Professional Documents

Culture Documents

MSS SP 58

Uploaded by

octa aldyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSS SP 58

Uploaded by

octa aldyCopyright:

Available Formats

[File]

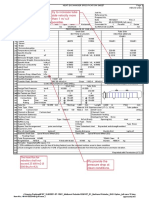

HEAT EXCHANGER DESIGN, INC.

P. O. Box 524 Heat Exchanger Specification Sheet Phone: (317)686-9000

Indianapolis, IN 46206-0524 Fax: (317)686-9100

Job No.

Customer Ref No.

Address Proposal No.

Plant Location Date 05/01/2007 Rev. 0

Service of Unit Beer Column Reboiler Item No

Size 72x 240 Type BEM - HORZ Connected in 1 Parallel 1 Series

Surf/Unit (Eff) 13687 ft² Shells/Unit 1 Surface/Shell (Effective) 13687 ft²

PERFORMANCE OF ONE UNIT

Fluid Allocation Shellside Tubeside

1 Fluid Name Steam Beer Column Bottoms

2 Total Fluid Entering lb/hr 70,399 4,196,328

3 Vapor 70,399 0

4 Liquid 0 4,196,328

5 Steam

6 Noncondensable

7 Fluid Vaporized or Condensed 70,399 0

8 Liquid Density (In/Out) lb/ft³ 57.349/57.587 64.000/64.000

9 Liquid Viscosity cP 0.198 5.000

10 Liquid Specific Heat Btu/lb-F 1.002 1.000

11 Liquid Thermal Conductivity Btu/hr-ft-F 0.395 0.397

12 Vapor Mol. Weight (In/Out) 18.0/18.0 0.0/0.0

13 Vapor Viscosity cP 0.0152 0.0000

14 Vapor Specific Heat Btu/lb-F 0.573 0.000

15 Vapor Thermal Conductivity Btu/hr-ft-F 0.017 0.000

16 Temperature (In/Out) °F 284.6/277.3 250.0/265.5

17 Operating Pressure psi(Abs) 52.935 44.076

18 Velocity ft/sec 30.660 6.153

19 Pressure Drop (Allow/Calc) psi 5.000/2.573 15.000/13.049

20 Fouling resistance hr-ft²-F/Btu 0.000500 0.002000

21 Heat Exchanged 65,149,920 Btu/hr mtd (corr) 22.121 °F

22 Transfer Rate, Service 215.2 Clean 373.1 Btu/hr-ft²-F

23 CONSTRUCTION OF ONE SHELL

24 Shellside Tubeside

25 Design/Test Pres. psi 75/Code 75/Code Maximum temperature difference = 70°F

26 Design Temp. °F 350 330

27 No. Passes per Shell 1 4

28 Corrosion Allow. in 0.0625 0.0000

29 Connections In 1-12.0 18.0

30 Size & Out 1-6.0 24.0

31 Rating Intermediate 150 # RFSO 150 # RFSO/WOL

32

33 Tube No 2668 OD 1.000 in Thk 0.049 Length 20.00 ft Pitch 1.25000 / 30.0°

34 Tube Type PLAIN Material SA249-304L

35 Shell SA516-70 I.D 72.00 OD in Shell Cover N/A INT

36 Channel or Bonnet CS+WOL Channel Cover N/A

37 Tubesheet-Stationary CS+WOL Tubesheet-Floating N/A

38 Floating Head Cover N/A Impingement Protection YES

39 Baffles Cross A-36 Type VERT-SEG %Cut 45.0 (Area) Spacing-cc 23.5

40 Baffles-Long N/A Seal Type

41 Supports-Tube A-36 U-Bend Type

42 Bypass Seal Arrangement Tube-Tubesheet Joint Rolled Expanded

43 Expansion Joint N/A Type

44 Rho-V2 Inlet Nozzle 4,939 Bundle Entrance 2,839 Bundle Exit 224

45 Gasket-Shellside Tubeside DJNA Floating Head

46 Code Requirement ASME Section 8, Divsion 1 TEMA Class B

47 Weight/Shell 51,404 Filled with Water 68,690 Bundle N/A

48 Remarks: Hardware Bid Only / Tubes to be furnished by purchaser

49 2. First baffle to be 22" from the tubesheet, then keep baffles spacing at 24.5

50 3. Ave. Tube metal temp = 272.1 / Ave. Shell Temp = 278.5 4/ All tubeside to be WOL or Lap Joint.

