Professional Documents

Culture Documents

Thrust Block Design

Uploaded by

Uttam Kumar Ghosh100%(2)100% found this document useful (2 votes)

906 views2 pagesThrust block

Original Title

Thrust block design

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThrust block

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

906 views2 pagesThrust Block Design

Uploaded by

Uttam Kumar GhoshThrust block

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

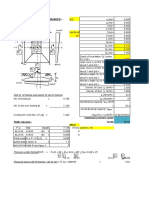

Design of Thrust Block

LVL. + 10.5 (FGL)

Fx

p2 LVL. +7.5 (BOP)

p1

X

L

Y

B

Consider Thrust Block at 45 degree pipe bend.

Force due to flow velocity = 2114.96 N

= 0.21 MT

Force due to flow pressure = 132748.9 N

= 13.27489 MT

Total Force = 13.49 MT

Force on thrust block in X direction = F cos 45 = 9.536 MT

Force on thrust block in Y direction = F sin 45 = 9.536 MT

Choose size of Thrust Block :

B= 4.5 m

L= 4.5 m

D= 0.6 m

Dia of Pipe = 1.4 m

Bulk Density of soil = 1.8 T/sqm

Calculation of Passive Earth Resistance :

Coefficient of passive earth pressure = 3 ( assuming angle of repose = 30 deg.)

Passive pressure at base of block, p1 = 19.44 T/sqm

Passive pressure at top of block, p2 = 16.2 T/sqm

Check for Bearing Pressure :

Consider Net Allowable Bearing Pressure at base = 10 T/sqm

Gross Allowable Bearing Pressure at base = 16.48 T/sqm

Resisting Moment at base due to passive pr. = 14.00 T.m

Moment at base of thrust block about X axis = -1.60 T.m

Moment at base of thrust block about Y axis = -1.60 T.m

Wt of thrust block including soil overburden = 139.73 T

( pipe is continuously supported on soil. So vertical load from pipe is not added.)

Maximum Gross Bearing Pressure = 6.69 T/sqm < 16.48 T/sqm

Minimum Gross Bearing Pressure = 7.11 T/sqm > 0

Hence OK

Check for Sliding :

Consider coefficient of friction between concrete and soil = 0.5

Sliding force in either direction = 13.49 T

Resisting force due to friction = 69.86 T

Resisting force due to passive pressure = 48.11 T

Total resisting force = 117.98 T

Factor of Safety against sliding = 8.75 > 1.5

Hence OK

Reinforcement :

At Bottom :

Maximum net pressure = 0.21 T/sqm

Maximum bending moment at centre of block = 0.53 T.m

Mu = 0.79 T.m

choose b = 1000 mm

d= 542 mm

Mu/b.d2 = 0.03 pt = 0.07

( for M30 conc. & Fe 500 steel)

As = 379.4 mm2

Provide 16 T @ 150 c/c at bottom in both direction

At Top :

Minimum net pressure = 0.63 T/sqm (creats tension at top)

Maximum bending moment at centre of block = 1.60 T.m

Mu = 2.39 T.m

choose b = 1000 mm

d= 542 mm

Mu/b.d2 = -0.08 pt = 0.07

( for M30 conc. & Fe 500 steel)

As = 379.4 mm2

Provide 16 T @ 150 c/c at top in both direction

You might also like

- Design of Thrust Blocks: A) 150 Dia 90 Degree BendDocument7 pagesDesign of Thrust Blocks: A) 150 Dia 90 Degree BendRajesh Babu100% (1)

- Summary of IS 3370 Detailing RequirementsDocument2 pagesSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethNo ratings yet

- Design of Thrust BlockDocument3 pagesDesign of Thrust Blockvishnumani3011No ratings yet

- Vertical Wall DesignDocument1 pageVertical Wall DesignEngr AhmadNo ratings yet

- Sump Well 20 KLDocument3 pagesSump Well 20 KLANKESH SHRIVASTAVA100% (1)

