Professional Documents

Culture Documents

Inspection Hiap Crane

Uploaded by

PurwanroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Hiap Crane

Uploaded by

PurwanroCopyright:

Available Formats

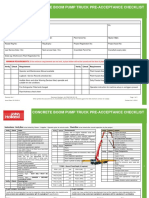

CRANE TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

PLANT DETAILS

Plant Owner: Address: Ph:

Plant Make: Plant Model: Plant Serial No: Hours / KM’s:

Roads Reg No: Reg Expiry: Project Registration No: Project Asset No:

Last Service Date / Hrs: Next service Date / Hrs: CraneSafe Permit No: CraneSafe expiry date:

State (eg: WorkCover) Plant Registration No

MINIMUM REQUIREMENTS (If the minimum requirements are not met, a plant sticker will not be issued and the item of plant is not to commence work)

Is this crane fitted with a free fall function if your answer is “Yes” the crane cannot be used unless an effective lockout system is installed and tested (while the lock is

installed) to verify that free fall cannot be inadvertently activated.

This test must be conducted by a competent operator as part of the Pre-Acceptance Inspection process and detailed within the Plant Hazard Assessment.

Verify Check Requirement Verify Check Requirement

Operator and Maintenance Manual available Plant Hazard Assessment Sighted & Current (within 2 yrs):

Logbook / Service Records (checked ok): Plant Hazard Assessment Inspection Date: / /

Audible Alarm and other Warning Devices fitted, operable and Daily Prestart Inspection Checklist is available for use.

suitable for site conditions

Fire Extinguisher Fitted and charged Operation instruction for machine setup on outriggers present

Revision No: 2 Document Number: JH-FRM-PAE-001-32 Page 1 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 31/12/2016 Printed: 31/12/2016

CRANE TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

Instructions: Verify Box to be ticked by Owner / Supplier / Operator prior to arrival onsite. Check Box to be ticked after visual inspection by the project

Verify Check

Cabin Verify Check Environmental Verify Check Crane assembly

Cleanliness Clean, free of organic materials (mud, dirt, weeds or Crane mounts secure

Door operational seeds) prior to arrival Crane Boom integrity

Deadman Pedal /Switch operational Engine baffling or noise reduction equipment fitted as Crane Instruction signage

per manufacturers specifications

Handrails and ladders fitted and secure Crane Controls

Smoke from internal combustion engines should not

Seat – adjustments operational secure be visible for more than ten seconds Crane Hooks

Seat belt fitted and in good working order Verify Check Lifting Equipment Accessories Rams

UHF Radio Fitted (If not fitted, has a hand held Pins / Mountings

Slings / ropes /chains / shackles (tagged and labelled

radio been supplied) in good working condition) Hoses / Connectors

First Aid Kit, triangle and road reflectors Steel or timber pads (check for excessive wear, leaks and

available creep)

Chains tagged in the last 12 months

Warning devices and other lights (flashing, Access points hand rails and steps

head, tail, etc) are appropriate for the Soft slings tagged in the last 3 months fitted and secured

environment in which plant is being used. SWL Crane charts Outriggers functional

(check environment noise criteria particularly if

Outrigger locking pins/mechanisms

working out of hours)

functioning effectively

Instruments operational & labelled

Verify Check Engine

Levers / Controls Operational Engine Mountings

Pedals in good condition Engine Guarding

Air conditioning operational Exhaust Guarding

Wipers / Washers operational

Oil Leaks/check levels

Rear View Mirrors

Coolant Leaks/check levels

Windows not damaged TYRES – Record Tread Depth (if required)

Coolant System

Warning Signs - Seat belt must be worn

POS 1 (LF) ____mm POS 2 (RF) ____mm Vee Belt Condition

Warning Signs - Danger – Beware Overhead

Air Cleaner System

Wires POS 3 (LF2) ____mm POS 4 (RF2) ____mm

Running Gear Battery Condition / Mounting

Verify Check

Tyres / Wheels undamaged POS 5 (LR3) ____mm POS 6 (RR3) ____mm

Brakes system operational

Park brake is operational

PLANT OWNER / OCCUPIER PLANT VERIFIER

I certify that the described plant has met the inspection criteria stipulated within this checklist and is I certify that I have verified that the described plant has met the inspection criteria stipulated within this

being serviced and maintained in accordance with the manufacturer’s specifications checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

