 days prior to bidding complete data in support of a. Factory applied reinforced vinyl fabric with woven backing,

compliance and a list of three past installations of products similar to those weighing not less than 20 oz. per lineal yard [620 g/m]. Color

listed. The submitting manufacturer guarantees the proposed substituted shall be selected from manufacturer’s standard color selectors.

product complies with the performance items specified and as detailed on b. Standard upgrade fabrics (color shall be selected from

the drawings. manufacturer’s standard color selector):

(1) Factory applied vertical ribbed carpet (N.R.C. .20)

2.02 MATERIALS (2) Factory applied stain resistant fabric

A. Product to be top supported Series 632 paired panels as manufactured by c. Optional:

Hufcor Inc. (1) Customer selected (requires factory approval for

1. Panels shall be nominally 3” [76] thick, to 48” [1219] in width, and hinged manufacturing compatibility)

in pairs. (2) Unfinished for field decoration

2. Panel faces shall be laminated to appropriate substrate to meet the STC (3) Wood veneer (factory installed on trimmed models)

requirement in 2.04 Acoustical Performance. (4) High pressure laminate (factory installed on trimmed models)

a. Optional substrate material (Not all substrates are available for all

STC ratings. Consult your Hufcor Distributor for more information): 2. Exposed metal trim and seal color shall be (select from Hufcor’s

Steel Standard Trim selector):

Non-steel a. Lamb’s Wool (standard)

Medium Density Fiberboard b. Brown (standard)

b. Horizontal Splice: Heights over 16'3" [4953] with non-steel faces c. Gray (standard)

require a structural splice placed at approximately 12’3' [3734] from d. Custom powder coated (optional upgrade for metal trim)

the floor. 3. Aluminum track shall be clear anodized

3. Frames shall be of 16 gauge [1.42mm] painted steel with integral factory a. Optional upgrade:

applied aluminum vertical edge and face protection. (1) Custom anodized

Optional: Face finish shall wrap around the vertical panel edges and (2) Custom powder coated

2 Figures in brackets [ ] are in millimeters unless otherwise noted

SERIES 632

E. Available Accessories/Options seal force against the adjacent wall for optimum sound control. The

1. ADA compliant pass door of the same thickness and construction as jamb activator shall be located approximately 45” [1143] from the

the basic panels. Pass door panel legs require bottom seals that floor in the panel face and be accessed from either side of the panel.

provide downward force to maintain stability during door operation. The jamb is equipped with a mechanical rack and pinion gear drive

Pass door leaf has perimeter trim to protect face finish and to provide mechanism and shall extend 4”-6” [100-152] by turning the

visual identification as required by International Building Code. Pass removable operating handle.

door leaf incorporates a self-adjusting retractable bottom seal 2. Pivot Panel (Optional for heights to 12’3” [3734] and a maximum of

providing sound control when door is closed. 10 panels): Pivot panel is attached to the wall and permits access

a. Automatic door closer between adjacent rooms. Pivot panel is of the same construction as

b. Door lock basic panels but with continuous contact multi-ply vinyl top and

c. Exit sign (consult your local code) bottom seals. The lead end of the panel has full height finger pull

d. Prepped for window and vertical seal of multi-ply vinyl

e. Peep hole E. Stack/Store Panels

2. Inset chalk/writing/projection surfaces 1. Retract seals and move to storage area. Panels may be stored at

3. Inset tackboards either or both ends of the track or in a pocket.

4. Inset eraser pocket 2.04 ACOUSTICAL PERFORMANCE

5. Segmented faces A. Acoustical performance shall be tested at a laboratory accredited by the

6. Finished end cover National Voluntary Laboratory Accreditation Program (NVLAP) and in

7. Pocket doors accordance with ASTM E90 Test Standards. Standard panel

8. Inset chair rail pan (for field installation of chair rail). construction shall have obtained an STC rating of (select as required):

9. Custom design options (consult your local Hufcor Distributor) 41, 43, 47, 49, 51

2.03 OPERATION (Not all substrates are available in all STC ratings)

A. Panels shall be manually moved from the storage area, positioned in 1. Complete, unaltered written test report is to be made available upon

the opening, and seals set. request.