- Construction of 800KL RCC ELSRDocument21 pagesConstruction of 800KL RCC ELSRSrinivasa_DRao_6174100% (1)

- Thrust Block Design JNT450Document15 pagesThrust Block Design JNT450p_ignatiusNo ratings yet

- Masonry Compound WallDocument4 pagesMasonry Compound Wallasingh4000% (1)

- Circular Water Tank (Flexible Joint)Document7 pagesCircular Water Tank (Flexible Joint)PUNARVI INFRASTRUCTURENo ratings yet

- Design of large thrust blocks for rising mainDocument20 pagesDesign of large thrust blocks for rising mainBalaji Rao Ch100% (1)

- Thrust Block Calculations for PipesDocument5 pagesThrust Block Calculations for PipesalbertooooooNo ratings yet

- Rectangular Ground Water TankDocument26 pagesRectangular Ground Water TankJhon DonNo ratings yet

- Design of Underground TankDocument20 pagesDesign of Underground TankMark Jendel Tomo100% (1)

- Design of Raft Foundation of Water TankDocument1 pageDesign of Raft Foundation of Water TankNIHARIKA KARETHANo ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- Thrust Block CalculationDocument12 pagesThrust Block CalculationMegatech Engineering Consultants100% (1)

- Water Tank Design (Aci 318-05)Document8 pagesWater Tank Design (Aci 318-05)arnoldNo ratings yet

- Pure Water SumpDocument8 pagesPure Water SumpVarad Sonawadekar100% (1)

- Sluice Valve ChampersDocument34 pagesSluice Valve ChampersWessam NourNo ratings yet

- Design of Clear Water Reservoir and Pump House of MahishnadiDocument25 pagesDesign of Clear Water Reservoir and Pump House of MahishnadiMukhlish AkhatarNo ratings yet

- Rectangular water tank designDocument225 pagesRectangular water tank designJule LobresNo ratings yet

- 2 Cell Box CulvertDocument22 pages2 Cell Box Culvertabhijeet sahuNo ratings yet

- Design Report 600 KL 25 MTR Gajabandh & BadkarliDocument70 pagesDesign Report 600 KL 25 MTR Gajabandh & BadkarlishailenderNo ratings yet

- Design of Over Head Water TankDocument20 pagesDesign of Over Head Water TankRomyMohan100% (1)

- IS3370 (PART1) - 1965 Concrete Structures For The Storage of Liquids (Genaral Requirements)Document26 pagesIS3370 (PART1) - 1965 Concrete Structures For The Storage of Liquids (Genaral Requirements)Uday Yerramsetty67% (3)

- Over Head ResevoirDocument8 pagesOver Head ResevoirPoulomi BiswasNo ratings yet

- Design Report - Pipe Support - R2 PDFDocument10 pagesDesign Report - Pipe Support - R2 PDFAkhilesh KajarekarNo ratings yet

- Staircase Design IS456-2000Document2 pagesStaircase Design IS456-2000Nitesh SinghNo ratings yet

- Design of Rectangular Water TankDocument280 pagesDesign of Rectangular Water TankNoppolNorasri95% (42)

- Design of - ESR (200KL)Document33 pagesDesign of - ESR (200KL)sanju middya100% (1)

- Tanks Lecture 3Document70 pagesTanks Lecture 3zikzak2011No ratings yet

- U8 l51 Design of Dog Legged Stair Case Numerical 015Document3 pagesU8 l51 Design of Dog Legged Stair Case Numerical 015Yogesh Baheti0% (2)

- Base Plate Design With Moment and AxialDocument2 pagesBase Plate Design With Moment and AxialMai CNo ratings yet

- Plate Stresses in STAADDocument7 pagesPlate Stresses in STAADARYANo ratings yet

- Shear Calculation For Beam: 12.0 MM Dia 2.00 Legged Stirrups ProvidingDocument1 pageShear Calculation For Beam: 12.0 MM Dia 2.00 Legged Stirrups ProvidingManan ParikhNo ratings yet

