Professional Documents

Culture Documents

Dimensions of Vessel

Uploaded by

Leon TanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dimensions of Vessel

Uploaded by

Leon TanCopyright:

Available Formats

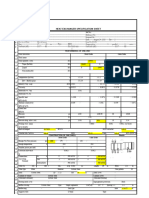

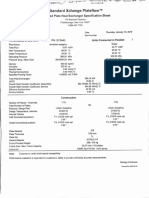

Project Name Johnson Matthey's low pressure methanol synthesis

Project Number Sheet 1 of

REV DATE BY APVD REV DATE BY

METPRO SDN. BHD 1 11/9/2017 Li Jie

Company Name: METPRO Sdn. Bhd

Plant Location: Units: Metric

Case Description

Equipment label: R-401 Equipment name : Radial steam raising methanol reactor

Plant section Section 4

Process service

Design code: ASME Exchanger type: BEM Orientation: Vertical

Shells per unit 1

DATA PER UNIT

SHELL SIDE TUBE SIDE

Conditions

IN OUT IN OUT

Stream No. 403 404 U-407 U-408

Phase Gas Liquid Vapour

Total mass flow rate kg/h 376350.24 113704.00

Total vapor flow kg/h 44330.61 44330.61 0.00 113704.00

Total liquid flow kg/h 0.00 0.00 113704.00 0.00

Density kg/m3 16.64 20.04 898.58 14.08

Dynamic viscosity N.s/m2 2.36E-05 2.30E-05 3.13E-04 1.74E-05

Specific heat capacity kJ/kg.K 3.06 2.85 4.80 2.27

Thermal conductivity W/m.K 1.50E-01 1.20E-01 1.18E+00 5.10E-02

Operating temperature ºC 239.69 243.26 90.11 243.26

Max temperature ºC 305.55 305.55 253.27 253.27

Min temperature ºC 239.69 239.69 80.11 80.11

Pressure bara 70.00 69.25 30.00 30.00

Pressure drop allowed bar 0.75 3

Pressure drop calculated bar 0.67 1.00E-05

Flow velocity m/s 15.00 30.00 1.00 30.00

DESIGN CONDITION

SHELL SIDE TUBE SIDE

Conditions

IN OUT IN OUT

Film transfer coefficient W/m2.K 1912.43 404.91

Fouling coefficient W/m2.K 5000 5000

Overall heat transfer coefficient W/m2.K 268.67

Heat duty kW 82412.93

FT factor 1.00

Effective mean temperature difference ºC 78.46

Design Temperature ºC Max : 305.55 ; Min :80.11 Max : 253.27 ; Min : 80.11

Design Pressure bara 77.00 33.00

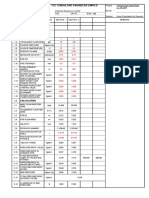

CONSTRUCTION & MATERIALS

SHELL TUBE PERFORATED PIPE

Material Stainless clad carbon steel (304) Material Duplex 2205 stainless steel Material Carbon steel

Inner Diameter (m) 5.24 Inner Diameter (mm) 0.05 Inner Diameter (m) 3.00

Outer Diameter (m) 5.57 Outer Diameter (mm) 0.05 Outer Diameter (m) 3.13

Thickness (mm) 327.19 Thickness (mm) 4.80 Thickness (mm) 130.22

Length (m) 9.00 Length (m) 9.00 Length (m) 512.00

Bundle Clearance (mm) 33.70 Total Number of Tubes 3714.00 Total Number of Holes 22.00

Baffle Spacing (m) 1 Type of Tube Plain Type of Tube Perforated

Number of Baffle 7.00 Pitch Length (mm) 62.50 Holes diameter (mm) 450.00

Baffle Percentage Cut (%) 25.00 Tube Arrangement/Pattern Triangular Total Weight (kN) 856.94

Type of Baffle Disc and dougnut Tube Pitch Orientation 30 deg

Number of Passes 1.00 Number of Passes per Shell 1.00

Weight (kN) 17187.99 Total Weight (kN) 904.81

STRESS ANALYSIS Catalyst

Maximum Allowable Stress (MPa) 94.38 Catalyst Type Copper/Zinc Oxide/Alumina

Dead weight stress (MPa) 3.22 Catalyst shape Cylindrical

Upwind (MPa) 27.51 Catalyst nominal diameter (mm) 4.20

Downwind (MPa) 27.76 Catalyst height (mm) 4.20

Hoop stress (MPa) 61.71 Catalyst bed depth (m) 5.12

Bending stress (wind loading) (MPa) 0.125 Catalyst bed volume (m3) 42.23

Hydrostatic pressure (MPa) 11.55 Catalyst bed bulk density (kg/m3) 1190.00

Greatest difference between principle stress (MPa) 66.83 Catalyst bed void fraction 0.29