51

You might also like

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- ASTM D3687-01 Analysis of Organic Compound Vapors Collected by The Activated Charcoal Tube Adsorption MethodDocument6 pagesASTM D3687-01 Analysis of Organic Compound Vapors Collected by The Activated Charcoal Tube Adsorption MethodFredi Cari Carrera50% (2)

- Heat Exchanger Specification SheetDocument32 pagesHeat Exchanger Specification SheetWijayantoNo ratings yet

- US Units Heat Exchanger Specification SheetDocument1 pageUS Units Heat Exchanger Specification SheetDwi PutraNo ratings yet

- Ayuda Asme B36.10M PDFDocument26 pagesAyuda Asme B36.10M PDFEdgargar100% (1)

- Ayuda Asme B36.10M PDFDocument26 pagesAyuda Asme B36.10M PDFEdgargar100% (1)

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Heat exchanger rating data sheetDocument1 pageHeat exchanger rating data sheetFadhila Ahmad AnindriaNo ratings yet

- Ansi/Asme ASME B31.3 ASME B31.1: Power PlantDocument60 pagesAnsi/Asme ASME B31.3 ASME B31.1: Power PlantMercyNo ratings yet

- Steam HXDocument1 pageSteam HXrajachemNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Document4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINo ratings yet

- General Biology 1: Quarter 2 - Module 3: When Cells BreatheDocument26 pagesGeneral Biology 1: Quarter 2 - Module 3: When Cells BreathePLS help me get 1k subsNo ratings yet

- HEAT EXCHANGER SPECIFICATION SHEETDocument1 pageHEAT EXCHANGER SPECIFICATION SHEETHudaFiHayyatNo ratings yet

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- Heat Exchanger Sizing E-7010 #1Document2 pagesHeat Exchanger Sizing E-7010 #1Luis Enrique Leyva OvalleNo ratings yet

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62No ratings yet

- Gas Chiller Datasheet PDFDocument2 pagesGas Chiller Datasheet PDFidilfitriNo ratings yet

- Gas-Gas Exchanger DatasheetDocument3 pagesGas-Gas Exchanger DatasheetidilfitriNo ratings yet

- DNV RP D101 October 2008Document42 pagesDNV RP D101 October 2008aop10468100% (1)

- Aspen Exchanger Design Rating SheetDocument2 pagesAspen Exchanger Design Rating SheetLuis Enrique Leyva OvalleNo ratings yet

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- 240-05-DTS-009 V-501 Air ReceiverDocument20 pages240-05-DTS-009 V-501 Air ReceiverEmran NazirNo ratings yet

- 08 - Section-3 Three Phase SeparationDocument19 pages08 - Section-3 Three Phase SeparationOladayo Siyanbola100% (1)

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Process Water Scrubber Cooling Exchanger ProjectDocument1 pageProcess Water Scrubber Cooling Exchanger ProjectDavid Muñoz CastroNo ratings yet

- General Purpose Epoxy Resin MSDSDocument4 pagesGeneral Purpose Epoxy Resin MSDSocta aldyNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetDocument2 pagesAspen Exchanger Design and Rating Shell & Tube V10: File: E-501-A - 1.edr Printed: 22/03/2019 at 05:07:09 A. M. TEMA SheetLandaNo ratings yet

- Gas Chiller DatasheetDocument2 pagesGas Chiller DatasheetidilfitriNo ratings yet

- Heat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriDocument1 pageHeat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriNatarajan RavisankarNo ratings yet

- Ea 102Document2 pagesEa 102Najmul SaqibNo ratings yet

- L-R Intercambiador Coraza y Tubos PDFDocument1 pageL-R Intercambiador Coraza y Tubos PDFAlejandro OsorioNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Luis NewballNo ratings yet

- 240-05-DTS-010 V-400 Regenaration Gas SeperatorDocument20 pages240-05-DTS-010 V-400 Regenaration Gas SeperatorEmran NazirNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V11Document1 pageAspen Exchanger Design and Rating Shell & Tube V11Ginna RodriguezNo ratings yet

- TEMA Sheet CorregidoDocument1 pageTEMA Sheet Corregidosaragineth.saNo ratings yet

- TEMA Sheed L-R ExchangerDocument1 pageTEMA Sheed L-R ExchangerAlejandra BuenoNo ratings yet

- F:/Aku/S V/Desain Perpipaan Thermal/Aku/Shell & Tube/Ainun Mustqaim - HtriDocument1 pageF:/Aku/S V/Desain Perpipaan Thermal/Aku/Shell & Tube/Ainun Mustqaim - HtriainunNo ratings yet

- Aspen Exchanger Design Rating Shell TubeDocument2 pagesAspen Exchanger Design Rating Shell TubeLuis Enrique Leyva Ovalle100% (1)

- CH-RA3 Page 1Document1 pageCH-RA3 Page 1Sonya LoveraNo ratings yet

- 240-05-DTS-000 Fire Water PumpDocument19 pages240-05-DTS-000 Fire Water PumpEmran NazirNo ratings yet