- HIgh Rise Buildings Design BasisDocument33 pagesHIgh Rise Buildings Design BasisAli ImranNo ratings yet

- Circular Steel Tank Design CalculationDocument9 pagesCircular Steel Tank Design CalculationabbasamuNo ratings yet

- Hydrodynamic Pressure in Circular TanksDocument6 pagesHydrodynamic Pressure in Circular TanksPrakash SIngh Rawal100% (1)

- RCC thrust block design analysisDocument6 pagesRCC thrust block design analysisHemant SonawadekarNo ratings yet

- Isolated Footing Design Excel SheetDocument2 pagesIsolated Footing Design Excel SheetAli ImranNo ratings yet

- Pile Cap ForDocument3 pagesPile Cap ForSunil SinghNo ratings yet

- Counter Fort Retaining WallDocument26 pagesCounter Fort Retaining WallSheikh Mizanur RahmanNo ratings yet

- Retaining Wall Design CalculationsDocument25 pagesRetaining Wall Design CalculationsAmit Patel100% (1)

- Underground Circular Tank R2Document16 pagesUnderground Circular Tank R2Nayeemuddin KhajaNo ratings yet

- Storm Water Drainage SystemDocument18 pagesStorm Water Drainage Systemankitbalyan100% (3)

- 100KL Sump Cum PH - Bhopal DesDocument10 pages100KL Sump Cum PH - Bhopal DesMAHENDRANo ratings yet

- Design As Per Is-456Document23 pagesDesign As Per Is-456ALOK THAKURNo ratings yet

- ONGC-PUMP ROOM - Purlin DesignDocument3 pagesONGC-PUMP ROOM - Purlin Designraghav abudhabiNo ratings yet

- Retaining Wall With Pile FoundationDocument42 pagesRetaining Wall With Pile FoundationPrashant JhaNo ratings yet

- Design of Hopper: 75 MM + 75 MMDocument2 pagesDesign of Hopper: 75 MM + 75 MMsamir bendreNo ratings yet

- Calculation For 1.4m X 1.5m RCC Box CulvertDocument4 pagesCalculation For 1.4m X 1.5m RCC Box CulvertManish BhatkarNo ratings yet

- Isolated Footing BumaatDocument6 pagesIsolated Footing BumaatJaphet BumaatNo ratings yet

- Col Fot Beam Calculations Affcons Office BuildingDocument47 pagesCol Fot Beam Calculations Affcons Office BuildingShaikh ImranNo ratings yet

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212No ratings yet

- References Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)Document10 pagesReferences Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)WycliffeNo ratings yet

- End Plate Moment ConnectionDocument4 pagesEnd Plate Moment Connectionteguh andriantoNo ratings yet

- Cement Silo Design As Per IsDocument12 pagesCement Silo Design As Per Issoumi bhattacharyaNo ratings yet

- Design Purlins Roof StructureDocument23 pagesDesign Purlins Roof StructureJoshua John JulioNo ratings yet

- Bolt TorqueDocument3 pagesBolt TorqueHeri KurniawanNo ratings yet

- Pile Cap Design for 83 kN LoadDocument3 pagesPile Cap Design for 83 kN LoadSabbir ChowdhuryNo ratings yet

- Q&A - Mughal dynastyDocument5 pagesQ&A - Mughal dynastyUttam Kumar GhoshNo ratings yet

- Period of TransitionDocument9 pagesPeriod of TransitionUttam Kumar GhoshNo ratings yet

- Crane DesignDocument3 pagesCrane DesignUttam Kumar GhoshNo ratings yet

- Temperature Moment Calculation: H + K A +a +a KDocument2 pagesTemperature Moment Calculation: H + K A +a +a KUttam Kumar GhoshNo ratings yet

- SK-001 R0Document1 pageSK-001 R0Uttam Kumar GhoshNo ratings yet

- Design of Concrete CorbelDocument2 pagesDesign of Concrete CorbelUttam Kumar GhoshNo ratings yet