Critical buckling stress (MPa) 1174.34 Catalyst Weight (kN) 352.15

Hydrotesting (MPa) 92.56 Insulation

Lifting Lug Insulation Type Mineral Wool

Material Carbon Steel Grade A285 Thickness (mm) 32.00

Length (m) 0.70 Weight (kN) 191.27

Width (m) 0.56 Cladding Type Aluminium Grade 110

Hole Diameter (m) 0.14 Thickness (mm) 5.00

Equipment Sketch Cladding Weight (kN) 161.17

Heads and Closure (Bonnet)

Type Ellipsoidal

Material Stainless Clad Carbon Steel (304)

Length (m) 1.76

Thickness (mm) 266.00

Corrosion Allowance (mm) 2.00

Vessel Support

Type Straight Skirt

Welding Type Bottom Head Welding

Material Stainless Steel Grade 304

Thickness (mm) 333.00

Height (m) 5.00

Tensile stress (Mpa 3.10

Compressive Stress (MPa) 3.13

Flange

Construction material: Carbon steel

Nozzle Description DN Flange Class Flange Rating (bar)

Reactor Inlet 750 600 83.9

Reactor Outlet 500 600 83.9

Boiling water Inlet 150 300 43.8

MP Steam outlet 200 300 39.8

Pressure Relief Device (tube) 65 400 41.9

Pressure Relief Device (shell) 80 400 41.9

Notes

Control and instruments were considered such as PRVs , detailed information will be discussed in P&ID of this equipment.

You might also like

- Water CalculateDocument8 pagesWater CalculateLeon TanNo ratings yet

- Heat Exchanger Specification Sheet Thermal NEC UnitsDocument1 pageHeat Exchanger Specification Sheet Thermal NEC Unitsmohsen ranjbarNo ratings yet

- Heat Exchanger Specification Sheet Thermal NEC UnitsDocument1 pageHeat Exchanger Specification Sheet Thermal NEC Unitsmohsen ranjbarNo ratings yet

- Juice Heater 1Document1 pageJuice Heater 1vijendrNo ratings yet

- Output Steam HeaterDocument2 pagesOutput Steam HeatervidyaNo ratings yet

- XB06H-1-40 - 15 L - MinDocument2 pagesXB06H-1-40 - 15 L - Minahmed ewisNo ratings yet

- Hoja de Especificaciones Intercambiador de Calor 3Document7 pagesHoja de Especificaciones Intercambiador de Calor 3Gómez López Ángel DamiánNo ratings yet

- VSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)Document7 pagesVSEP-Calc: Vertical Gas/Liquid Separator Design Calculations (2 Phase)rudi 010% (1)

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- CCT ShellAndTubeReportDocument2 pagesCCT ShellAndTubeReportLuthfi LegooNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Hexch TemplateDocument1 pageHexch TemplatejtirentiNo ratings yet

- Steam Heater E-002Document2 pagesSteam Heater E-002vidyaNo ratings yet

- BTÑ HTDS - H 10Document1 pageBTÑ HTDS - H 10Juan Pablo Sanchez MelgarejoNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument1 pageHeat Exchanger Specification Sheet SI UnitsdhaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- Data Sheet Gas Scrubber 42 InchDocument32 pagesData Sheet Gas Scrubber 42 InchWijayantoNo ratings yet

- 106-E-01 (Netralizing Unit) - TEMA SheeDocument1 page106-E-01 (Netralizing Unit) - TEMA SheeMekar MeinaNo ratings yet

- Steam Generator Boiler-3Document1 pageSteam Generator Boiler-3ToniNo ratings yet

- ME-Calc+: Finepac StructuresDocument2 pagesME-Calc+: Finepac StructuresAnonymous pVoSWn8yh0No ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- Pump Head Calculation For Viva Bahriya Project: Page 1 of 4Document4 pagesPump Head Calculation For Viva Bahriya Project: Page 1 of 4Hamdy AdelNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- Steam Heater: Printed: 4/13/2019 at 2:44:46 PM TEMA SheetDocument2 pagesSteam Heater: Printed: 4/13/2019 at 2:44:46 PM TEMA SheetvidyaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- Quotation Plan For Naz Bangladesh 21-01-15Document4 pagesQuotation Plan For Naz Bangladesh 21-01-15fakir mohammadNo ratings yet

