Professional Documents

Culture Documents

Ferritic Stainless Steel Core 441/4509 Guide

Uploaded by

Enrique Ruiz HonoratoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ferritic Stainless Steel Core 441/4509 Guide

Uploaded by

Enrique Ruiz HonoratoCopyright:

Available Formats

Core 441/4509

EN 1.4509, ASTM UNS S43940

General characteristics Typical applications

Core 441/4509 is a nickel-free 17% chromium ferritic stainless • Indoor cladding

steel originally designed for exhaust systems, with good • Restaurant equipment and appliances

corrosion resistance and high-temperature strength. Core • Tubes

441/4509 is available with a single (niobium) or dual (niobium • Heat exchangers

and titanium) stabilizer. Due to good formability and weldability,

it is often a suitable replacement for Core 301/4310.

Core 441/4509 can be supplied with a wide range of functional

and aesthetic surface finishes.

Products & dimensions

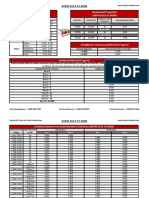

Cold rolled products, available dimensions (mm)

Coil / Strip Plate / Sheet

Surface finish Thickness Width Thickness Width

2B Cold rolled, heat treated, pickled, skin passed 0.30-3.58 12-1550 0.30-3.58 18-1550

2BB Bright-pickled 0.30-3.50 30-1500 0.30-3.50 350-1530

2C Cold rolled, heat treated 0.80-3.50 30-1500

2D Cold rolled, heat treated, pickled 0.40-3.50 30-1530 0.40-3.50 350-1530

2E Cold rolled, heat treated, mech. desc. pickled 0.33-3.58 12-1530 0.33-3.58 18-1530

2F Cold rolled, heat treated, skin passed 0.33-3.58 12-1524 0.33-3.58 18-1524

2G Ground 0.30-3.58 12-1550 0.30-3.58 18-1550

2H Work hardened 0.80-3.50 30-1530

2J Brushed or dull polished 0.30-3.00 30-1530 0.30-3.00 350-1530

2K Satin finish 0.53-3.58 12-1524 0.53-3.58 18-1524

2M Patterned 0.30-3.50 30-1500 0.30-3.50 350-1500

2R Cold rolled, bright annealed 0.05-1.50 3-1500 0.40-1.50 350-1500

1 - Outokumpu 4509 Printed: 2 Jul 2018, supersedes all previous editions.

Continous hot rolled products, available dimensions (mm)

Coil / Strip Plate / Sheet

Surface finish Thickness Width Thickness Width

1C Hot rolled, heat treated, not descaled 2.00-8.00 50-1550

1D Hot rolled, heat treated, pickled 3.00-6.36 50-1550 3.00-6.36 350-1524

1E Hot rolled, heat treated, mech. desc. 5.00-5.00 50-1550

1G Ground 2.00-3.00 750-1455 2.00-3.00 750-1455

1M Patterned 2.00-3.00 750-1455 2.00-3.00 750-1455

1U Black hot rolled 2.00-8.00 50-1550

Chemical composition

The chemical composition may vary slightly between different product standards. The required standard will be fully met as specified in

the order.

The typical chemical composition for this grade is given in the table below, together with composition limits given for the product

according to different standards. The required standard will be fully met as specified on the order.

The chemical composition is given as % by mass.

C Mn Cr Ni Mo N Other

Typical 0.02 17.6 Ti Nb

ASME II A SA-240 0.030

≤0.030 1.00

≤1.00 17.0-19.0 0.50

≤0.50 0.030

≤0.030

ASME II A SA-240 0.030

≤0.030 1.00

≤1.00 17.5-18.5 Ti

ASTM A240 0.030

≤0.030 1.00

≤1.00 17.0-19.0 0.50

≤0.50 0.030

≤0.030

ASTM A240 0.030

≤0.030 1.00

≤1.00 17.5-18.5 Ti

EN 10028-7 0.030

≤0.030 1.00

≤1.00 17.50-18.50 Ti

EN 10088-2 0.030

≤0.030 1.0

≤1.0 17.5-18.5 Ti

EN 10088-4 0.030

≤0.030 1.0

≤1.0 17.5-18.5 Ti

Corrosion resistance

Outokumpu Core 441/4509 has good corrosion resistance in solutions of many halogen-free organic and inorganic compounds over a