Name: Signature: Date: Name: Signature: Date:

Revision No: 2 Document Number: JH-FRM-PAE-001-32 Page 2 of 2

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 31/12/2016 Printed: 31/12/2016

You might also like

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenNo ratings yet

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDocument2 pagesJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- JH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistDocument3 pagesJH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistYoung Lin SaengNo ratings yet

- Piling Rig Pre-Acceptance ChecklistDocument2 pagesPiling Rig Pre-Acceptance ChecklistMuhammad Shahzad100% (1)

- Boom Placer ChecklistDocument3 pagesBoom Placer ChecklistAlves Edattukaran100% (3)

- Piling Rig Plant Pre-Acceptance ChecklisDocument3 pagesPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedNo ratings yet

- JAPL-F-HE-007-Concrete Pump ChecklistDocument1 pageJAPL-F-HE-007-Concrete Pump ChecklistAli HassanNo ratings yet

- Crane ChecklistDocument1 pageCrane Checklistsajin0% (1)

- Crawler Crane Checklist Rev 0Document2 pagesCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- Road Grader Daily Inspection by OperatorDocument1 pageRoad Grader Daily Inspection by OperatorNasrullah Khan Yousafzai100% (1)

- Heavy Equipment Inspection ChecklistDocument18 pagesHeavy Equipment Inspection ChecklistJuned Hamid Khan89% (9)

- Angle Grinder ChecklistDocument4 pagesAngle Grinder Checklistshakti123456789No ratings yet

- Bulldozer Daily Inspection ChecklistDocument2 pagesBulldozer Daily Inspection ChecklistAndri AnwarNo ratings yet

- Rel Constrotech LLP: Check List For Arc Welding MachineDocument10 pagesRel Constrotech LLP: Check List For Arc Welding MachineAkNo ratings yet

- Truck Crane Inspection FormDocument3 pagesTruck Crane Inspection FormAdhy Darmawan100% (1)

- Checklist For Equipment Inspection BOOM PLACERDocument2 pagesChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- Mobile CraneDocument2 pagesMobile CraneRashidi Rahman50% (2)

- Drum Rooller Daily ChecklistDocument1 pageDrum Rooller Daily ChecklistMD AbdullahNo ratings yet

- Checklist For Equipment Inspection CONCRETE PUMPDocument1 pageChecklist For Equipment Inspection CONCRETE PUMPbagas prakosoNo ratings yet

- Machinery Inspection Checklist - Wah FungDocument4 pagesMachinery Inspection Checklist - Wah FungMKhairulMDNo ratings yet

- Mobile Plant ChecklistDocument2 pagesMobile Plant Checklistosama F. MohamedNo ratings yet

- Mobile Crane ChecklistDocument2 pagesMobile Crane Checklistabe_sein100% (1)

- EQUIPMENT INSPECTION REPORTDocument9 pagesEQUIPMENT INSPECTION REPORTPedro Antonio P. PaniaguaNo ratings yet

- Hino Tipper Risk AssesmentDocument9 pagesHino Tipper Risk AssesmentGnamaSayaNo ratings yet

- Checklist For Heavy Equipment - 1Document15 pagesChecklist For Heavy Equipment - 1Katita ChascaNo ratings yet

- Vehicle Entry Check ListDocument6 pagesVehicle Entry Check ListcgnanaponNo ratings yet

- JAPL-F-HE-004-Weekly Water Tanker Inspection LogDocument1 pageJAPL-F-HE-004-Weekly Water Tanker Inspection LogAli Hassan100% (1)

- Excavator Monthly Check ListDocument2 pagesExcavator Monthly Check ListJoy BDNo ratings yet

- Dump Truck Monthly Inspection ChecklistDocument1 pageDump Truck Monthly Inspection ChecklistJoy BDNo ratings yet

- Daily crane checklistDocument3 pagesDaily crane checklistNurma Rifah100% (4)