B. Retractable Horizontal Seals

1. Retractable horizontal seals shall be activated by a removable quick- PART 3 - EXECUTION

set operating handle located approximately 42” [1067] from the floor A. Installation. The complete installation of the operable wall system shall

in the panel edge. be by an authorized factory-trained installer and be in strict accordance

2. All retractable seals in each hinged pair shall be operated with the approved shop drawings and manufacturer’s standard printed

simultaneously. specifications, instructions, and recommendations.

3. Seal activation requires approximately 15 lbs. [6.8 kg] of force per B. Cleaning

panel and approximately a 190 degree turn of the removable handle. 1. All track and panel surfaces shall be wiped clean and free of

C. Automatic Floor Seals handprints, grease, and soil.

1. Horizontal seals shall be activated by pressing the edge of the panel 2. Cartoning and other installation debris shall be removed to onsite

into the edge of the adjacent panel or wall. waste collection area, provided by others.

2. Seal activation requires approximately 15 lbs. [6.8 kg] of force per C. Training

panel. 1. Installer shall demonstrate proper operation and maintenance

D. Final partition closure to be by (select one): procedures to owner’s representative.

1. Lever closure panel with expanding jamb which compensates for 2. Operating handle and owners manuals shall be provided to owner’s

minor wall irregularities and provides a minimum of 250 lbs. [113.4kg] representative.

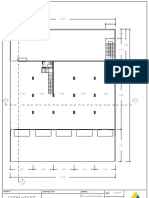

Header shown for 2 1/4"

plenum sound SOUND ATTENUATION BY OTHERS

[57]

enclosure is one of 1/2" [13] (MIN.) GYPSUM BOARD ON

several that may be CONTINUOUS METAL STUDS BY OTHERS

8" [203] MIN.

used. See ASTM

3/8" [10] Ø HANGER RODS

E557 Standard

Practice for Archl

Application &

CEILING BY OTHERS

Installation of

Operable Partitions 2 1/2" [64]

for other

4 3/4" [121]

recommendations.

1" [25] 1" [25]

Type 38 Aluminum

track. Standard for

weights to 400 lbs.

[182 kg]. Alternate

track system to be

UNIT HEIGHT

used for weights

exceeding 400 lbs.

3" [76]

3 1/2" [89]

2" [51] MAX

TOP OF FIN. FLOOR

TOP OF SLAB

FLOOR

COVERING No Scale

THICKNESS Vertical Section

Figures in brackets [ ] are in millimeters unless otherwise noted. 3

DETAILS SERIES 632

HORIZONTAL SECTION No Scale

Final partition closure using an expanding jamb closure. Recommended for optimum sound control. Solid

blocking is required at both ends to withstand 250 lbs. [113.4 kg] of lateral force.

6" [152] 1" [25]

Lever Closure Panel Joint Bulb Seal

(Expanding Jamb)

Optional: No vertical

face trim panel joint.

OPTIONAL CLOSURES

2 1/2" [64] Pivot Panel. This closure is

1 3/4" 1 3/4"

optional for heights to 12’3” and/or

[45] [45] openings with a maximum of 10

panels per opening.

PIVOT 4"

POINT [102]

4 1/2" [114]

4" ± 7/8"

[102] ± [22]

Optional: Wall

Jamb Angle Jamb.

Assembly Solid blocking 3/8" [6]

required.

OPTIONS & ACCESSORIES ELEVATION

1. Expanding Jamb Closure (Lever Closure) Panel. a. Markerboard and projection/writing surfaces (from

Expanding jamb exerts 250 lbs. [113.4kg] force against Hufcor standard color selector).

adjacent wall for optimum sound control. b. Tackboards of 2mm cork board covered with vinyl (from

2. Basic panel Hufcor standard color selector).

3. ADA compliant pass doors - Single 3/0 x 7/0 [914 x c. Chalk/marker tray (standard on chalk and

2132] or 3/0 x 6/8 [914 x 2030]. Of the same construction, projection/writing boards).

thickness, and finish as the basic panels. Push/pull 6. Recessed Eraser Pocket (8” x 2” x 1-1/4” deep

latching handle. Options include key lock, windows, and [203 x 50 x 31]).

automatic door closer. No threshold is required.

3a. Double (batwing) pass doors also available. 7. Lead panel with bulb seal to prevent sound leaks at

adjacent wall.