- 2400-05-DTS-005cooling TowerDocument19 pages2400-05-DTS-005cooling TowerEmran NazirNo ratings yet

- 240-05-DTS-XXX Flare StackDocument18 pages240-05-DTS-XXX Flare StackEmran NazirNo ratings yet

- Juice Heater 1Document1 pageJuice Heater 1vijendrNo ratings yet

- Output PDFDocument1 pageOutput PDFAlex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocument1 pageAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNo ratings yet

- Data Desain CCHE-TEMA PDFDocument1 pageData Desain CCHE-TEMA PDFFilippo AlfendroNo ratings yet

- 100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorDocument1 page100-Mc-417-Ra3-Hx-Ra3 - HDB Condensador ReactorSonya LoveraNo ratings yet

- Ea 101Document2 pagesEa 101Najmul SaqibNo ratings yet

- T1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segDocument1 pageT1 235, T2 116, 219 Tubos, 2 Pases, Aire 448308 LB - HR Rev1.segTIPAZONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- 4-PassDocument1 page4-PasstauasiNo ratings yet

- Htri PDFDocument1 pageHtri PDFLuigy L-aNo ratings yet

- Heat exchanger specification sheet vibration analysisDocument3 pagesHeat exchanger specification sheet vibration analysisSRINo ratings yet

- ShellTubeHE Hot PT Konigs E-202 ColdDocument1 pageShellTubeHE Hot PT Konigs E-202 Coldeka prasetiaNo ratings yet

- Caso de Studio Xchanger 1Document5 pagesCaso de Studio Xchanger 1fabianNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification Sheettatiana alvarezNo ratings yet

- Serial Number:: Document TypeDocument19 pagesSerial Number:: Document TypeAhmed KhairiNo ratings yet

- Heat Exchanger Spec SheetDocument2 pagesHeat Exchanger Spec Sheettatiana alvarezNo ratings yet

- Heat exchanger specification sheetDocument1 pageHeat exchanger specification sheetSonya LoveraNo ratings yet

- IC-PER-01-02 SpecDocument1 pageIC-PER-01-02 Specroberto.hernandezNo ratings yet

- PASES, AIRE 448308 LB - HR REVaa1.SEGDocument1 pagePASES, AIRE 448308 LB - HR REVaa1.SEGTIPAZONo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument1 pageHeat Exchanger Specification Sheet SI UnitsdhaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V9Document1 pageAspen Exchanger Design and Rating Shell & Tube V9Maira Alejandra GuzmánNo ratings yet

- Process Design Report SummaryDocument3 pagesProcess Design Report Summarymuhd.qasimNo ratings yet

- Final DRWDocument13 pagesFinal DRWK.l. DhanaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10Document1 pageAspen Exchanger Design and Rating Shell & Tube V10Alex AgualemaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Submittal Data: CM10-2 A-R-A-E-AQQEDocument9 pagesSubmittal Data: CM10-2 A-R-A-E-AQQEocta aldyNo ratings yet

- Perencanaan Jadwal Inspeksi Pada Jalur Pipa Penyalur Minyak Mentah Dengan Metode Risk Based Inspection (Rbi)Document6 pagesPerencanaan Jadwal Inspeksi Pada Jalur Pipa Penyalur Minyak Mentah Dengan Metode Risk Based Inspection (Rbi)octa aldyNo ratings yet

- Epoxy ResinDocument3 pagesEpoxy Resinocta aldyNo ratings yet

- Volume III Rules For Machinery Installations 2009Document279 pagesVolume III Rules For Machinery Installations 2009octa aldyNo ratings yet

- SEO Safety Engineering Conference ProceedingsDocument6 pagesSEO Safety Engineering Conference Proceedingsocta aldyNo ratings yet

- Testing Erosion For FRPDocument6 pagesTesting Erosion For FRPocta aldyNo ratings yet

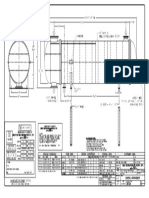

- Pressure Vessel - 3872A SHT1 R1Document1 pagePressure Vessel - 3872A SHT1 R1octa aldyNo ratings yet

- Introduction To Pipe Stress Analysis - Sam Kannappan 1986Document129 pagesIntroduction To Pipe Stress Analysis - Sam Kannappan 1986octa aldyNo ratings yet

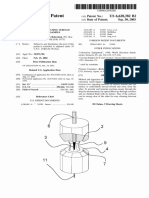

- United States Patent (10) Patent No.: Us 6,628,382 B2: Robertson (45) Date of Patent: Sep. 30, 2003Document14 pagesUnited States Patent (10) Patent No.: Us 6,628,382 B2: Robertson (45) Date of Patent: Sep. 30, 2003LazScibdNo ratings yet