wide temperature and concentration range. It can withstand many sufficiently diluted organic and mineral acids depending on the

temperature and concentration of the solution. Core 441/4509 may suffer from uniform corrosion in strong organic and mineral acids, as

well as in hot concentrated alkaline solutions. More detailed information on corrosion properties of Core 441/4509 can be found in

Outokumpu’s Corrosion Tables published in the Outokumpu Corrosion Handbook and on Stainless Steel Finder Finder..

In aqueous solutions containing halogenides, e.g. chlorides or bromides, pitting and crevice corrosion may occur depending on the

halogenide concentration, temperature, pH-value, concentration of oxidizing compounds, or crevice geometry, if applicable. For short

periods of time, for instance when cooking food in stainless steel dishes, Core 441/4509 can even tolerate relatively high chloride

concentrations. The presence of corrosion inhibiting or accelerating compounds like e.g. transition metal ions or organic compounds may

influence the corrosion behavior of Core 441/4509. Due to its ferritic crystal structure, Core 441/4509 is not prone to chloride-induced

stress corrosion cracking.

Core 441/4509 can be used for indoor applications in rural areas and urban environments where chloride contamination is low. The best

material performance is typically achieved with the help of adequate design, correct post-weld treatment, and regular cleaning during use

(if applicable).

2 - Outokumpu 4509 Printed: 2 Jul 2018, supersedes all previous editions.

Due to its titanium and niobium content, the risk of sensitization for intergranular corrosion is strongly reduced when compared to non-

stabilized ferritic grades. Core 441/4509 can be used in the temperature range in which chromium carbides would precipitate in non-

stabilized ferritic grades. Its maximum service temperature in dry air is 950 °C. The presence of other corrosive compounds in the hot

environment like water or sulfur compounds may reduce the maximum service temperature significantly.

Pitting corrosion resistance Crevice corrosion resistance

PRE CPT CCT

18 <10 <0

Pitting Resistance Equivalent (PRE) is calculated using the following formula: PRE = %Cr + 3.3 x %Mo + 16 x %N

Corrosion Pitting Temperature (CPT) as measured in the Avesta Cell (ASTM G 150), in a 1M NaCl solution (35,000 ppm or mg/l chloride

ions).

Critical Crevice Corrosion Temperature (CCT) is obtained by laboratory tests according to ASTM G 48 Method F

For more information on corrosion resistance, please refer to the Outokumpu Corrosion Handbook or contact our corrosion experts.

Mechanical properties

The mechanical properties of the available products are given in the table below.

Rp0.2 Rp1.0 Rm Elongation1) Impact

Cold rolled coil and sheet MPa MPa MPa % strength J Rockwell HB HV

Typical (thickness 1 mm) 310 330 480 55

ASTM A240 ≥ 205 ≥ 415 ≤ 89HRB ≤ 183

ASTM A240 ≥ 250 ≥ 430 ≤ 88HRB ≤ 180

EN 10088-2 ≥ 230 430 - 630 ≥ 18

EN 10088-4 ≥ 230 430 - 630 ≥ 18

Rp0.2 Rp1.0 Rm Elongation1) Impact

Hot rolled coil and sheet MPa MPa MPa % strength J Rockwell HB HV

Typical (thickness 4 mm) 365 395 500 31 78

1)

Elongation according to EN standard:

A80 for thickness below 3 mm.

A for thickness = 3 mm.

Elongation according to ASTM standard A2” or A50.