4. Exit Sign - Recessed or surface mounted, self-illuminated. Optional: Lead panel closure to 4” adjustable, full height,

5. Work Surfaces 4’0” [1219] high x panel width, recessed, acoustic wall jamb assembly.

mounted approx. 30” [762] above the floor:

Figures in brackets [ ] are in millimeters unless otherwise noted. 4

LAYOUT OPTIONS SERIES 632

Paired Operable Partitions

STACK DIMENSIONS

The following stack depth and width dimensions are based on standard construction with

vinyl faces. Optional construction and/or face covering may increase stack depth

requirements.

Single Opening, Using an Expanding Jamb (Lever Closure) Panel (Recommended for Optimum Acoustics)

Optional Pass Door

Equal

B

Equal

A = Stack Depth: For Type 38 track, allow 3-3/4” [95] per panel plus 1” [25].

A For Type 40 track, allow 4” [100] per panel plus 1” [25].

Optional panic hardware will add to the depth of the stack. Please contact your Hufcor

distributor for assistance.

Stack Width:

Retractable & sweep seal models: Panel width + 8" [204] clearance.

Automatic bottom seals: Panel width + 14” [356] clearance

Optional - Bi-parting (with expanding jamb (lever closure) panels at both ends).

(same stack formula at each end as single)

Equal Equal

B B

Equal Equal

A A

Optional Pivot Panel (for heights to 12’3” [3734])

(Pivot panel is limited to 10 panels in opening).

Equal

B

D Equal

A = Stack Depth:

A Pivot Panel - For Type 38 track, allow 3-3/4” [95] per panel plus 4-1/4” [108].

For Type 40 track, allow 4” [102] per panel plus 4-1/4” [108].

B = Basic Panel Stack Width: Widest panel + 8” [204]

Automatic bottom seals: Panel width + 14” [356] clearance

C = Pivot Panel Stack Width: Pivot panel width + 4” [102]

D = Total Stack Width without pocket: 1/2 of B + C

5 Figures in brackets [ ] are in millimeters unless otherwise noted

DETAILS/OPTIONS - NOT TO SCALE SERIES 632

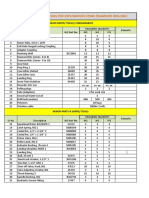

HANGER ROD LAYOUT

6" EQ. SPACES EQUAL SPACES @ 20" [508] O.C. 6"

[152] @ 10" [254] O.C. VARIES [152]

2 1/4" [57] (TYP.) 7/16" [11] Ø HOLES (TYP.) 6" TO 20"

OPTIONS

1" [25]

Hanging Weight

3" [76]

STC Lbs./Sq. Ft. Kgs./Sq. M

41 5.7 27.8 3 1/2" [89]

43 7.3 35.6

2" [51] MAX Optional finished end cover -

47 7.8 38.1 provides finished panel end

49 8.9 43.5 when partition run does not

extend from wall-to-wall.

51 10.2 49.8 Optional

Optional

continuous contact

retractable top seal

(sweep) bottom seal.

OPTIONAL TRACKS - Alternate Hufcor track systems may be used providing the height and weight limits are within

manufacturer’s guidelines.

5 1/4" [133]

2 1/4"

[57]

3 1/8" [79] 3 1/8" [79]

5" [127]

5"

[127]

Type 40 Aluminum Track Type 40 Aluminum Track

Optional for panel weights to 900 lbs. [408 kg]. shown with Optional suspension bracket available

for 5-1/4” [133] spacing.

The manufacturer reserves the right to

Worldwide headquarters: improve and change product without notice.

Hufcor Inc.

P.O. Box 5591

Janesville, WI USA 53547-0591

1-800-542-2371 ext. 214; 1-608-756-1241

FAX: 1-608-758-8253

E-mail: info@hufcor.com

Website: www.hufcor.com

F-4149F Figures in brackets [ ] are in millimeters unless otherwise noted 6

You might also like

- 642 Spec Paired F4148HDocument6 pages642 Spec Paired F4148Hdoody.dpujaNo ratings yet

- Hufcor 633E Cont Hinged F4151EDocument6 pagesHufcor 633E Cont Hinged F4151Edoody.dpujaNo ratings yet

- Hufcor 633 Cont Hinged F4152DDocument6 pagesHufcor 633 Cont Hinged F4152Ddoody.dpujaNo ratings yet