- Daily Backhoe Inspection ChecklistDocument1 pageDaily Backhoe Inspection ChecklistChaudhary Wasim Murtaza100% (1)

- Brush Cutter Pre Use ChecklistDocument1 pageBrush Cutter Pre Use ChecklistBruce Hove100% (2)

- Boom Placer Inspection ChecklistDocument1 pageBoom Placer Inspection ChecklistMyo LwinNo ratings yet

- Monthly vehicle inspection checklistDocument1 pageMonthly vehicle inspection checklistRísês Ãfröz0% (1)

- Crane Assembling Check ListDocument2 pagesCrane Assembling Check ListBaldev SinghNo ratings yet

- Excavator Inspection ChecklistDocument1 pageExcavator Inspection ChecklistArsalan Ahmad100% (2)

- S-OS-21-01 Hand Tool Inspection RegisterDocument1 pageS-OS-21-01 Hand Tool Inspection RegisterCharles Lamb100% (1)

- Tower Crane Inspection ChecklistDocument4 pagesTower Crane Inspection Checklistmailme_viju100% (1)

- Crane Inspection Check ListDocument9 pagesCrane Inspection Check ListSyauqi RamadhanNo ratings yet

- Scheduled MaintenanceDocument1 pageScheduled MaintenanceTan Minh Tam TruongNo ratings yet

- Road Roller ChecklistDocument1 pageRoad Roller ChecklistNasrullah Khan YousafzaiNo ratings yet

- 8 B Pick and Carry Hydra Crane Daily ChecklistDocument1 page8 B Pick and Carry Hydra Crane Daily Checklistjohn raj100% (1)

- Vehicle Crane Inspection ChecklistDocument2 pagesVehicle Crane Inspection ChecklistSn Ahsan100% (1)

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Transit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksDocument1 pageTransit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksRísês ÃfrözNo ratings yet

- Generator Daily Inspection ChecklistDocument1 pageGenerator Daily Inspection ChecklistMd Azizul MawlaNo ratings yet

- Editable Inspection Checklist For Heavy Equipment PDFDocument1 pageEditable Inspection Checklist For Heavy Equipment PDFchassas0% (1)

- Crane Inspection Checklist: General InformationDocument7 pagesCrane Inspection Checklist: General InformationArunachu ArunachuNo ratings yet

- Mobile Crane Monthly ChecklistDocument3 pagesMobile Crane Monthly ChecklistDAOUMY YOUNESSNo ratings yet

- CDC - Heavy Equipment Daily Inspection ChecklistDocument2 pagesCDC - Heavy Equipment Daily Inspection ChecklistJonathan CambaNo ratings yet

- Monthly Crane Inspection ChecklistDocument2 pagesMonthly Crane Inspection Checklistslamet4riadiNo ratings yet

- Tower Cranes CommisioningDocument15 pagesTower Cranes Commisioningpammu18No ratings yet

- Inspection Sheet For Roller and ConveyorDocument2 pagesInspection Sheet For Roller and ConveyorPaintsil BrightNo ratings yet

- Crane ChecklistDocument3 pagesCrane ChecklistAbdul Rehman SheikhNo ratings yet

- Excavator Pre-Use Inspection ChecklistDocument1 pageExcavator Pre-Use Inspection ChecklistFyan SaputraNo ratings yet

- GD380A-L ListDocument6 pagesGD380A-L ListNam Won HongNo ratings yet

- HSE Precheck List 1611927511Document22 pagesHSE Precheck List 1611927511sharathNo ratings yet

- Maintenence Record FormDocument10 pagesMaintenence Record FormIgoen YandriNo ratings yet

- Concrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsDocument2 pagesConcrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsBassam HSENo ratings yet

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistDocument2 pagesConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahNo ratings yet

- Media5-Fone Android UsersGuideDocument49 pagesMedia5-Fone Android UsersGuideacastroy100% (1)

- ITDP Presentation - C4C W5Document49 pagesITDP Presentation - C4C W5ITDP IndiaNo ratings yet

- CFR 2012 Title46 Vol7 Chapi SubchaptDocument127 pagesCFR 2012 Title46 Vol7 Chapi SubchaptshahjadaNo ratings yet

