Professional Documents

Culture Documents

T4 Ecm

Uploaded by

Heart Hacker HarryOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T4 Ecm

Uploaded by

Heart Hacker HarryCopyright:

Available Formats

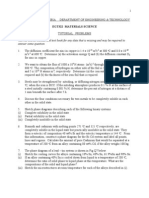

Dr. B.R.

AMBEDKAR

NATIONAL INSTITUTE OF TECHNOLOGY, JALANDHAR

Advanced Manufacturing Processes

Tutorial Sheet 4

B.TECH 6th Semester

1. Calculate the material removal rate and the electrode feed rate in the

electrochemical machining of an iron surface that is 25mmx25mm in cross-section

using NaCl in water as electrolyte. The gap between the tool and the work piece is

0.25 mm. The supply voltage 12V DC. The specific resistance of the electrolyte is

3 Ω cm.

2. For example 1 estimate the electrolyte flow rate .specific heat of the electrolyte

is given as 0.997cal/g °C. The ambient temperature is 35 °C and electrolyte boiling

temperature is 95 °C.

3. Electrochemical machining is performed to remove material from an iron

surface of 20 mm x 20 mm under the following conditions:

Inter electrode gap = 0.2 mm Supply voltage (DC) = 12 V

Specific resistance of electrolyte = 2 Ω cm Atomic weight of Iron = 55.85

Valency of Iron = 2 Faraday's constant = 96540 Coulombs

Find the material removal rate (in g/s).

4. A researcher conducts electrochemical machining (ECM) on a binary alloy

(density 6000 kg/m3 ) of iron (atomic weight 56, valency 2) and metal P (atomic

weight 24, valency 4). Faraday's constant = 96500 coulomb/mole. Volumetric

material removal rate of the alloy is 50 mm3 /s at a current of 2000 A. Find the

percentage of the metal P in the alloy.

You might also like

- Electrocorrosion and Protection of Metals: General Approach with Particular Consideration to Electrochemical PlantsFrom EverandElectrocorrosion and Protection of Metals: General Approach with Particular Consideration to Electrochemical PlantsNo ratings yet

- Lecture 24 - ECMDocument32 pagesLecture 24 - ECMDivyam GargNo ratings yet

- High-Temperature Superconducting Materials Science and Engineering: New Concepts and TechnologyFrom EverandHigh-Temperature Superconducting Materials Science and Engineering: New Concepts and TechnologyNo ratings yet

- Electro-Chemical Machining: Presented By: Keisham Sushima Devi DIP/14/ME/12Document18 pagesElectro-Chemical Machining: Presented By: Keisham Sushima Devi DIP/14/ME/12Fawad HussainNo ratings yet

- Teknik Manufaktur 6Document2 pagesTeknik Manufaktur 6M SHAFARA ALMADANINo ratings yet

- MPS HW (10) Soln 011518Document4 pagesMPS HW (10) Soln 011518Renaldi NafiawanNo ratings yet

- Ban 2011Document6 pagesBan 2011Humberto ArceNo ratings yet

- Electrorecovery ProcessesDocument2 pagesElectrorecovery ProcessesThembi MatebulaNo ratings yet

- AM Week 2 ECM NOTESDocument19 pagesAM Week 2 ECM NOTESa38659158No ratings yet

- ECM - 1st Lecture Chapter 3Document15 pagesECM - 1st Lecture Chapter 3KAMALJEET SINGHNo ratings yet

- ECmDocument32 pagesECmAmit BedareNo ratings yet

- CHEM E6180 Assignment 5 2017Document2 pagesCHEM E6180 Assignment 5 2017Joshua LunguNo ratings yet

- Final DoneDocument12 pagesFinal DoneRockson YuNo ratings yet

- EcmhjghjgjDocument19 pagesEcmhjghjgjhfhtgfhgNo ratings yet

- ECM and EDMDocument23 pagesECM and EDMVinay KumarNo ratings yet

- Electrochemical Machining (ECM) Is A Non-Traditional Machining (NTM) Process Belonging ToDocument11 pagesElectrochemical Machining (ECM) Is A Non-Traditional Machining (NTM) Process Belonging ToMd Sultan AhemadNo ratings yet