- H.A.J. Oonk, M.T. Calvet - Equilibrium Between Phases of Matter - Phenomenology and Thermodynamics-Springer (2007) PDFDocument413 pagesH.A.J. Oonk, M.T. Calvet - Equilibrium Between Phases of Matter - Phenomenology and Thermodynamics-Springer (2007) PDFSebastian Lopez GomezNo ratings yet

- Unit 3 Mass Transfer: StructureDocument22 pagesUnit 3 Mass Transfer: StructureUdop CharlesNo ratings yet

- 5054 Space Physics Practice QuestionsDocument14 pages5054 Space Physics Practice QuestionsSoya BeansNo ratings yet

- IRRIGATION SYSTEMS DESIGN NOTES - MR Mpala LSUDocument163 pagesIRRIGATION SYSTEMS DESIGN NOTES - MR Mpala LSUPanashe GoraNo ratings yet

- In Vitro Evaluation of Glimepiride Solid Dispersions for Dissolution Rate EnhancementDocument12 pagesIn Vitro Evaluation of Glimepiride Solid Dispersions for Dissolution Rate Enhancementmanvitha varmaNo ratings yet

- Principles and Applications of Analytical TechniquesDocument2 pagesPrinciples and Applications of Analytical TechniquesArham Ahmed100% (1)

- 9.0-BUL107 1.10 en Water QualityxDocument2 pages9.0-BUL107 1.10 en Water QualityxmohamadNo ratings yet

- Sensi Sensi Sensitech: Temptale UltraDocument1 pageSensi Sensi Sensitech: Temptale Ultrayondi hermawanNo ratings yet

- Nitrogen Cycle Definition and ProcessesDocument5 pagesNitrogen Cycle Definition and ProcessesNNo ratings yet

- Experiment 9 Measurement of Hydraulic Conductivity of Granular SoilsDocument12 pagesExperiment 9 Measurement of Hydraulic Conductivity of Granular SoilsAllyssa SuyatNo ratings yet

- Determination of The Diffraction Intensity at Slit and Double Slit SystemsDocument5 pagesDetermination of The Diffraction Intensity at Slit and Double Slit SystemsJose Galvan100% (1)

- Computational Study of Critical Flow Discharge in Supercritical W PDFDocument129 pagesComputational Study of Critical Flow Discharge in Supercritical W PDFThiago RobertoNo ratings yet

- T Tai: U YstDocument7 pagesT Tai: U YstDani Romero GarzònNo ratings yet

- Determination of Perfluorinated Compounds in Aquatic Organisms A ReviewDocument18 pagesDetermination of Perfluorinated Compounds in Aquatic Organisms A Reviewvictor romeroNo ratings yet

- AQA Physics GCSE Combined P9 Practice AnswersDocument1 pageAQA Physics GCSE Combined P9 Practice AnswersMahebul MazidNo ratings yet

- Concrete ADM STD Specifications For K-140 SRC & K-250 SRC ROAD WorksDocument22 pagesConcrete ADM STD Specifications For K-140 SRC & K-250 SRC ROAD WorksMubashar Islam JadoonNo ratings yet

- Four Types of FrictionDocument3 pagesFour Types of FrictionAna Joy PeredaNo ratings yet

- The Rate Equation KnockhardyDocument67 pagesThe Rate Equation KnockhardyStaniaNo ratings yet

- Fundamentals of ChemistryDocument385 pagesFundamentals of Chemistryalexmulengamusonda214No ratings yet

- US8049052 - System and Method of Deactivating and Quenching An Oligomerization CatalystDocument32 pagesUS8049052 - System and Method of Deactivating and Quenching An Oligomerization CatalystDINESH KUMARNo ratings yet

- Dwnload Full Introduction To Management Accounting 15th Edition Horngren Solutions Manual PDFDocument36 pagesDwnload Full Introduction To Management Accounting 15th Edition Horngren Solutions Manual PDFcalymene.perdurel7my100% (11)

- Al-Falah Group of Schools and Colleges Jhumra City CHP (2,3,4,5) Mcqs Time: 120 MintsDocument12 pagesAl-Falah Group of Schools and Colleges Jhumra City CHP (2,3,4,5) Mcqs Time: 120 MintsAhsan RazaNo ratings yet

- Problem C: Standard:Hs-Ps2-1 Newton'S Second Law ProblemDocument2 pagesProblem C: Standard:Hs-Ps2-1 Newton'S Second Law ProblemMona Mohamed SafwatNo ratings yet

- 1.5 LipidsDocument19 pages1.5 Lipidsasifh76543No ratings yet

- Earth Science ActivitiesDocument10 pagesEarth Science ActivitiescykenNo ratings yet

- INTRODUCTION TO COMPASS SURVEYyDocument13 pagesINTRODUCTION TO COMPASS SURVEYyCristiano RonaldoNo ratings yet