Physical properties

Data according to EN 10088

Modulus of Thermal exp. at Thermal Thermal Electrical

Density elasticity 100 °C conductivity capacity resistance Magnetizable

3 -6

kg/dm GPa 10 /°C W/m°C J/kg°C µΩm

7.7 220 10,0 25 460 0.60 Yes

3 - Outokumpu 4509 Printed: 2 Jul 2018, supersedes all previous editions.

Fabrication

Core 441/4509 can be formed using typical forming processes like folding, bending, drawing, etc. It has slightly higher proof strength

than standard austenitic stainless steel grade 1.4301 / AISI 304 in combination with lower work hardening. Due to the titanium

stabilization, its R-value is higher compared to non-stabilized ferritic stainless steel. These characteristics mean excellent deep-

drawability.

Welding

Conventional welding methods and filler materials applied to austenitic 300-series can be used. Heat input in welding should be kept to a

minimum level. Welded structures generally show lower ductility compared to that of base material.

More detailed information concerning welding procedures can be obtained from the Outokumpu Welding Handbook, available from our

sales offices.

Standards & approvals

The most commonly used international product standards are given in the table below.

Standard Designation

ASME SA-240M Code Sect. II. Part A UNS S43940; UNS S43940

ASTM A240/A240M UNS S43940; UNS S43940

EN 10028-7, PED 2014/68/EU 1.4509

EN 10088-2 1.4509

EN 10088-4 1.4509

Contacts & Enquiries

Contact your nearest sales office

www.outokumpu.com/contacts

4 - Outokumpu 4509 Printed: 2 Jul 2018, supersedes all previous editions.

Working towards forever.

We work with our customers and

partners to create long lasting solutions

for the tools of modern life and the

world’s most critical problems: Clean

energy, clean water and efficient

infrastructure. Because we believe in a

world that lasts forever.

Information given in this brochure may be subject to alterations without notice. Care has been taken to ensure that the contents of this

publication are accurate but Outokumpu and its affiliated companies do not accept responsibility for errors or for information which is

found to be misleading. Suggestions for or descriptions of the end use or application of products or methods of working are for information

only and Outokumpu and its affiliated companies accept no liability in respect thereof. Before using products supplied or manufactured by

the company the customer should satisfy himself of their suitability

outokumpu.com

steelfinder.outokumpu.com

5 - Outokumpu 4509 Printed: 2 Jul 2018, supersedes all previous editions.

You might also like

- Core 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Document8 pagesCore 321/4541: EN 1.4541, ASTM TYPE 321 / UNS S32100Nguyen03No ratings yet

- Equivalent TableDocument1 pageEquivalent Tableliamcs88% (8)

- Material delivery specificationsDocument2 pagesMaterial delivery specificationsviyfNo ratings yet

- Pipe Roughness and C-Factors TableDocument48 pagesPipe Roughness and C-Factors Tablesaroat moongwattanaNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- Plates Steel MetalDocument12 pagesPlates Steel MetalAnonymous aWpx7nENo ratings yet

- Milling Speeds and FeedsDocument1 pageMilling Speeds and FeedsirinaNo ratings yet

- Seamless Carbon and Alloy Steel Mechanical Tubing: Standard Specification ForDocument13 pagesSeamless Carbon and Alloy Steel Mechanical Tubing: Standard Specification ForTamil funNo ratings yet

- HSS & Cobalt Drill Speed - FeedDocument1 pageHSS & Cobalt Drill Speed - FeedPuneeth KumarNo ratings yet

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- Hot-rolled carbon steel data sheetDocument7 pagesHot-rolled carbon steel data sheetwulfgang66No ratings yet

- Pakistan Ssteel Mills Mild Steel Grades SpecificationDocument3 pagesPakistan Ssteel Mills Mild Steel Grades SpecificationWaqas WaqasNo ratings yet

- DIN EN 10268 Steel Pipe and Fittings SpecificationsDocument4 pagesDIN EN 10268 Steel Pipe and Fittings SpecificationsAlex LacerdaNo ratings yet