- Design Parameters - Concrete Is 456Document5 pagesDesign Parameters - Concrete Is 456Uttam Kumar GhoshNo ratings yet

- Shear With TensionDocument1 pageShear With TensionUttam Kumar GhoshNo ratings yet

- Section 10 ExemptDocument2 pagesSection 10 ExemptUttam Kumar GhoshNo ratings yet

- Wood and Armer MethodDocument1 pageWood and Armer MethodUttam Kumar GhoshNo ratings yet

- Is Steel SectionDocument38 pagesIs Steel SectionUttam Kumar GhoshNo ratings yet

- Lap DevelopmentDocument4 pagesLap DevelopmentUttam Kumar GhoshNo ratings yet

- Chimney FootingDocument3 pagesChimney FootingUttam Kumar GhoshNo ratings yet

- Design of Unburned Clinker Silo Based On BS EN 1991-4:2006Document4 pagesDesign of Unburned Clinker Silo Based On BS EN 1991-4:2006Uttam Kumar GhoshNo ratings yet

- Settlement - CalculationDocument2 pagesSettlement - CalculationUttam Kumar GhoshNo ratings yet

- Stair Wall JointDocument3 pagesStair Wall JointUttam Kumar GhoshNo ratings yet

- Pile Load For 10 PilesDocument3 pagesPile Load For 10 PilesUttam Kumar GhoshNo ratings yet

- Circular Hollow Concrete ColumnDocument3 pagesCircular Hollow Concrete ColumnUttam Kumar GhoshNo ratings yet

- 1.5DL+1.5LL 1.5DL+1.5WLX+ 1.5DL+1.5WLX-1.5DL+1.5WLZ+ 1.5DL+1.5WLZ - 1.2DL+1.2LL+1.2WLX+ 1.2DL+1.2LL+1.2WLX - 1.2DL+1.2LL+1.2WLZ+ 1.2DL+1.2LL+1.2WLZDocument1 page1.5DL+1.5LL 1.5DL+1.5WLX+ 1.5DL+1.5WLX-1.5DL+1.5WLZ+ 1.5DL+1.5WLZ - 1.2DL+1.2LL+1.2WLX+ 1.2DL+1.2LL+1.2WLX - 1.2DL+1.2LL+1.2WLZ+ 1.2DL+1.2LL+1.2WLZUttam Kumar GhoshNo ratings yet

- Bearing Capacity of Soil As Per IS-6403:1981: Input DataDocument1 pageBearing Capacity of Soil As Per IS-6403:1981: Input DataUttam Kumar GhoshNo ratings yet

- Design of Concrete CorbelDocument2 pagesDesign of Concrete CorbelUttam Kumar GhoshNo ratings yet

- Design Lined CanalsDocument2 pagesDesign Lined CanalsUttam Kumar GhoshNo ratings yet

- Steel Silo Quantity EstimationDocument4 pagesSteel Silo Quantity EstimationUttam Kumar Ghosh100% (1)

- Construction JointDocument3 pagesConstruction JointUttam Kumar GhoshNo ratings yet

- For NB 300: Stress Diagram Is Drawn Only For Load Case-1Document7 pagesFor NB 300: Stress Diagram Is Drawn Only For Load Case-1Uttam Kumar GhoshNo ratings yet

- Stair Wall JointDocument3 pagesStair Wall JointUttam Kumar GhoshNo ratings yet

- For NB 300: Stress Diagram Is Drawn Only For Load Case-1Document7 pagesFor NB 300: Stress Diagram Is Drawn Only For Load Case-1Uttam Kumar GhoshNo ratings yet

- Base Mom ServiceDocument1 pageBase Mom ServiceUttam Kumar GhoshNo ratings yet

- 13C09-008-BBS-001 R0Document2 pages13C09-008-BBS-001 R0Uttam Kumar GhoshNo ratings yet

- The Effect of Dodd-Frank On Divorcing Citizens 1Document5 pagesThe Effect of Dodd-Frank On Divorcing Citizens 1Noel CookmanNo ratings yet

