Professional Documents

Culture Documents

Aci 207 Restraint Effect

Uploaded by

Chhour CEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aci 207 Restraint Effect

Uploaded by

Chhour CECopyright:

Available Formats

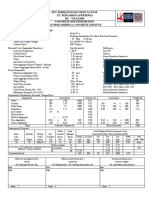

Made Sheet No.

Date

ARG 1 22-Oct-12

Check Rev. Date

SR 23-Oct-12

PROJECT TITLE: DAMAC TWIN TOWERS

LOCATION: RIYADH-SAUDI ARABIA

STRENGTH OF CONCRETE " F'c " 35 MPa Maximum crack width at surface " w " 0.40 mm

Modulus of Elasticity of steel " Es "

200000 MPa Spacing between bars " b " 200 mm

THICKNESS OF RAFT 2700 mm Diameter of bar 25 mm

30 o

C Concrete cover " Cc " 50 mm

PLACEMENT TEMPERATURE

86 o

F Degree of restraint " Kr " 0.42

Type of aggregate in concrete Calcareous

20 o

C LINEAR THERMAL COEFFICIENT "CT" 5.00E-06 in/in/oF

Lowest service temp.

52 o

F FT/E 0.00015 long term

RAFT FOUNDATION REINFORCEMENT DUE TO SUBGRADE RESTRAINT PER ACI 207.2R

Te mpe rature Ri s e (oF)

AVAREAGE DEPTH " dc " 75 mm 2.95 in

Effictive depth " d " 2625 mm 60

Ft 3.67 MPa 532 psi

Temperture rise when cement content 50

48.1 o

F

is 200 kg/m3 from graph 2.5

Volume to exposed surface ratio " V/S 2025 mm 6.33 ft

40

Actual rise when cement content is

96.15402 o

F

400 kg/m3

30

Peak temperture & concrete 182 o

F

Δ (Temperutre) Long term 130

o

F 55 o

C

20

Crack spacing " L' " (Eq. 6.4)

7.09 ft 2165 mm

10

Restraint moment requiredn of

reinforcing steel for full-height

cracking " MRH " (Eq 4.4) 473 k-ft 0

640.72 kN.m/bar 0 1 2 3 4 5 6 7 8 9 10

Vol ume to Surfa ce Ratio (ft)

percentage of steel " ρ " 0.000935

n = Es/Ec 7.2

ρn 0.006725

K = [(pn)2+2(pn)]1/2- pn 0.11

Ratio of distance between centroid of

fcompresion

J = 1-K/3 0.96

Distance from neutral axis to the

tensile face

b=[dc+d(1-k)] / [d(1-K)] 1.03

Average effective concrete around a 46 in2

reinforcing bar "A"

Steel stress " fs " 39 ksi 273 MPa

Area of steel required per/bar

As = [MRH/fs.J.d] 929 mm2 / bar

###

You might also like

- Construction JointDocument3 pagesConstruction JointUttam Kumar GhoshNo ratings yet

- Design of Ground Anchors SandDocument2 pagesDesign of Ground Anchors SandMUHAMMAD ALINo ratings yet

- Bi Axial GeogridDocument1 pageBi Axial Geogridsundra0No ratings yet

- Crack Width CalculationsDocument1 pageCrack Width CalculationsdfdgggNo ratings yet

- Calculations by Yg Plot 55 & 56 01.02.23Document63 pagesCalculations by Yg Plot 55 & 56 01.02.23Shanil BussooaNo ratings yet

- Anchorage To ConcreteDocument10 pagesAnchorage To ConcretemakakkNo ratings yet

- Manual on Seismic Evaluation and Retrofit of RC BuildingsDocument294 pagesManual on Seismic Evaluation and Retrofit of RC Buildingsmayas100% (1)

- SPT Correlation n60 and n'60 To Odst As Per AashtoDocument4 pagesSPT Correlation n60 and n'60 To Odst As Per AashtoAstrid AubryNo ratings yet

- Concrete Box Culvert Design Based On AASHTO 17th & ACI 318-14Document6 pagesConcrete Box Culvert Design Based On AASHTO 17th & ACI 318-14Iman RahmatullahNo ratings yet

- RCC54 Circular Column ChartingDocument25 pagesRCC54 Circular Column ChartingCioabla BogdanNo ratings yet

- Appendix - Ii: Principles of Construction, Material and Design of Ferrocement TankDocument5 pagesAppendix - Ii: Principles of Construction, Material and Design of Ferrocement TankbenzzenhdNo ratings yet

- Bracing PipeDocument81 pagesBracing PipeSajid IqbalNo ratings yet

- Heat of Hydration StressesDocument7 pagesHeat of Hydration StressesAnkur BarsainyaNo ratings yet