- (Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingDocument2 pages(Note: All Speeds Are in Feet/min) - Multiply The Listed Speeds by A Factor of 2 To 4 When Using Carbide ToolingSanjay KumarNo ratings yet

- Astm-A519 - 06Document13 pagesAstm-A519 - 06claudiaNo ratings yet

- Vulcan Industrial Engineering Co. Pvt. LTDDocument3 pagesVulcan Industrial Engineering Co. Pvt. LTDk koradiaNo ratings yet

- Square Rectangular Hollow SectionDocument76 pagesSquare Rectangular Hollow Sectionbusiness.developmentNo ratings yet

- Vulcan steel alloy specificationsDocument4 pagesVulcan steel alloy specificationsk koradiaNo ratings yet

- Ben Brand PDFDocument80 pagesBen Brand PDFrojasautoparts24100% (1)

- Din 17175 PDFDocument22 pagesDin 17175 PDFMilica Antic0% (1)

- Product Datasheet: 6.3 MM (.250) UP-TP TerminalsDocument2 pagesProduct Datasheet: 6.3 MM (.250) UP-TP TerminalsAmine MaaouiNo ratings yet

- Annex A: (Normative)Document6 pagesAnnex A: (Normative)calvente27No ratings yet

- BS 3059-2Document11 pagesBS 3059-2abhiNo ratings yet

- Extracto Norma ASTM A792Document2 pagesExtracto Norma ASTM A792Christian Latorre VielmaNo ratings yet

- Corus Tinplate Packaging Products Range 2006Document8 pagesCorus Tinplate Packaging Products Range 2006gtorre77No ratings yet

- DIN 17174 SEAMLESS STEEL TUBES FOR LOW TEMP USEDocument7 pagesDIN 17174 SEAMLESS STEEL TUBES FOR LOW TEMP USEdjmattmNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument2 pagesEquivalents of Carbon Steel QualitiesmichaelNo ratings yet

- Plate A36 (2016)Document4 pagesPlate A36 (2016)eko kusumoNo ratings yet

- Is 2062 Steel Plates_ is 2062 Grade B Steel Plate is 2062 E250 Steel Plate_ is 2062 E350 Steel Plate_ is 2062 E350 Steel Plate_ A36 Steel Plate_ Carbon Steel Plate_ Mild Steel Plate_ Prosaic Steel and AlloysDocument12 pagesIs 2062 Steel Plates_ is 2062 Grade B Steel Plate is 2062 E250 Steel Plate_ is 2062 E350 Steel Plate_ is 2062 E350 Steel Plate_ A36 Steel Plate_ Carbon Steel Plate_ Mild Steel Plate_ Prosaic Steel and AlloysAmit GauravNo ratings yet

- Forta 316L/4404 Stainless Steel PropertiesDocument7 pagesForta 316L/4404 Stainless Steel Propertiespcman147No ratings yet

- Mould SteelsDocument32 pagesMould SteelsAnonymous B3I6zYNhqdNo ratings yet

- ASTM A513-T5 DOM Mechanical Properties and SpecificationsDocument3 pagesASTM A513-T5 DOM Mechanical Properties and SpecificationsOscar JuárezNo ratings yet

- Valve Material SpecificationDocument5 pagesValve Material Specificationapi-9572051No ratings yet

- ASTM A830 Steel Grades: General Product DescriptionDocument2 pagesASTM A830 Steel Grades: General Product DescriptionsachedalNo ratings yet

- Stainless Steel Properties PDFDocument8 pagesStainless Steel Properties PDFprajash007No ratings yet

- Rules For Materials and Welding 2021 AmendmentsDocument29 pagesRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- Stainless Steel GradesDocument8 pagesStainless Steel Gradesnathan1979No ratings yet

- New 4340 Alloy SteelDocument3 pagesNew 4340 Alloy Steeljimmy julian pava vargasNo ratings yet

- Thành phần hóa học thép - Steel bars for concrete reinforcementDocument3 pagesThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũNo ratings yet