- Comprehensive Review of Literature On SignageDocument66 pagesComprehensive Review of Literature On Signageagvelazquez100% (1)

- 83 - Al Ghubaiba Bus Station To Nakheel Metro Station Dubai Bus Service TimetableDocument4 pages83 - Al Ghubaiba Bus Station To Nakheel Metro Station Dubai Bus Service TimetableDubai Q&ANo ratings yet

- Ship Particulars CerencanDocument1 pageShip Particulars CerencanMAVR7319No ratings yet

- Sample Bibliography Cards: Book Internet SiteDocument2 pagesSample Bibliography Cards: Book Internet Siteapi-30192479No ratings yet

- 0 0 24 Aug 2015 1717472101prefeasibilityreport PDFDocument136 pages0 0 24 Aug 2015 1717472101prefeasibilityreport PDFManjunath JadhavNo ratings yet

- ManualDocument255 pagesManualblogeraryanNo ratings yet

- Manual de PartesDocument25 pagesManual de PartesLuis AlegríaNo ratings yet

- Tankfarm Brochure SiemensDocument10 pagesTankfarm Brochure Siemensstavros7No ratings yet

- AHR6000LEDocument38 pagesAHR6000LEthe707No ratings yet

- Fiesta Titanium 1.5 (Labuan) PDFDocument2 pagesFiesta Titanium 1.5 (Labuan) PDFAbdillah AhmadNo ratings yet

- STO With Delivery Via ShippingDocument52 pagesSTO With Delivery Via ShippingJonnalagadda Lakshman100% (1)

- RadNav Chp16 PBNDocument95 pagesRadNav Chp16 PBNNiyazi Cem GürsoyNo ratings yet

- Development of An Auto Rickshaw Suspension SystemDocument125 pagesDevelopment of An Auto Rickshaw Suspension Systemmawais15No ratings yet

- Scriptwriting and Radio Broadcasting ExercisesDocument2 pagesScriptwriting and Radio Broadcasting ExercisesJosephine PatanNo ratings yet

- Optical Transceiver Market2016 PDFDocument8 pagesOptical Transceiver Market2016 PDFjim1234u0% (1)

- Urinary Tract PhysiologykulDocument72 pagesUrinary Tract PhysiologykulAya KamajayaNo ratings yet

- Article PT3 ESSAY - Form 2 - Exam 2b (KELVIN)Document2 pagesArticle PT3 ESSAY - Form 2 - Exam 2b (KELVIN)Kelvin83% (6)

- Asp Sealing Products LTD.: Pending Indent (Purchase Order) On Dated 05-JAN-2017 For "All" GroupDocument46 pagesAsp Sealing Products LTD.: Pending Indent (Purchase Order) On Dated 05-JAN-2017 For "All" GroupAnkit BinjolaNo ratings yet

- Main GeofabricsDocument16 pagesMain GeofabricsThota RevanthNo ratings yet

- Cross Drainage Works and Their FunctionsDocument27 pagesCross Drainage Works and Their FunctionsMuhammad Nadeem100% (6)

- Nerdir Catalog 2022 V01Document33 pagesNerdir Catalog 2022 V01Ed MenēndezNo ratings yet

- Globalization's Impact on Postcolonial EnglishesDocument20 pagesGlobalization's Impact on Postcolonial EnglishesNatalia PinedaNo ratings yet

- Ea 0002Document1 pageEa 0002fereetNo ratings yet

- 12-Zagazig University-2018-hpvc-South America - Ibrahim OufDocument33 pages12-Zagazig University-2018-hpvc-South America - Ibrahim OufCesar Gabriel Zapata CasariegoNo ratings yet

- Storm 100 I spare parts price listDocument58 pagesStorm 100 I spare parts price listNaveen SahaNo ratings yet

- RESUME - Eduardo Sausen Mallmann - ImportDocument2 pagesRESUME - Eduardo Sausen Mallmann - ImportEduardo Sausen MallmannNo ratings yet

- Factor Influencing On Purchase Decision of Two Wheeler-Bilal LuharDocument76 pagesFactor Influencing On Purchase Decision of Two Wheeler-Bilal LuharVishal Patel100% (1)