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Document9 pagesCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDNo ratings yet

- Spring Stiffnes CalculationDocument13 pagesSpring Stiffnes Calculationyadav04_abhishekNo ratings yet

- Seismic Design For Special Moment Resisting Frame Based On ACI 318-19 Input Data & Design SummaryDocument6 pagesSeismic Design For Special Moment Resisting Frame Based On ACI 318-19 Input Data & Design SummaryBryan Perez0% (1)

- Gabion DesignDocument6 pagesGabion DesignyasirjurabaNo ratings yet

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PonceNo ratings yet

- Precast Roof Slab PDFDocument3 pagesPrecast Roof Slab PDFChuksbozmentNo ratings yet

- Full Thesis PDFDocument112 pagesFull Thesis PDFAlaaBadwy100% (1)

- Design of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayDocument57 pagesDesign of Concrete Structures: Amit Das Department of Civil Engineering I.I.T BombayKC Paguinto100% (1)

- Stone Column CapacityDocument10 pagesStone Column CapacityMonal Raj100% (1)

- Pile Group AnalysisDocument4 pagesPile Group AnalysisrahimNo ratings yet

- Water-Tank-Joint Pattern-Surface LoadDocument10 pagesWater-Tank-Joint Pattern-Surface LoadYakni IdrisNo ratings yet

- Lecture23 Retaining WallsDocument76 pagesLecture23 Retaining WallsMayMSTNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- Booth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)Document219 pagesBooth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)CRISTIAN OMAR TUCTO ARANDANo ratings yet

- Hilti Webinar - Anchor Design Influencing Factors PDFDocument57 pagesHilti Webinar - Anchor Design Influencing Factors PDFDoug WeirNo ratings yet

- Pile Reinforcement - DPL Ver 0.6Document8 pagesPile Reinforcement - DPL Ver 0.6Antony GodwinNo ratings yet

- Bored CIP Piles - Capacity Calculation - International Practice - Updated-1Document13 pagesBored CIP Piles - Capacity Calculation - International Practice - Updated-1dineshNo ratings yet

- Dowel Calculation For Ramp DDocument2 pagesDowel Calculation For Ramp DaselabambarandageNo ratings yet

- Design of Coping Beam (Portal) : A. Basic DataDocument7 pagesDesign of Coping Beam (Portal) : A. Basic DataUzziel Abib GabiolaNo ratings yet

- IksaPro en v1.0 Demo 3anchorsDocument20 pagesIksaPro en v1.0 Demo 3anchorsEduardo MarquesNo ratings yet

- Anchors Design 1 (3 Rows) ADocument34 pagesAnchors Design 1 (3 Rows) Aedc1312No ratings yet

- Design of Retaining WallDocument13 pagesDesign of Retaining WallVedesh SinghNo ratings yet

- SlopeBishopVBA v1.0.2Document3 pagesSlopeBishopVBA v1.0.2SRINIVAS D100% (1)

- Karol Ghati Pile Calc 2Document2 pagesKarol Ghati Pile Calc 2Muhammad BilalNo ratings yet

- Chapter 2 Design For Serviceability PDFDocument14 pagesChapter 2 Design For Serviceability PDFChee Fong MakeNo ratings yet

- Strip Footing (Exterior)Document4 pagesStrip Footing (Exterior)Kelvin MutetiNo ratings yet

- Analysis of Steel ShutterDocument30 pagesAnalysis of Steel Shuttersalahuddin sakuNo ratings yet

- 09 Strut DesignDocument1 page09 Strut DesignThaungMyintNo ratings yet

- Design of Substructure 4 PileDocument328 pagesDesign of Substructure 4 PileisurupushNo ratings yet

- Liquefaction Analysis: U C 7.5 1 60 1 60cs 7.5 DDocument1 pageLiquefaction Analysis: U C 7.5 1 60 1 60cs 7.5 DMehedi HasanNo ratings yet

- Anchor Design ManualDocument392 pagesAnchor Design ManualveselinNo ratings yet

- Design of Structures: Design of Retaining Wall With Surcharge Load Inclined at Some AngleDocument10 pagesDesign of Structures: Design of Retaining Wall With Surcharge Load Inclined at Some AngleLUKMANNo ratings yet

- Epc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteDocument4 pagesEpc Pembangunan Open Access Pt. Pertamina (Persero) Ru - Vii Kasim Concrete Mix Proportion Method America Concrete InsituteBengkulu BetonNo ratings yet

- Evaluation of Strength Test Results of Concrete (ACI 214R-02)Document44 pagesEvaluation of Strength Test Results of Concrete (ACI 214R-02)abdallah abdurhman aliNo ratings yet

