Professional Documents

Culture Documents

2014 Ref Flyer Redesur Peru SIP 5 en V1

Uploaded by

josseCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2014 Ref Flyer Redesur Peru SIP 5 en V1

Uploaded by

josseCopyright:

Available Formats

www.siemens.

com/smartgrid

Supply of Digital Fault Recorders

Red Eléctrica del Sur S.A.

Arequipa – Perú

The compliance with a new regulatory standard of the

system operator COES – Comité de Operación del

Sistema Interconectado Nacional del Perú - which

requires the implementation of Digital Fault Recorders in

all transmission lines with voltages above 100 kV, in

order to perform a comprenhensive analysis of the faults

that occur in the Peruvian electricity system – SEIN- has

given origen to this project.

Siemens participation includes the supply, training and

supervision of commissioning of Digital Fault Recorders

for the transmission lines in 220 kV of Red Electrica del

Sur - REDESUR, the electricity transmission company

customer project who serves the energy transmission among the cities of

Arequipa, Moquegua, Tacna and Puno in southern Peru.

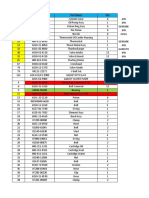

Substations within the scope of the project are:

Socabaya Substation

Moquegua Substation

Los Héroes Substation

Puno Substation

"All fault recorders on the market

have similar technical

characteristics. However, the

SICAM PQS software grants remote

management benefits, fundamental

for the selection of the solution

Imagen referencial

offered by Siemens"

Eng. Javier Jácobo; Management Coordinator of

Operations and Maintenance - REDESUR

customer project customer project

Challenges for REDESUR Devices are installed and in operation in altitudes up to

Customer's foundation to install a Fault Register System 4000 m a.s.l.

is based on the need to be aligned to the "Technical

Procedure 40", demanded by the regulatory entity COES,

which refers to equipment capable to record up to 6 kHz Benefits for REDESUR

in both system events: transient type (faults) and By virtue of the implemented solution, REDESUR nowadays

dynamic type (power oscillations). possesses the following advantages:

Customer Objective Oscillographic records storage up to 15 GB in each of the

REDESUR's objective has been to implement a continous installed devices.

management system that allows an automatic storage of Centralized management of oscillographic records for

oscillographic records on a server, and able to send transmission lines with geographical distance of 527 km.

notification messages via e-Mail in case of a failure event

Oscillographic records with a sampling rate of up to 16 kHz.

in REDESUR's electrical system. In such a way improves

Access to information of fault records due to the gradual and

the efficiency in its operations, obtaining as much

controlled registration.

information as possible from its energy network in order to

Sending automated information via e-mail upon the

analyze the power system phenomena, such as

occurrence of an event in the system.

distortions of the network, voltages and currents faults

values, among others. With the highest quality standards Increased availability of the transmission system supported

is to be aligned with the requirements of the COES. by the data analysis and effective coordination of corrective

actions.

Siemens Solution

Thanks to the comprenhensive Siemens’ proposal,

REDESUR has decided to innovate technologically.

The solution is composed by fault recorders

SIPROTEC 7KE85 belonging to the new platform

SIPROTEC 5, altogether with the software SICAM PQS,

Published by and copyright © 2014

specially designed to centrally archive and evaluate all Siemens AG

the power quality information gathered in field, open also Infrastructure & Cities Sector

to receive information from equipment of other suppliers, Smart Grid Division

providing in a clear and simple way information of the Energy Automation

Humboldtstr. 59

global quality condition of the system.

90459 Nuremberg, Germany

The scope of supply has included:

For more information,

11 SIPROTEC 7KE85 including the software license please contact our

for configuration, operation and management DIGSI5, Customer Support Center.

Phone: +49 180/524 70 00

SIGRA, SICAM PQS and SICAM PQ Analyzer.

Fax: +49 180/524 24 71

Training REDESUR engineers at SIEMENS POWER (Charges depending on provider)

ACADEMY in Nuremberg and participation in FAT E-mail: support.ic@siemens.com

Testing in Berlin.

Supervision of assembly, configuration and Order No. ICXXXX-XXXX-XXXX | Printed in Germany | AL=N ECCN=N

Dispo XXXXX | c4bs No. XXXX | GB XXXXXX RP XXXXXX WS XX13X.X |

commissioning of equipment.