- Hufcor Hufcorsummitbro2011 F4329a 45712Document4 pagesHufcor Hufcorsummitbro2011 F4329a 45712TereReneNo ratings yet

- Multotec Injection Moulded Screening Systems-Digital-4c504Document6 pagesMultotec Injection Moulded Screening Systems-Digital-4c504Nilton Inca TitoNo ratings yet

- Altssvoces ExteriorDocument3 pagesAltssvoces ExteriorCarlos Rafael Acosta MolinaNo ratings yet

- M Series DM Series Inclined Screens: Terex Minerals Processing Systems Simplicity M and DMDocument8 pagesM Series DM Series Inclined Screens: Terex Minerals Processing Systems Simplicity M and DMjahangir_alam44_6764No ratings yet

- Custom Noise Control EnclosuresDocument2 pagesCustom Noise Control EnclosuresVõ Ngọc Phát ĐặngNo ratings yet

- Usg Shaft Wall Systems Catalog en SA926Document40 pagesUsg Shaft Wall Systems Catalog en SA926Abdi Juryan LadiantoNo ratings yet

- LP Osb Sheathing SpecificationsDocument5 pagesLP Osb Sheathing SpecificationsMwaNo ratings yet

- Acousti-Seal 933E TDS PDFDocument20 pagesAcousti-Seal 933E TDS PDFsheenaho88No ratings yet

- CE Movable Wall Group OptimizedDocument11 pagesCE Movable Wall Group OptimizedDhafir MohammedNo ratings yet

- Sl45 BinderDocument23 pagesSl45 BindernicoleNo ratings yet

- Selection Guide For Flexible ConnectorsDocument7 pagesSelection Guide For Flexible ConnectorsAmal SaNo ratings yet

- Aluminator HFC Brochure Rev0_02-02-2018Document2 pagesAluminator HFC Brochure Rev0_02-02-2018DeonNo ratings yet

- Acoustic Movable Wall Systems GuideDocument12 pagesAcoustic Movable Wall Systems GuideVikasSainiNo ratings yet

- Airodek Brochure UKDocument16 pagesAirodek Brochure UKKovacs Zsolt-IstvanNo ratings yet

- ROCTEX Install SheetsDocument2 pagesROCTEX Install SheetsRadanu1No ratings yet

- Allen Bradley 800T-CatalogDocument96 pagesAllen Bradley 800T-CatalogChen LiuNo ratings yet

- Usf 1250Document3 pagesUsf 1250Ahad-Ur RahmanNo ratings yet

- Series Anff: Adjustable Neoprene Floating FloorDocument4 pagesSeries Anff: Adjustable Neoprene Floating FloorCarlos Torres OliverosNo ratings yet

- FaneBR18XS ReflexEnclosure111019Document10 pagesFaneBR18XS ReflexEnclosure111019Sanjaya Leelananda RajathewaNo ratings yet

- Unitile Raised Access FlooringDocument23 pagesUnitile Raised Access Flooringsaloni patilNo ratings yet

- CGC Shaft ConstructionDocument40 pagesCGC Shaft ConstructionMartin LarinNo ratings yet

- CGC Construction Handbook ch09 Acoustical Ceiling Design and Applicationcan enDocument26 pagesCGC Construction Handbook ch09 Acoustical Ceiling Design and Applicationcan enDoha AlazharyNo ratings yet

- GravityVentilators Catalog RemovedDocument8 pagesGravityVentilators Catalog RemovedLuz MVNo ratings yet

- Grid Ceiling Construction GuidanceDocument2 pagesGrid Ceiling Construction GuidancerahuljoagNo ratings yet

- Downloaded From Manuals Search EngineDocument7 pagesDownloaded From Manuals Search EngineHigor FelipeNo ratings yet

- Acousti-Seal® BrochureDocument16 pagesAcousti-Seal® BrochureMelvin RubioNo ratings yet

- 2-Way Trapezoidal 10" Reflex Enclosure: Cabinet Design ForDocument3 pages2-Way Trapezoidal 10" Reflex Enclosure: Cabinet Design ForferdinandNo ratings yet

- SureBuilt Concrete Form Accessories and Form BookDocument36 pagesSureBuilt Concrete Form Accessories and Form BookChris ChanonaNo ratings yet

- EQUITONE Installation Guide AU 15Document44 pagesEQUITONE Installation Guide AU 15anon_250483148No ratings yet