- Typical Section For Gabion WallDocument2 pagesTypical Section For Gabion WallBiju Chandra MenonNo ratings yet

- Cam ClayDocument44 pagesCam ClayWan100% (1)

- Caculation ReportDocument9 pagesCaculation ReportEngineeri TadiyosNo ratings yet

- Shear Design SpreadsheetDocument15 pagesShear Design SpreadsheetCivilax.com0% (1)

- Corbel Analysis Design 1.0Document19 pagesCorbel Analysis Design 1.0Eduardo Marques0% (1)

- Jubail Island Development crack width calculationsDocument16 pagesJubail Island Development crack width calculationstaha abu el hanaNo ratings yet

- QT200 Bored Piles Sls Crack Width - Pile: Section SpecificationDocument1 pageQT200 Bored Piles Sls Crack Width - Pile: Section SpecificationMohamedAbdelnasserNo ratings yet

- Concrete Industrial Ground Floor Slab Desig1Document3 pagesConcrete Industrial Ground Floor Slab Desig1Mahata PriyabrataNo ratings yet

- RC Corbel Design EC2Document3 pagesRC Corbel Design EC2Tommaso PasconNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- CADANGAN MEMBINA DAN MENYIAPKAN SEBUAH STESEN MINYAK PETRONAS DI ATAS LOT 4Document1 pageCADANGAN MEMBINA DAN MENYIAPKAN SEBUAH STESEN MINYAK PETRONAS DI ATAS LOT 4NILRATAN SARKARNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- Section "RS": MM MM MM MM Mpa MM KN M KN M MDocument1 pageSection "RS": MM MM MM MM Mpa MM KN M KN M MChhour CENo ratings yet

- Column ReportDocument20 pagesColumn ReportChhour CENo ratings yet

- HHHDocument1 pageHHHChhour CENo ratings yet

- Footing: Total 3.125 0.1156 0.01998Document2 pagesFooting: Total 3.125 0.1156 0.01998Chhour CENo ratings yet

- RC Shear Wall 1.2Document16 pagesRC Shear Wall 1.2mailmaverick8167No ratings yet

- Column ReportDocument20 pagesColumn ReportChhour CENo ratings yet

- Hello AllsDocument1 pageHello AllsChhour CENo ratings yet

- Design and Construction DocumentsDocument24 pagesDesign and Construction DocumentsChhour CENo ratings yet

- Good MornigDocument1 pageGood MornigChhour CENo ratings yet

- Mathcad - Pile Cap Design Report Method02Document7 pagesMathcad - Pile Cap Design Report Method02Chhour CENo ratings yet

- RC water tank design and reinforcement calculationDocument10 pagesRC water tank design and reinforcement calculationChhour CE100% (1)

- RC water tank design and reinforcement calculationDocument10 pagesRC water tank design and reinforcement calculationChhour CE100% (1)

- Behavoir of MaterialsDocument19 pagesBehavoir of MaterialsChhour CENo ratings yet

- Bundled BarDocument1 pageBundled BarChhour CENo ratings yet

- DocumentDocument3 pagesDocumentChhour CENo ratings yet

- Arup Vietnam: Waist Landing Strength of MaterialsDocument1 pageArup Vietnam: Waist Landing Strength of MaterialsChhour CENo ratings yet

- Beam - Deflection CheckDocument3 pagesBeam - Deflection CheckChhour CENo ratings yet

- 0 5253 1 PDFDocument400 pages0 5253 1 PDFIhtesham HussainNo ratings yet

- RC water tank design and reinforcement calculationDocument10 pagesRC water tank design and reinforcement calculationChhour CE100% (1)

- Materials Weight and Mass: Mass Per Unit Volumn For Normal ConcreteDocument3 pagesMaterials Weight and Mass: Mass Per Unit Volumn For Normal ConcreteChhour CENo ratings yet

- Column ReportDocument20 pagesColumn ReportChhour CENo ratings yet

- RC water tank design and reinforcement calculationDocument10 pagesRC water tank design and reinforcement calculationChhour CE100% (1)

- Bundled BarDocument1 pageBundled BarChhour CENo ratings yet

- Beam - Deflection CheckDocument8 pagesBeam - Deflection CheckChhour CENo ratings yet

- Materials Weight and Mass: Mass Per Unit Volumn For Normal ConcreteDocument3 pagesMaterials Weight and Mass: Mass Per Unit Volumn For Normal ConcreteChhour CENo ratings yet

- Input: Dp+0.2m Larger Than 0.75 BDocument3 pagesInput: Dp+0.2m Larger Than 0.75 BChhour CENo ratings yet

- Steel ExamplesDocument3 pagesSteel Examplesrasiq7No ratings yet

- Proposed IT Media Hub ProjectDocument21 pagesProposed IT Media Hub ProjectChhour CENo ratings yet