- Hojas de DatosDocument8 pagesHojas de DatosEdson MoraNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Technip Document No. 068107C001-702-PDS-0610-003-0Document10 pagesTechnip Document No. 068107C001-702-PDS-0610-003-0Ryan Goh Chuang HongNo ratings yet

- Example 1Document1 pageExample 1M. Nasikhun WahidinNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetDocument7 pagesAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũNo ratings yet

- PPGJ-PRO-CAL-192 Hot Oil Demand CalculationDocument24 pagesPPGJ-PRO-CAL-192 Hot Oil Demand CalculationTifano Khristiyanto100% (1)

- ОЛ №3 от 12062020 PDFDocument3 pagesОЛ №3 от 12062020 PDFВалентин СелищевNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- SQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21Document3 pagesSQ8167 - 02 - Column Feed Bottoms Exchanger Process DS Rev B (Alt Case 10 Deg Approach) - HTRI 6th Aug 21SRINo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNo ratings yet

- 1 PDFDocument1 page1 PDFWael BadriNo ratings yet

- Master Calculation ScrubberDocument14 pagesMaster Calculation ScrubberViqiNo ratings yet

- Unit Status at 08:00 HRS: 105 MW Gazipur Power Plant Morning Meeting Discussion at 9:30 HrsDocument2 pagesUnit Status at 08:00 HRS: 105 MW Gazipur Power Plant Morning Meeting Discussion at 9:30 Hrsquazi mohiuddinNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9MAYANK AGRAWALNo ratings yet

- 2 Phase VerticalDocument4 pages2 Phase VerticalJAZEEL ALAVINo ratings yet

- Data Sheet 65 DS 51.5Document4 pagesData Sheet 65 DS 51.5Gokula Krishnan CNo ratings yet

- Heat Exchanger Sizing E-3010A #1Document2 pagesHeat Exchanger Sizing E-3010A #1Luis Enrique Leyva Ovalle100% (1)

- Aspen Exchanger Design and Rating Plate V9Document4 pagesAspen Exchanger Design and Rating Plate V9samara navasNo ratings yet

- Major Equipment List Cilacap LNG TerminalDocument2 pagesMajor Equipment List Cilacap LNG Terminalwong_949618676No ratings yet

- Inter Cambiado RDocument2 pagesInter Cambiado RmilenarixNo ratings yet

- 11 3M50-160-7 5Document6 pages11 3M50-160-7 5tinhNo ratings yet

- Input Data: Tce Consulting Engineers LimitedDocument2 pagesInput Data: Tce Consulting Engineers Limitedsaptarshi samantaNo ratings yet

- NV Series 30 36 Service ManualDocument1 pageNV Series 30 36 Service Manualangel1573065412No ratings yet

- Submersible Pump CatalogueDocument8 pagesSubmersible Pump CatalogueFILID MADNo ratings yet

- WH1716-70-B-010-4 S-7004 Storage Tank Specification Datasheet Rev1Document4 pagesWH1716-70-B-010-4 S-7004 Storage Tank Specification Datasheet Rev1Ionut FloricaNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- File: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Document14 pagesFile: C:/Users/carre/Downloads/E-104 OK - EDR Printed: 27/08/2020 at 17:37:22Camila Florencia ScarlatoNo ratings yet

- 9.... Evmsg 1023F5 Hq1bege-11Document7 pages9.... Evmsg 1023F5 Hq1bege-11tinhNo ratings yet

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- CHE 4173 Sustainable Processing II: Water Network - Limiting Water Profile & MRPDDocument91 pagesCHE 4173 Sustainable Processing II: Water Network - Limiting Water Profile & MRPDLeon TanNo ratings yet

- Lecture Content: Dr. Irene ChewDocument13 pagesLecture Content: Dr. Irene ChewLeon TanNo ratings yet

- Lecture Content: Heat Exchanger Network - PTA & GCCDocument6 pagesLecture Content: Heat Exchanger Network - PTA & GCCLeon TanNo ratings yet

- CHE 4173 Sustainable Processing II: Heat Exchanger Network (HEN) - Composite CurvesDocument32 pagesCHE 4173 Sustainable Processing II: Heat Exchanger Network (HEN) - Composite CurvesLeon TanNo ratings yet

- Chapter 4Document35 pagesChapter 4Leon TanNo ratings yet

- Freehand Drawing SketchingDocument80 pagesFreehand Drawing SketchingGonzalo MeloNo ratings yet

- ND RD ND RD RD: 1e12 Low Carbon Steel Stainless Steel NickelDocument3 pagesND RD ND RD RD: 1e12 Low Carbon Steel Stainless Steel NickelLeon TanNo ratings yet