- Bergvik Isofloor US WebDocument12 pagesBergvik Isofloor US WebMuhammad Noshad RizviNo ratings yet

- TDS Conbextra GP1 India PDFDocument4 pagesTDS Conbextra GP1 India PDFvikash singh tomarNo ratings yet

- T10 Manual 1.1 enDocument12 pagesT10 Manual 1.1 enOscar MapelliNo ratings yet

- Technical Brochure Facade 84R en-EUDocument8 pagesTechnical Brochure Facade 84R en-EUszaaa0603No ratings yet

- Panel Rib™ Wall Panel: Varco Pruden BuildingsDocument3 pagesPanel Rib™ Wall Panel: Varco Pruden BuildingsRuxell CarganilloNo ratings yet

- Signature Series 8500 Paired Panels: Part 1 - GeneralDocument6 pagesSignature Series 8500 Paired Panels: Part 1 - GeneralZameer AhmedNo ratings yet

- Specification For FRP Weir and Scum BafflesDocument4 pagesSpecification For FRP Weir and Scum BafflesTS WongNo ratings yet

- Catalog PDFDocument92 pagesCatalog PDFSolomon Ndugwa BalemeziNo ratings yet

- Sonardyne ModularDocument2 pagesSonardyne ModularMuhamad AlfaniNo ratings yet

- Compact 2-Way Loudspeaker System With 1 - 8" LF Key FeaturesDocument2 pagesCompact 2-Way Loudspeaker System With 1 - 8" LF Key FeaturesKama Raj KrNo ratings yet

- Data Sheet For Al 800 AltairDocument4 pagesData Sheet For Al 800 Altairirfan vpNo ratings yet

- Hufcor Series 600Document4 pagesHufcor Series 600couteauNo ratings yet

- Luxaflex - Products - Softshades and Fabrics - Roller Blinds - EdgeDocument12 pagesLuxaflex - Products - Softshades and Fabrics - Roller Blinds - EdgeDindi Marie DecatoriaNo ratings yet

- Transfloor CatalogDocument56 pagesTransfloor Catalogbappy01_cuet9921No ratings yet

- Ceiling DetailDocument4 pagesCeiling DetailABDULNo ratings yet

- HT 5 Ring Cable ManagersDocument2 pagesHT 5 Ring Cable ManagersDavidNo ratings yet

- Gyprock Party Wall Manual Gyp513 2021 PDFDocument48 pagesGyprock Party Wall Manual Gyp513 2021 PDFMuz shirzaiNo ratings yet

- Inertia Base FrameDocument2 pagesInertia Base FrameLasandu WanniarachchiNo ratings yet

- Osb 4004Document8 pagesOsb 4004jeanphilipperousseau78No ratings yet

- Don't Design An Open Office With A Closed Floor.: Paradigm-B MumbaiDocument7 pagesDon't Design An Open Office With A Closed Floor.: Paradigm-B MumbaimanprateekNo ratings yet

- Nylofor: Panel SystemsDocument44 pagesNylofor: Panel Systemsfreespace1No ratings yet

- 200litre Cabinet For 1 X 18" Driver: Project - 200 Litre - 18" Reflex EnclosureDocument3 pages200litre Cabinet For 1 X 18" Driver: Project - 200 Litre - 18" Reflex EnclosurebetoNo ratings yet

- PD EN0001 EnclosureDesignDocument2 pagesPD EN0001 EnclosureDesignmaxbod1981.jkNo ratings yet

- MFS 01 UkDocument6 pagesMFS 01 UkhepcomotionNo ratings yet

- CGC Construction Handbook Ch9 Acoustical Ceiling Design and Application Can en PDFDocument26 pagesCGC Construction Handbook Ch9 Acoustical Ceiling Design and Application Can en PDFKeri Gobin SamarooNo ratings yet

- Kadant Blade Operating ManualDocument25 pagesKadant Blade Operating ManualbdfeduardoNo ratings yet

- August 2018 Economic Indicators ReportDocument7 pagesAugust 2018 Economic Indicators Reportdoody.dpujaNo ratings yet

- Home About Us Products Gallery Contact: Profil StandardDocument3 pagesHome About Us Products Gallery Contact: Profil Standarddoody.dpujaNo ratings yet