- BOQ King SlandDocument7 pagesBOQ King SlandChhour CENo ratings yet

- Inspection Test Plan (Itp) of PVC Conduits: Project: DateDocument6 pagesInspection Test Plan (Itp) of PVC Conduits: Project: Dateshinto_thekkekkaraNo ratings yet

- Active Professional Facility Management CompaniesDocument102 pagesActive Professional Facility Management CompaniesPankhuri NautiyalNo ratings yet

- Smart Cleat 0212Document12 pagesSmart Cleat 0212Ozan AtıcıNo ratings yet

- Smart' Polymers and What They Could Do in Biotechnology and MedicineDocument6 pagesSmart' Polymers and What They Could Do in Biotechnology and MedicineAlexander KritikopoulosNo ratings yet

- Tecordia Example RELIABILITY ANALYSIS PDFDocument18 pagesTecordia Example RELIABILITY ANALYSIS PDFPravin SasatteNo ratings yet

- Indium Tin Oxide PDFDocument25 pagesIndium Tin Oxide PDFadhityaNo ratings yet

- Bend Stretch Forming AluminumDocument8 pagesBend Stretch Forming AluminumMomoNo ratings yet

- Schneider BreakerDocument170 pagesSchneider BreakerJon Lopez50% (2)

- Knife Edges and PivotsDocument8 pagesKnife Edges and PivotsYineth100% (3)

- Vacuum Pump Systems BrochureDocument10 pagesVacuum Pump Systems BrochureMelissa WilliamsNo ratings yet

- Construction Chemicals Conference Success StoryDocument45 pagesConstruction Chemicals Conference Success StoryShikhin GargNo ratings yet

- Corrosion and PaintingDocument13 pagesCorrosion and PaintingManeet GogiaNo ratings yet

- Eclipse Airheat Burners: Ah-Ma SeriesDocument4 pagesEclipse Airheat Burners: Ah-Ma Seriespanait trofinNo ratings yet

- 1 s2.0 S092702561830034X MainDocument8 pages1 s2.0 S092702561830034X Mainicpsdt.cuetNo ratings yet

- Reducing Fabric Waste in Cutting Through Marker EfficiencyDocument43 pagesReducing Fabric Waste in Cutting Through Marker EfficiencyMênfës Mgb GèdēchãNo ratings yet

- Schneider Electric Staj DefteriDocument15 pagesSchneider Electric Staj DefteriYavuz KaplanNo ratings yet

- Detail of Mesh-1 Reinforcement Details of Pier Cap Section D-DDocument1 pageDetail of Mesh-1 Reinforcement Details of Pier Cap Section D-DSaurabh PandeyNo ratings yet

- Communication With Laser BeamDocument17 pagesCommunication With Laser BeamJagruti MulayNo ratings yet

- PF Ds The Ultimate Technology in Separation and Washing 2020 05-27-608185Document40 pagesPF Ds The Ultimate Technology in Separation and Washing 2020 05-27-608185Marcel MendivilNo ratings yet

- Types, Properties and Uses of Bituminous MaterialsDocument8 pagesTypes, Properties and Uses of Bituminous MaterialsOctavian StoichitaNo ratings yet

- Recarburization of Ductile IronDocument2 pagesRecarburization of Ductile IronWalton BangladeshNo ratings yet

- New Material Seals Better On HVOF CoatingsDocument2 pagesNew Material Seals Better On HVOF Coatingssandbad2100% (2)

- Deutz 165 MK3 Electrial 1Document100 pagesDeutz 165 MK3 Electrial 1chrideerNo ratings yet

- Calculation of Sio Diffusion Coefficients Based On Kinetic Curves of Silica Grain DissolutionDocument3 pagesCalculation of Sio Diffusion Coefficients Based On Kinetic Curves of Silica Grain DissolutionNallely CasasNo ratings yet

- Day 2 200 ItemsDocument25 pagesDay 2 200 ItemsRobert DelfinNo ratings yet

- Brazing Methods GuideDocument9 pagesBrazing Methods GuideVitorHugoNo ratings yet

- PP Cast FilmDocument4 pagesPP Cast FilmMiguel MarujoNo ratings yet

- Product Catalogue 2017: AquathermDocument183 pagesProduct Catalogue 2017: AquathermZeeshanNo ratings yet

- Application of NanotubesDocument28 pagesApplication of Nanotubesarian2arian2No ratings yet

- Keywords: Sanitary Napkins, Chlorine, Uv-Vis SpectrophotometryDocument10 pagesKeywords: Sanitary Napkins, Chlorine, Uv-Vis SpectrophotometryFajar PriyonoNo ratings yet