- Chapter 3 - Process Variables PDFDocument30 pagesChapter 3 - Process Variables PDFLeon TanNo ratings yet

- Steam DistillationDocument28 pagesSteam Distillationami tiuNo ratings yet

- Dialnet NewTechnologyUsedInGasTurbineBladeMaterials 4792527Document5 pagesDialnet NewTechnologyUsedInGasTurbineBladeMaterials 4792527hasnaNo ratings yet

- Quotation For Arc Gun With Power Source DC Drive 400amp ExportDocument5 pagesQuotation For Arc Gun With Power Source DC Drive 400amp ExportClaudio Fica RamirezNo ratings yet

- Medium of Visual ArtsDocument58 pagesMedium of Visual Artsfernandez ararNo ratings yet

- Anorganik TitleDocument24 pagesAnorganik TitleAura TangahuNo ratings yet

- CARBOSORB NC 830 - Comelt - TDS - ENDocument1 pageCARBOSORB NC 830 - Comelt - TDS - ENilkerNo ratings yet

- Tarakky Sir First QuestionDocument7 pagesTarakky Sir First QuestionKhondokar TarakkyNo ratings yet

- AISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundDocument2 pagesAISI 1035 Steel, Cold Drawn, High Temperature, Stress Relieved, 16-22 MM (0.625-0.875 In) RoundJakJhonNo ratings yet

- GF Central Catalog Electrofusion Products Section PDFDocument54 pagesGF Central Catalog Electrofusion Products Section PDFjose03No ratings yet

- Silty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-52Document8 pagesSilty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-5201 - HUTOMO KASPAR KURNIAWANNo ratings yet

- Basf Masterglenium 110m TdsDocument2 pagesBasf Masterglenium 110m TdsshunanlatheefNo ratings yet

- Sethco Bulletin 354Document10 pagesSethco Bulletin 354edgar vasquezNo ratings yet

- CE-112 Lecture 1Document25 pagesCE-112 Lecture 1Muhammad Israr KhanNo ratings yet

- MC Wall: Curtain Wall System For Traditional and Semi Structural Curtain Walls With Thermal BreakDocument4 pagesMC Wall: Curtain Wall System For Traditional and Semi Structural Curtain Walls With Thermal BreakSara HusejnovicNo ratings yet

- PowerPoint IonsDocument11 pagesPowerPoint IonsAlly100% (1)

- MSDS Listing AlphabeticalDocument9 pagesMSDS Listing AlphabeticalAdrian RodriguezNo ratings yet

- Foam Concrete PresentationDocument27 pagesFoam Concrete PresentationMuhammad FarooqNo ratings yet

- ES 22 Color Coding of Piping MaterialsDocument3 pagesES 22 Color Coding of Piping MaterialsjojeecaresNo ratings yet

- Argus Metals International (2019-01-30) PDFDocument20 pagesArgus Metals International (2019-01-30) PDFahmed awadNo ratings yet

- Aws Publications Catalog: Summer 2010Document20 pagesAws Publications Catalog: Summer 2010saeedahmad901No ratings yet

- Lab Report-Elle Necole QuimadaDocument5 pagesLab Report-Elle Necole QuimadaElleNo ratings yet

- Aromaticity NotesDocument6 pagesAromaticity NotesSLIMBOI OpNo ratings yet

- Toko CareManual 2014 ENDocument17 pagesToko CareManual 2014 ENalNo ratings yet

- Kondi and Reku: Traditional Techniques of Weaving Handloom Silk SareesDocument10 pagesKondi and Reku: Traditional Techniques of Weaving Handloom Silk SareesJoyce SequeiraNo ratings yet

- TODO Catalogo Tecnico 2Document67 pagesTODO Catalogo Tecnico 2Abrar HussainNo ratings yet

- Failure Analysis of API 5L (Grade B) Oil Field Separator Flowline PipeDocument6 pagesFailure Analysis of API 5L (Grade B) Oil Field Separator Flowline PipedouglasncamiloNo ratings yet

- OJC Vol27 No1 P 245-252Document8 pagesOJC Vol27 No1 P 245-252Zahra l زهرةNo ratings yet

- General Chemistry Lab Manual With DEMO DATADocument42 pagesGeneral Chemistry Lab Manual With DEMO DATAshihab shoronNo ratings yet

- Lakhmir Singh Chemistry Class 9 Solutions Chapter 2Document34 pagesLakhmir Singh Chemistry Class 9 Solutions Chapter 2Devanshi DwivediNo ratings yet

- Sdarticle 18 PDFDocument8 pagesSdarticle 18 PDFPpa Gpat AmitNo ratings yet