- Perkayuan Arus17 PDFDocument2 pagesPerkayuan Arus17 PDFdoody.dpujaNo ratings yet

- Home About Us Products Gallery Contact: Profil StandardDocument3 pagesHome About Us Products Gallery Contact: Profil Standarddoody.dpujaNo ratings yet

- Home About Us Products Gallery Contact: Profil StandardDocument3 pagesHome About Us Products Gallery Contact: Profil Standarddoody.dpujaNo ratings yet

- Perkayuan Arus17 PDFDocument2 pagesPerkayuan Arus17 PDFdoody.dpujaNo ratings yet

- Home About Us Products Gallery Contact: Profil StandardDocument2 pagesHome About Us Products Gallery Contact: Profil Standarddoody.dpujaNo ratings yet

- W AtapDocument1 pageW Atapdoody.dpujaNo ratings yet

- Ceiling & Partition-Jeeves Cipinang Jaya 39Document13 pagesCeiling & Partition-Jeeves Cipinang Jaya 39doody.dpujaNo ratings yet

- Waterproffing Dinding SampingDocument1 pageWaterproffing Dinding Sampingdoody.dpujaNo ratings yet

- Rencana Renovasi Block O-15 untuk Perbaikan Bocoran dan Saluran TersumbatDocument1 pageRencana Renovasi Block O-15 untuk Perbaikan Bocoran dan Saluran Tersumbatdoody.dpujaNo ratings yet

- R.meeting LT.2Document1 pageR.meeting LT.2doody.dpujaNo ratings yet

- Waterproffing Dinding Sopi2 LT - AtapDocument1 pageWaterproffing Dinding Sopi2 LT - Atapdoody.dpujaNo ratings yet

- Waterproffing Dinding BelakangDocument1 pageWaterproffing Dinding Belakangdoody.dpujaNo ratings yet

- Perhitungan Volume Swimming Pool Ibu Melyana Tjahyadikarta RESIDENCE Casamora Residence Block E 08 Jakarta SelatanDocument1 pagePerhitungan Volume Swimming Pool Ibu Melyana Tjahyadikarta RESIDENCE Casamora Residence Block E 08 Jakarta Selatandoody.dpujaNo ratings yet

- Denha LT AtapDocument1 pageDenha LT Atapdoody.dpujaNo ratings yet

- Bill of Quantity Ibu Melyana Tjahyadikarta RESIDENCE Mock Up Finishing Works Jakarta SelatanDocument1 pageBill of Quantity Ibu Melyana Tjahyadikarta RESIDENCE Mock Up Finishing Works Jakarta Selatandoody.dpujaNo ratings yet

- Dadr-Blok E-16-29-Juli-2016 PDFDocument38 pagesDadr-Blok E-16-29-Juli-2016 PDFdoody.dpujaNo ratings yet

- Beban Tapak F.2 C.2 (140 X 140)Document2 pagesBeban Tapak F.2 C.2 (140 X 140)doody.dpujaNo ratings yet

- Dadr Blok C 16 29 Juli 2016Document21 pagesDadr Blok C 16 29 Juli 2016doody.dpujaNo ratings yet

- Denha LT 3Document1 pageDenha LT 3doody.dpujaNo ratings yet

- YPKC - Salemba Raya ModelDocument1 pageYPKC - Salemba Raya Modeldoody.dpujaNo ratings yet

- Denha LT AtticDocument1 pageDenha LT Atticdoody.dpujaNo ratings yet

- Denha LT 2Document1 pageDenha LT 2doody.dpujaNo ratings yet

- YPKC - Salemba Raya Model (1) 1Document1 pageYPKC - Salemba Raya Model (1) 1doody.dpujaNo ratings yet

- Muhammad Tri Azmi - LinkedInDocument3 pagesMuhammad Tri Azmi - LinkedIndoody.dpujaNo ratings yet

- Series 631 Specifications: Individual, Omni-Directional PanelsDocument6 pagesSeries 631 Specifications: Individual, Omni-Directional Panelsdoody.dpujaNo ratings yet

- ASHIDA Product CatalogueDocument4 pagesASHIDA Product Cataloguerahulyadav2121545No ratings yet

- DepEd Memo Early Registration CommitteeDocument2 pagesDepEd Memo Early Registration CommitteeDERICK REBAYNo ratings yet