- MMG - International Conference On Mechanical and Industrial EngineeringDocument4 pagesMMG - International Conference On Mechanical and Industrial EngineeringMM GoudNo ratings yet

- Electrochemical Machining: Dr. P KuppanDocument35 pagesElectrochemical Machining: Dr. P KuppanMandar ChikateNo ratings yet

- Electro Chemical MachiningDocument21 pagesElectro Chemical MachiningShashank AgarwalNo ratings yet

- BY Debabrata Sahu REGD NO:-1721109146: Production EngineeringDocument20 pagesBY Debabrata Sahu REGD NO:-1721109146: Production EngineeringRabindra DashNo ratings yet

- Icmerepi 357Document5 pagesIcmerepi 357Renalyn TorioNo ratings yet

- Electroplating-Objectives, Operations and ProcessesDocument17 pagesElectroplating-Objectives, Operations and ProcessesVishalMehtreNo ratings yet

- 83 To MSJDocument6 pages83 To MSJSella Ntuwh EldaNo ratings yet

- Unit-2 MMPDocument20 pagesUnit-2 MMPpardhuduNo ratings yet

- Analysis On Fabrication of Micro-Tools by Micro-Electrochemical Machining ProcessDocument33 pagesAnalysis On Fabrication of Micro-Tools by Micro-Electrochemical Machining ProcessXu WeixingNo ratings yet

- ElectrolysisDocument16 pagesElectrolysisFaizal HalimNo ratings yet

- BY Debabrata Sahu REGD NO:-1721109146: Production EngineeringDocument20 pagesBY Debabrata Sahu REGD NO:-1721109146: Production EngineeringRabindra DashNo ratings yet

- Electro Chemical Process: Shivam JaiswalDocument19 pagesElectro Chemical Process: Shivam JaiswalNadee BanneNo ratings yet

- Qand ADocument4 pagesQand AAnuj SharmaNo ratings yet

- Elect Oly SisDocument14 pagesElect Oly Sissamwelch1819No ratings yet

- LESSON 4 (B)Document12 pagesLESSON 4 (B)learntomindyourownbusinessokayNo ratings yet

- Electrochemical Discharge Machining of Small Diameter Holes: M. Coteaţă, L. Slătineanu, O. Dodun, C. CiofuDocument4 pagesElectrochemical Discharge Machining of Small Diameter Holes: M. Coteaţă, L. Slătineanu, O. Dodun, C. Ciofusoumya2011No ratings yet

- Science of Engineerin G Manufactu Re-Ii: Assignment - 1Document17 pagesScience of Engineerin G Manufactu Re-Ii: Assignment - 1amit_kumar_dtuNo ratings yet

- Electro GravimetryDocument18 pagesElectro GravimetryCbn NoonNo ratings yet

- Materials Science Manual REVIEW QUESTIONSDocument4 pagesMaterials Science Manual REVIEW QUESTIONSaoguNo ratings yet

- Electrochemical Machining (ECM)Document36 pagesElectrochemical Machining (ECM)Abhishek KumarNo ratings yet

- Determination of The Weibull Modulus by ElectricalDocument9 pagesDetermination of The Weibull Modulus by ElectricalTiago GonçalvesNo ratings yet

- Article IJMME 123Document5 pagesArticle IJMME 123Jakin RookNo ratings yet

- Electrochemical MachiningDocument16 pagesElectrochemical MachiningParthiban SoundarrajanNo ratings yet

- Enhancement of Material Removal Rate of Electrochemical Machining by Using Rotating Tool ON AISI 1035Document4 pagesEnhancement of Material Removal Rate of Electrochemical Machining by Using Rotating Tool ON AISI 1035kaushalshah28598No ratings yet

- Design of High Strength Bainitic SteelsDocument6 pagesDesign of High Strength Bainitic SteelsK S RamakrishnaNo ratings yet

- Question Bank: UNIT-1 Conducting MaterialsDocument6 pagesQuestion Bank: UNIT-1 Conducting MaterialspriyaNo ratings yet

- SheetDocument3 pagesSheetBarun BeheraNo ratings yet

- Lec2 - Machining Equipment - PRE 314Document70 pagesLec2 - Machining Equipment - PRE 314Mahmoud EldesoukiNo ratings yet