- Stainless Steel - Grade 304: Chemical Formula Topics CoveredDocument4 pagesStainless Steel - Grade 304: Chemical Formula Topics CoveredvibishnanNo ratings yet

- Structural Steel Plate and Strip To EN 10025Document4 pagesStructural Steel Plate and Strip To EN 10025Ibrahim BashaNo ratings yet

- A 213 Â " A 213M Â " 03 - QTIXMY9BMJEZTS1SRUQDocument14 pagesA 213 Â " A 213M Â " 03 - QTIXMY9BMJEZTS1SRUQhNo ratings yet

- Sa 240Document9 pagesSa 240ismaelarchilacastilloNo ratings yet

- Asme 0387.1Document9 pagesAsme 0387.1Servando LozanoNo ratings yet

- Steel SpecificationsDocument3 pagesSteel SpecificationsMazlan MansorNo ratings yet

- QuadriDocument76 pagesQuadrisvenNo ratings yet

- AISI 304 Vs 304L Stainless Steel Properties (UNS S30403) Difference Between 304 and 304L (SS304L)Document6 pagesAISI 304 Vs 304L Stainless Steel Properties (UNS S30403) Difference Between 304 and 304L (SS304L)masoodkamalNo ratings yet

- SA/AS 1548 - PT460NR (L0, L20) XLERPLATE Steel: Plate - PL Pressure Vessel - PVDocument3 pagesSA/AS 1548 - PT460NR (L0, L20) XLERPLATE Steel: Plate - PL Pressure Vessel - PVJang CoiNo ratings yet

- Din en 12329 PDFDocument16 pagesDin en 12329 PDFAdrian Sasek100% (2)

- DS INOX UR2202v4 PDFDocument6 pagesDS INOX UR2202v4 PDFEnrique Ruiz HonoratoNo ratings yet

- Din en 12329 PDFDocument16 pagesDin en 12329 PDFAdrian Sasek100% (2)

- Guia Extendida Fisica Parte 1 de 2Document5 pagesGuia Extendida Fisica Parte 1 de 2Enrique Ruiz HonoratoNo ratings yet

- Al Alloy Tec DataDocument5 pagesAl Alloy Tec DataDhanus KodiNo ratings yet

- Astm A27 2010 PDFDocument4 pagesAstm A27 2010 PDFEnrique Ruiz HonoratoNo ratings yet

- Guide To Stainless Steel Finishes PDFDocument24 pagesGuide To Stainless Steel Finishes PDFAnup George ThomasNo ratings yet

- DS INOX UR2202v4 PDFDocument6 pagesDS INOX UR2202v4 PDFEnrique Ruiz HonoratoNo ratings yet

- ASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFDocument7 pagesASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFCarlos Sanchez MarinNo ratings yet

- ASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFDocument7 pagesASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFCarlos Sanchez MarinNo ratings yet

- FR Elem SB PDFDocument13 pagesFR Elem SB PDFEnrique Ruiz HonoratoNo ratings yet

- The Metric System: ConversionsDocument4 pagesThe Metric System: ConversionsEnrique Ruiz HonoratoNo ratings yet

- GD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free ResourceDocument7 pagesGD&T Symbols - GD&T Terms - Geometric Dimensioning and Tolerancing Glossary - GD&T Free ResourceEnrique Ruiz HonoratoNo ratings yet

- Stainless Steel Cold Rolled en StandardsDocument4 pagesStainless Steel Cold Rolled en StandardsMichael DavidNo ratings yet

- Colakoglu Metalurji BrosurDocument5 pagesColakoglu Metalurji BrosurEnrique Ruiz HonoratoNo ratings yet

- Características perfiles estructurales circularesDocument4 pagesCaracterísticas perfiles estructurales circularesCarlos Julio Ramirez BelloNo ratings yet

- Functional Properties of StarchesDocument14 pagesFunctional Properties of StarchesHappie DilaoNo ratings yet