- Baremos Espanoles CBCL6-18 PDFDocument24 pagesBaremos Espanoles CBCL6-18 PDFArmando CasillasNo ratings yet

- Why Why Analysis Presentation-TPm-training-materialDocument43 pagesWhy Why Analysis Presentation-TPm-training-materialsaravanananusha67% (6)

- Catalogo 3wl lv10-1 2016 en PDFDocument116 pagesCatalogo 3wl lv10-1 2016 en PDF- witaratamaNo ratings yet

- Basic Principles of Counseling ProcessDocument2 pagesBasic Principles of Counseling ProcessBhavna SinghalNo ratings yet

- Semantics-Based Image Retrieval by Region SaliencyDocument9 pagesSemantics-Based Image Retrieval by Region SaliencyRazzougui SarahNo ratings yet

- Honda S2000 (00-03) Service ManualDocument0 pagesHonda S2000 (00-03) Service Manualmcustom1No ratings yet

- A Bendable and Wearable Cardiorespiratory Monitoring Device Fusing Two Noncontact Sensor PrinciplesDocument10 pagesA Bendable and Wearable Cardiorespiratory Monitoring Device Fusing Two Noncontact Sensor PrinciplesMd arshatNo ratings yet

- Presentation On Pre Bid MeetingDocument23 pagesPresentation On Pre Bid MeetinghiveNo ratings yet

- Principles of Failure AnalysisDocument2 pagesPrinciples of Failure AnalysisLuis Kike Licona DíazNo ratings yet

- Physics Sample ProblemsDocument5 pagesPhysics Sample ProblemsEdin Abolencia0% (1)

- Raft Slab DesignDocument5 pagesRaft Slab DesignLekins Sefiu Yekini100% (2)

- R6 Relay ValveDocument2 pagesR6 Relay ValveveereshNo ratings yet

- BGA ENG MATL TS 0006 Cathodic Protection Rev 02aDocument26 pagesBGA ENG MATL TS 0006 Cathodic Protection Rev 02aGururaj P KundapurNo ratings yet

- CircuitsDocument26 pagesCircuitsDarian ShiNo ratings yet

- C.6 Time-Domain EM MethodsDocument20 pagesC.6 Time-Domain EM MethodsRickyRiccardoNo ratings yet

- Precision Waveform Generator/Voltage Controlled Oscillator FeaturesDocument12 pagesPrecision Waveform Generator/Voltage Controlled Oscillator FeaturesCharles Tineo0% (1)

- OpenSees Geotechnical Analysis Workshop 2017Document70 pagesOpenSees Geotechnical Analysis Workshop 2017Tariq MahmoodNo ratings yet

- Jared Diamond. Guns Germs and Steel 1999 PDFDocument3 pagesJared Diamond. Guns Germs and Steel 1999 PDFSabah MushtaqNo ratings yet

- EnergyDocument24 pagesEnergywaelNo ratings yet

- ServiceLink Release 4.94 Upgrade InstructionsDocument4 pagesServiceLink Release 4.94 Upgrade InstructionsOsvaldo Mamani TiconaNo ratings yet

- Analytics For Sustainable BusinessDocument6 pagesAnalytics For Sustainable BusinessDeloitte AnalyticsNo ratings yet

- Recruitment of Junior Associates (Customer Support & Sales)Document5 pagesRecruitment of Junior Associates (Customer Support & Sales)Revanth TallaNo ratings yet

- Ramon Magsaysay Memorial College-Marbel INC Bachelor of Science in Tourism ManagementDocument7 pagesRamon Magsaysay Memorial College-Marbel INC Bachelor of Science in Tourism ManagementRam G. MorteraNo ratings yet

- Minimum drilling supplies stockDocument3 pagesMinimum drilling supplies stockAsif KhanzadaNo ratings yet

- TH3122 004 PDFDocument14 pagesTH3122 004 PDFSasa MitrovicNo ratings yet

- Dilg Joincircular 2018814 - 80736aa36cDocument10 pagesDilg Joincircular 2018814 - 80736aa36clexay.mangadosiervoNo ratings yet

- A Homemade Edison Tinfoil PhonographDocument32 pagesA Homemade Edison Tinfoil PhonographGabriel MedinaNo ratings yet

- Tiempos de entrega y actividades de aprendizajeDocument2 pagesTiempos de entrega y actividades de aprendizajejuanNo ratings yet