© XX.2014, Siemens AG

Training for operators and technical staff of the

company in the substation.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- GEA-S1203 Mark VIe Steam Turbine Control For New Combined-Cycle PlantsDocument2 pagesGEA-S1203 Mark VIe Steam Turbine Control For New Combined-Cycle PlantsjosseNo ratings yet

- CT-VT Testing PDFDocument9 pagesCT-VT Testing PDFusmanNo ratings yet

- Transformer ConstructionDocument82 pagesTransformer ConstructionTuấn Ngụy100% (3)

- Control Panels Iec Norms Ec Directives En-Us PDFDocument364 pagesControl Panels Iec Norms Ec Directives En-Us PDFFábio SeabraNo ratings yet

- ATM MachineDocument19 pagesATM Machinevikas00707No ratings yet

- 06 Jun 2023Document331 pages06 Jun 2023josse0% (1)

- ITM Nterruptor 400 EATONDocument1 pageITM Nterruptor 400 EATONjosseNo ratings yet

- DMD Jun 2023Document197 pagesDMD Jun 2023josseNo ratings yet

- Meter Configuration Report For Meter1 (SN# 600036794)Document8 pagesMeter Configuration Report For Meter1 (SN# 600036794)josseNo ratings yet

- Phasor VieweDocument1 pagePhasor ViewejosseNo ratings yet

- Group 1 Data Log #1 Chanc Prim CCMDocument1 pageGroup 1 Data Log #1 Chanc Prim CCMjosseNo ratings yet

- Interruptor 400 EATONDocument1 pageInterruptor 400 EATONjosseNo ratings yet

- Sweep Frequency Response Analyzer: Sfra Tool For Detecting "Hidden" Transformer FaultsDocument2 pagesSweep Frequency Response Analyzer: Sfra Tool For Detecting "Hidden" Transformer FaultsjosseNo ratings yet

- Example QuickCMC Overcurrent PDFDocument16 pagesExample QuickCMC Overcurrent PDFjosseNo ratings yet

- ANSI 56-2 13kN BIL 160kV porcelain insulator electrical properties mechanical physicalDocument1 pageANSI 56-2 13kN BIL 160kV porcelain insulator electrical properties mechanical physicaljosseNo ratings yet

- CT Saturation Tolerance For 87L ApplicationsDocument26 pagesCT Saturation Tolerance For 87L ApplicationsBolivar Martinez100% (1)

- Application Line Relays Dual Breaker TerminalsDocument13 pagesApplication Line Relays Dual Breaker TerminalsBolivar MartinezNo ratings yet

- GEA-S1215 Mark VIe Integrated Control System (ICS) For IWPP PDFDocument2 pagesGEA-S1215 Mark VIe Integrated Control System (ICS) For IWPP PDFjosseNo ratings yet

- SIPROTEC 6MU85 Profile PDFDocument2 pagesSIPROTEC 6MU85 Profile PDFjosseNo ratings yet

- SIP5 APN 017 Stub Protection enDocument10 pagesSIP5 APN 017 Stub Protection enRahul MandalNo ratings yet

- ValenceDocument2 pagesValencejosseNo ratings yet

- CychgDocument4 pagesCychgjosseNo ratings yet

- GHT-200021 How To Configure Time Synchronization in The ToolboxST ApplicationDocument10 pagesGHT-200021 How To Configure Time Synchronization in The ToolboxST ApplicationjosseNo ratings yet

- GEA-S1215 Mark VIe Integrated Control System (ICS) For IWPP PDFDocument2 pagesGEA-S1215 Mark VIe Integrated Control System (ICS) For IWPP PDFjosseNo ratings yet

- 2010 11 PotM Negative Dissipation Factor P 09064 EDocument8 pages2010 11 PotM Negative Dissipation Factor P 09064 EAnil PanjaniNo ratings yet

- GEA-S1216 Performance Monitoring With The ControlST Software SuiteDocument2 pagesGEA-S1216 Performance Monitoring With The ControlST Software SuitejosseNo ratings yet

- GEA-S1212 Mark VIe IO Modules IndexDocument4 pagesGEA-S1212 Mark VIe IO Modules IndexjosseNo ratings yet

- GEA-S1209 Mark VIe Control Cabinets For Plant ControlsDocument2 pagesGEA-S1209 Mark VIe Control Cabinets For Plant ControlsjosseNo ratings yet

- GHT-200012 How To Interface To Third Parties Using WorkstationST OPC DADocument10 pagesGHT-200012 How To Interface To Third Parties Using WorkstationST OPC DAjosseNo ratings yet

- GEA-14803 Mark IV To Mark VIe Migration GT Controls UpgradeDocument2 pagesGEA-14803 Mark IV To Mark VIe Migration GT Controls UpgradejosseNo ratings yet