- Experiment No.: 3: - Objective: - Apparatus: - IntroductionDocument2 pagesExperiment No.: 3: - Objective: - Apparatus: - IntroductionBiswadeep Roy ChoudhuryNo ratings yet

- Electrochemical Studies in Laboratory Determination of Behaviour To Corrosion of Some Chrome-Based Alloys For Surgical Implants Prof. Dr. Ing. LIDIA CRISTEADocument7 pagesElectrochemical Studies in Laboratory Determination of Behaviour To Corrosion of Some Chrome-Based Alloys For Surgical Implants Prof. Dr. Ing. LIDIA CRISTEAAnonymous 1hOgJqwZuzNo ratings yet

- Abstract-Electroplating Industry Is A Metal Coating Industry by Way ofDocument5 pagesAbstract-Electroplating Industry Is A Metal Coating Industry by Way ofEdo SeptiansyahNo ratings yet

- Electrochemistry Prelab 2Document2 pagesElectrochemistry Prelab 2Alexis ChicaizaNo ratings yet

- Capacitors: Capacitor Is Basically Used To Store Electrical Energy & Realizes It Whenever DesiredDocument16 pagesCapacitors: Capacitor Is Basically Used To Store Electrical Energy & Realizes It Whenever Desireddipak1980No ratings yet

- Electro Chemical MachiningDocument3 pagesElectro Chemical MachiningGunabalan SellanNo ratings yet

- Electrochemical MachiningDocument9 pagesElectrochemical MachiningROONE SHOWNo ratings yet

- Literatur CaCuTiO12Document6 pagesLiteratur CaCuTiO12prianNo ratings yet

- 01 Coulometric Titration ExperimentDocument3 pages01 Coulometric Titration ExperimentAndres VaronNo ratings yet

- Schiavi Electrochemical-Synthesis 2019Document8 pagesSchiavi Electrochemical-Synthesis 2019kkamolvisitNo ratings yet

- COPEN-9 Full Paper Upload 77Document6 pagesCOPEN-9 Full Paper Upload 77aghosh704100% (1)

- Power Losses FD ItDocument4 pagesPower Losses FD ItSavatul De La GravaNo ratings yet

- Comparison of Electrochemical Behaviors Between FSW and MIG Joints For 6082 Aluminum AlloyDocument5 pagesComparison of Electrochemical Behaviors Between FSW and MIG Joints For 6082 Aluminum AlloyV.v. TaguisNo ratings yet

- Effect of Surface Shallow Traps On FlashoverDocument7 pagesEffect of Surface Shallow Traps On FlashoverVU Thi Thu NgaNo ratings yet

- Influencia de Resistividad Electrica...Document9 pagesInfluencia de Resistividad Electrica...Cristian Perez AnguloNo ratings yet

- Particle Characterization of Copper Nanoparticles by Electrochemical MethodDocument5 pagesParticle Characterization of Copper Nanoparticles by Electrochemical MethodIJSTENo ratings yet

- Ohs CH1,2Document52 pagesOhs CH1,2Heart Hacker HarryNo ratings yet

- GB NIT Jalandhar-7-9 Apr17Document233 pagesGB NIT Jalandhar-7-9 Apr17Heart Hacker HarryNo ratings yet

- 1 A Review of Statistical ConceptsDocument24 pages1 A Review of Statistical ConceptsHeart Hacker HarryNo ratings yet

- ToxicologyDocument31 pagesToxicologyHeart Hacker HarryNo ratings yet

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityFrom EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityRating: 5 out of 5 stars5/5 (2)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Fundamentals of Risk Management for Process Industry EngineersFrom EverandFundamentals of Risk Management for Process Industry EngineersNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Culture, Health and Illness: An Introduction for Health ProfessionalsFrom EverandCulture, Health and Illness: An Introduction for Health ProfessionalsNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- What Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedFrom EverandWhat Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedRating: 5 out of 5 stars5/5 (2)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Tensor Technology Guide: Tensor Ring Benefits and UsesFrom EverandTensor Technology Guide: Tensor Ring Benefits and UsesRating: 5 out of 5 stars5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)