- Create a seat booking form with Google Forms, Google Sheets and Google Apps Script - Yagisanatode - AppsScriptPulseDocument3 pagesCreate a seat booking form with Google Forms, Google Sheets and Google Apps Script - Yagisanatode - AppsScriptPulsebrandy57279No ratings yet

- Bluetooth Home Automation Using ArduinoDocument25 pagesBluetooth Home Automation Using ArduinoRabiNo ratings yet

- Inbound 9092675230374889652Document14 pagesInbound 9092675230374889652Sean Andrew SorianoNo ratings yet

- Ali ExpressDocument3 pagesAli ExpressAnsa AhmedNo ratings yet

- Key formulas for introductory statisticsDocument8 pagesKey formulas for introductory statisticsimam awaluddinNo ratings yet

- SQL Server 2008 Failover ClusteringDocument176 pagesSQL Server 2008 Failover ClusteringbiplobusaNo ratings yet

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Document16 pagesTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDocument12 pages2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalNo ratings yet

- Spsi RDocument2 pagesSpsi RBrandy ANo ratings yet

- Reinvestment Allowance (RA) : SCH 7ADocument39 pagesReinvestment Allowance (RA) : SCH 7AchukanchukanchukanNo ratings yet

- Suband Coding in MatlabDocument5 pagesSuband Coding in MatlabZoro Roronoa0% (1)

- SYNOPSIS - Impact of GST On Small Traders!Document21 pagesSYNOPSIS - Impact of GST On Small Traders!Laxmi PriyaNo ratings yet

- Optimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDocument7 pagesOptimization of The Spray-Drying Process For Developing Guava Powder Using Response Surface MethodologyDr-Paras PorwalNo ratings yet

- Key ssl101 Academic Skills For University Success ssl101cDocument196 pagesKey ssl101 Academic Skills For University Success ssl101cHùng NguyễnNo ratings yet

- Domingo V People (Estafa)Document16 pagesDomingo V People (Estafa)Kim EscosiaNo ratings yet

- Extensive Reading Involves Learners Reading Texts For Enjoyment and To Develop General Reading SkillsDocument18 pagesExtensive Reading Involves Learners Reading Texts For Enjoyment and To Develop General Reading SkillsG Andrilyn AlcantaraNo ratings yet

- 2019 May Chronicle AICFDocument27 pages2019 May Chronicle AICFRam KrishnaNo ratings yet

- MMW FinalsDocument4 pagesMMW FinalsAsh LiwanagNo ratings yet

- Computer Portfolio (Aashi Singh)Document18 pagesComputer Portfolio (Aashi Singh)aashisingh9315No ratings yet

- A General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDocument37 pagesA General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDiego JesusNo ratings yet

- 10 Slides For A Perfect Startup Pitch DeckDocument6 pages10 Slides For A Perfect Startup Pitch DeckZakky AzhariNo ratings yet

- Overview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsDocument11 pagesOverview of Quality Gurus Deming, Juran, Crosby, Imai, Feigenbaum & Their ContributionsVenkatesh RadhakrishnanNo ratings yet

- Mechanics of Deformable BodiesDocument21 pagesMechanics of Deformable BodiesVarun. hrNo ratings yet

- Sieve Shaker: Instruction ManualDocument4 pagesSieve Shaker: Instruction ManualinstrutechNo ratings yet

- Report Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIDocument26 pagesReport Daftar Penerima Kuota Telkomsel Dan Indosat 2021 FSEIHafizh ZuhdaNo ratings yet

- IMM Indian Oil Case Group 3Document13 pagesIMM Indian Oil Case Group 3Soniya AgnihotriNo ratings yet

- Ramdump Memshare GPS 2019-04-01 09-39-17 PropsDocument11 pagesRamdump Memshare GPS 2019-04-01 09-39-17 PropsArdillaNo ratings yet

- SD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Document6 pagesSD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Lawrence PeNo ratings yet

- EE290 Practice 3Document4 pagesEE290 Practice 3olgaNo ratings yet