- GHT-200008 How To Display A Variable On An HMI ScreenDocument6 pagesGHT-200008 How To Display A Variable On An HMI ScreenjosseNo ratings yet

- Hypercar Pollution PreventionDocument32 pagesHypercar Pollution Preventionnagesh patilNo ratings yet

- Metek Yamauchi (M) SDN BHD - Project - Memo1Document3 pagesMetek Yamauchi (M) SDN BHD - Project - Memo1danu azharNo ratings yet

- Huawei HCNA-VC Certification TrainingDocument3 pagesHuawei HCNA-VC Certification TrainingArvind JainNo ratings yet

- MT 17 - LeanDocument48 pagesMT 17 - LeanRuíz Figueroa, Jean E.No ratings yet

- Arduino Interfacing With LCD Without Potentiometer - InstructablesDocument6 pagesArduino Interfacing With LCD Without Potentiometer - Instructablesakinlabi aderibigbeNo ratings yet

- Arkel Door Control KM 10Document3 pagesArkel Door Control KM 10thanggimme.phanNo ratings yet

- Components of A Computer - Information Technology and CommunicationDocument7 pagesComponents of A Computer - Information Technology and CommunicationDarryl John PasambaNo ratings yet

- Ipc Hdbw3841r Zas Datasheet 20210330Document4 pagesIpc Hdbw3841r Zas Datasheet 20210330gustavo saucedoNo ratings yet

- Hitachi Air-Cooled Chiller Installation, Operation and Maintenance ManualDocument52 pagesHitachi Air-Cooled Chiller Installation, Operation and Maintenance Manualmgs nurmansyahNo ratings yet

- PYTHON HACKING GUIDEDocument34 pagesPYTHON HACKING GUIDEElias JuniorNo ratings yet

- Quick Start Guide InfiNet Wireless R5000Document32 pagesQuick Start Guide InfiNet Wireless R5000Iveth Carrillo CasasNo ratings yet

- Intouch BrochureDocument2 pagesIntouch BrochureYash PaliwalNo ratings yet

- Ansible PresentationDocument23 pagesAnsible Presentationstanislaw.jachuraNo ratings yet

- Adayo ReplacementDocument13 pagesAdayo Replacementkwf7yjpr26No ratings yet

- Gama Urban LED - Iguzzini - EspañolDocument52 pagesGama Urban LED - Iguzzini - EspañoliGuzzini illuminazione SpANo ratings yet

- Midshire Business Systems - Ricoh MP CW2200SP - A0 Wide Format Colour BrochureDocument8 pagesMidshire Business Systems - Ricoh MP CW2200SP - A0 Wide Format Colour BrochureadietoppingNo ratings yet

- Sd5-E-423 - Caterpillar SparesDocument1 pageSd5-E-423 - Caterpillar Spareskamal kamalNo ratings yet

- 850 Fast Secure Redundant CommunicationsDocument2 pages850 Fast Secure Redundant CommunicationsamruthkiranbabujiNo ratings yet

- Social Media Usage in The PhilippinesDocument12 pagesSocial Media Usage in The PhilippinesInigo DelfinNo ratings yet

- DMR XW380Document124 pagesDMR XW380Mirella VerdeNo ratings yet

- Final Service Closure NoticeDocument2 pagesFinal Service Closure Noticeanudasari1301No ratings yet

- Metal Gas Cabinets Metal Gas Cabinets: (With Back Wall)Document1 pageMetal Gas Cabinets Metal Gas Cabinets: (With Back Wall)Cak NhassNo ratings yet

- Engine Parts Listing with 40 PartsDocument9 pagesEngine Parts Listing with 40 PartsGeno CideNo ratings yet

- HVDC Transmission Systems Textbook Chapter SummaryDocument24 pagesHVDC Transmission Systems Textbook Chapter SummaryWillam MetzNo ratings yet

- Flare Dec+JanDocument87 pagesFlare Dec+Janfarooq_flareNo ratings yet

- Computer Science & Engineering: Branch: All Branches of B.TechDocument9 pagesComputer Science & Engineering: Branch: All Branches of B.TechBella HadidNo ratings yet

- L11 - Design A Network-2022Document36 pagesL11 - Design A Network-2022gepoveNo ratings yet

- Binder1 PDFDocument94 pagesBinder1 PDFrakeshNo ratings yet

- Assignment 3 3Document4 pagesAssignment 3 3api-236083981No ratings yet