- Tech Tips 4 - How To Repair A Galvanized Coating PDFDocument2 pagesTech Tips 4 - How To Repair A Galvanized Coating PDFRa'oufAli-zadehNo ratings yet

- CHEMISTRY 12th Sample Paper 2023-24Document15 pagesCHEMISTRY 12th Sample Paper 2023-24Hitesh ChoudharyNo ratings yet

- Science & Technology NIOSDocument112 pagesScience & Technology NIOSbalajiieceNo ratings yet

- Astm A185 A185m-07Document6 pagesAstm A185 A185m-07HelisNo ratings yet

- 0271.SAS-BR-Inorganics Siral Siralox WEBDocument16 pages0271.SAS-BR-Inorganics Siral Siralox WEBMrutunjay PatraNo ratings yet

- 1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)Document1 page1663-43691010-Me-Dwg-7380-00-Cu-Cl2-Bdu-Fru-Assy-1 (R1)raacontreras21No ratings yet

- Sunil Sharma AhpDocument2 pagesSunil Sharma AhpPrudhvi RajNo ratings yet

- Pyrrole MSDS Safety GuideDocument5 pagesPyrrole MSDS Safety GuideAmalina HazwaniNo ratings yet

- Api 510 Exam: Api576 Questions - 01Document3 pagesApi 510 Exam: Api576 Questions - 01korichiNo ratings yet

- KSG 30-50 Vertical - User and Service ManualDocument26 pagesKSG 30-50 Vertical - User and Service Manualluis100% (1)

- Bbet+tre-2018-C-Xi (Paper-2) PCMDocument22 pagesBbet+tre-2018-C-Xi (Paper-2) PCMPankaj DhankerNo ratings yet

- Technical Data Sheet Loctite 5438 UnderDocument2 pagesTechnical Data Sheet Loctite 5438 UnderajoilhamNo ratings yet

- Glassfibre Reinforced Concrete Principles, Production, Properties and Applications by Professor Peter J. M. BartosDocument209 pagesGlassfibre Reinforced Concrete Principles, Production, Properties and Applications by Professor Peter J. M. Bartoscelso100% (1)

- Alkaloids 1Document4 pagesAlkaloids 1Mr nobodyNo ratings yet

- 3 301 PDFDocument32 pages3 301 PDFJusto Paniagua ChampaNo ratings yet

- Modeling Species Transport and Gaseous CombustionDocument48 pagesModeling Species Transport and Gaseous Combustionali_naghedifarNo ratings yet

- IodometriyDocument3 pagesIodometriySarvesh GaonkarNo ratings yet

- BykDocument5 pagesByksamratsamudraguptaNo ratings yet

- Iccesd 2020 PDFDocument12 pagesIccesd 2020 PDFzeekoNo ratings yet

- Cmos Process FlowDocument29 pagesCmos Process FlowPushparaj Karu100% (1)

- Kevlar Composite JurnalDocument10 pagesKevlar Composite JurnalJakbrother 28No ratings yet

- A About Desalters Detailed StudyDocument3 pagesA About Desalters Detailed Studymuzaffar_malik138580% (5)

- FDU BrochureDocument5 pagesFDU BrochureBožidar Gaćinović100% (1)

- Properties of Cellulosic Fabrics Treated by Water-Repellent EmulsionsDocument7 pagesProperties of Cellulosic Fabrics Treated by Water-Repellent EmulsionsQuyen Tran Thi AnhNo ratings yet

- 1 2714Document1 page1 2714K Mohana PraneshNo ratings yet

- Overhaul kit contents for Cummins AFC fuel pumpsDocument2 pagesOverhaul kit contents for Cummins AFC fuel pumpsJoffre Lautaro Benavides SeminarioNo ratings yet

- N5 Biology 2014Document41 pagesN5 Biology 2014FarooqAhmadLashariNo ratings yet

- BytuvyamDocument3 pagesBytuvyamapi-355478865No ratings yet

- Biological IndicatorsDocument24 pagesBiological IndicatorsLinh Nguyen100% (2)